Patents

Literature

35results about How to "Promote complete combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

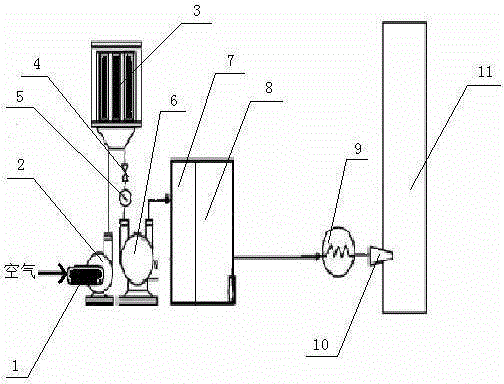

Waste gas and waste liquid incineration system and method

ActiveCN104359113AIncrease contentReduce exhaustIncinerator apparatusAir quality improvementPtru catalystPollution

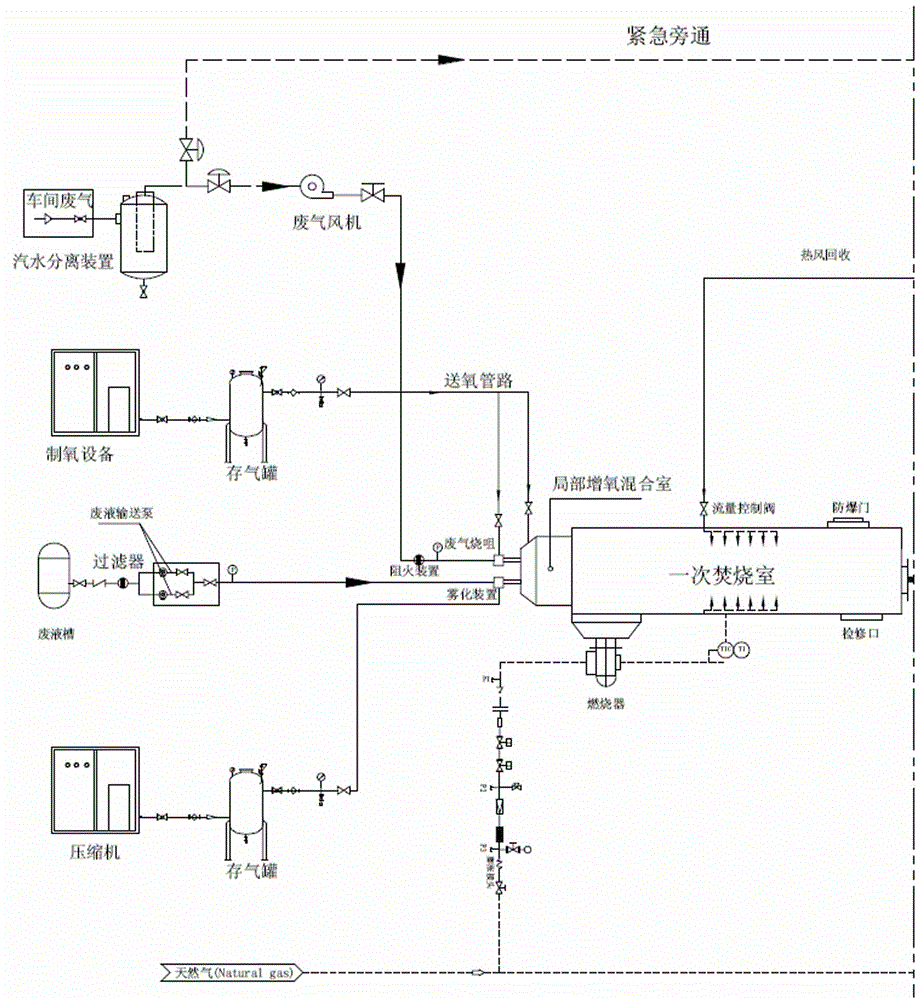

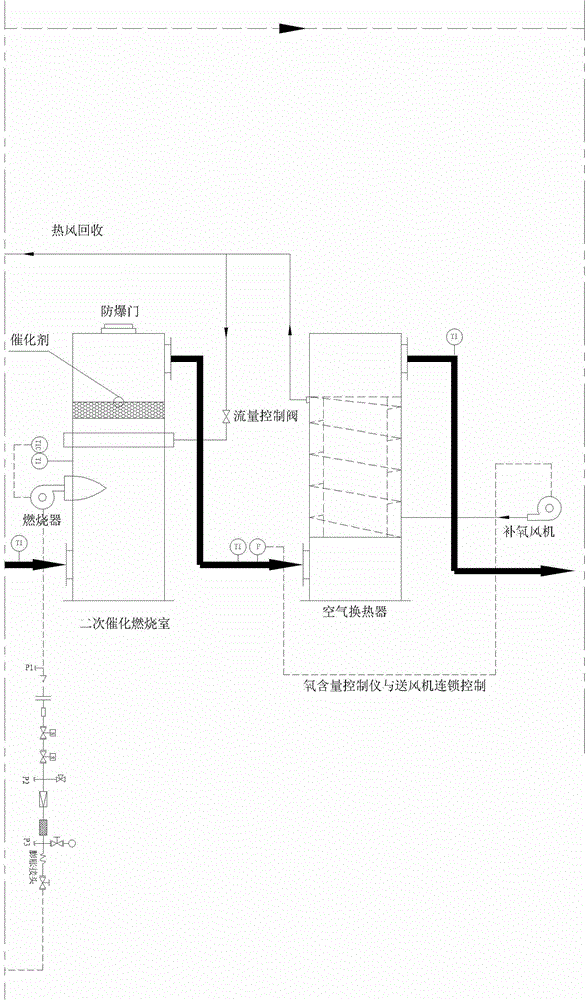

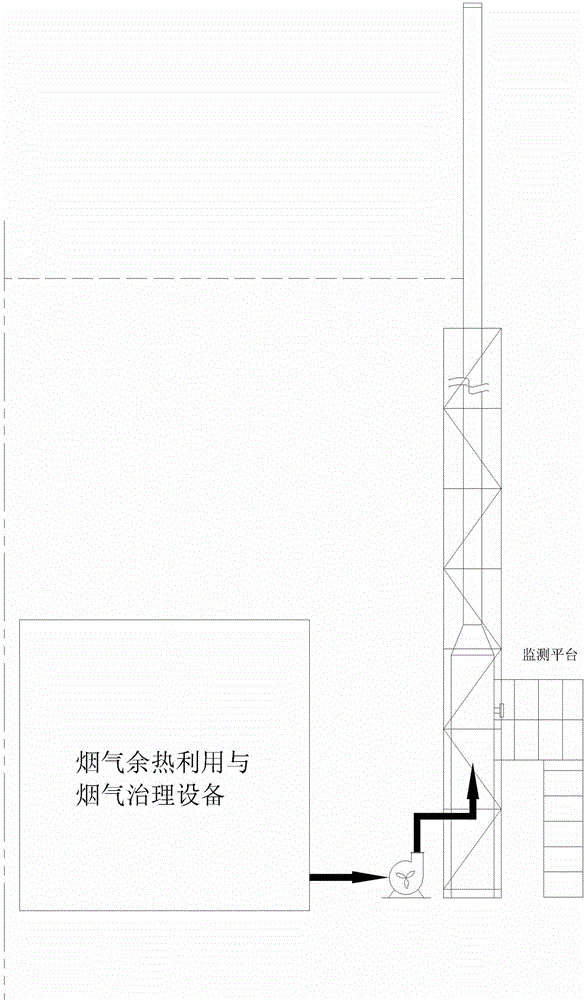

The invention discloses a waste gas and waste liquid incineration system. The system comprises oxygen production equipment, a local oxygen increasing, combustion and mixing chamber, a primary incineration chamber, a secondary catalytic incineration chamber, an air heat exchanger and a waste heat utilization and smoke purification device which are sequentially connected; harmful waste gas or atomized waste liquid, compressed air and pure oxygen are proportionally mixed in the mixing chamber and then are fed into the primary incineration chamber for incineration. The waste gas and waste liquid incineration system has the advantages that the content of oxygen is locally improved in the primary incineration chamber for waste gas and waste liquid, the combustion speed is accelerated, the complete combustion is facilitated, the smoke exhaust amount after combustion is reduced, and the heat utilization ratio is improved; smoke after primary incineration enters the secondary catalytic incineration chamber and reacts with catalyst, toxic gases such as ammonia and hydrogen cyanide produced after primary incineration is decomposed into N2, H2 and CO2, the problem of environmental pollution caused by smoke exhaust is solved, and the energy saving and emission reduction are facilitated.

Owner:宜兴市智博环境设备有限公司

Oxygen-enriched combustion process for improving cement kiln clinker calcining temperature and apparatus thereof

InactiveCN101407381AQuality assuranceRaise the ignition temperatureTemperature resistanceCement kiln

The invention relates to an oxygen-enriched combustion technical method for improving heating power of a cement kiln and a device thereof. During the process of cement clinker calcination, the invention is characterized in that: 1) a pure oxygen (over 90 percent) feeding device is added at a coal dust combustion zone of the cement kiln so as to lead the combustion zone to form a local thermonuclear area, and with the gradual diffusion of high temperature at the thermonuclear area, the heating power of the whole cement kiln is further improved and stably controlled; and 2) an oxygen feeding device is added at a combustion area of the cement kiln so as to improve and stably control the oxygen content in combustion air within the range of 21.8-33 percent at the combustion area. In a coal supplying system and an air supplying system of the cement kiln, an oxygen-enriched combustion system is formed by arranging at least one high temperature resistance oxygen jet, a pipeline for transmitting oxygen, an oxygen generation device, an oxygen supply-quantity regulating device, a DCS control device and the like inside each independent combustion area of the cement kiln. The invention has the advantages of improving combustion efficiency of faulty coal and the heating power of the cement kiln, and stabilizing thermal regulation of the kiln so as to enhance the quality of the cement and prolong the service life of various heating equipment of the cement kiln.

Owner:昆明阳光基业股份有限公司

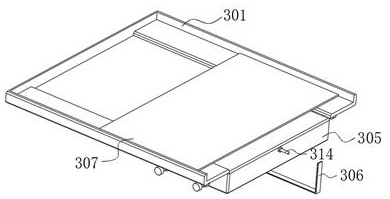

Device and method for cooling clinker by liquid oxygen and liquid nitrogen of cement kiln

ActiveCN103968671ASpeed up heat exchangeImprove stabilityDomestic cooling apparatusHandling discharged materialDecompositionNitrogen

The invention discloses a device and a method for cooling clinker by liquid oxygen and liquid nitrogen of a cement kiln. The device is characterized in that a high-temperature cooling region of a grate cooler of the cement kiln is provided with a liquid oxygen input connector, and a middle-temperature cooling region of the grate cooler is provided with a liquid nitrogen input connector. The method comprises the steps of adding liquid oxygen the volume of which is 1%-12% of the total volume of cooling air fed by an air blower of a high temperature section of the grate cooler of the cement kiln, and adding liquid nitrogen the volume of which is 1%-45% of the total volume of cooling air fed by an air blower of a middle temperature section of the grate cooler of the cement kiln. The device and the method provided by the invention have the advantages that the cooling rate of clinker is improved by inputting liquid oxygen, and high-temperature clinker is cooled suddenly, so that the decomposition of D3S at 1250 DEG C is prevented or alleviated, the crystallization of MgO is prevented or alleviated, and the stability of the clinker is improved; a C3S crystal is prevented from growing, and thus the grindability of clinker is improved; the C2S crystal transfer is effectively prevented or alleviated by introduced liquid nitrogen.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

Glass kiln natural gas oxygen-enriched combustor

InactiveCN101303124AIncrease profitReduce surplus factorIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorEngineering

The invention relates to a natural gas oxygen-enriched burner with a glass kiln. Based on the normal natural gas burner, by adopting oxygen enrichment technology, the original larger air port is changed to a relatively smaller oxygen-enriched air port according to the oxygen content of the oxygen-enriched air so as to heighten the temperature of flame, reduce air displacement after combustion, promote heat utilization ratio and lower excess air coefficient.

Owner:SHANGHAI INST OF TECH

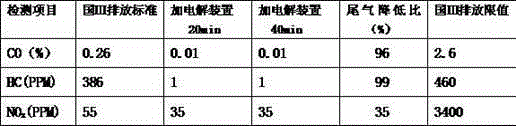

Nonmetallic gasoline additive and method for preparing same

ActiveCN107916147ASimple stepsSave raw materials and energy consumptionLiquid carbonaceous fuelsFuel additivesNitrogen oxidesNOx

The invention discloses a nonmetallic gasoline additive and a method for preparing the same. The nonmetallic gasoline additive comprises, by weight, 0.5-12% of polyether, 0.5-12% of polyether polyol,0.5-10% of poly-alcohol, 0.1-15% of catalysts, 0.1-15% of stabilizers, 1-16% of soluble silicic acid and 55.9-92% of polyol. The method includes adding the polyether, the polyether polyol, the poly-alcohol and the catalysts into the polyol; carrying out stirring reaction to obtain transparent oily liquid; adding the soluble silicic acid into the liquid; carrying out stirring reaction at the temperature of 80-110 DEG C until solution turns clear; filtering the clear solution to obtain the nonmetallic gasoline additive. The nonmetallic gasoline additive and the method have the advantages that more than 18% of gasoline can be saved by the aid of the nonmetallic gasoline additive under identical conditions, emission of hydrocarbon HC, carbon monoxide CO, PM (particulate matters) and nitrogen oxide NOx can be reduced to a great extent, the smoke intensity can be lowered to a great extent, and effects of inhibiting carbon deposit generation and eliminating carbon deposits can be realized; the nonmetallic gasoline additive is stable in property, can be safely stored and transported and is free of damage to gasoline cylinders and engines, the nonmetallic gasoline additive and gasoline arecompletely mutually soluble, precipitation and layering can be prevented.

Owner:保定市瑞方生物科技有限公司

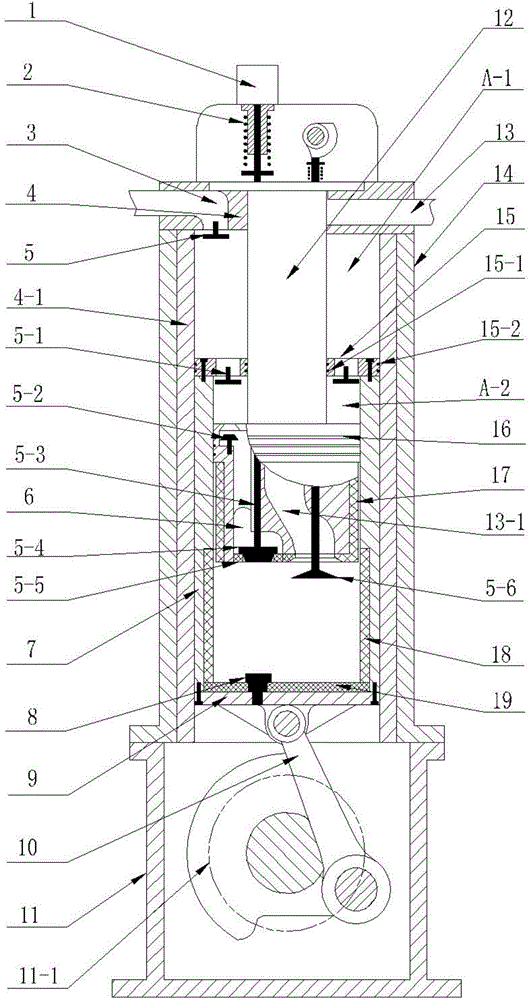

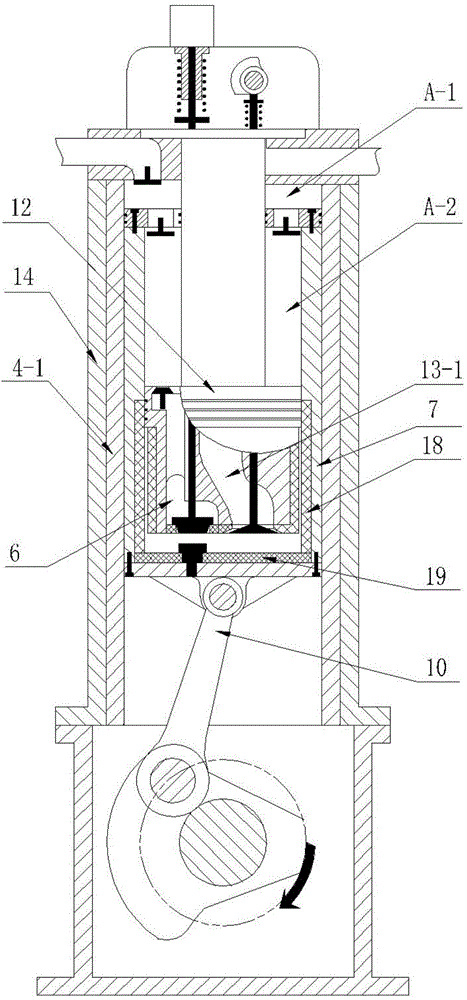

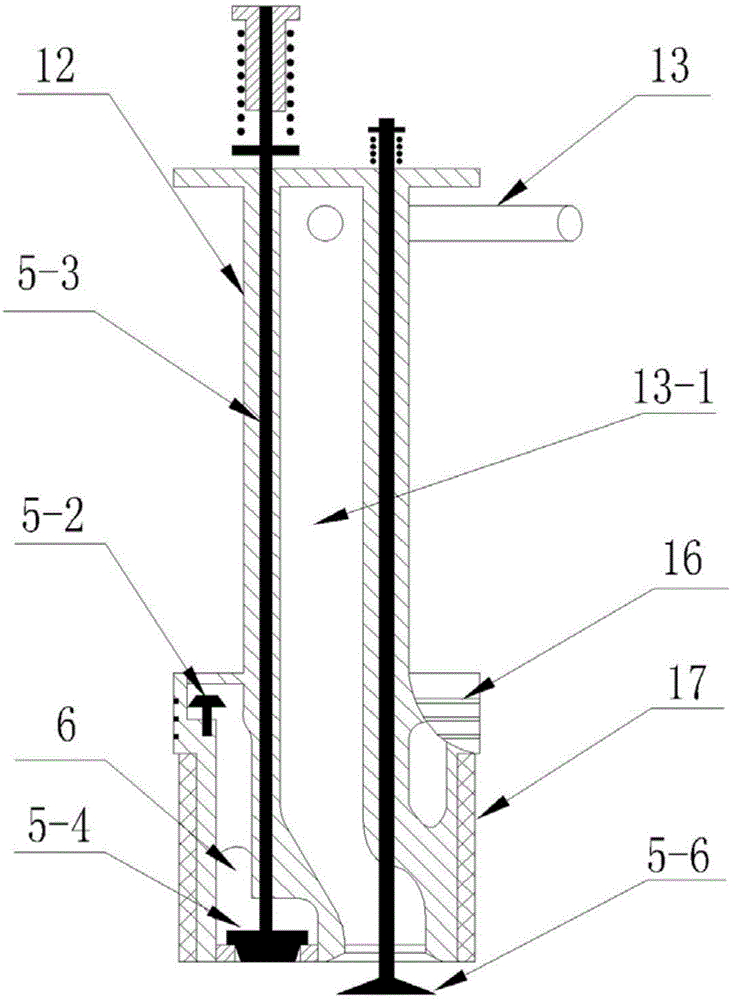

Cylinder-driving two-stroke engine

ActiveCN104863706APromote complete combustionWeaken the strong cooling systemInternal combustion piston enginesCylinder headsFour-stroke engineCylinder block

