Slow-descending type automatic sheet sorting machine

A sorting machine, automatic technology, applied in the manufacture of stator/rotor body, etc., can solve the problems of increased production cost, low efficiency, high labor intensity, etc., and achieve the effect of convenience, low cost and good working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

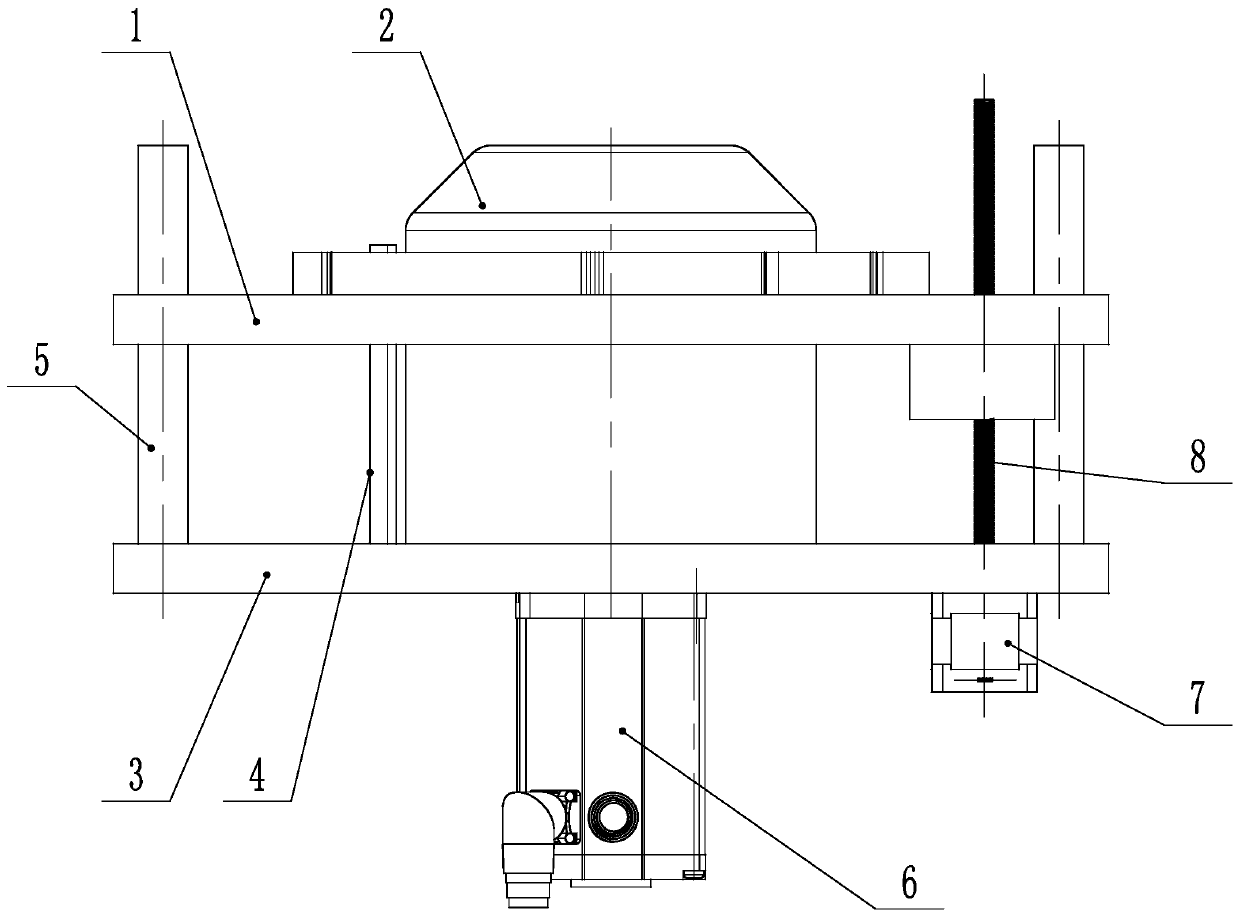

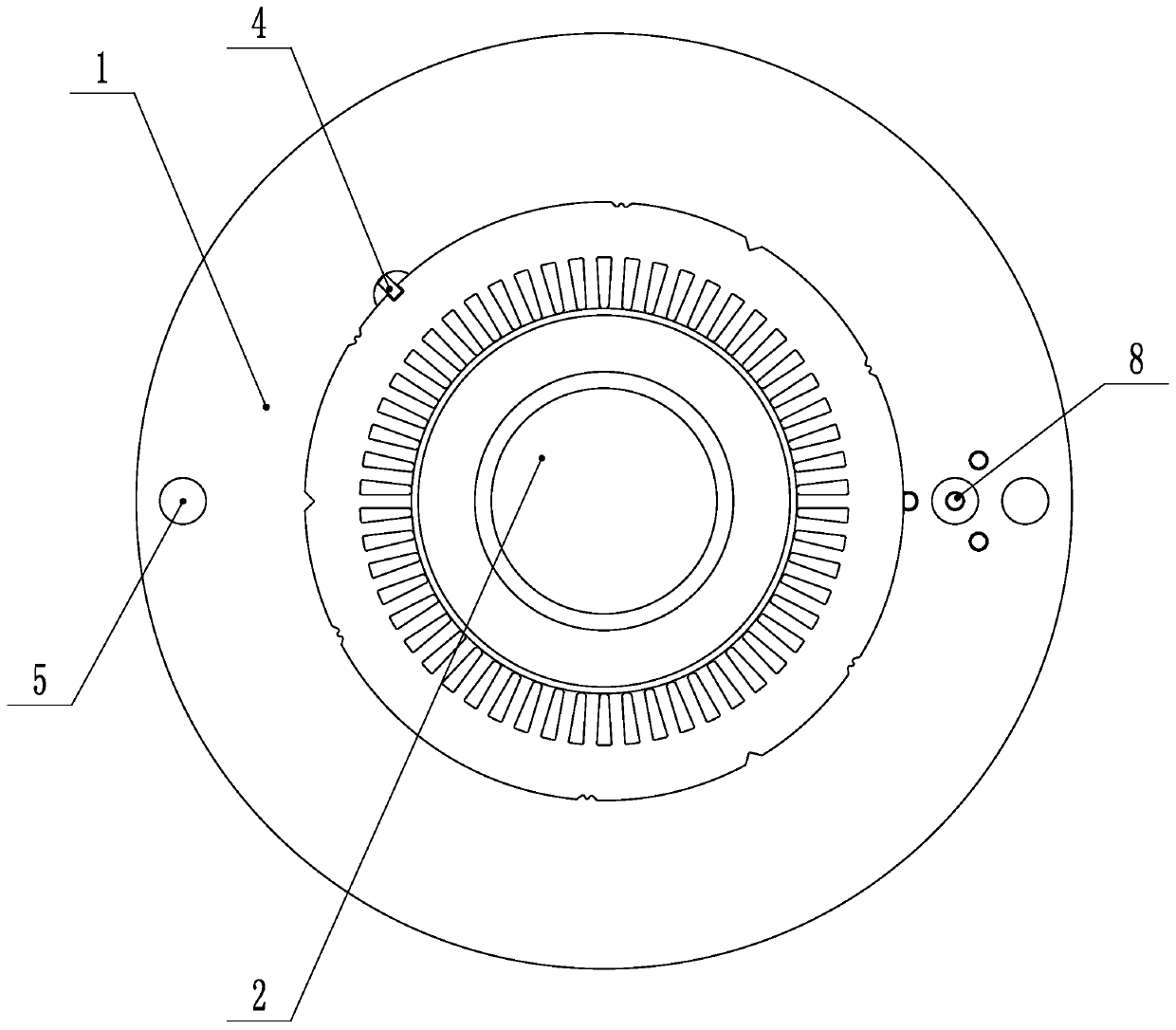

