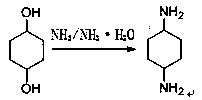

Method for preparing 1,4-cyclohexanediamine at high pressure

A technology of cyclohexanediamine and cyclohexanediol, applied in the field of preparation of cyclohexanediamine, can solve the problems of hidden dangers in production safety, expensive metal catalysts and the like, and achieve the effects of improving safety and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 53g of 1,4-cyclohexanediol and 30g of liquid ammonia into a 1L autoclave, control the temperature of 10-15MPa, and react at a temperature of 220°C-250°C for 12-14h, and take samples for analysis by GC. 1,4-cyclohexanediol Amines 95.1%, 1,4-cyclohexanediol 0.2%, polymer 3.8%.

Embodiment 2

[0021] Put 116g of 1,4-cyclohexanediol and 60g of liquid ammonia into a 1L autoclave, control the temperature of 10-15MPa, and react for 12-14h at a temperature of 220°C-250°C, and take samples for analysis by GC. 1,4-cyclohexanediol Amine 95.7%, 1,4-cyclohexanediol 0.15%, polymer 3.54%;

[0022] The sample was taken out, the water was distilled off, and rectified under reduced pressure to obtain 106.3 g of white solid 1,4-cyclohexanediamine, with a yield of 93.1% and a GC purity of 99.84%.

Embodiment 3

[0024] Add 232g of 1,4-cyclohexanediol and 120g of liquid ammonia into a 1L autoclave, control the reaction pressure at 10-15MPa, and the temperature at 220°C-250°C, react for 12-14h, take samples and analyze GC, 1,4 - Cyclohexanediamine 96.1%, 1,4-cyclohexanediol 0.13%, polymer 3.04%;

[0025] The sample was taken out, the water was distilled off, and rectified under reduced pressure to obtain 213.4 g of white solid 1,4-cyclohexanediamine, with a yield of 93.5% and a GC purity of 99.88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com