The invention discloses a cylinder-driving two-stroke engine which comprises a cylinder body, a crankcase and a cylinder head, wherein a crankshaft and a connecting rod are arranged in the crankcase; a fixed cylinder sleeve is mounted in the cylinder body; a movable cylinder capable of moving in a reciprocating manner along the fixed cylinder sleeve is arranged in the fixed cylinder sleeve; the center at the outer end of the baseplate of the movable cylinder is hinged to the connecting rod, so as to drive the crankshaft to rotate; a piston which can extend into the cylinder body and is fixed, is arranged on the cylinder head; a piston head at the front end of the piston is mounted in the movable cylinder; the movable cylinder conducts reciprocating movement relative to the piston; a combustion chamber and an exhaust passage are formed in the piston head. The cylinder-driving two-stroke engine adopting the design has the advantages that the single cylinder power can be improved; the size as well as the production cost can be reduced; energy conservation is further realized; harmful emission is reduced.

Owner:威海神舟信息技术研究院有限公司

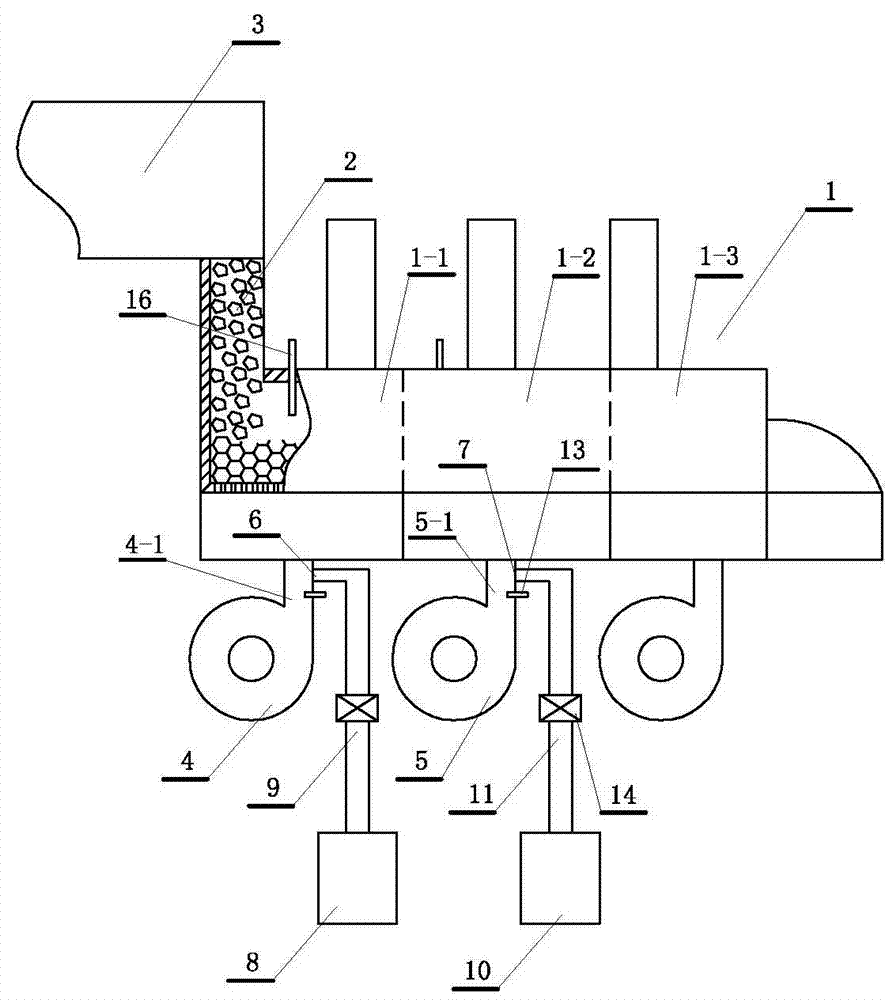

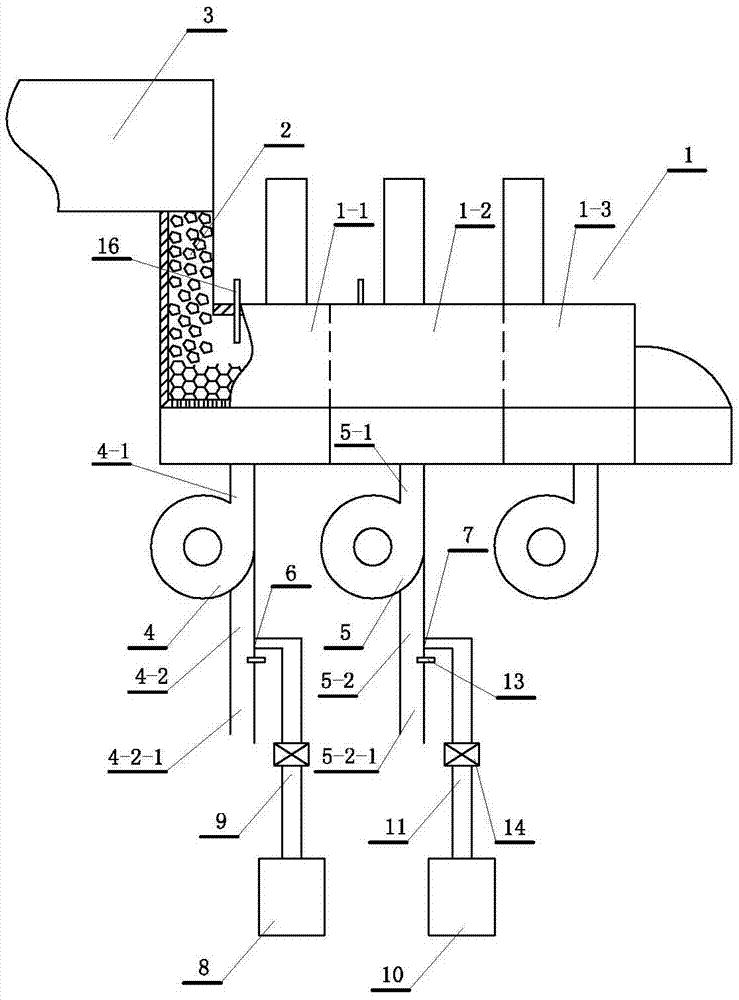

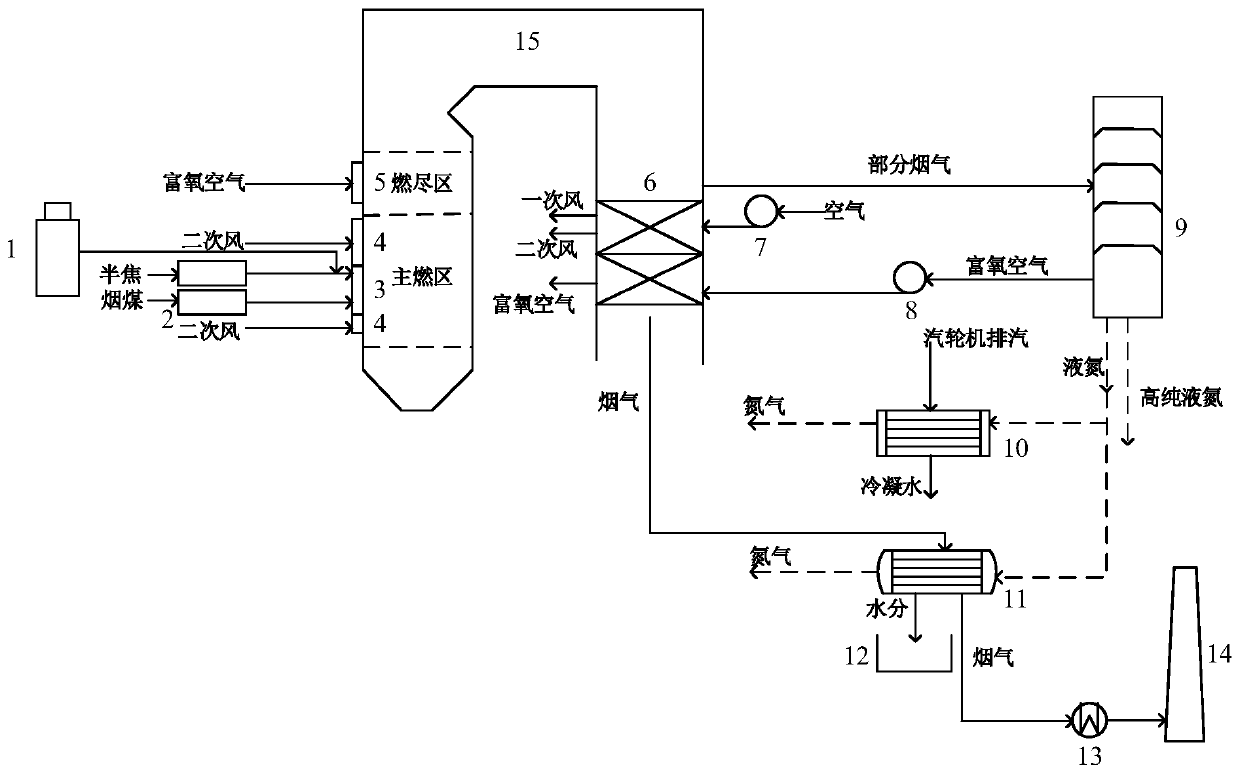

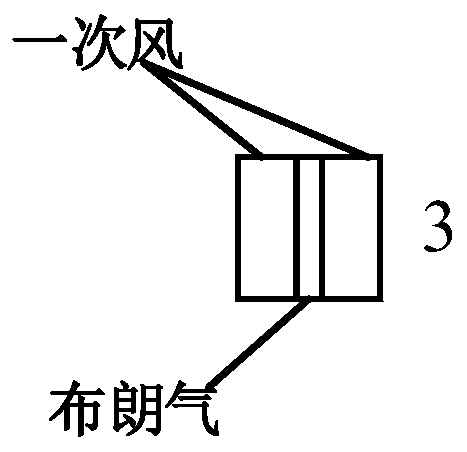

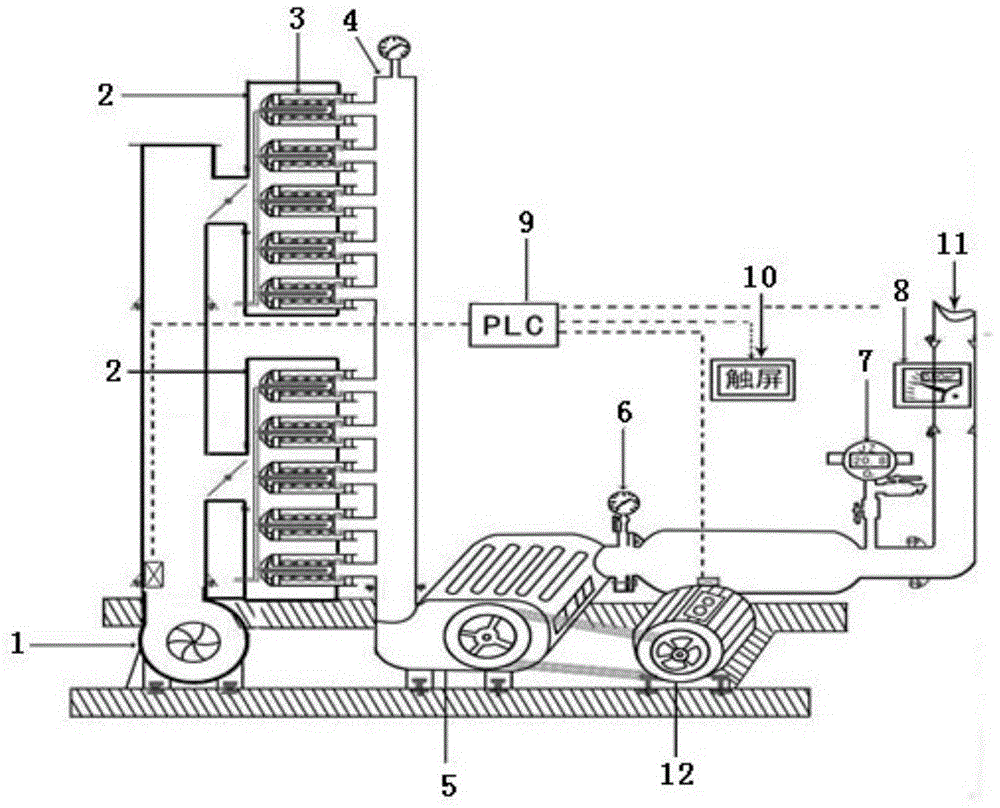

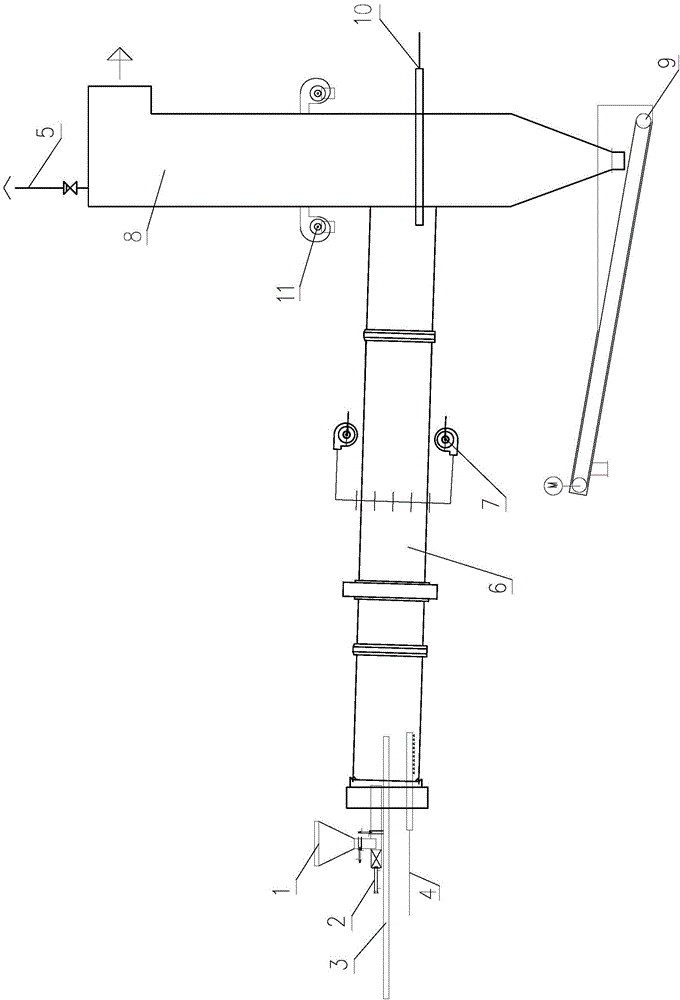

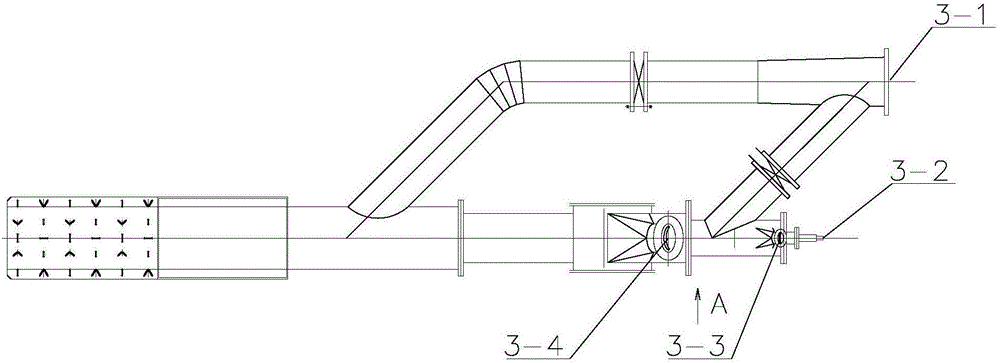

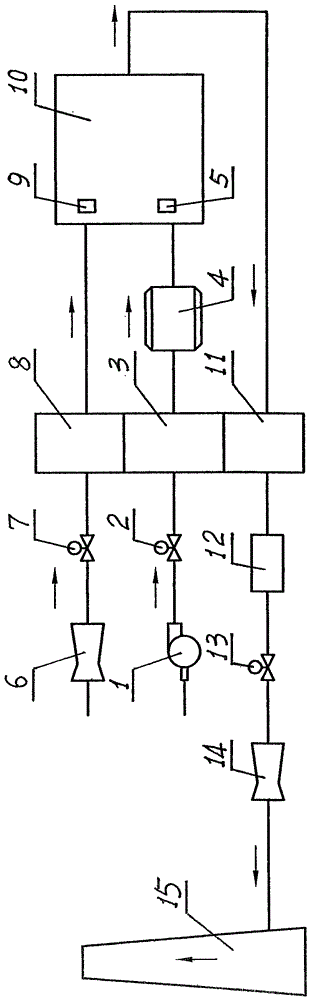

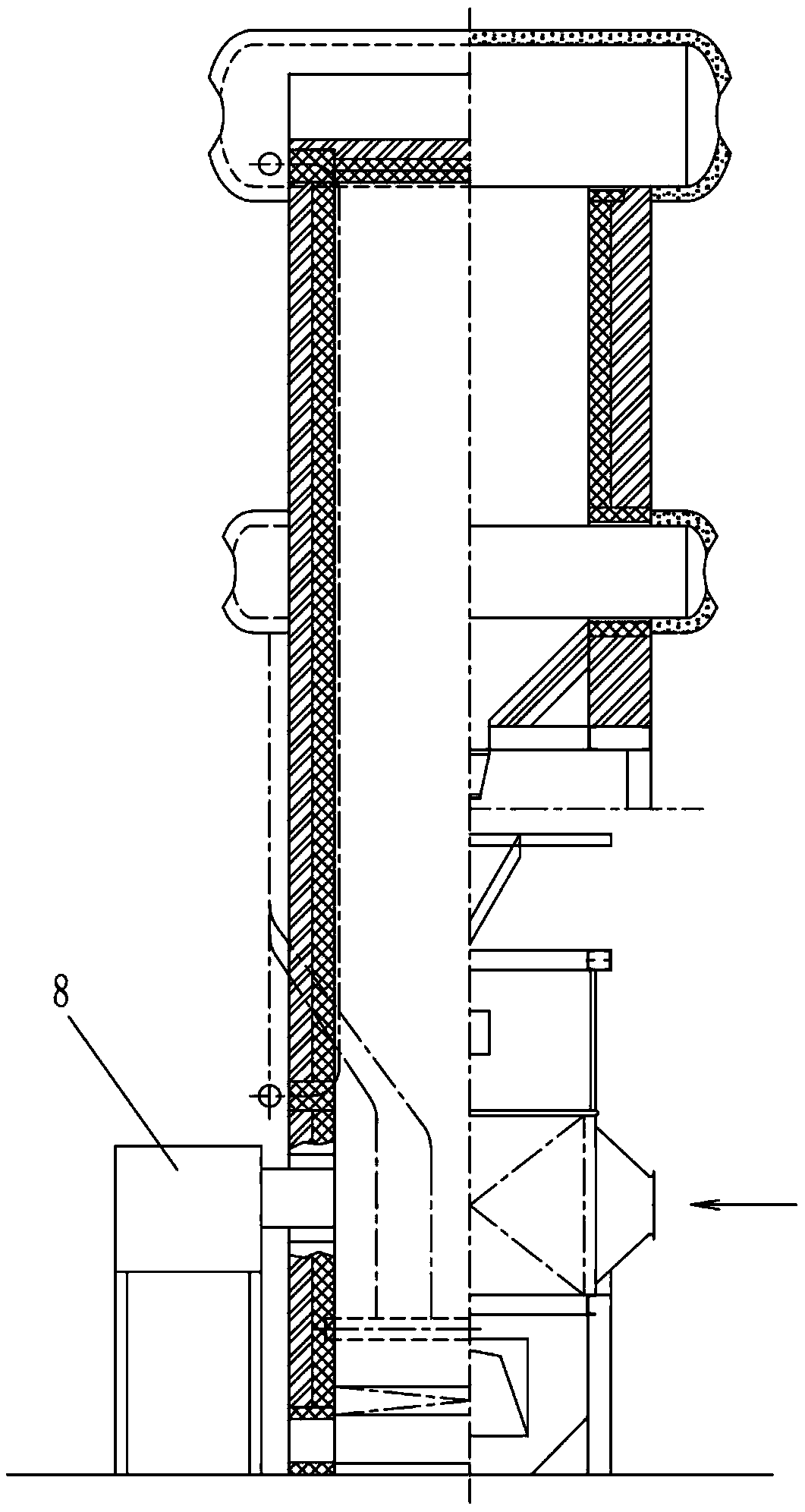

System and method for semi-coke blending combustion of coal-fired power plant with Brown gas for catalytic combustion supporting

ActiveCN110529839AHigh purityImprove combustion efficiencySolidificationLiquefactionAir preheaterNitrogen gas

The invention discloses a system and a method for semi-coke blending combustion of a coal-fired power plant with Brown gas for catalytic combustion supporting. Low-rank coal pyrolysis semicoke and bituminous coal are subjected to mixed combustion, the Brown gas is distributed at a primary air nozzle in a sandwich air mode for catalytic combustion supporting on the semicoke, so that the problems that the semicoke is difficult to burn and poor in burnout performance can be effectively solved. Oxygen-rich air generated by a cryogenic air separation nitrogen making machine is preheated through smoke and then serves as oxygen-rich over-fire air, and the excess air coefficient of the main combustion area is controlled to be 0.8 or below, so that the reducibility of the main combustion area is enhanced, sufficient combustion of fuel can be guaranteed while NOx emission is effectively