Cylinder-driving two-stroke engine

A two-stroke, engine technology, applied in engine control, engine components, combustion engines, etc., can solve the problems of low-speed diesel engine bulky, oil film damage, long piston stroke, etc., to improve exhaust turbine power, purify exhaust emissions, and promote complete burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

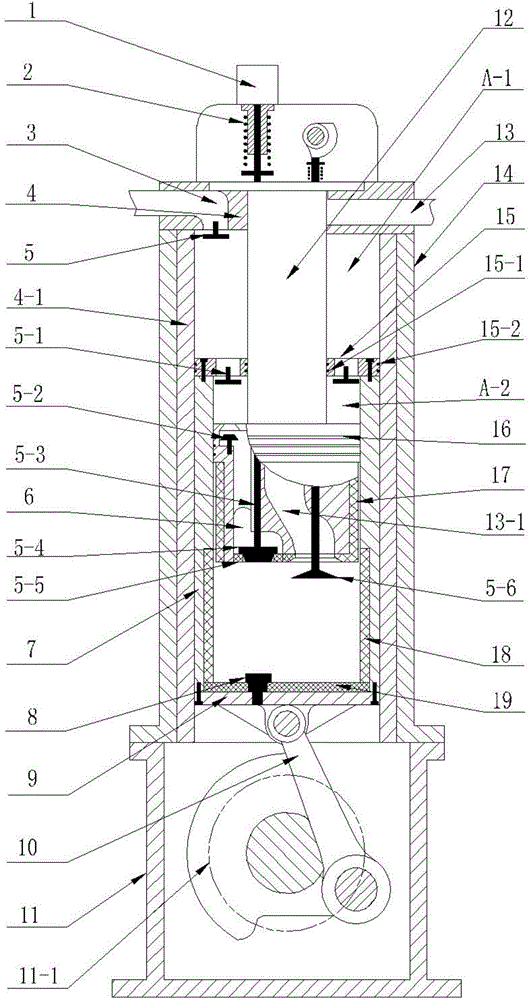

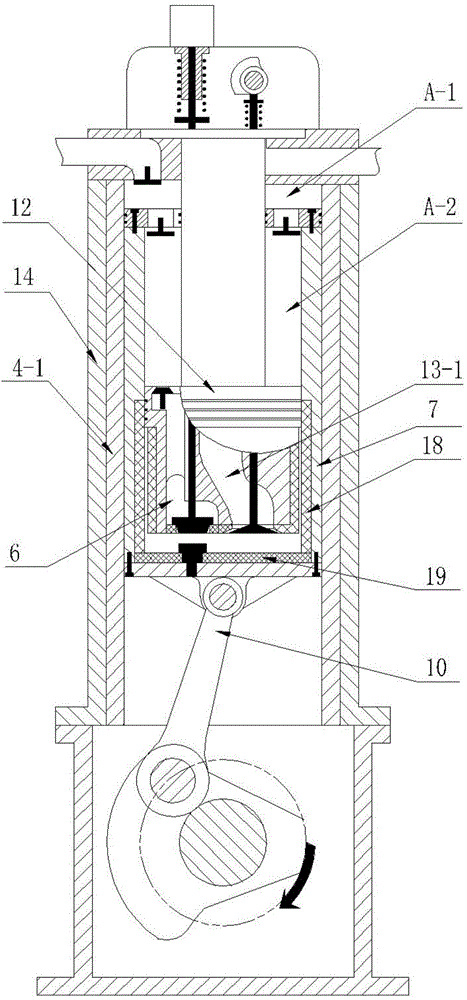

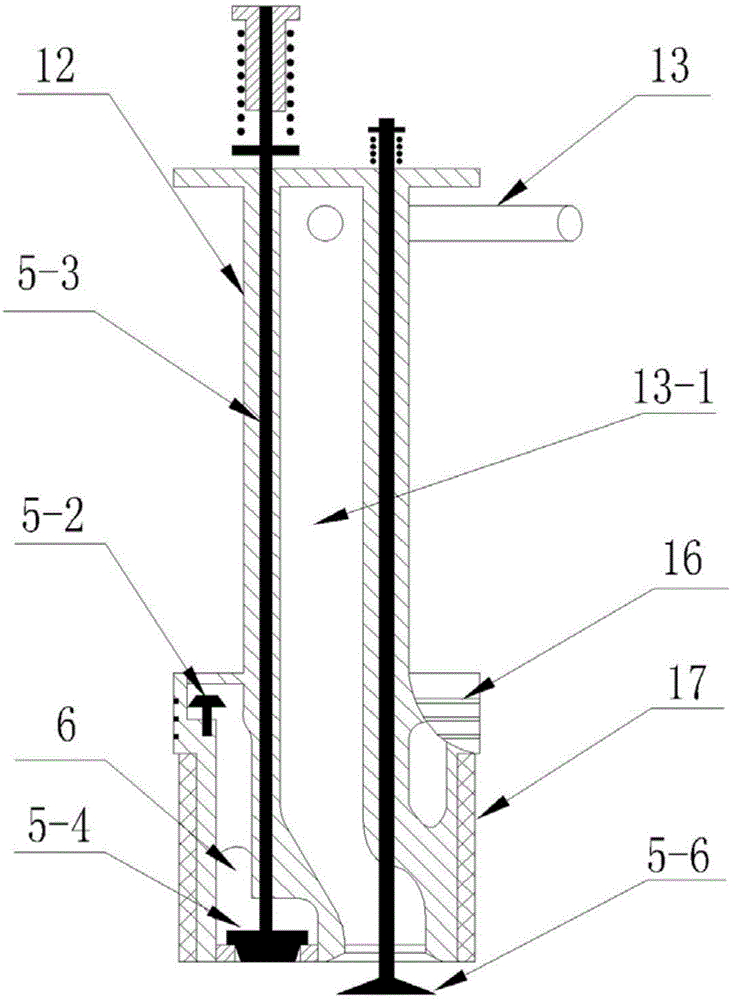

[0024] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0025] see figure 1 — Figure 4 , the engine main body of the present embodiment is assembled by cylinder block 14, crankcase 11, cylinder head 4, and crankcase 11 is equipped with crankshaft 11-1, and cylinder head 4 is provided with intake pipe 3, exhaust pipe 13. Its features are: the inner wall of the cylinder body 14 is fixed with a fixed cylinder liner 4-1, the movable cylinder 7 is set in the fixed cylinder liner 4-1 and can slide back and forth, and the movable cylinder 7 is equipped with an insulating cylinder liner 18, a movable cylinder bottom plate 9. Insulation plate 19, top block 8, compressor plate 15, one end of connecting rod 10 is hinged to crankshaft 11-1, and the other end is hinged to movable cylinder bottom plate 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com