A biomass burning power boiler

A technology for burning power generation and biomass, which is applied in the field of boilers, can solve the problems of low combustion efficiency, unstable combustion of biomass fuel, and high concentration of smoke and dust, and achieves the effects of high combustion efficiency, ensuring water circulation power, and increasing the flow rate of flue gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

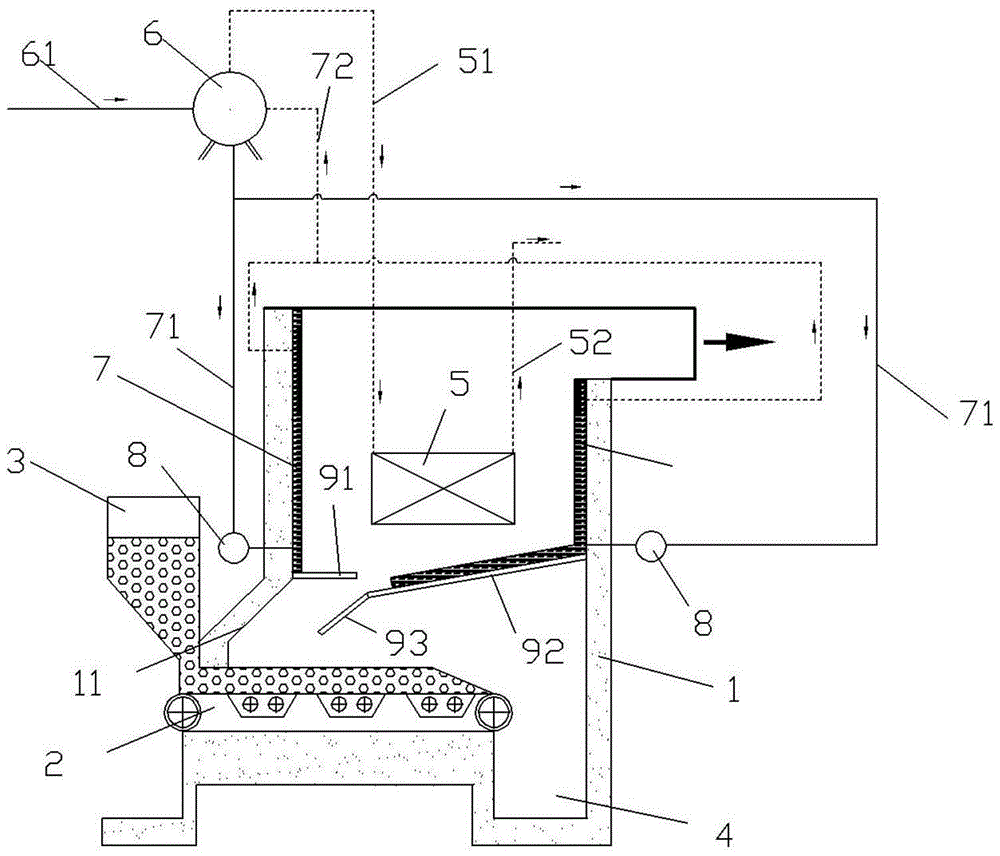

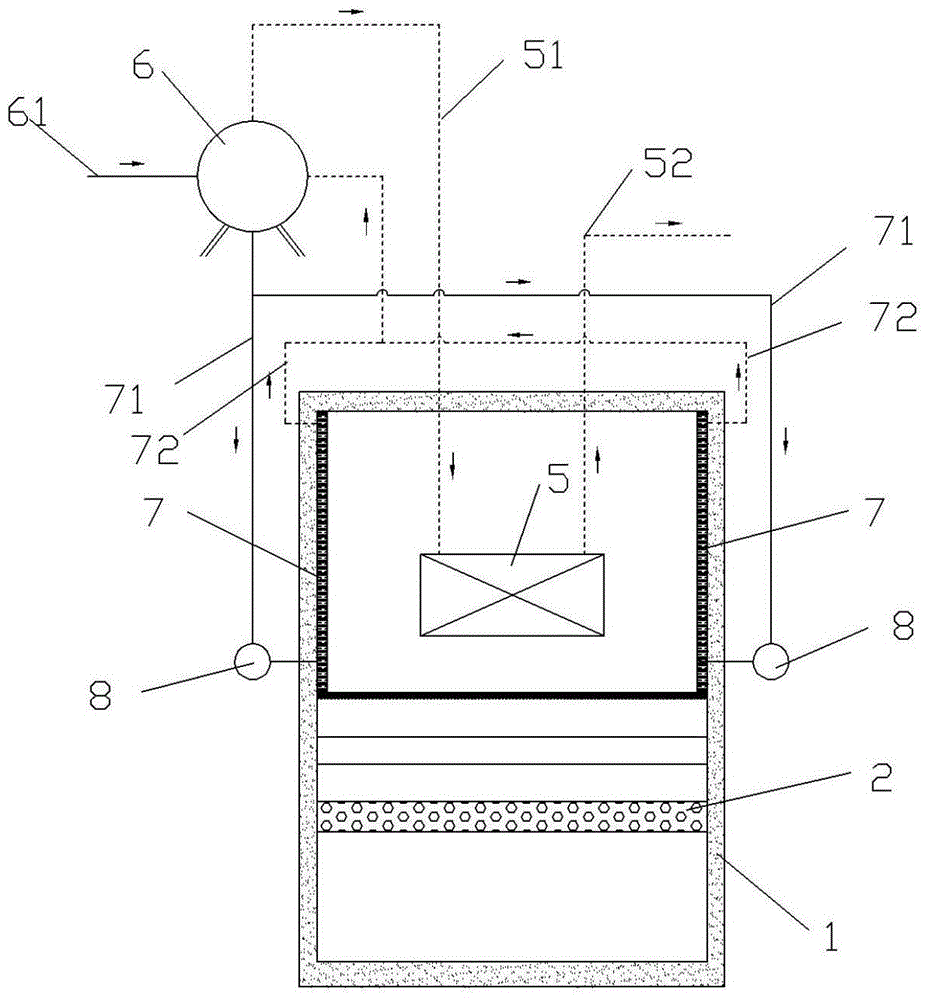

[0025] Such as figure 1 with figure 2 As shown, a biomass combustion power generation boiler includes a furnace wall 1, a fire grate 2, a steam superheater 5, a feed port 3 and a slag discharge port 4, the space surrounded by the furnace wall 1 is the furnace, and the steam superheater 5 is hoisted on In the furnace, the fire grate 2 is a movable fire grate, and the furnace wall 1 is provided with a front arch 11 above the feed opening 3, which is characterized in that it also includes a front cover 91 and a flow deflector 92, and the front cover 91 is arranged above the front arch 11 On the front furnace wall 1, the front cover 91 extends horizontally from the front furnace wall 1 to the direction of the furnace, and the length of the front cover 91 is 1 / 4 of the length of the furnace. Above, the air guide cover 92 extends obliquely downward at 20 degrees from the rear furnace wall 1 to the furnace, and the length of the air guide cover 92 is 3 / 5 of the length of the furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com