controlled, and the combustion efficiency of the boiler is improved. Flue gas and exhaust steam of a steam turbine are condensed through liquid nitrogen, equipment of the cryogenic air separation nitrogen making machine is heated through the flue gas in front of an air preheater, high-purity nitrogen can be made while moisture in the flue gas is collected and utilization of circulating cooling water of a power plant is reduced, and the efficiency of a boiler and the cryogenic air separation nitrogen making machine is improved.

Owner:XI AN JIAOTONG UNIV

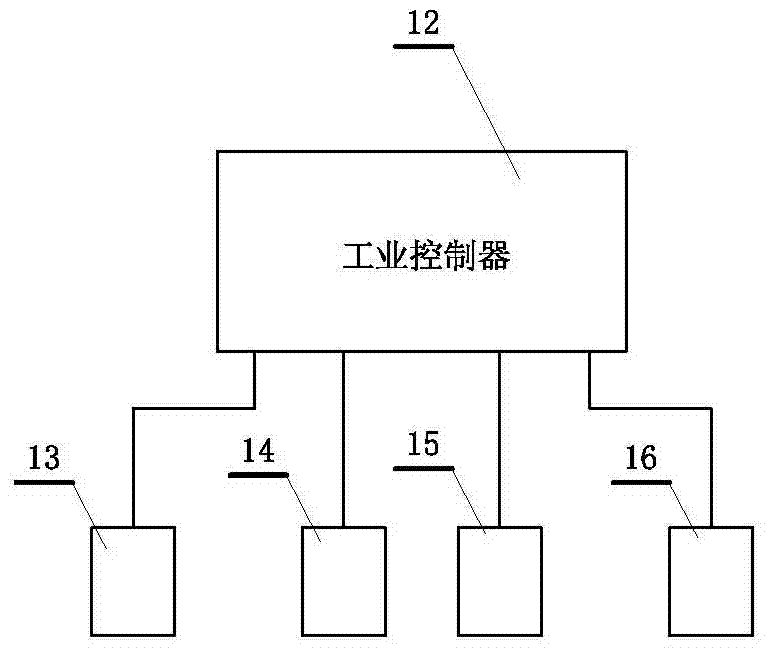

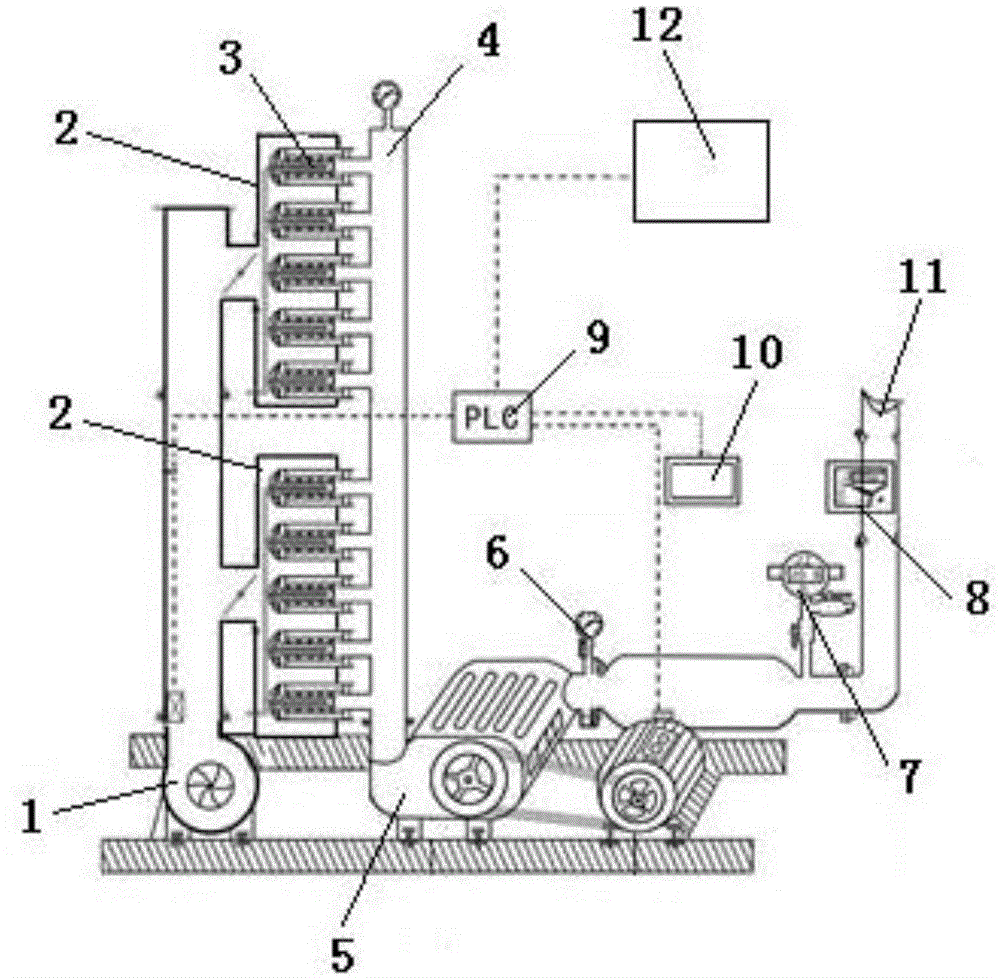

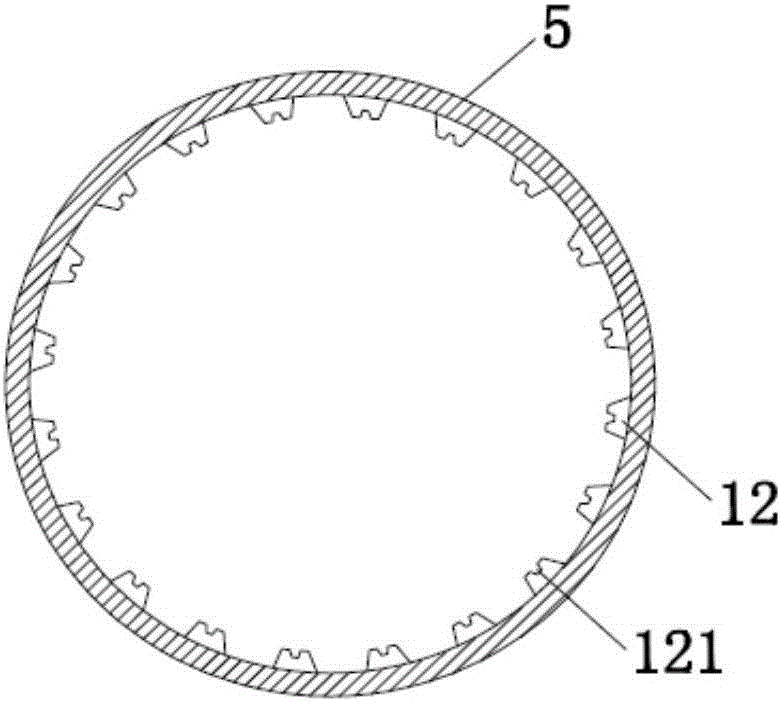

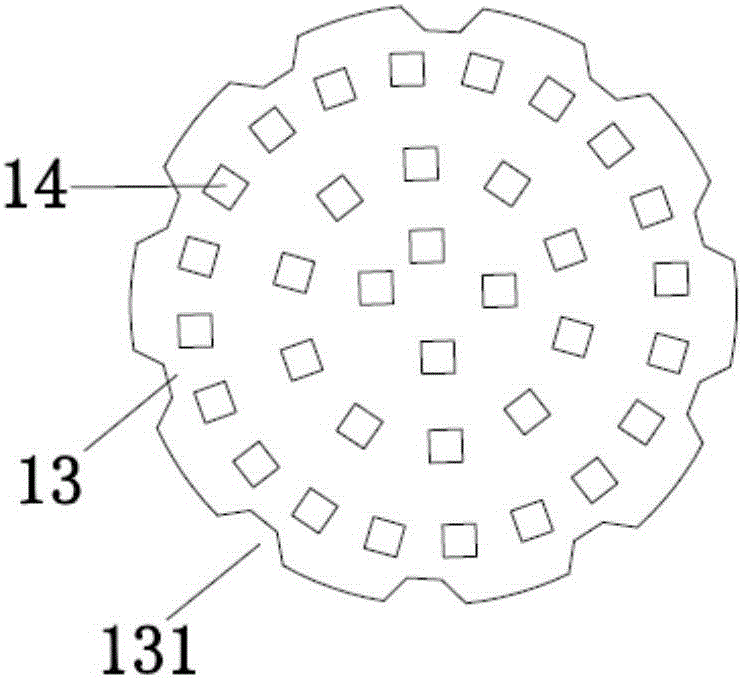

Intelligent linear oxygen-concentrated and thermally-ionized adsorptive-type magnetically-induced airflow combustion-supporting and energy-saving system with magnetic effect

InactiveCN104595923AReduce usageIncrease temperatureAir supply regulationIndirect carbon-dioxide mitigationMagnetizationVacuum pump

The invention relates to an intelligent linear oxygen-concentrated and thermally-ionized adsorptive-type magnetically-induced airflow combustion-supporting and energy-saving system with a magnetic effect. The system comprises a raw material air supply machine, a magnetic effect magnetically-induced airflow pressure-equalizing distribution box and a single stage type roots vacuum pump, wherein an outlet of the raw material air supply machine is connected with the magnetic effect magnetically-induced airflow pressure-equalizing distribution box; a tunnel-type annular linear thermally-ionized magnetization group is arranged in the magnetic effect magnetically-induced airflow pressure-equalizing distribution box and is connected with an adsorption pipeline; the adsorption pipeline is connected with an oxygen-rich magnetized gas output pipeline through the single stage type roots vacuum pump; an oxygen-rich air output pressure gauge, an intelligent online oxygen content analyzer and an intelligent online oxygen-rich output flowmeter are arranged on the oxygen-rich magnetized gas output pipeline; a PLC (Programmable Logic Controller) intelligent industrial control system is connected with a liquid crystal display operation touch screen and an energy-saving variable-frequency control motor. According to the system disclosed by the invention, the combustion speed is accelerated and the complete combustion is facilitated; the combustion environment is optimized, and the life of a stove is prolonged; the product yield and the product quality are improved; the smoke volume after combustion is reduced.

