Alcohol biomass clean diesel fuel

A biomass and clean technology, applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve problems such as incomplete combustion, air pollution, and high emissions, so as to save resources, reduce emissions and carbon deposits, and reduce emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The mixed ester in this example is a vegetable oil fatty acid monoester (methyl or ethyl) obtained by esterification of residual oil (oil feet) from a vegetable oil plant. The measured water content is 0.98% and the kinematic viscosity is 5mm at 40°C. 2 / s, density 0.85g / cm 3 , PH value is 7. The water content of the mixed alcohol is 9.8%. The antioxidant preservative uses zinc diaryl dithiophosphate.

[0026] This embodiment will be configured in the following proportions:

[0027] Mixed ester 60%

[0028] Carbon nine 20%

[0029] Mixed alcohol 15%

[0030] Zinc diaryl dithiophosphate 2%

[0031] Emulsifier 3%

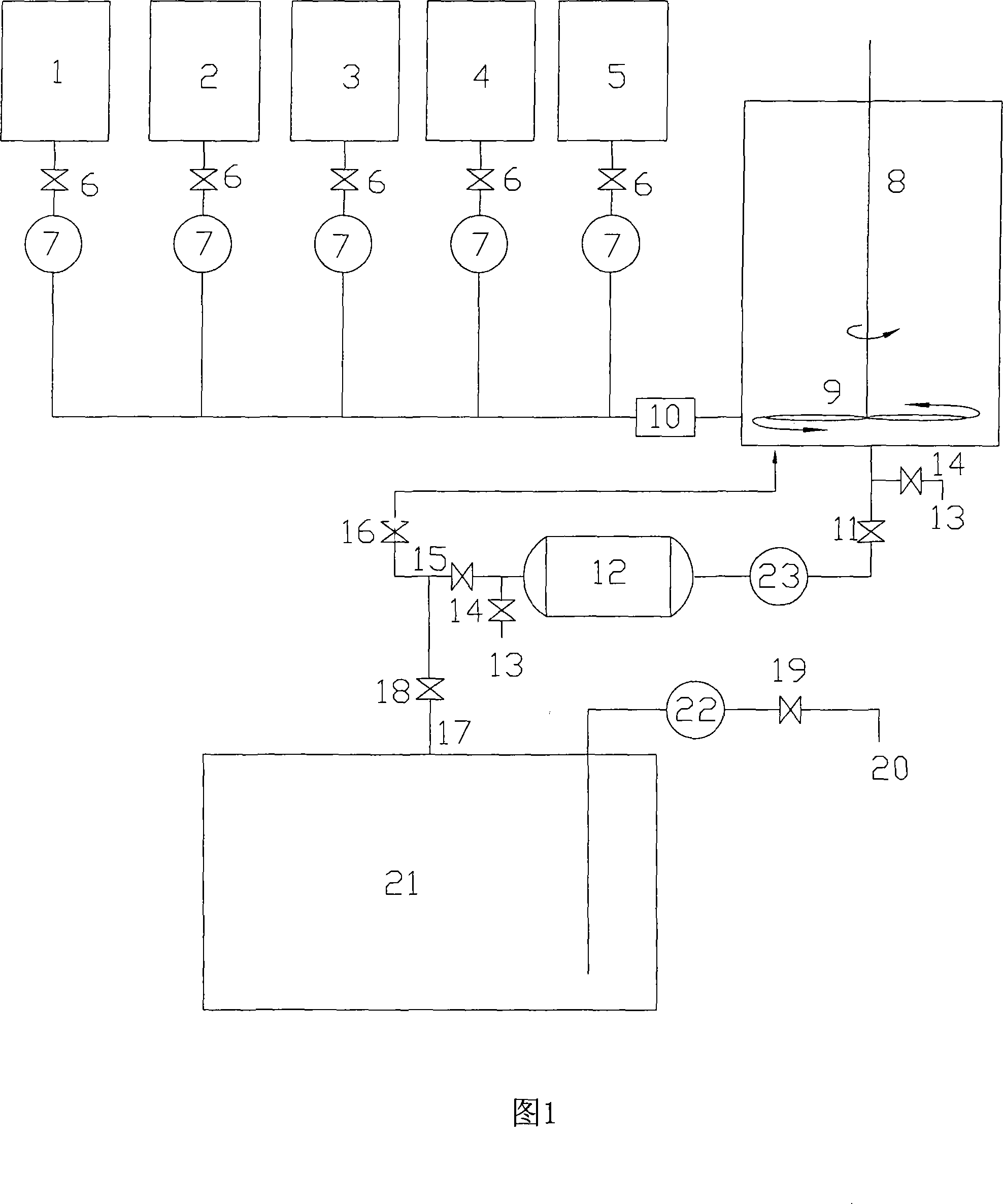

[0032] The above-mentioned raw materials are respectively tanked in corresponding storage tanks, and each storage tank is connected to the preliminary mixing tank through pipes, valves, metering pumps and filters. Please refer to Fig. 1. The preliminary mixing tank in this embodiment is a 5-ton tank.

[0033] In the production process shown in Figure 1, firstly ope...

Embodiment 2

[0043] The mixed ester in this example is animal and vegetable oil fatty acid monoester (methyl or ethyl) obtained by esterification with waste oil. The measured water content is 1.0%, and the kinematic viscosity is 5.5mm at 40°C. 2 / s, density 0.88g / cm, PH value is 6. The water content of the mixed alcohol is 9.2%. The antioxidant preservative uses zinc dialkyl dithiophosphate.

[0044] This embodiment will be configured in the following proportions:

[0045] Mixed ester 80%

[0046] Carbon nine 10%

[0047] Mixed alcohol 8%

[0048] Zinc dialkyl dithiophosphate 1%

[0049] Emulsifier 1%

[0050] The production process of this embodiment is the same as that of the above embodiment, which can be seen in Fig. 1. The preliminary mixing tank is also a 5 ton tank. The raw materials in the above weight percentage examples are stirred and mixed in the initial mixing tank 8 for 20 minutes, and the initial mixed liquid formed therefrom is emulsified by the emulsifying disperser 12 to form...

Embodiment 3

[0057] The mixed ester in this embodiment is the animal oil fatty acid monoester obtained by esterification of animal fat leftovers from leather factories and slaughterhouses. The measured water content is 0.93%, and the kinematic viscosity is 6mm at 40℃ 2 / s, density 0.91g / cm 3 . The water content of the mixed alcohol is 8%. The anti-oxidant preservative adopts the calcium salt of selenium phosphate selenium hydrocarbon.

[0058] In this embodiment, biodiesel will be configured in the following proportions:

[0059] Mixed ester 70%

[0060] Carbon 9 15%

[0061] Mixed alcohol 10%

[0062] Selenium phosphate selenium hydrocarbon calcium salt 3%

[0063] Emulsifier 2%

[0064] The production process of this embodiment is the same as that of embodiment 1, which can be seen in Fig. 1. The preliminary mixing tank is also a 5 ton tank. The raw materials in the above weight percentage examples are stirred and mixed in the initial mixing tank 8 for 15 minutes, and the initial mixed liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com