Magnetization oxygen-enriched energy conservation and emission reduction system of gaseous suspension roaster

A gaseous suspension, energy-saving and emission-reducing technology, applied to furnaces, fluidized bed furnaces, furnace types, etc., can solve the problems of high air pollutants, low product output, low thermal efficiency, etc., and achieve improved flame temperature, optimized combustion environment, The effect of improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

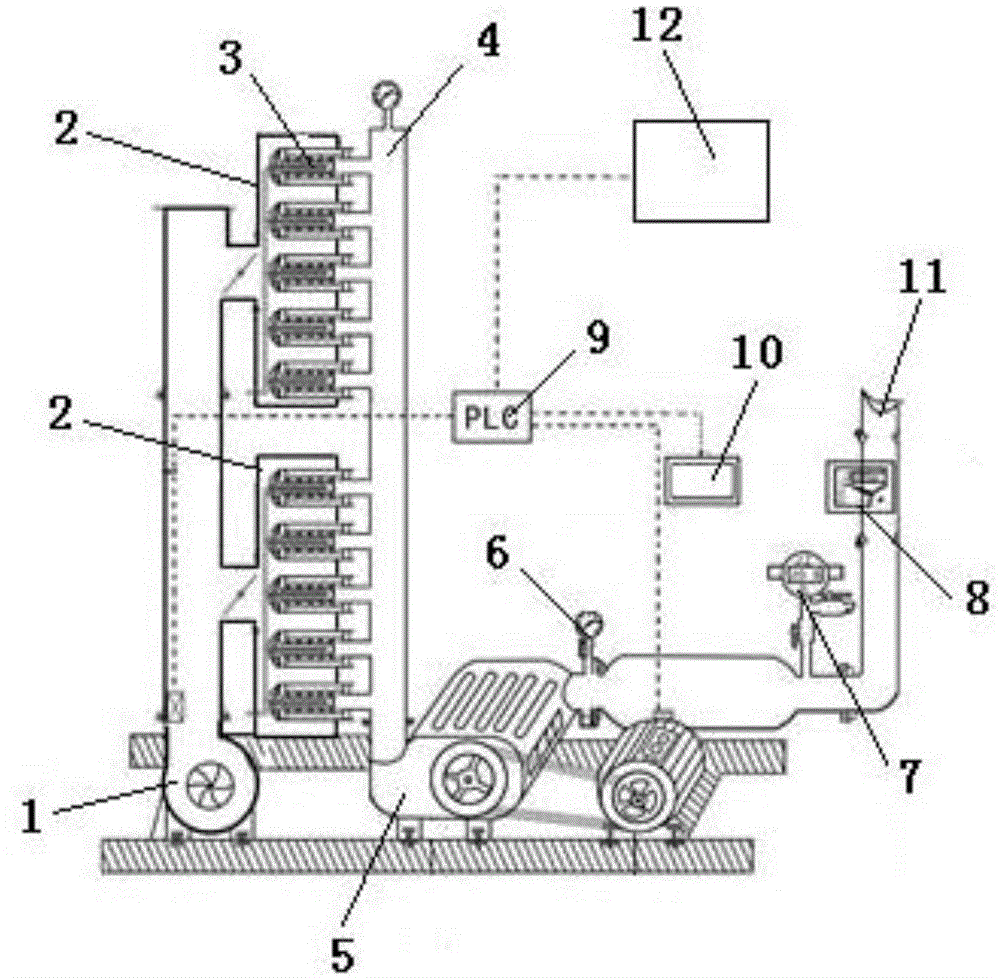

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] like figure 1 As shown, the magnetized oxygen-enriched energy-saving and emission-reduction system of gaseous suspension roaster includes raw material air supply fan 1, multi-channel pressure equalization distribution box 2, double-stage booster Roots pump unit 5, PLC intelligent system 9, and oxygen-enriched gas output Pipeline 11, the multi-channel pressure equalization distribution box 2 has two, the raw material air supply fan 1 is respectively connected with two multi-channel pressure equalization distribution boxes 2, and the two multi-channel pressure equalization distribution boxes 2 All are provided with a swirl concave-convex thermoisotropic magnetic group 3, the swirl concave-convex thermoisotropic magnetic group 3 is connected to a vacuum adsorption pipeline 4, and a negative pressure gauge is provided on the vacuum adsorption pipeline 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com