Owner:YANTAI JIUZHOU FUEL OIL & FUEL GAS ENERGY SAVING TECH

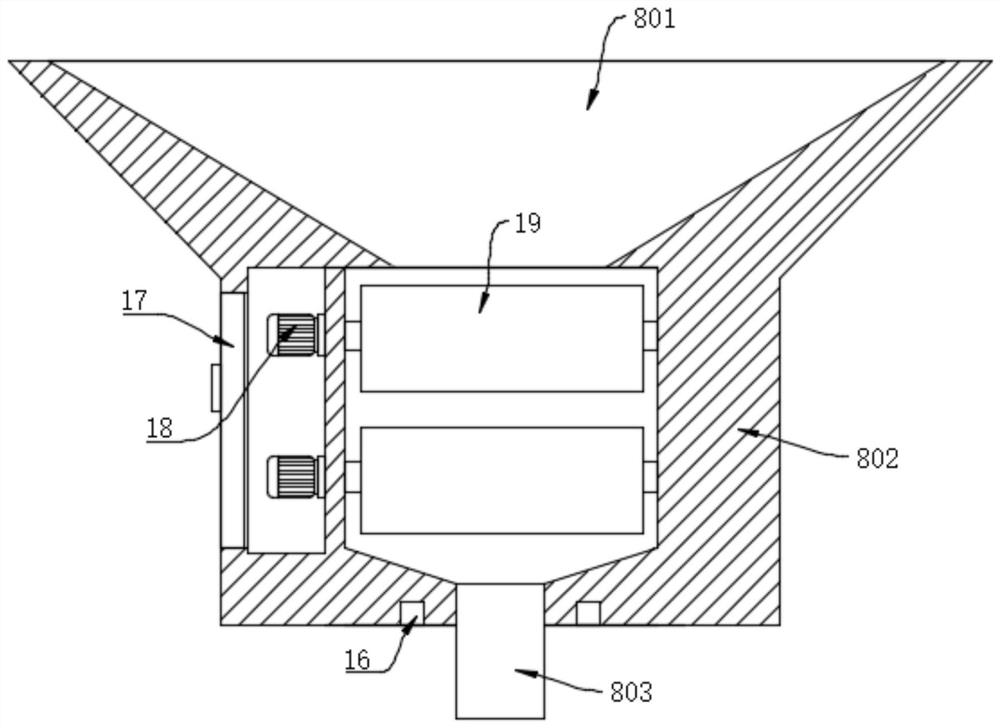

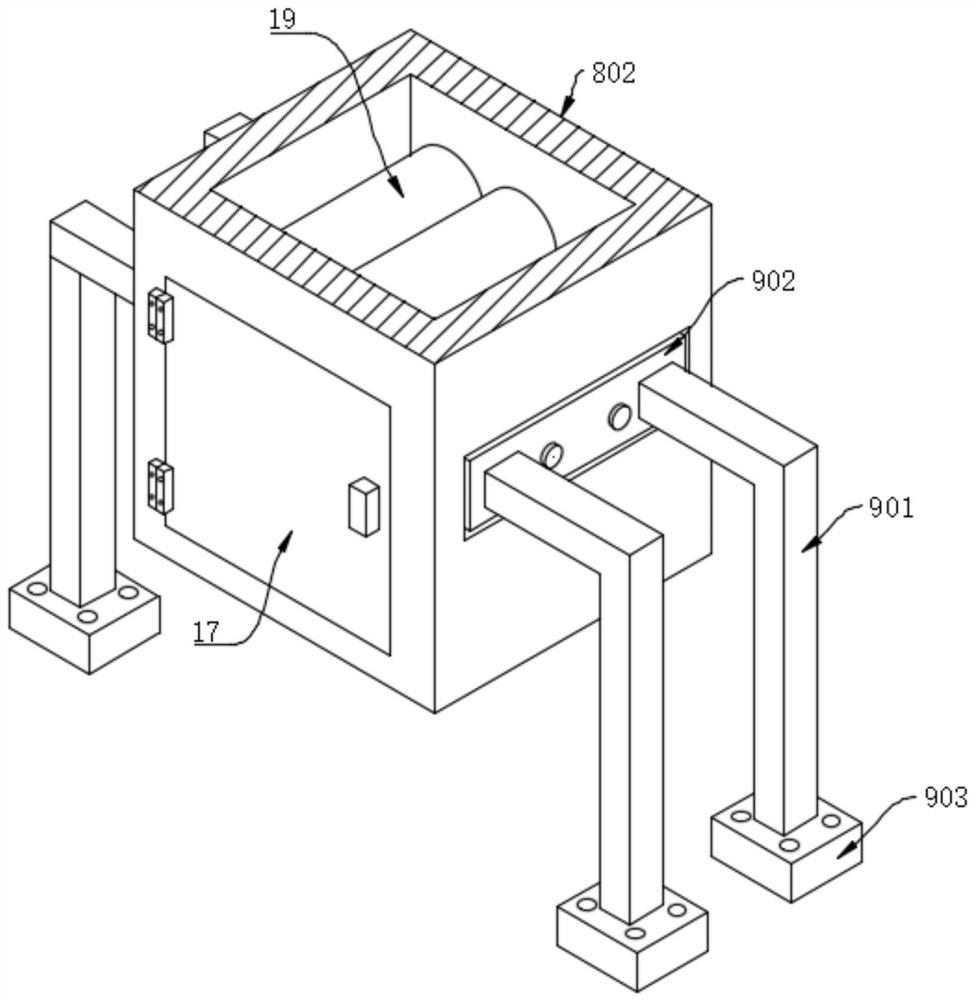

Large-size hazardous waste rotary kiln type incinerator device taking sludge as main target

InactiveCN106402894APromote complete combustionLow oxygenIncinerator apparatusHot blastCombustion chamber

The invention discloses a large-size hazardous waste rotary kiln type incinerator device taking sludge as a main target. The device comprises a receiver bin, a feeder, a multifunctional fuel nozzle, a kiln internal hot blast blowing unit, a rotary kiln, a power suspension unit, a secondary combustion chamber and a scraper slag discharging machine. The feeder, the multifunctional fuel nozzle and the kiln internal hot blast blowing unit are arranged at an inlet of the rotary kiln. The receiver bin is arranged above the feeder. The power suspension unit is arranged in the middle of the rotary kiln. The secondary combustion chamber is arranged at the tail of the rotary kiln. The scraper slag discharging machine is arranged at the lower end of the secondary combustion chamber. Three fuels, namely the solid fuel, the gas fuel, and the liquid fuel can be simultaneously or independently used for providing heat for the incinerator, and steam or nitrogen or water can be used for cooling the fiery furnace under the emergent incinerator shutdown condition. The power suspension unit and the kiln internal hot blast blowing unit are used for increasing the contact area of materials and the gas, so that the heat transferring, drying and combusting effects are improved, and the disposal capacity and efficiency of the kiln type incinerator device are improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

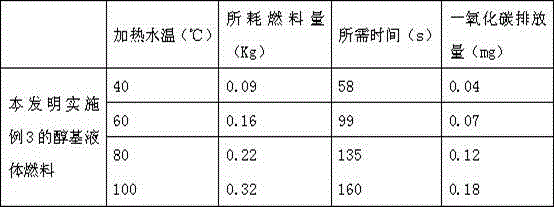

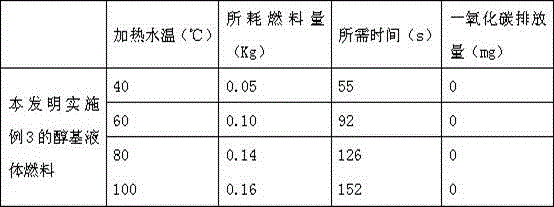

Alcohol-based liquid fuel

InactiveCN106753605AReduce sulfur contentReduce wear rateLiquid carbonaceous fuelsFuel additivesAlcoholJatropha

The invention relates to alcohol-based liquid fuel. The fuel comprises the following raw materials in parts by weight: 80 to 85 parts of methyl alcohol, 5 to 10 parts of water, 1 to 2 parts of petrol, 1 to 3 parts of sodium hydroxide, 1 to 3 parts of castor oil, 3 to 8 parts of jatropha carcas fruit oil, 2 to 5 parts of edible oil, 1 to 3 parts of essence, 1 to 5 parts of industrial salt, and 1 to 5 parts of ethyl alcohol. The fuel has the characteristics that the fuel does not produce poisonous gas when being burnt and is odor-free; the fuel can be completely burnt, the heat value produced through burning is high, the flash point of the fuel can be reduced, the fuel can be easily ignited, can be completely burnt, does not produce poisonous gas, and is low in cost, economical and practical, and green and environmental-friendly.

Owner:吴良善 +2

Antiknock clean solvent used for motor gasoline

InactiveCN105838459APrevent decomposition and condensationPromote complete combustionLiquid carbonaceous fuelsFuel additivesEthyl acetateSolvent

The invention discloses an antiknock clean solvent used for motor gasoline. The antiknock clean solvent includes a clean dispersant, a combustion improver, an antiknock agent, a polar solvent and an inert solvent, wherein the clean dispersant comprises 10-20wt% of a petroleum sulfonate agent, 5-8wt% of succinate and 8-12wt% of salicylate; the combustion improver is 5-8wt% of benzyl alcohol ; the antiknock agent is 5-8wt% of methyl tert-butyl ether; the polar solvent is 25-35wt% of trifluoroacetic acid or acetylferrocene; and the inert solvent is obtained through mixing fatty oil, liquid paraffin, ethyl acetate and isopropyl myristate. The antiknock clean solvent allows gasoline components and even gasoline components not according with national relevant regulation to be processed in order to produce qualified 93# or above gasoline, so some resources which cannot be used are changed into valuables and become national effective energy.

