High-moisture fuel fired steam boiler

A technology for fuel steam and boilers, which is applied in the field of boilers, can solve problems such as not being properly designed, and achieve the effects of increasing fuel burnout rate, prolonging residence time, and facilitating combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

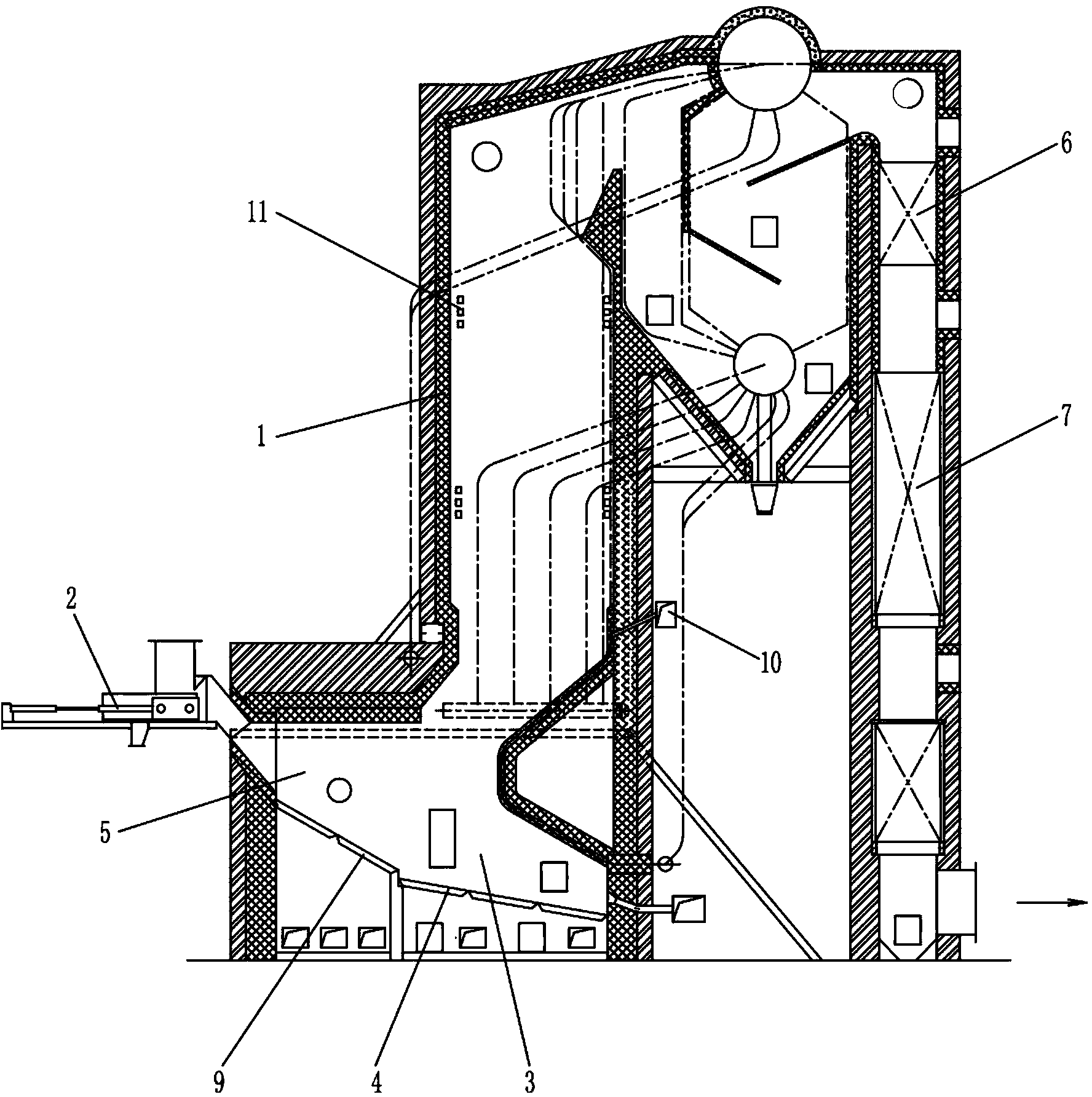

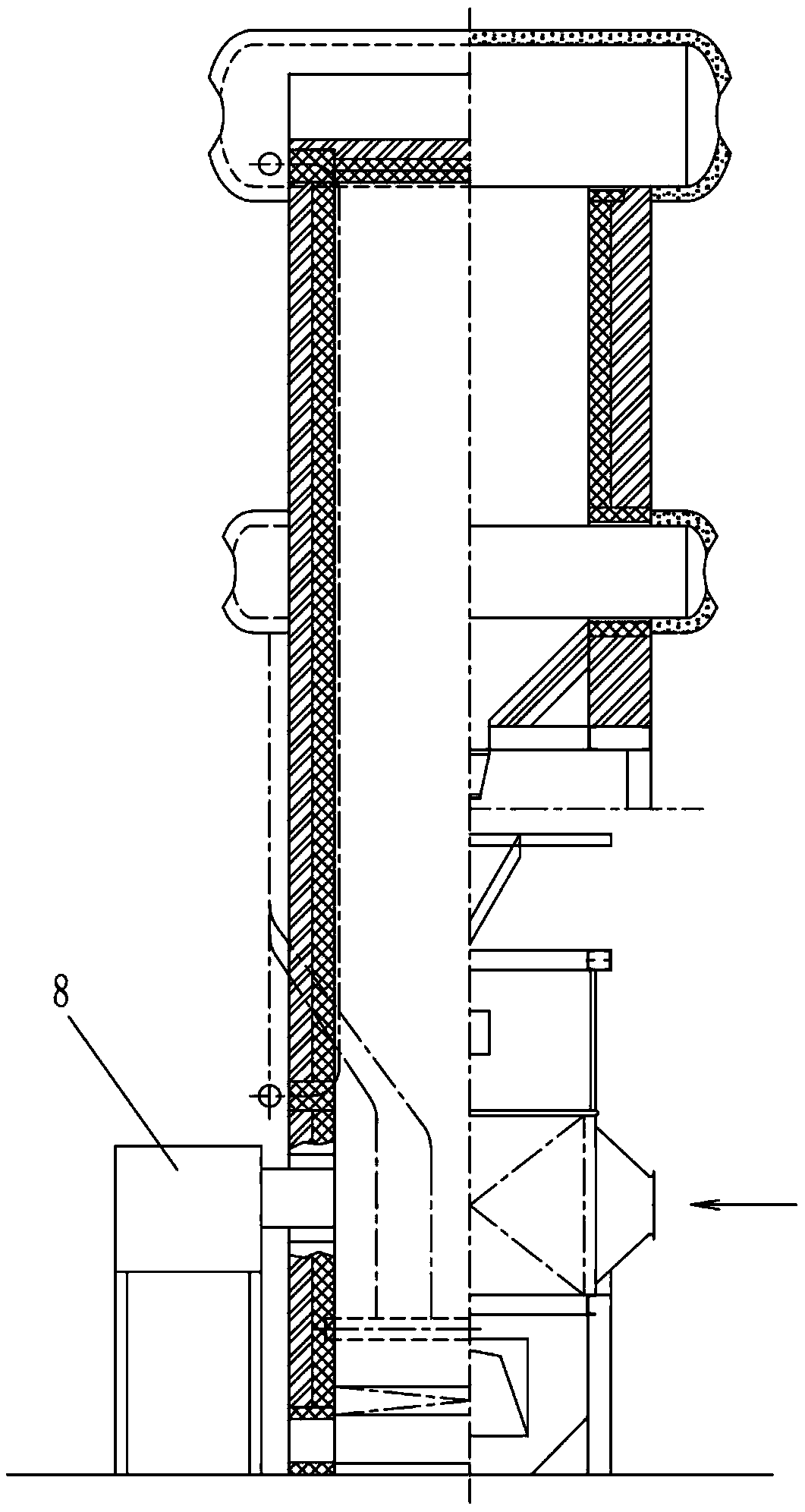

[0015] like figure 1 and figure 2 As shown, the high-moisture fuel steam boiler is composed of a boiler body 1, a feeding device 2, a furnace 3, a grate 4, a pre-combustion chamber 5, an economizer 6, a preheater 7, and a gasification burner 8.

[0016] A pre-combustion chamber 5 is designed at the front of the boiler body 1. The pre-combustion chamber 5 is located in front of the furnace 3 and above the reciprocating grate 9 with a large inclination angle. The inlet of the pre-combustion chamber 5 and the outlet of the feeding device 2 Connected. The pre-combustion chamber does not have a heating surface, and is made of refractory bricks and refractory concrete. This thermal insulation design can generate a lot of radiant heat around the pre-combustion chamber when the fuel is pre-combusted, and further strengthens the drying and drying of high-moisture fuel. pre-ignition. The high-moisture fuel is fed to the pre-combustion chamber 5 through the specially designed feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com