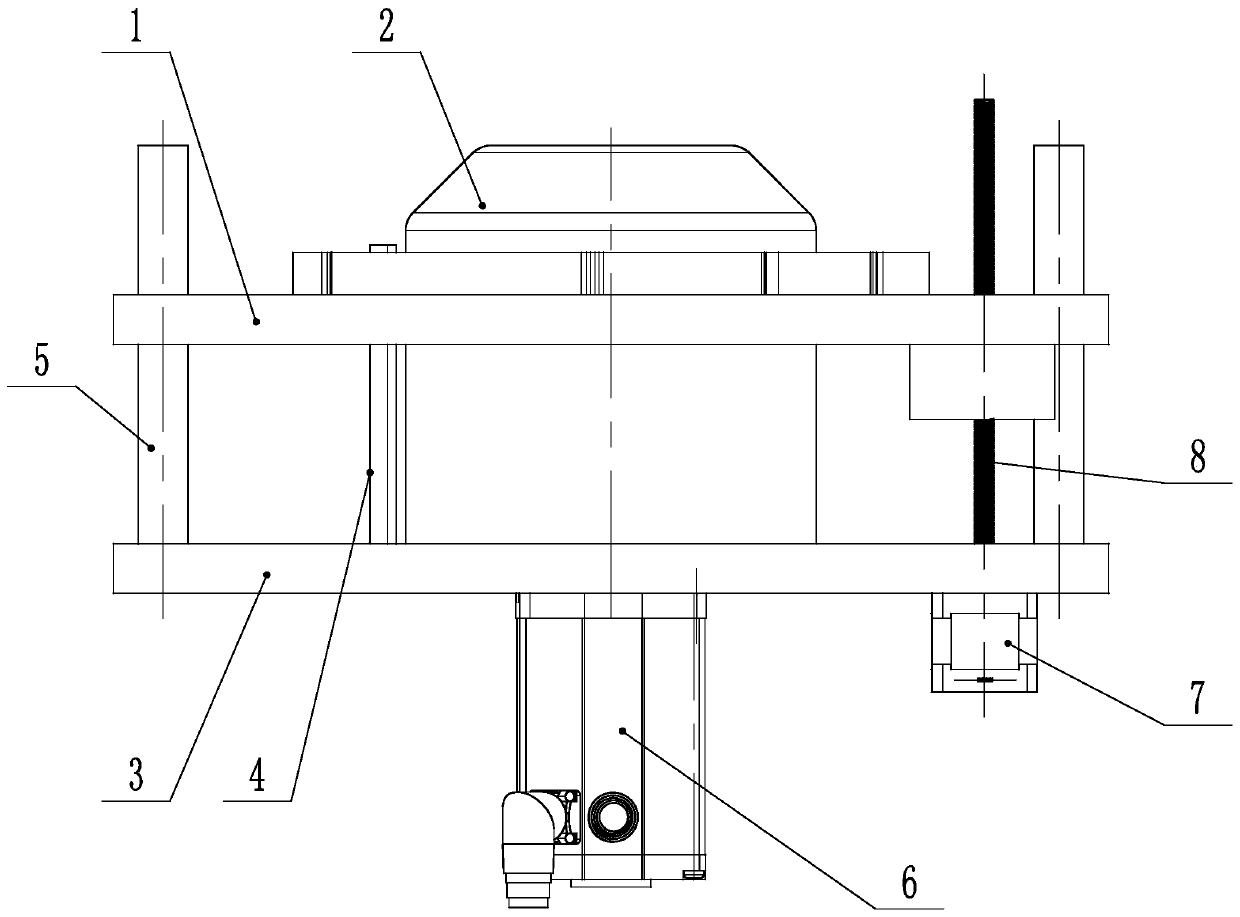

[0018] like Figure 1-2 As shown, a slow-down automatic film sorting machine includes a mounting plate 3, a guide post 5, a mandrel 2, a supporting plate 1, a first servo motor 6 and a second servo motor 7, and the first servo motor 6 is located on the installation The lower end surface in the middle of the plate 3, the lower end of the mandrel 2 passes through the through hole set in the middle of the mounting plate 3 and is connected with the upper end of the first servo motor 6 to realize the rotational drive of the mandrel 2, and the guide post 5 is arranged on the mounting plate 3 The upper end of the supporting plate 1 is provided with a shaft hole in the middle, the mandrel 2 passes through the shaft hole and fits with the supporting plate 1 in a clearance, the supporting plate 1 and the second servo motor 7 are connected by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com