Owner:CHENGDU TIANFENG CLEANING ENERGY DEV CO LTD

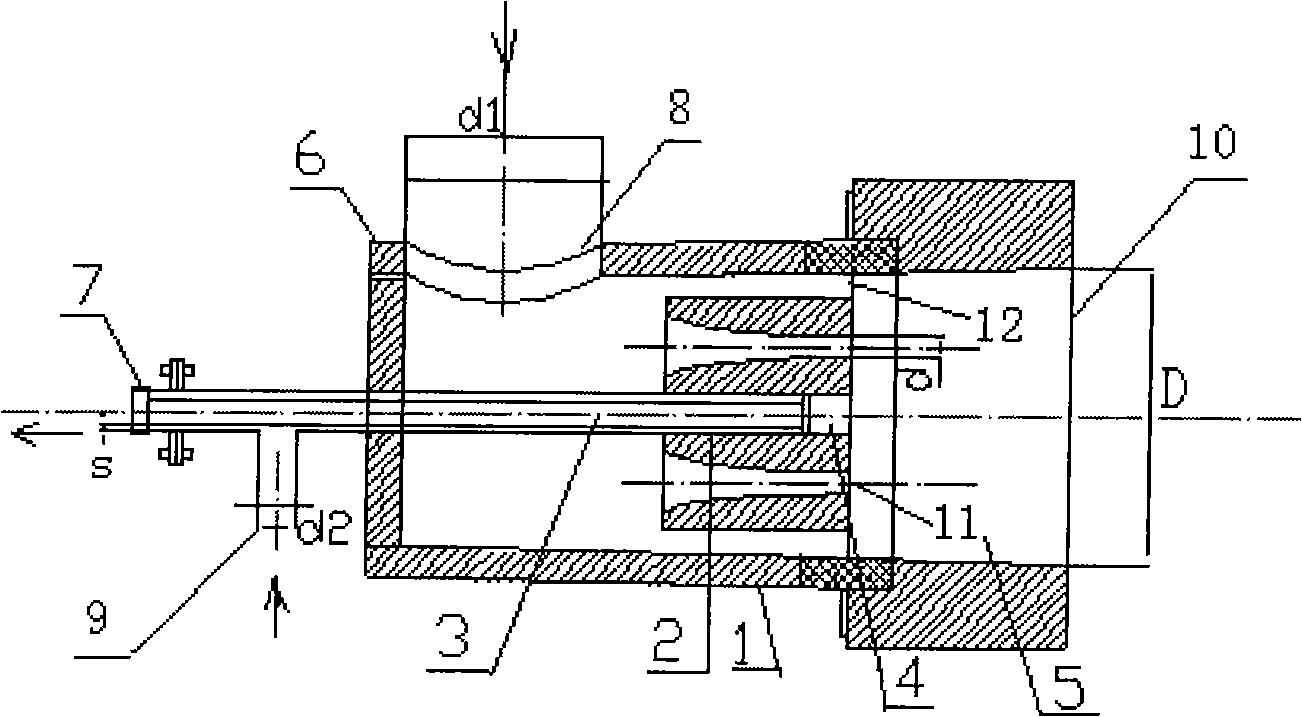

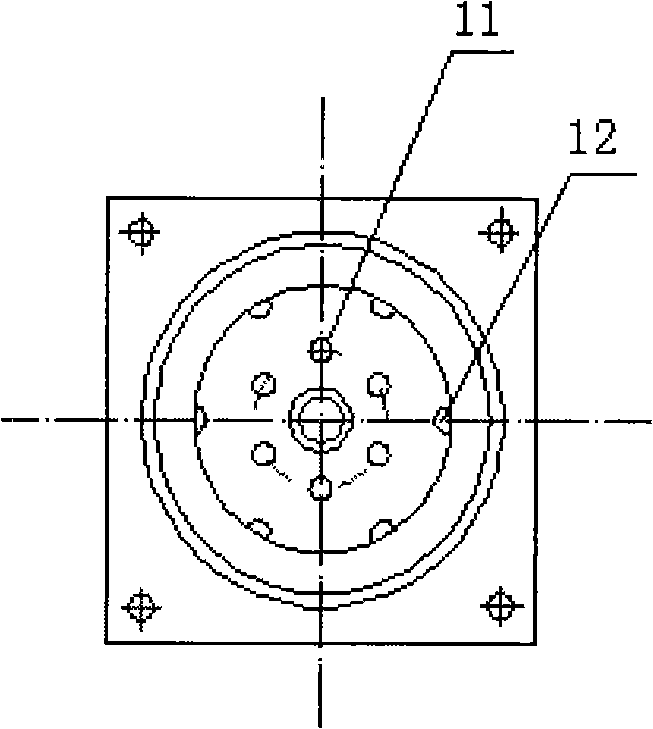

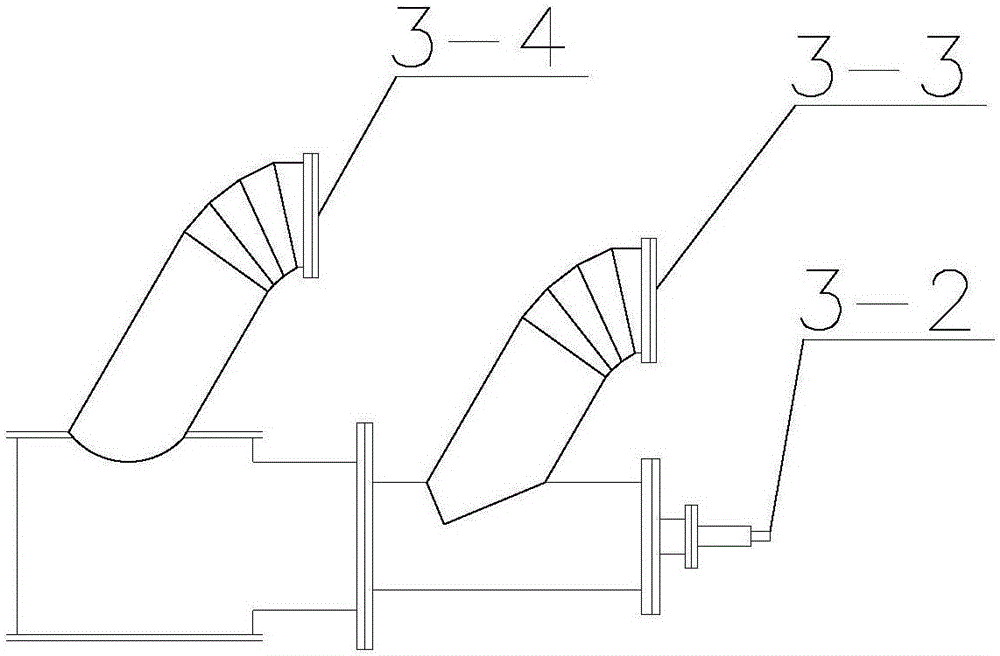

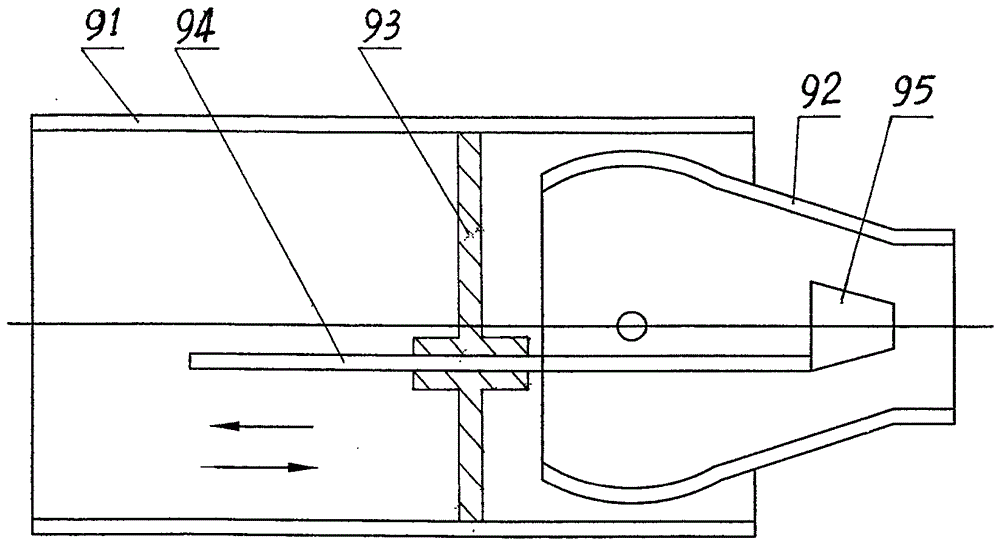

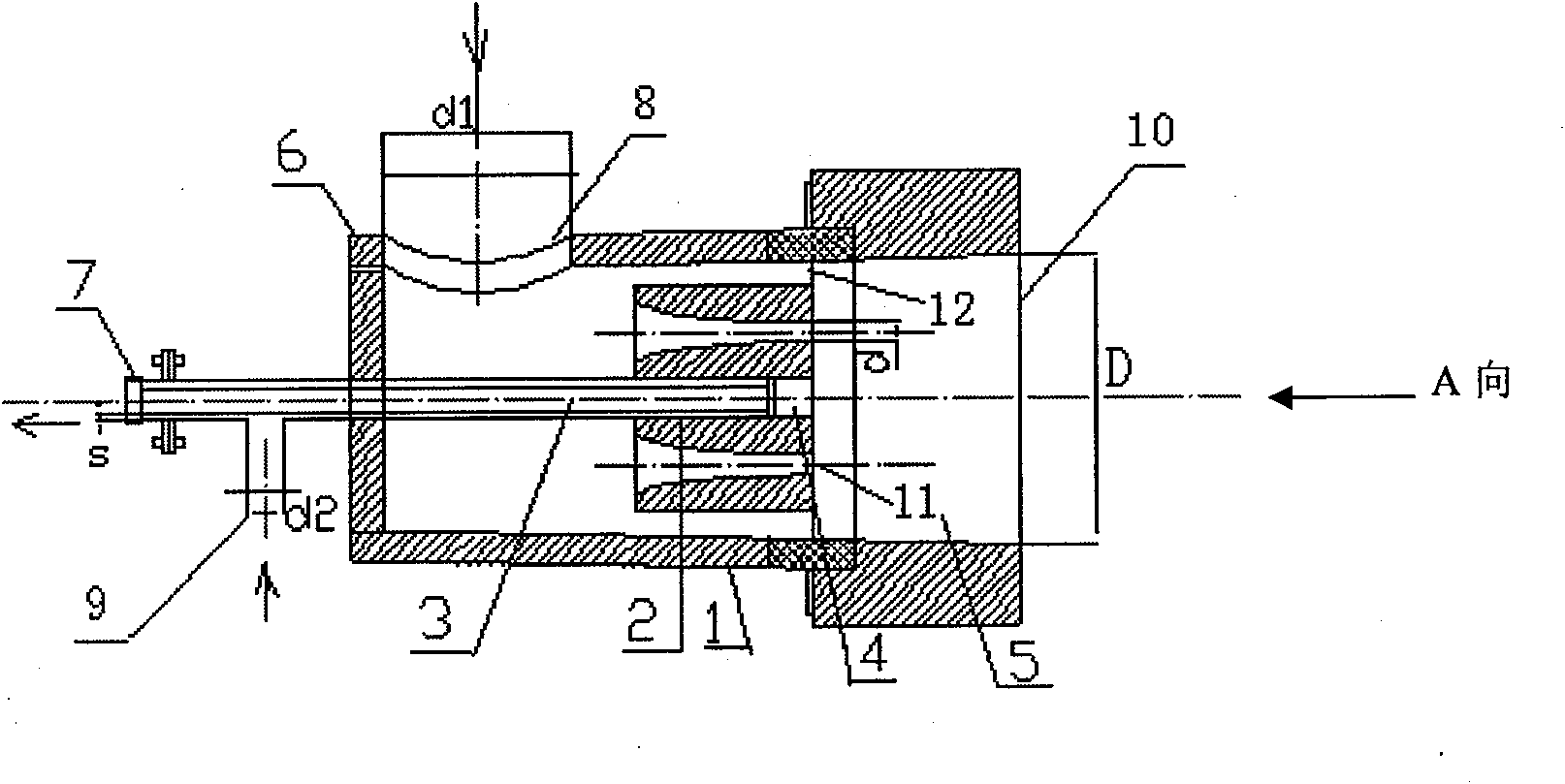

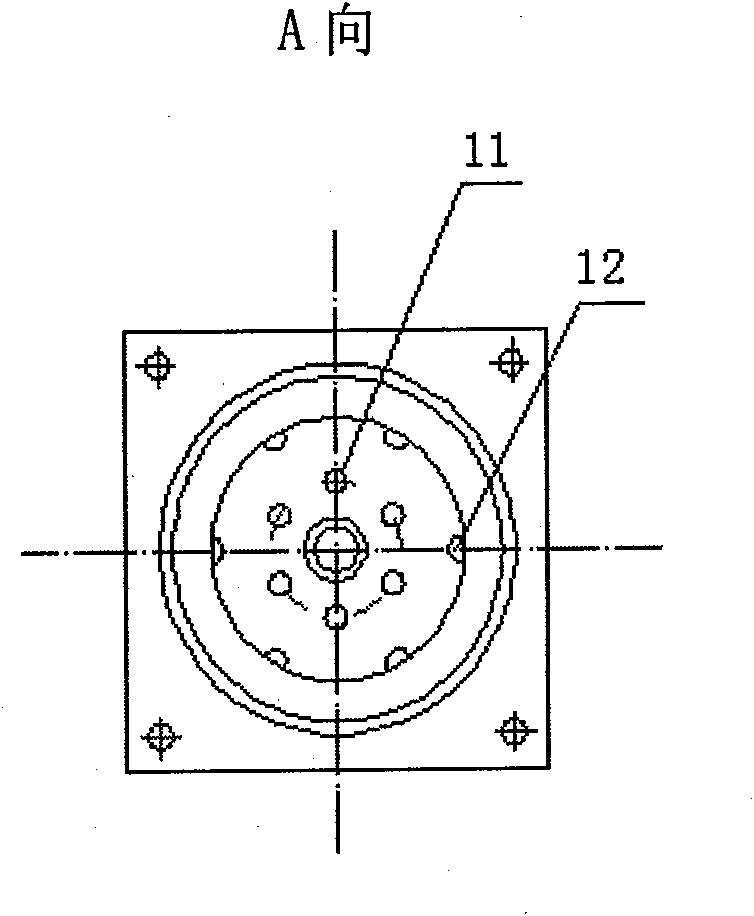

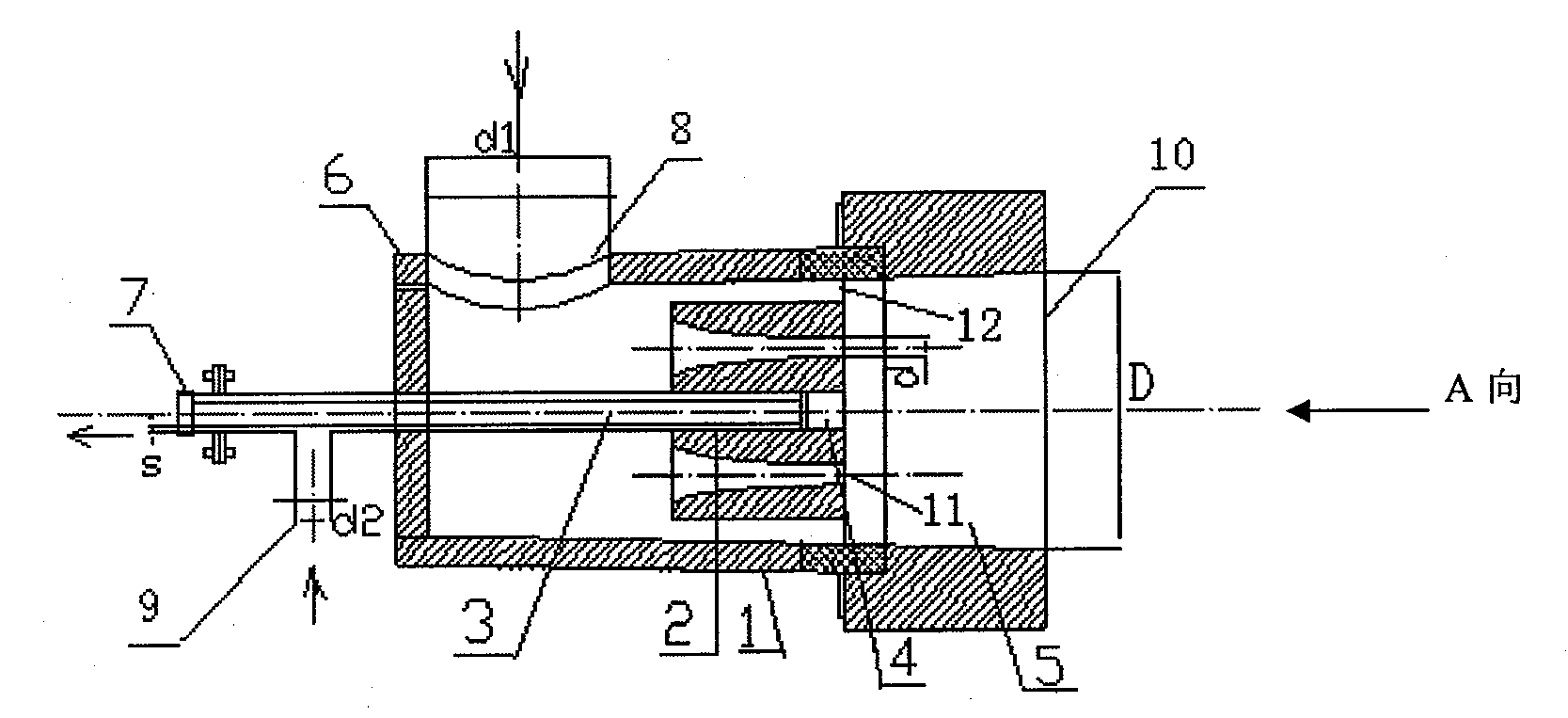

The method of adjusting the cross-sectional area of the nozzle to keep the wind speed constant

InactiveCN104132330BSimple methodIncrease exposureCombustion using gaseous and pulverulent fuelFuel supply regulationEyelidCombustor

A method for maintaining wind speed by adjusting cross-sectional area of a nozzle belongs to the field for boiler. A primary air fan, an valve A, a preheater A, a coal grinding machine and a combustor A are fixed by pipes; a secondary air fan, a valve, B, a preheater B and a combustor B are fixed by pipes; the combustor B and the combustor A are fixed with a hearth furnace; the hearth furnace, a preheater C, a dust collector, a valve C, a fan and a chimney are fixed by pipes; a frame body and a nozzle, the frame body and a support are fixedly connected, and a pull rod and a blunt body are fixedly connected, and the support and the pull rod are in sliding connection; an outer frame and the upper and lower nozzles are connected by a rotating shaft; the upper and lower nozzles are fixed with the upper and lower pulling blocks; the upper and lower pulling blocks are connected with upper and lower connecting rods by the upper and lower shafts; a cylinder frame and the nozzle are connected, the cylinder frame and the support are connected, and a three-connecting is fixed with a blade and the pull rod; the cylinder frame and the blade are connected by the shaft; and the pull rod and the support are in sliding connection. The method adjusts nozzle cross-sectional area through change of distance between the bluff body and the nozzle outlet, adjusts overall nozzle cross-sectional area through the swing of the upper and lower nozzles, and regulates nozzle cross-sectional area through blade angle change driven by the three-connecting to keep the air speed at the nozzle unchanged, wherein one of the three adjustment modes is employed at one time. The method is applicable to boilers.

