Film coating equipment for curved glass and film coating processing method thereof

A technology for curved glass and lamination, which is used in electrostatic cleaning, chemical instruments and methods, cleaning methods and utensils, etc. It can solve the problems of increasing the processing cost of curved glass lamination, affecting the quality and effect of lamination, and low applicability. , to reduce the time and labor intensity of manual adjustment, improve the quality and effect of the film, and reduce the labor intensity and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

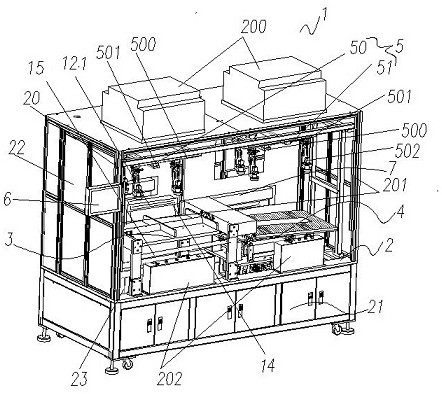

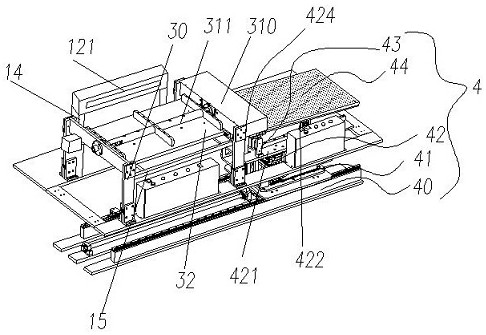

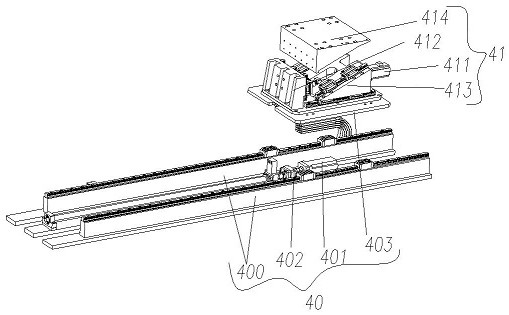

[0037] Examples, see attached Figure 1~Figure 10 A coating device 1 for curved glass includes a workbench 2, a curved glass material placement device 3 and an automatic film sticking device 4, the workbench 2 is provided with a frame 20 and a control box 21, and the frame 20 is provided with an outer cover 22. The frame 20 is also provided with a plurality of visual positioning devices 5 and displays 6. The displays 6 are used to display the processing quantity and parameters of other mechanism components. A dust removal device 7 is provided behind the workbench 2. The curved surface The glass material placement device 3 includes a mounting bracket 30, a rotating mechanism 31, an electrostatic precipitator 33 and a placement platform 32. The electrostatic precipitator 33 is provided with a static removal compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com