Alcohol-based liquid fuel

A liquid fuel, alcohol-based technology, used in liquid carbon-containing fuels, fuels, fuel additives, etc., can solve the problems of incomplete combustion, low calorific value, and smoke generation, and achieve easy ignition, high calorific value, Reduce the effect of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] An alcohol-based liquid fuel, the active ingredient of which is made of the following traditional Chinese medicine raw materials in parts by weight:

[0042] 80 parts of methanol, 5 parts of water, 1 part of gasoline, 1 part of sodium hydroxide, 1 part of castor oil, 3 parts of jatropha fruit oil, 2 parts of edible oil, 1 part of essence, 1 part of industrial salt, 1 part of ethanol;

[0043] The described fuel preparation process steps are:

[0044] (1) Pour jatropha fruit oil and edible oil into the compounder and mix evenly; first add 90% concentrated sulfuric acid with a weight content of 5% and methanol with a weight content of 5% to the compounder for mixing, and esterify at 60°C Processing, reaction time 3 hours, distillation then, obtain fatty acid methyl ester, standby;

[0045] (2) Pour methanol, water, gasoline, castor oil, fatty acid methyl ester, sodium hydroxide, industrial salt and ethanol into the compounder, stir evenly, add an appropriate amount of es...

Embodiment 2

[0047] An alcohol-based liquid fuel, the active ingredient of which is made of the following traditional Chinese medicine raw materials in parts by weight:

[0048] 82 parts of methanol, 6 parts of water, 1 part of gasoline, 2 parts of sodium hydroxide, 2 parts of castor oil, 5 parts of jatropha fruit oil, 3 parts of edible oil, 2 parts of essence, 2 parts of industrial salt, 2 parts of ethanol;

[0049] The described fuel preparation process steps are:

[0050] (1) Pour jatropha fruit oil and edible oil into the compounder and mix evenly; first add 90% concentrated sulfuric acid with a weight content of 7% and methanol with a weight content of 5% to the compounder for mixing, and esterify at 75°C Processing, reaction time 4 hours, distillation then, obtain fatty acid methyl ester, standby;

[0051] (2) Pour methanol, water, gasoline, castor oil, fatty acid methyl ester, sodium hydroxide, industrial salt and ethanol into the compounder, stir evenly, add an appropriate amount ...

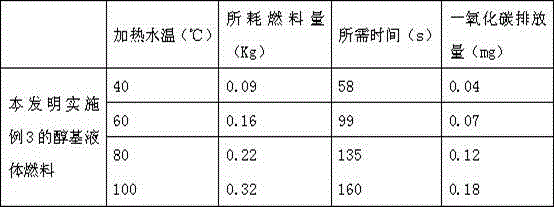

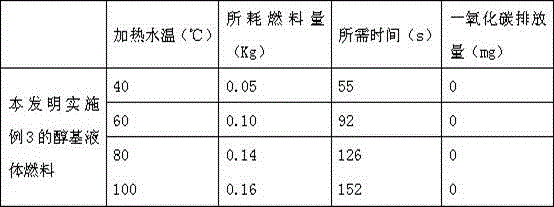

Embodiment 3

[0053] An alcohol-based liquid fuel, the active ingredient of which is made of the following traditional Chinese medicine raw materials in parts by weight:

[0054] 84 parts of methanol, 7 parts of water, 2 parts of gasoline, 3 parts of sodium hydroxide, 3 parts of castor oil, 6 parts of jatropha fruit oil, 4 parts of edible oil, 3 parts of essence, 4 parts of industrial salt, and 4 parts of ethanol.

[0055] The described fuel preparation process steps are:

[0056] (1) Pour jatropha fruit oil and edible oil into the compounder and mix evenly; first add 90% concentrated sulfuric acid with a weight content of 10% and methanol with a weight content of 5% to the compounder for mixing, and esterify at 90°C Processing, reaction time 5 hours, distillation then, obtain fatty acid methyl ester, standby;

[0057] (2) Pour methanol, water, gasoline, castor oil, fatty acid methyl ester, sodium hydroxide, industrial salt and ethanol into the compounder, stir evenly, add an appropriate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com