Owner:中节环(北京)环境科技股份有限公司

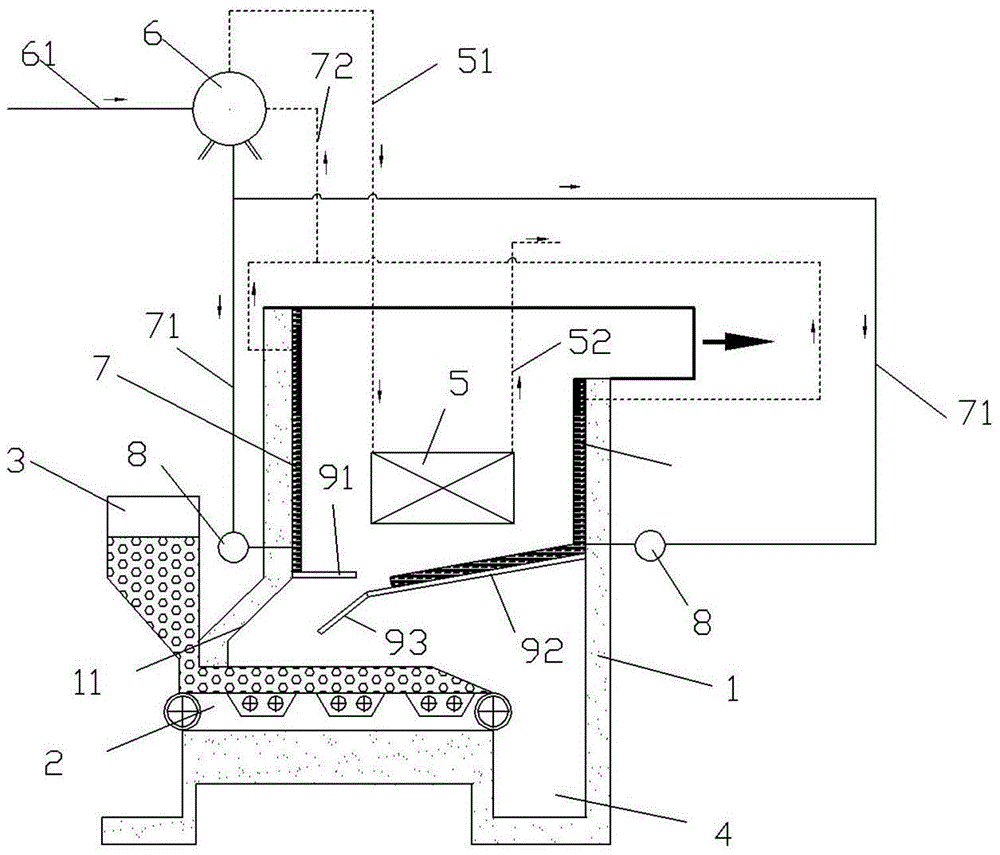

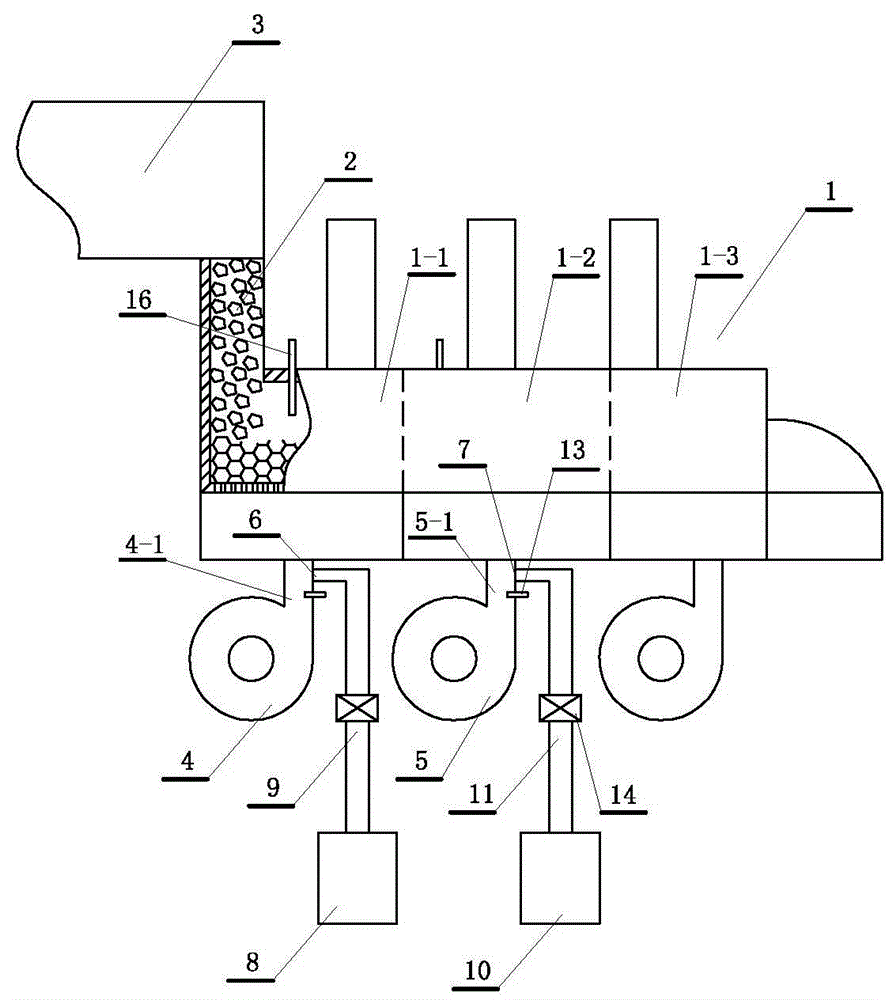

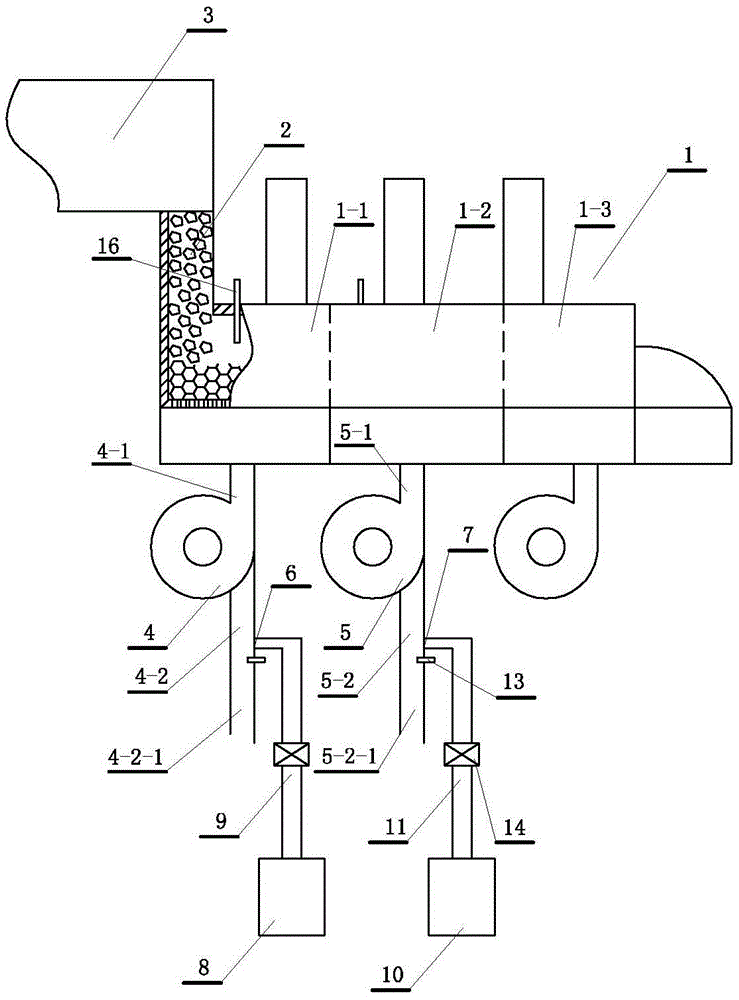

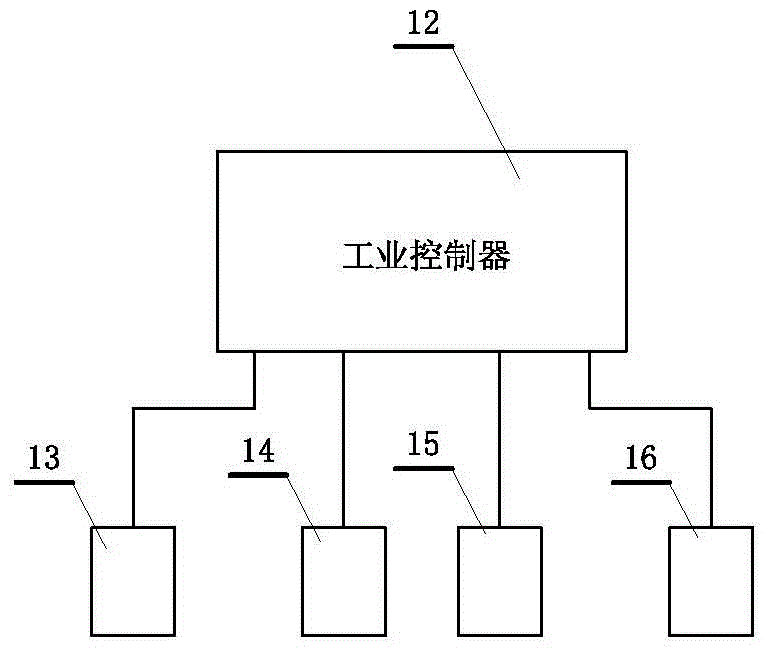

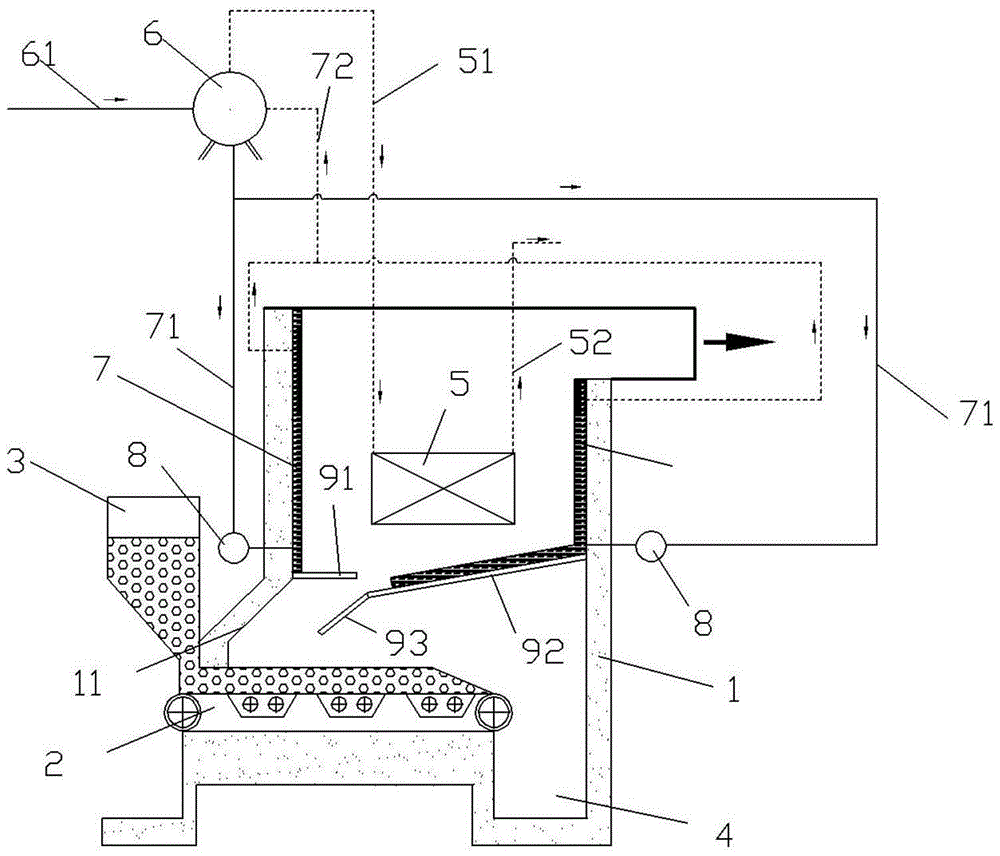

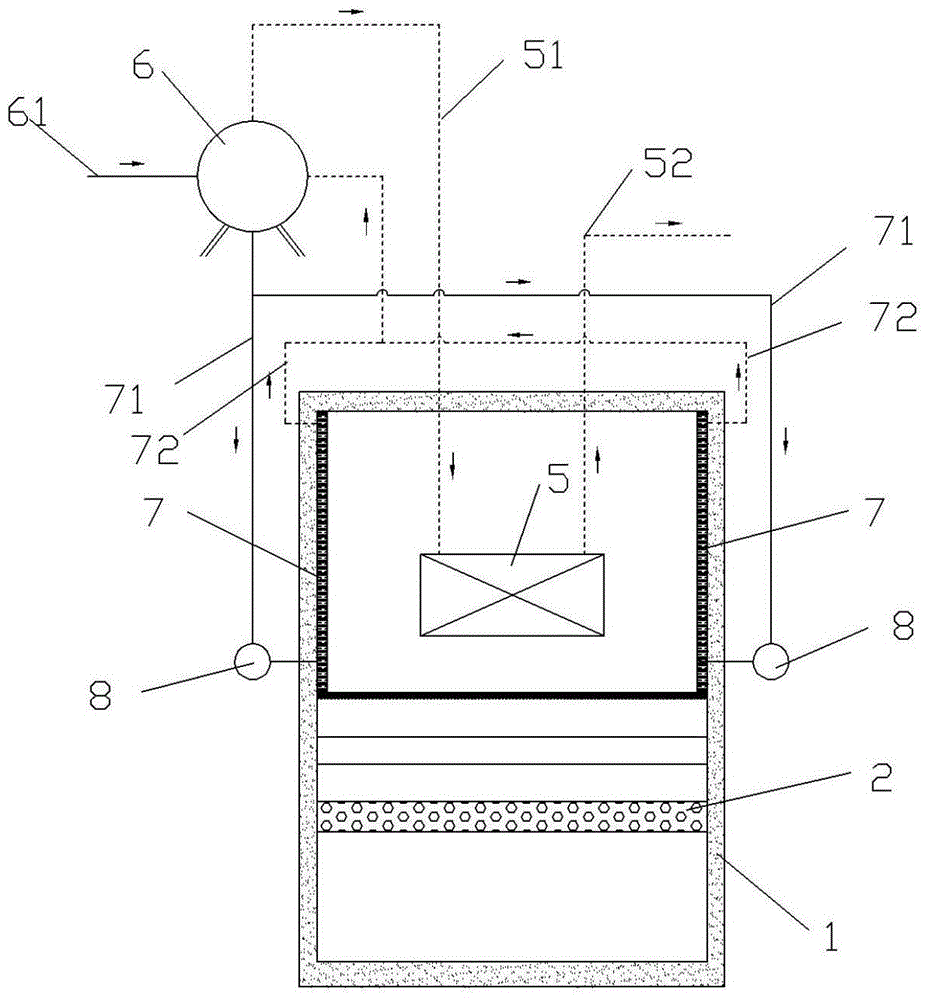

High-moisture fuel fired steam boiler

InactiveCN104279547ADry completelyIncrease burn rateSolid fuel combustionSteam boilersCombustion chamberCombustor

The invention discloses a high-moisture fuel fired steam boiler. The high-moisture fuel fired steam boiler comprises a boiler body, a combustion cavity and a feeding device, a pre-combustion chamber is arranged in front of the combustion cavity and communicated with a vaporizing combustor outside the boiler body, a discharging port of the feeding device is communicated with a feeding port of the pre-combustion chamber, and a high-inclination-angle reciprocal grate is arranged below the pre-combustion chamber. High-moisture fuel in the pre-combustion chamber is dried by high-temperature smoke generated by the vaporizing combustor and then fed to a central combustion area of the combustion chamber for combustion, and consequently completeness in fuel drying is realized, and fuel burn-off rate is increased.

Owner:广州优的新能源科技有限公司

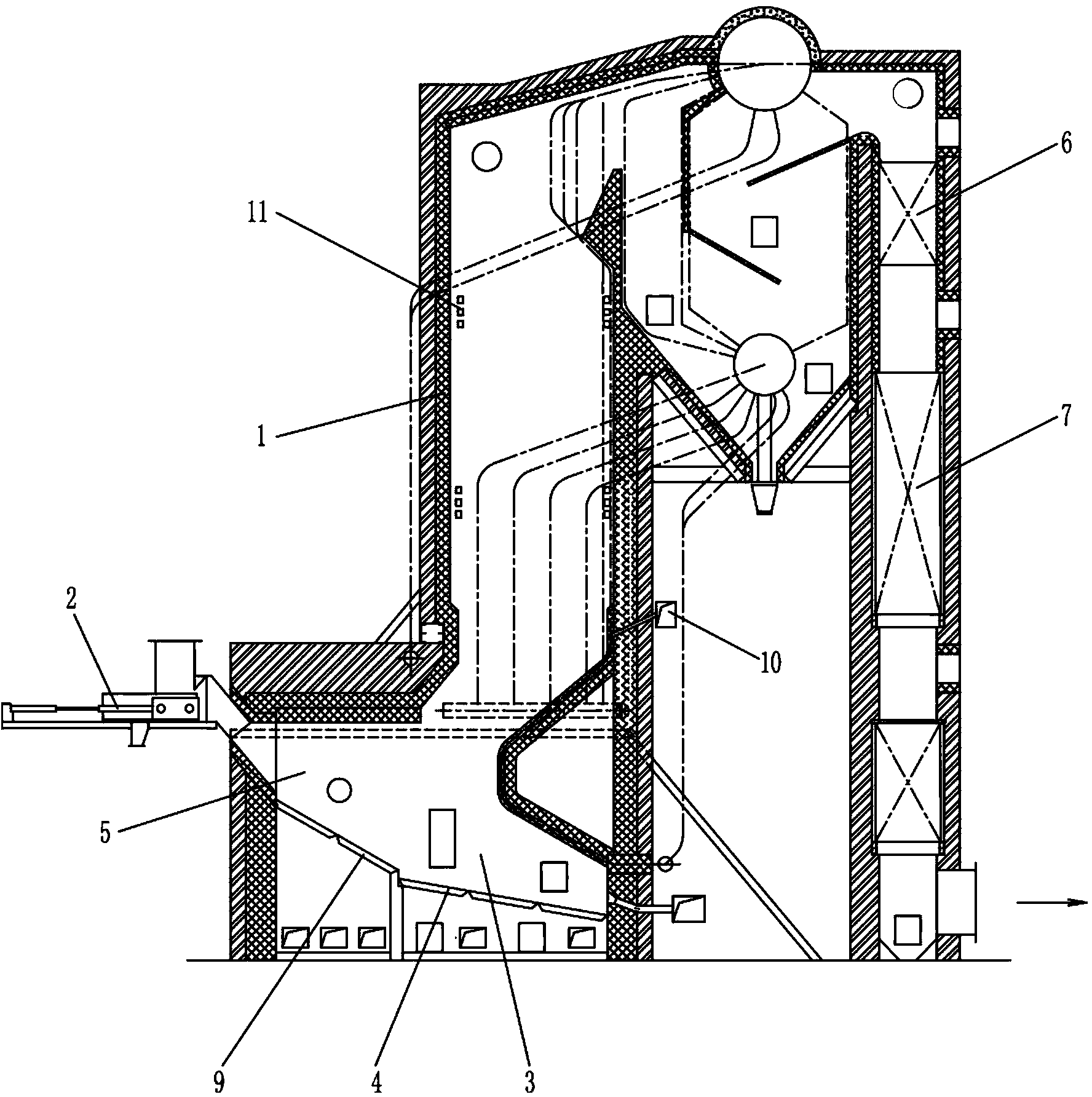

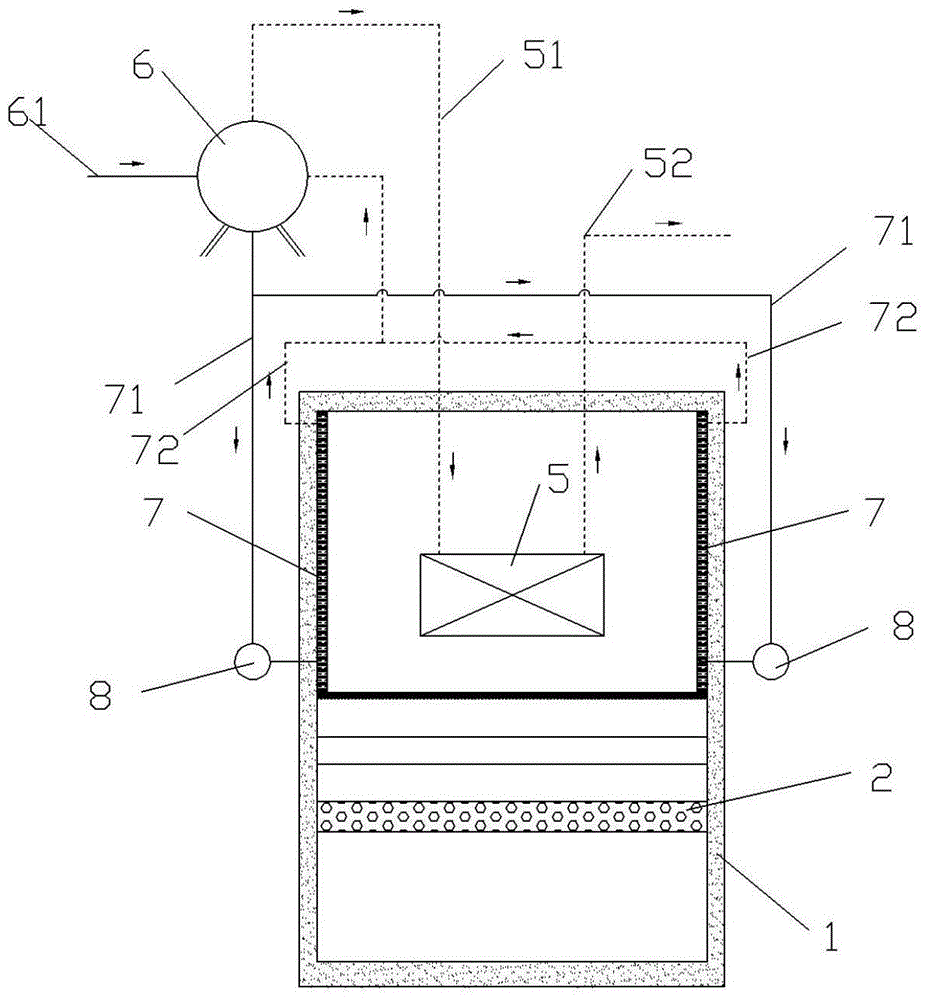

Biomass combustion power generation boiler

InactiveCN104359100AIncrease heat loadBurn completelySolid fuel combustionSteam boilersCombustion chamberSlag

The invention discloses a biomass combustion power generation boiler, which comprises a boiler wall, a boiler grate, a steam overheater, a material inlet, a slag outlet, a front cover, a water cooling wall, a steam bag, a flow guide cover, an auxiliary flow guide cover and the like, wherein the boiler hearth is separated into a combustion chamber and a heat transfer chamber by the front cover and the flow guide cover, and biomass is centrally combusted in the combustion chamber under the area surrounded by the front cover and the flow guide cover. Compared with the prior art, the biomass combustion power generation boiler has the advantages that the biomass is centrally combusted in the area surrounded by the front cover and the flow guide cover, so the volume heat load of the combustion area is large; the turbulence of smoke in the combustion area is improved by the flow guide cover, the delivered biomass can be sufficiently and completely dried, the combustion is complete, and the combustion efficiency is high; the smoke flowing direction is turned by the flow guide cover, and the combustion dust is furthest settled in the combustion area by the centrifugal force of air flow, so the discharge amount of boiler pollutants is less.

