Novel membrane module oxygen-enriched combustion equipment

A technology of oxygen-enriched combustion and membrane group, which is applied in combustion equipment, combustion method, controlled combustion, etc., can solve the problems of low combustion efficiency of industrial kilns, reduce the residual solid incomplete combustion, reduce the ignition point, and solve the problem of low combustion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

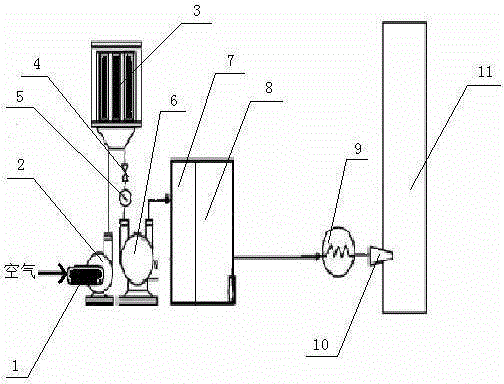

[0016] see figure 1 As shown, the oxygen-enriched combustion equipment of the novel membrane group key of the present invention includes an air filter 1, a blower 2, an oxygen-enriched membrane group key 3, a water ring vacuum pump 6, a vacuum gauge 5, a regulating valve 4, a gas-water separator 7, a dehumidifier Booster electronic control system 8, oxygen-enriched preheater 9 and nozzle 10. One end of the air filter 1 is connected to the left end of the blower 2, and the right end of the blower 2 is connected to the oxygen-enriched membrane group key 3, and the oxygen-enriched membrane group key 3 is connected to one end of the regulating valve 4, and the regulating valve The other end of 4 is connected to vacuum gauge 5, and the other end of said vacuum gauge 5 is connected to one end of water ring vacuum pump 6, and the other end of said water ring vacuum pump 6 is connected to gas-water separator 7, and said gas-water separator 7 is connected to The dehumidification boost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com