Patents

Literature

44results about "Non-electrical control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

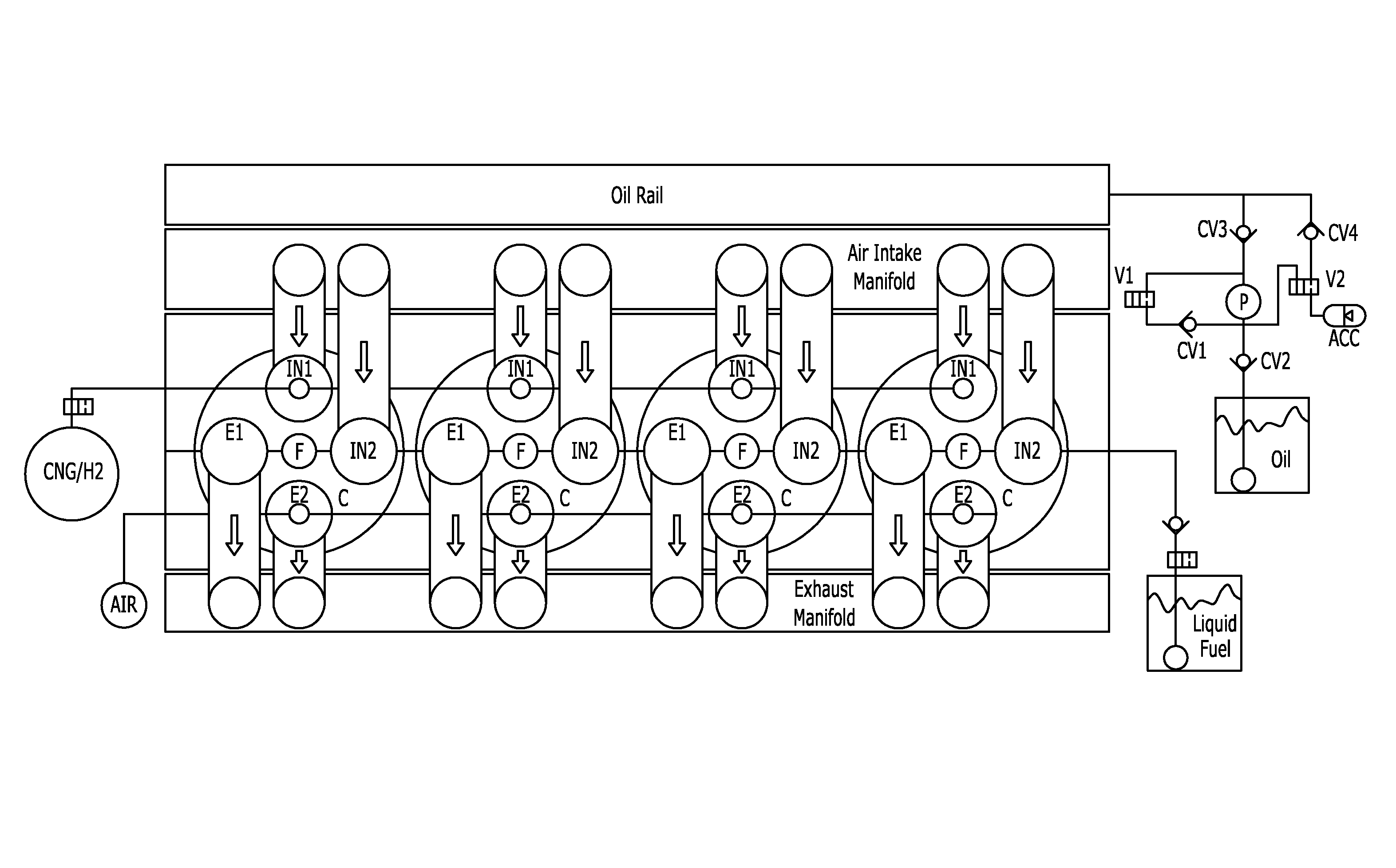