Owner:HEFEI UNIV OF TECH

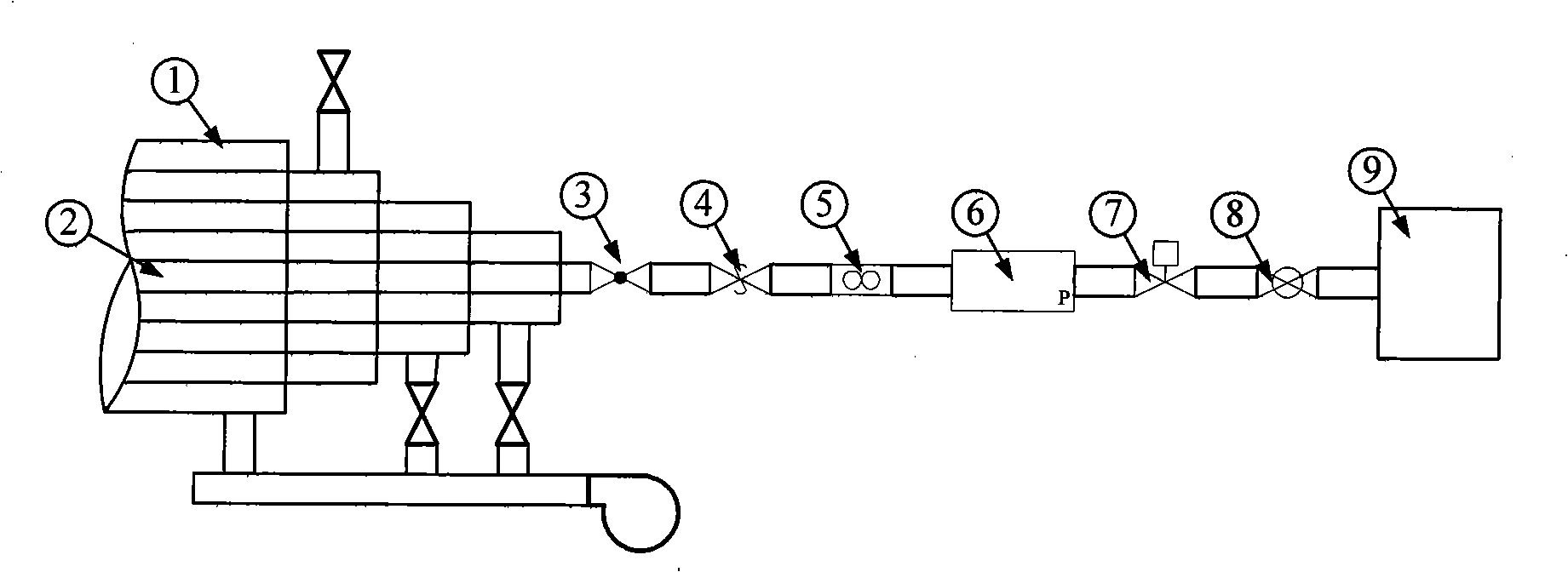

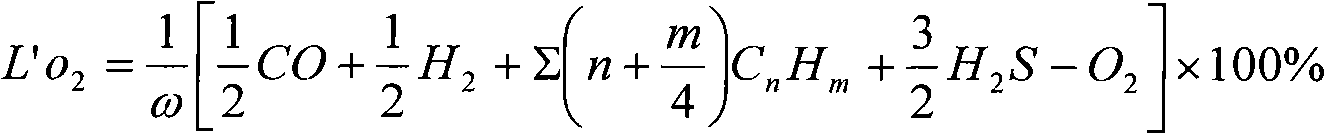

Magnetization oxygen-enriched energy conservation and emission reduction system of gaseous suspension roaster

The invention relates to a magnetization oxygen-enriched energy conservation and emission reduction system of a gaseous suspension roaster. The magnetization oxygen-enriched energy conservation and emission reduction system comprises a raw air supply fan, two multi-duct pressure equalization distribution tanks, a double-stage booster roots pump set, an intelligent PLC (programmable logic control) system and an oxygen-enriched gas output pipeline. The raw air supply fan is connected with the two multi-duct pressure equalization distribution tanks, cyclone concave-convex thermal separation magnetic groups are arranged in the two multi-duct pressure equalization distribution tanks and are connected with an inlet of the double-stage booster roots pump set by vacuum absorption pipelines, the double-stage booster roots pump set is connected with an oxygen-enriched injection point of the gaseous suspension roaster by the oxygen-enriched gas output pipeline, the raw air supply fan, an intelligent oxygen analyzer and an intelligent gas flow meter are connected with the intelligent PLC system, and the intelligent PLC system is connected with a remote computer. The magnetization oxygen-enriched energy conservation and emission reduction system has the advantages that the combustion speeds can be increased, and complete combustion can be promoted; ignition temperatures of fuel can be lowered, combustion environments can be optimized, and the service life of the roaster can be prolonged; the yield of products can be increased, the quality of the products can be improved, and the post-combustion smoke quantity can be reduced.

Owner:YANTAI JIUZHOU ENVIRONMENTAL PROTECTION & ENERGY SAVING TECH

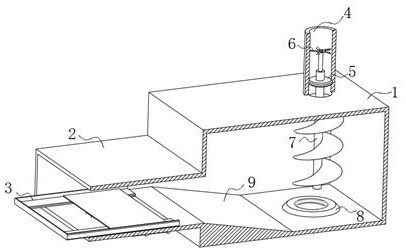

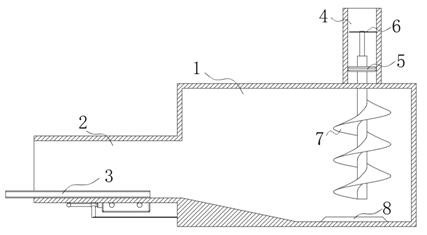

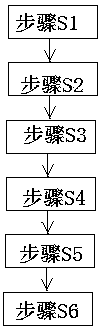

Biomass energy combustion treatment process

PendingCN113339832AImprove combustion heat release efficiencyImprove combustion efficiencyFuel feeding arrangementsSolid fuelsPtru catalystEngineering

The invention discloses a biomass energy combustion treatment process. The process is characterized by comprising the following steps of S1, dispersing biomass fuel, screening impurities doped in the biomass fuel through screening equipment, and pulverizing the biomass fuel into powder through a pulverizer after the biomass fuel is dispersed, screened and subjected to impurity removal; and S2, conveying the crushed biomass fuel through a spiral conveyor, and spraying a combustion-supporting catalyst to the biomass fuel at a material guide-in opening of the spiral conveyor. According to the biomass energy combustion treatment process, the biomass fuel is subjected to pre-combustion treatment, the combustion-supporting catalyst is sprayed on the surfaces of biomass powder fuel particles, and then biomass is combusted and fully dried, so that the combustion-supporting catalyst can be fused with the biomass fuel to the maximum extent, and the combustion-supporting efficiency of the combustion-supporting catalyst is improved; and different from a traditional manner that biomass fuel is directly combusted to release heat, thorough combustion of biomass powder fuel is facilitated, and the combustion heat release efficiency of biomass energy combustion is improved to the maximum extent.

Owner:徐州永路生物质能源有限公司

Composition for improving fuel or coal quality

ActiveCN105886493AHigh immobilization efficiencyImprove live stabilityTransferasesSolid fuelsCoalHaze

The invention provides a composition for improving fuel or coal quality. The composition, when applied to fuel or coal, can promote the complete combustion of the fuel or coal under an oxygen-enriched condition, so that the combustion efficiency of the fuel or coal is improved; and meanwhile, emission of NOX, SOX and the like is obviously reduced, so that the problem of haze is relieved.

Owner:NANJING BEI SHENG RONG ENERGY TECH CO LTD

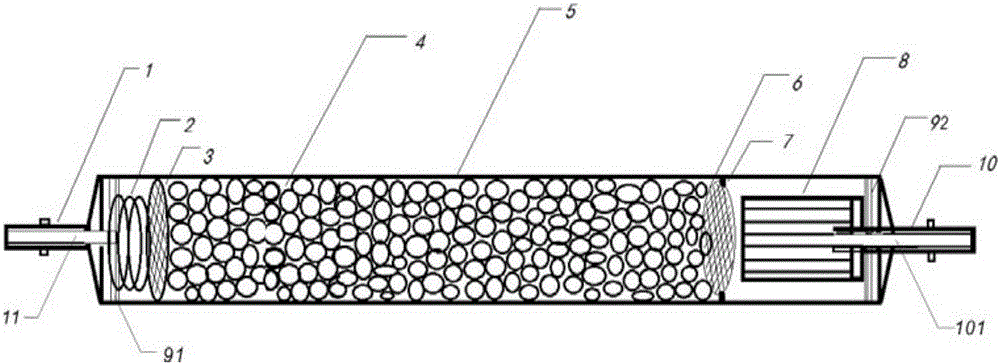

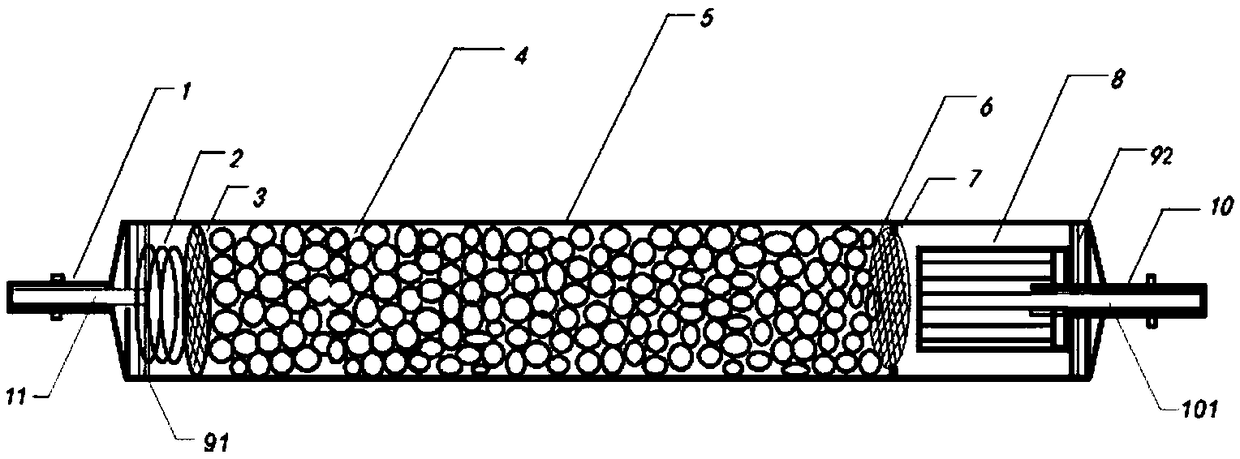

Energy conservation and emission reduction fuel-saving device

InactiveCN106050487APromote complete combustionIncrease profitInternal combustion piston enginesCombustion-air/fuel-air treatmentEngineeringMechanical engineering

The invention provides an energy conservation and emission reduction fuel-saving device. The device comprises a barrel body. The two ends of the barrel body are provided with an inlet end and an outlet end correspondingly. A fuel inlet plug is mounted at the inlet end. A fuel outlet plug is mounted at the outlet end. The barrel body is provided with a cavity which is filled with catalyst particles. The two ends of the catalyst particles are fixed through a first grid close to the fuel inlet plug and a second grid close to the fuel outlet plug correspondingly. A first inner fuel pipe is arranged on the fuel inlet plug. A second inner fuel pipe is arranged on the fuel outlet plug. The extension sections of the first inner fuel pipe and the second inner fuel pipe both extend into the cavity. The energy conservation and emission reduction fuel-saving device is simple in structure. The catalyst particles are arranged in the barrel body to shatter and catalyze fuel, so that the fuel is burned completely, the fuel utilization rate is increased, and the purpose of fuel economization is achieved. The energy conservation and emission reduction fuel-saving device is simpler in structure. The service life of a whole fuel economizer cannot be affected by magnetization reaction. The high-temperature-resisting and anticorrosive barrel body and a high-temperature-resisting and anticorrosive oil seal are adopted, and the service life of the whole fuel economizer is further prolonged.

Owner:张金庆

Efficient nuisanceless emulsified oil and preparation method thereof

InactiveCN107858178APromote interface activityPromote complete combustionLiquid carbonaceous fuelsFuel additivesChemistry

The invention discloses efficient nuisanceless emulsified oil and a preparation method thereof, and belongs to the field of fuel oil. The emulsified oil is prepared from the following ingredients in percent by mass: 50 to 90 percent of oil, 50 to 10 percent of water and 0.01 to 0.1 percent of additives, wherein the oil performance is similar to that of Bunker-C oil. The method comprises the stepsthat 1, after the water is heated, an emulsifying agent, an inorganic combustion improver and an oxidation accelerator are sequentially added and are dissolved to obtain a water solution; 2, the oil is heated to the same temperature as the water; high-speed stirring is performed; the water solution obtained in the first step is slowly added; after the stirring is performed for 1 minute, the emulsified oil is prepared. The emulsified oil is used as fuel oil.

Owner:深圳市国能环保科技有限公司

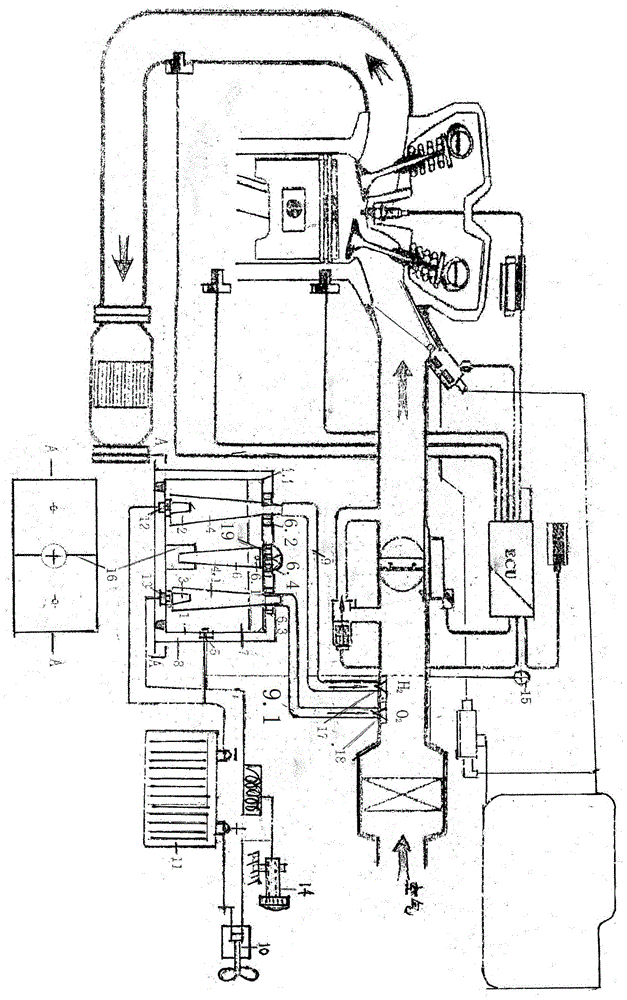

Independent auxiliary complete combustion device for internal combustion engine

InactiveCN105114212AMake sure it never dries upStructure has no effectNon-fuel substance addition to fuelMachines/enginesHydrogenExternal combustion engine

The invention belongs to the technical field of energy conservation and environmental protection, and particularly to an independent auxiliary complete combustion device for an internal combustion engine. The whole complete combustion device is an auxiliary system with independent hydrogen and oxygen supplies at the outside of the internal combustion engine, and can directly transport separated hydrogen and oxygen to a throttle, so the complete combustion device only can promote complete combustion without influence on the whole engine structure, the energy can be saved by 25% to 50%, more than 90% of pollution source in the internal combustion engine can be thoroughly eliminated, the effect can be got instantly. A vehicle-mounted inclination sensor can play its original role to protect the independent auxiliary complete combustion device for the internal combustion engine.

Owner:WUHAN UNIV

A composition for improving the quality of fuel oil or coal

ActiveCN105886493BHigh immobilization efficiencyImprove live stabilityTransferasesSolid fuelsEngineeringCoal

The invention provides a composition for improving fuel or coal quality. The composition, when applied to fuel or coal, can promote the complete combustion of the fuel or coal under an oxygen-enriched condition, so that the combustion efficiency of the fuel or coal is improved; and meanwhile, emission of NOX, SOX and the like is obviously reduced, so that the problem of haze is relieved.

Owner:NANJING BEI SHENG RONG ENERGY TECH CO LTD

Device and method for cooling clinker by using liquid oxygen and liquid nitrogen in a cement kiln

ActiveCN103968671BSpeed up heat exchangeImprove stabilityDomestic cooling apparatusHandling discharged materialDecompositionNitrogen

The invention discloses a device and a method for cooling clinker by liquid oxygen and liquid nitrogen of a cement kiln. The device is characterized in that a high-temperature cooling region of a grate cooler of the cement kiln is provided with a liquid oxygen input connector, and a middle-temperature cooling region of the grate cooler is provided with a liquid nitrogen input connector. The method comprises the steps of adding liquid oxygen the volume of which is 1%-12% of the total volume of cooling air fed by an air blower of a high temperature section of the grate cooler of the cement kiln, and adding liquid nitrogen the volume of which is 1%-45% of the total volume of cooling air fed by an air blower of a middle temperature section of the grate cooler of the cement kiln. The device and the method provided by the invention have the advantages that the cooling rate of clinker is improved by inputting liquid oxygen, and high-temperature clinker is cooled suddenly, so that the decomposition of D3S at 1250 DEG C is prevented or alleviated, the crystallization of MgO is prevented or alleviated, and the stability of the clinker is improved; a C3S crystal is prevented from growing, and thus the grindability of clinker is improved; the C2S crystal transfer is effectively prevented or alleviated by introduced liquid nitrogen.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

Glass kiln natural gas oxygen-enriched combustor

InactiveCN101303124BIncrease profitReduce surplus factorIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorEngineering

The invention relates to a natural gas oxygen-enriched burner with a glass kiln. Based on the normal natural gas burner, by adopting oxygen enrichment technology, the original larger air port is changed to a relatively smaller oxygen-enriched air port according to the oxygen content of the oxygen-enriched air so as to heighten the temperature of flame, reduce air displacement after combustion, promote heat utilization ratio and lower excess air coefficient.

