Comprehensive treatment method and system for red mud resource utilization

A comprehensive treatment and resource recovery technology, applied in the field of resource utilization of industrial waste residues, can solve problems such as inability to realize industrialization promotion, poor industrial applicability, and unsatisfactory effects, and achieve cost reduction, simple process methods and equipment, and high returns. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

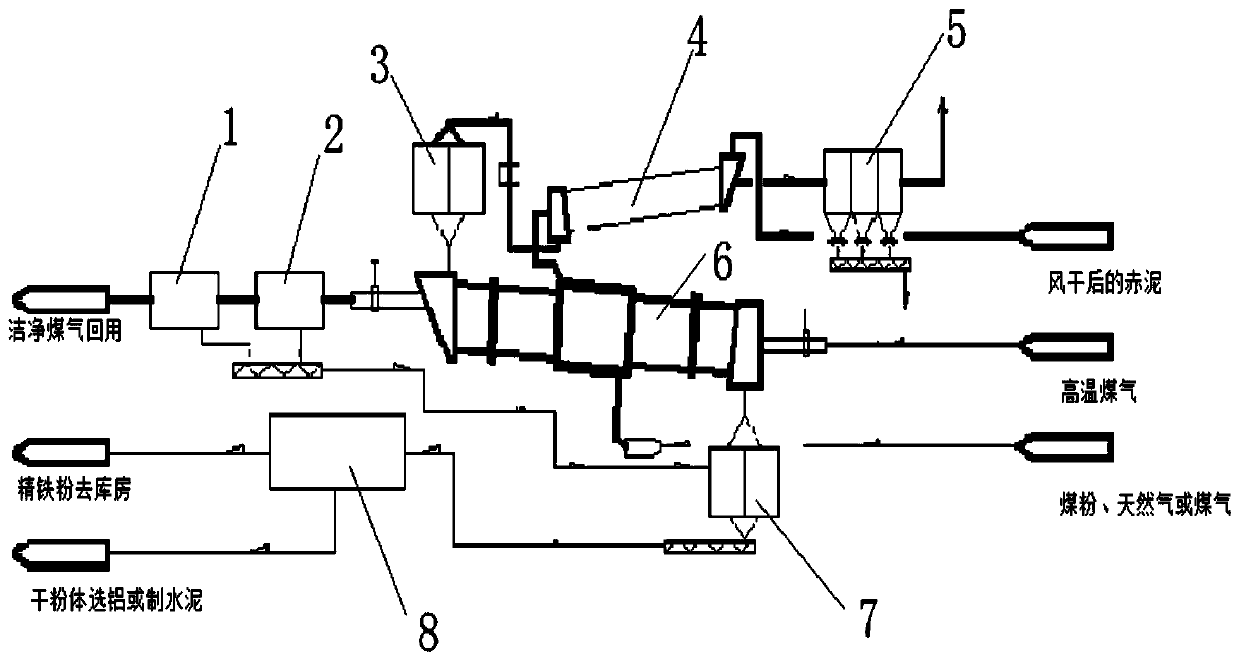

Embodiment 1

[0061] A comprehensive treatment system for resource utilization of red mud. The comprehensive treatment system includes an externally heated rotary kiln. The reaction device is provided with a viewing window, so that operators can observe the reaction conditions in the reaction device. The comprehensive treatment system can also include a red mud pretreatment device and a red mud feeding device, and the red mud pretreatment device includes a dehydration drying device and a crushing device connected in sequence; wherein, the dehydration drying device is a heating Rotary kiln drying. The red mud feeding device is a vacuum displacement feeding device, and the red mud that has been dehydrated, dried and crushed (controlling the red mud particle size to be less than 300 microns, and 74 microns or less accounts for 80%) is sent to the vacuum displacement feeding device, and then The reaction device is input through the pipeline to prevent the external oxygen and other gases from en...

Embodiment 2

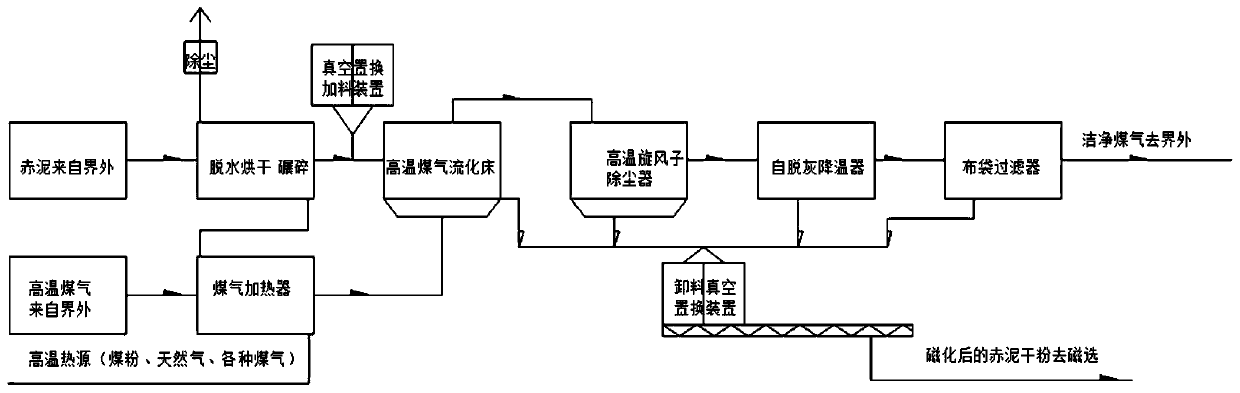

[0070] A comprehensive treatment system for resource utilization of red mud, the comprehensive treatment system includes a reaction device that is a high-temperature gas fluidized bed. The reaction device is provided with an object window, so that it is convenient for the operator to observe the reaction situation in the reaction device. The comprehensive treatment system may also include a red mud pretreatment device and a red mud feeding device, and the red mud pretreatment device includes a dehydration drying device and a crushing device connected in sequence; wherein, the dehydration drying device may be Heating and drying rotary kiln. The red mud feeding device is a vacuum displacement feeding device, and the dehydrated, dried and crushed red mud (the particle size of the red mud is controlled to be less than 300 microns, and 74 microns or less accounts for 80%) is sent to the vacuum displacement feeding device, Then it is fed into the reaction device through the pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com