Closed circulatory phase-change heat supply system for heat and power cogeneration

A heating system and closed cycle technology, which is applied in the field of closed cycle phase change heating system of cogeneration and peak shaving, eliminating the heat recovery system, and improving the effect of thermal energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

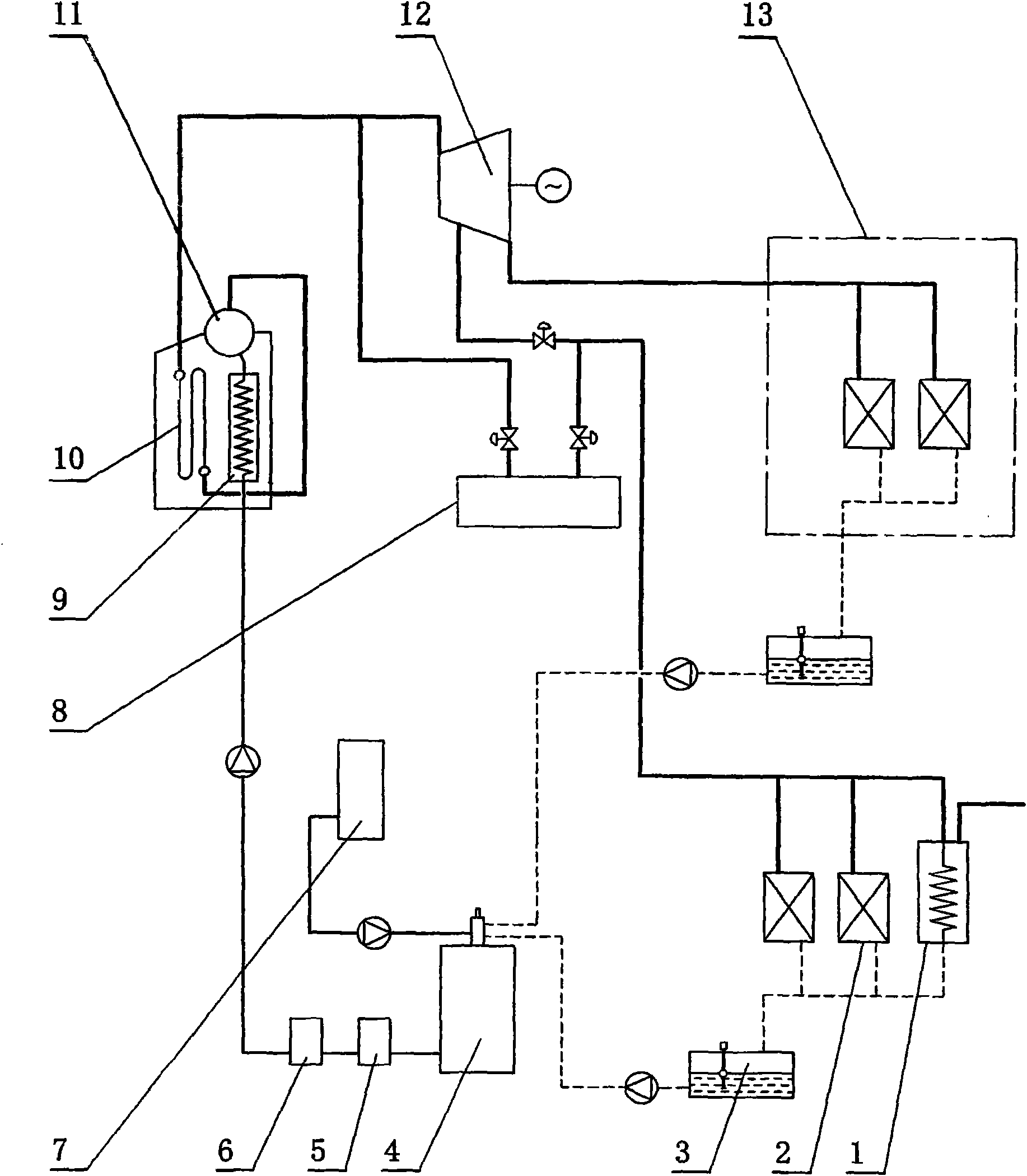

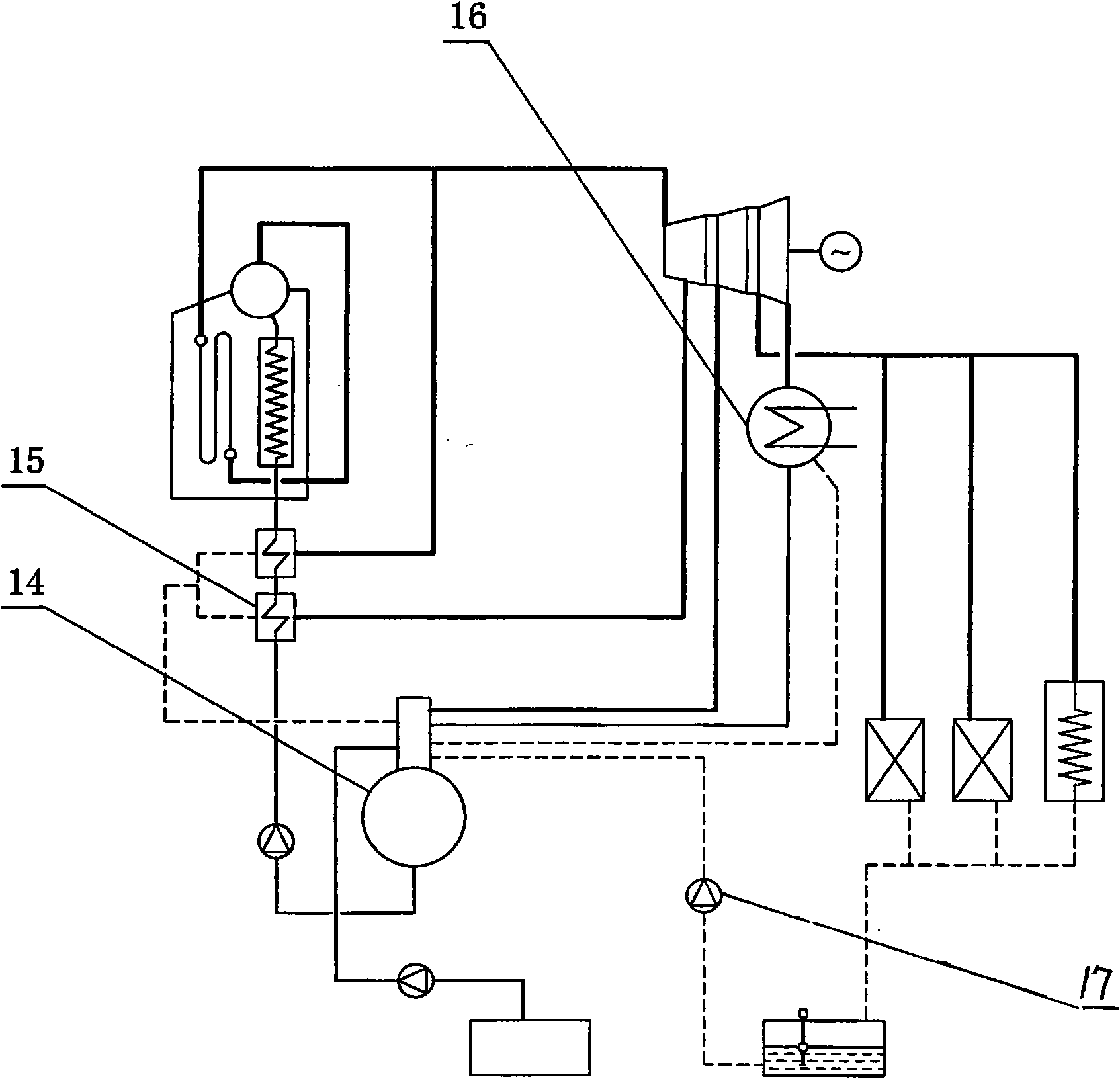

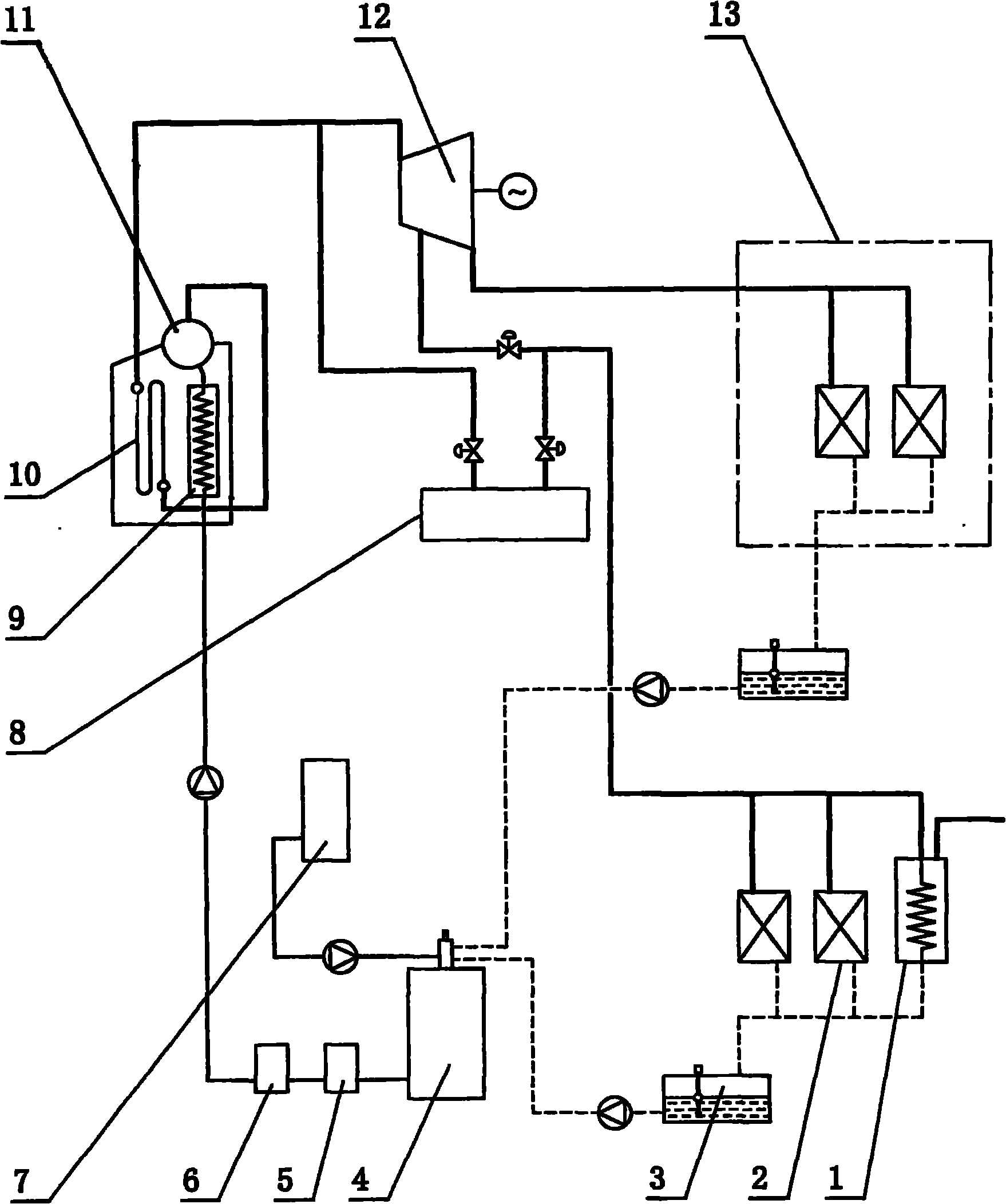

[0013] The content of the present invention will be further described below in conjunction with the accompanying drawings, but the actual application form of the present invention is not limited to the illustrated embodiment.

[0014] Referring to the accompanying drawings, the cogeneration closed-cycle phase-change heating system of the present invention consists of a boiler 11, a turbogenerator set 12, a heat accumulator 8, heat-using equipment 2, a secondary steam generator 1, a drain tank 3, Water storage tank 4, soft water station 7 and matching valves, water pumps and connecting pipelines etc. are formed. The boiler 11 is respectively connected with the steam turbine generator set 12, the heat accumulator 8, the heat utilization equipment 2 and the secondary steam generator 1 through steam pipes. The condensed water outlet of the thermal equipment 2 and the secondary steam generator 1 is connected with the upper part of the drain box 3 through the condensed water pipe. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com