Owner:SHANGHAI INST OF TECH

Solid waste treatment incineration device convenient to operate

PendingCN113175676APromote complete combustionGood for full combustionIncinerator apparatusExhaust fumesProcess engineering

The invention discloses a solid waste treatment incineration device convenient to operate. The solid waste treatment incineration device comprises a combustion furnace body, an igniter and an external carbon monoxide collecting device; and a pushing box used for transporting straw blocks is arranged on the side wall of the combustion furnace, an exhaust pipe used for exhausting is arranged at the top of the combustion furnace, and a straw block crushing device is arranged in the exhaust pipe. According to the solid waste treatment incineration device, discharged carbon monoxide gas outlets are distributed in the slope, a large amount of high-speed carbon monoxide rushes into the straw blocks, the packaged straw blocks can be scattered through flushing, the straw blocks are rapidly scattered, the gas is carbon monoxide, the ignition effect can be achieved, and complete combustion of straw can be accelerated; and fan blades are arranged at the top of a spiral cutter, the spiral cutter rotates downwards, waste gas can drive the fan blades at the top of the spiral cutter to rotate, then the spiral cutter is driven to rotate, the straw blocks can be crushed conveniently, and sufficient combustion of straw is facilitated.

Owner:辽宁兴东科技有限公司

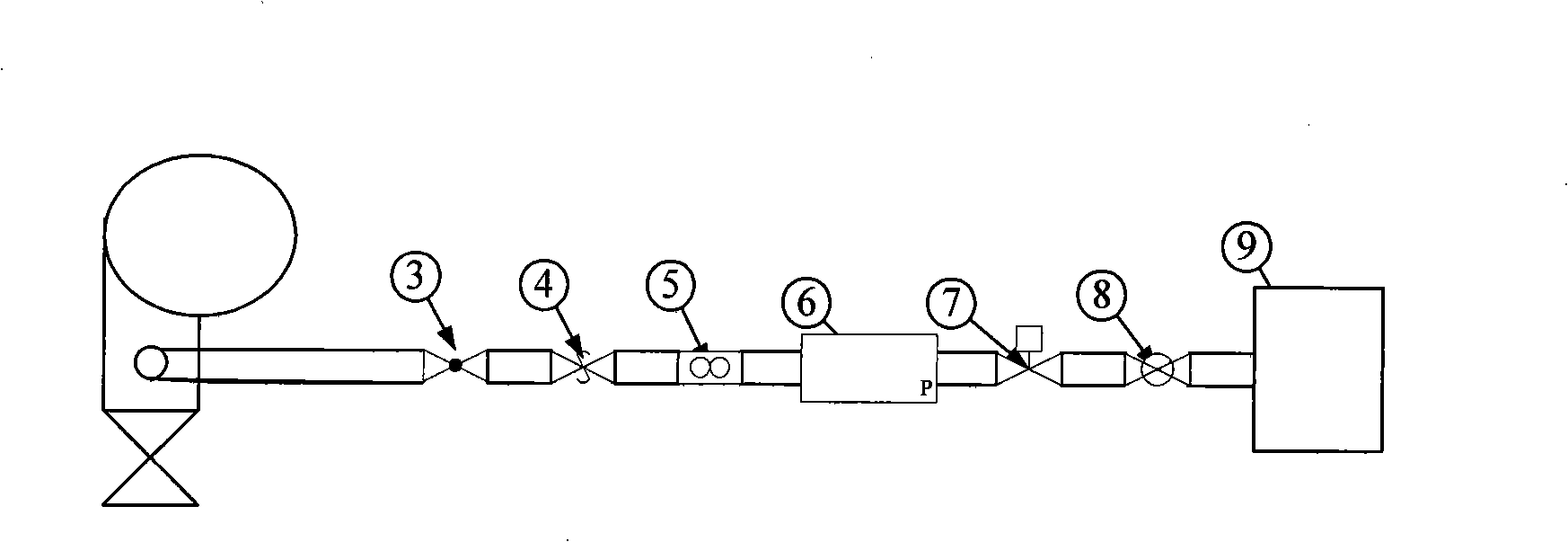

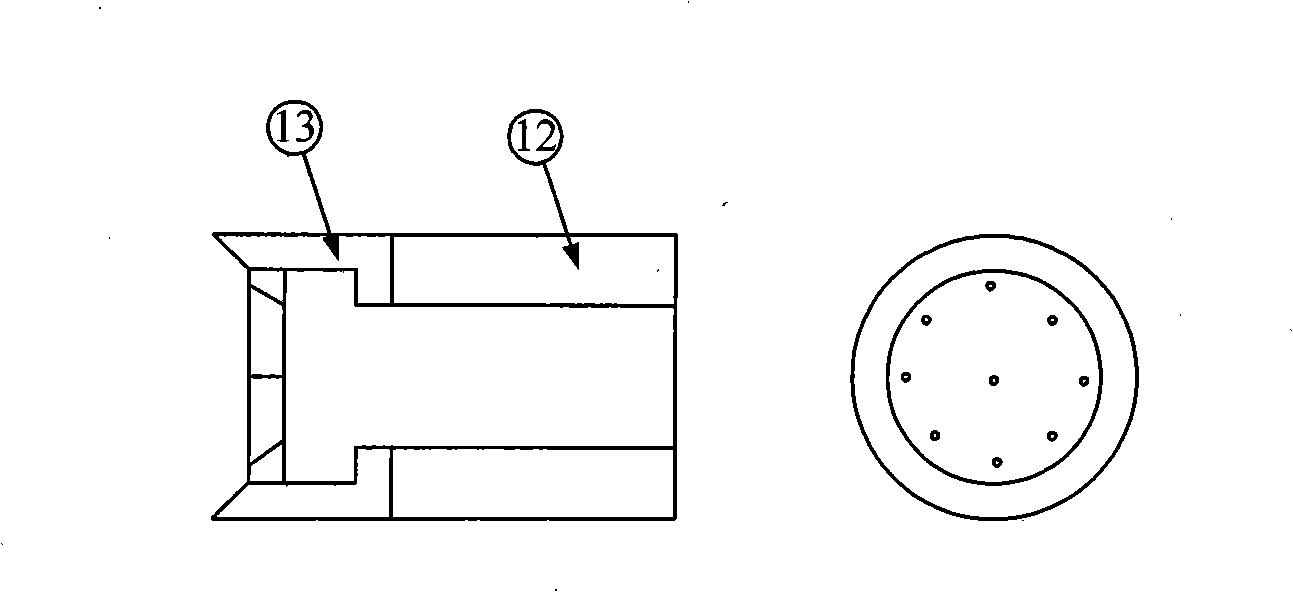

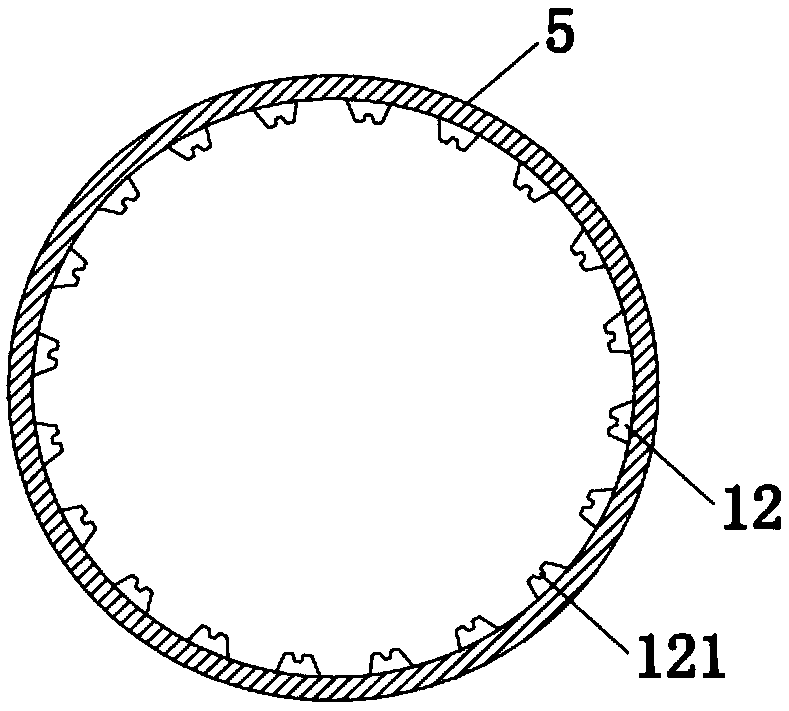

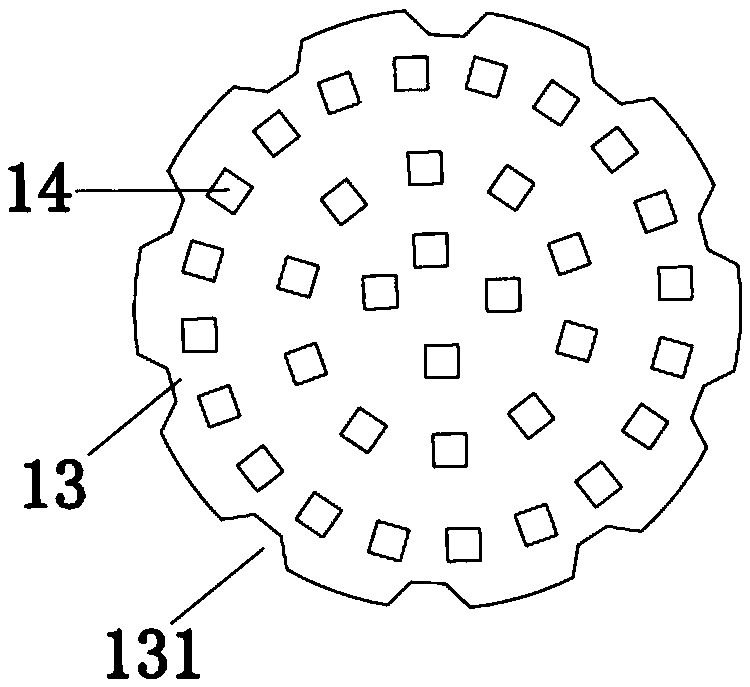

Novel membrane module oxygen-enriched combustion equipment

InactiveCN105650668AImprove combustion efficiencyBurn fullyIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyAir filterEngineering

The invention relates to novel membrane module oxygen-enriched combustion equipment. The equipment comprises an air filter, an air blower, an oxygen-enriched membrane assembly, a water ring vacuum pump, a vacuum gauge, a regulating valve, a gas-water separator, a dehumidification and pressurization electric control system, an oxygen-enriched preheater and a nozzle. One end of the air filter is connected with the left end of the air blower. The right end of the air blower is connected with the oxygen-enriched membrane assembly. The oxygen-enriched membrane assembly is connected with one end of the regulating valve. The other end of the regulating valve is connected with the vacuum gauge. The other end of the vacuum gauge is connected with one end of the water ring vacuum pump. The other end of the water ring vacuum pump is connected with the gas-water separator. The gas-water separator is connected with the dehumidification and pressurization electric control system. The dehumidification and pressurization electric control system is connected with one end of the oxygen-enriched preheater. The other end of the oxygen-enriched preheater is connected with the nozzle. The nozzle is embedded in an industrial kiln stove.

Owner:王明山

A process for burning petroleum coke in a cfb boiler

InactiveCN107726307BLow costImprove economyFluidized bed combustionSolid fuel pretreatmentCombustion chamberSlag

The invention discloses a petroleum coke mixed burning process using a CFB boiler. The process comprises the steps that materials are mixed and prepared, and limestone powder is blown from four limestone powder pipelines to a stokehold to be mixed and stirred with petroleum coke through clap valves; a material bed is used for conveying the materials to a combustion chamber of the boiler, the bed temperature of the material bed is controlled to be 870-940 DEG C, and the bed pressure is controlled to be 3.5-5.5 kPa; sand is regularly added to the material bed; after the sand is added, the materials are fed into the combustion chamber for high-temperature combustion; and after the materials are combusted at high temperature in the combustion chamber, the solid waste is returned to the combustion chamber through a bed material returning device, the smoke after passing a rear smoke channel is separated from materials and then is returned to the combustion chamber through a recirculating machine, and the redundant gas is discharged through a chimney. According to the process, abrasion of the heated surface of the boiler is effectively reduced, the service life of the wear-resistant casting material in the boiler is prolonged, and the maintenance amount of the casting material is reduced; and the bottom slag amount of the boiler is reduced, and after a bottom slag system is properly transformed, the bottom slag system can normally run.

Owner:南京泰润电力工程有限公司

A kind of non-metal gasoline additive and preparation method thereof

ActiveCN107916147BReduce sulfur contentPromote decompositionLiquid carbonaceous fuelsFuel additivesFuel conservationPtru catalyst

The invention discloses a nonmetallic gasoline additive and a method for preparing the same. The nonmetallic gasoline additive comprises, by weight, 0.5-12% of polyether, 0.5-12% of polyether polyol,0.5-10% of poly-alcohol, 0.1-15% of catalysts, 0.1-15% of stabilizers, 1-16% of soluble silicic acid and 55.9-92% of polyol. The method includes adding the polyether, the polyether polyol, the poly-alcohol and the catalysts into the polyol; carrying out stirring reaction to obtain transparent oily liquid; adding the soluble silicic acid into the liquid; carrying out stirring reaction at the temperature of 80-110 DEG C until solution turns clear; filtering the clear solution to obtain the nonmetallic gasoline additive. The nonmetallic gasoline additive and the method have the advantages that more than 18% of gasoline can be saved by the aid of the nonmetallic gasoline additive under identical conditions, emission of hydrocarbon HC, carbon monoxide CO, PM (particulate matters) and nitrogen oxide NOx can be reduced to a great extent, the smoke intensity can be lowered to a great extent, and effects of inhibiting carbon deposit generation and eliminating carbon deposits can be realized; the nonmetallic gasoline additive is stable in property, can be safely stored and transported and is free of damage to gasoline cylinders and engines, the nonmetallic gasoline additive and gasoline arecompletely mutually soluble, precipitation and layering can be prevented.

Owner:保定市瑞方生物科技有限公司

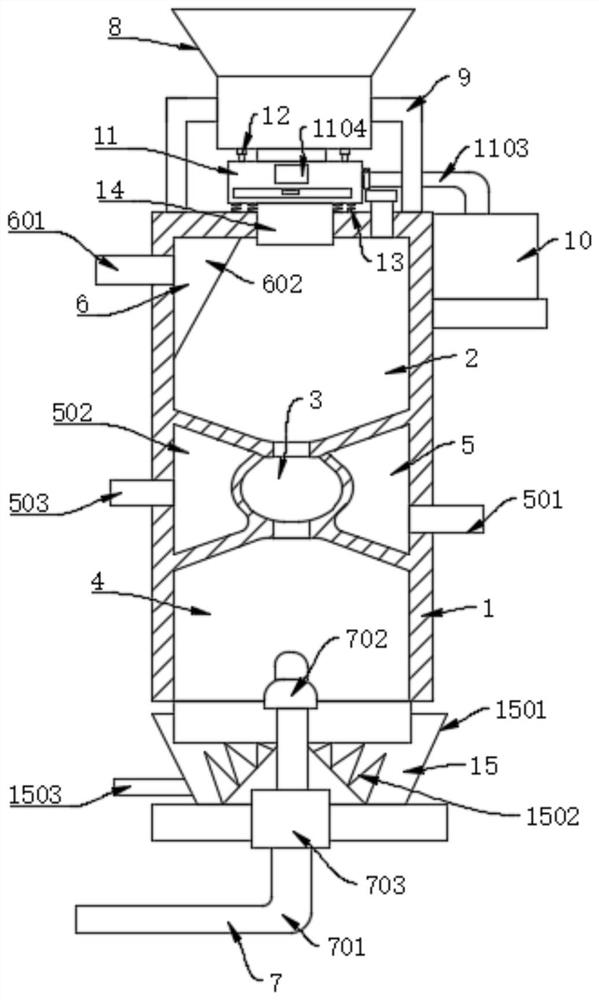

A kind of catalytic dry distillation equipment and dry distillation process of oil shale organic waste

ActiveCN113684046BEasy to installWith grinding functionDispersed particle filtrationLiquid hydrocarbon mixture productionThermodynamicsOil shale

The invention relates to the field of dry distillation of oil shale, in particular to a catalytic dry distillation equipment for oil shale organic waste and a dry distillation process, including a dry distillation furnace body, a feeding component, a filtering component, a recovery component and a rock ash collection component. The cooperation of the feeding component and the supporting component is convenient to install the feeding component on the upper end of the retort furnace body, and the feeding component has a grinding function, which can regrind the oil shale entering the feeding component, which is convenient for oil shale The large particles in the raw material are pulverized; through the cooperation of the filter assembly and the feed assembly, it is convenient to filter the oil shale after the grinding of the feed assembly, so that the smaller particles of oil shale enter the interior of the retort furnace body, shorten the oil shale Combustion time to ensure complete combustion of oil shale, and the filter assembly is detachable, which is convenient to replace filters with different mesh sizes according to actual use requirements.

Owner:宁夏回族自治区矿产地质调查院

A biomass burning power boiler

InactiveCN104359100BIncrease heat loadBurn completelySolid fuel combustionSteam boilersCombustion chamberSlag

The invention discloses a biomass combustion power generation boiler, which comprises a boiler wall, a boiler grate, a steam overheater, a material inlet, a slag outlet, a front cover, a water cooling wall, a steam bag, a flow guide cover, an auxiliary flow guide cover and the like, wherein the boiler hearth is separated into a combustion chamber and a heat transfer chamber by the front cover and the flow guide cover, and biomass is centrally combusted in the combustion chamber under the area surrounded by the front cover and the flow guide cover. Compared with the prior art, the biomass combustion power generation boiler has the advantages that the biomass is centrally combusted in the area surrounded by the front cover and the flow guide cover, so the volume heat load of the combustion area is large; the turbulence of smoke in the combustion area is improved by the flow guide cover, the delivered biomass can be sufficiently and completely dried, the combustion is complete, and the combustion efficiency is high; the smoke flowing direction is turned by the flow guide cover, and the combustion dust is furthest settled in the combustion area by the centrifugal force of air flow, so the discharge amount of boiler pollutants is less.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com