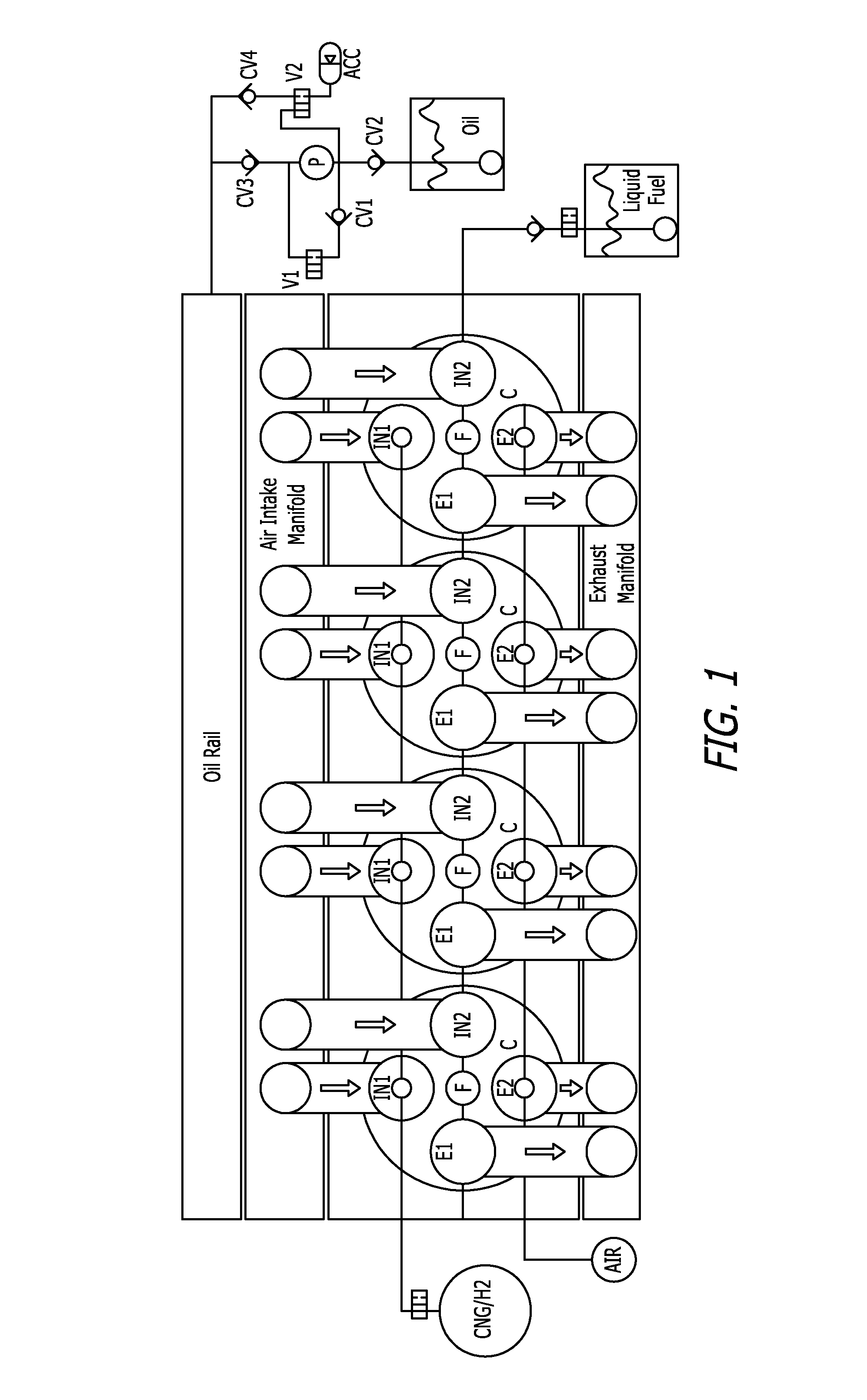

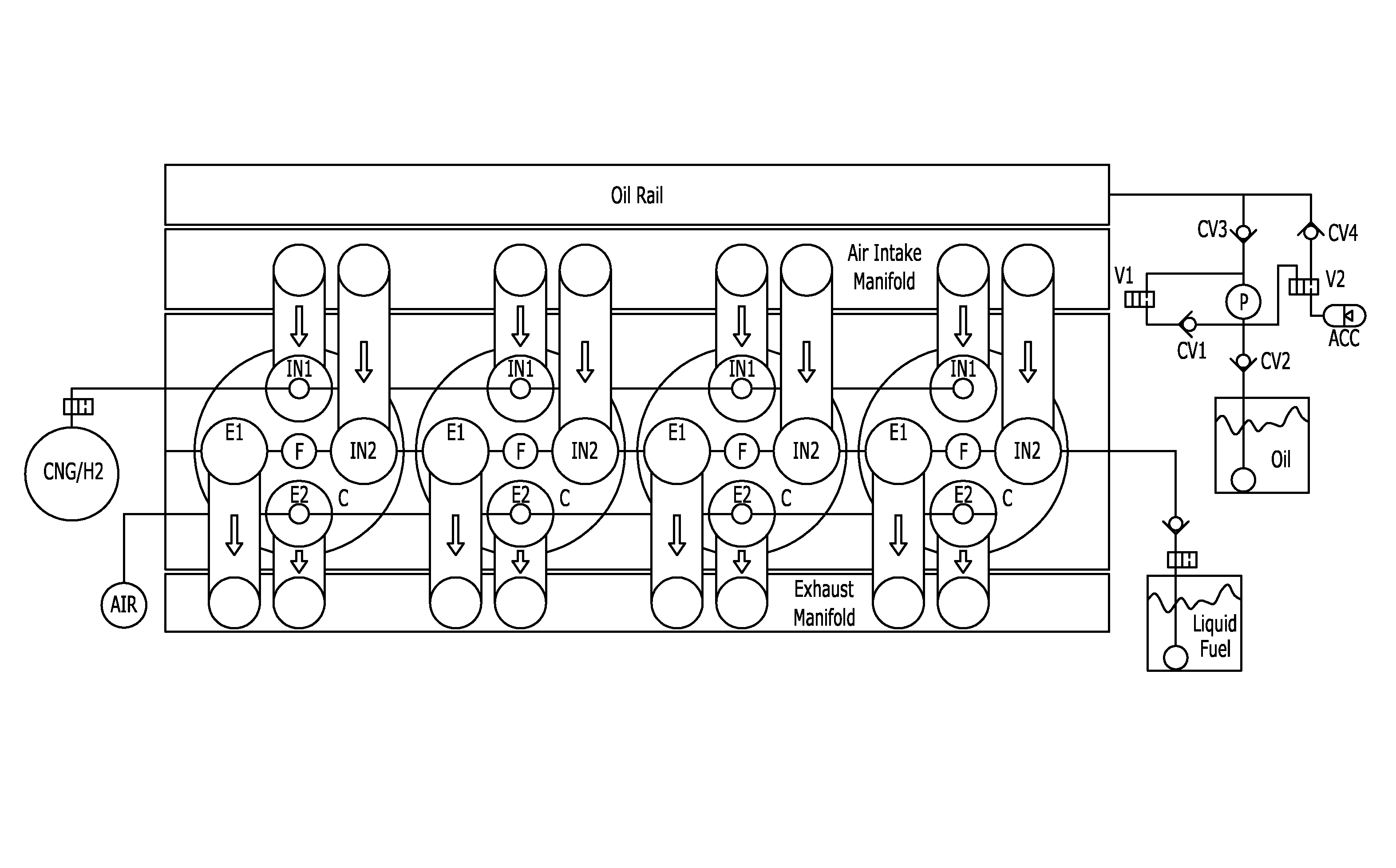

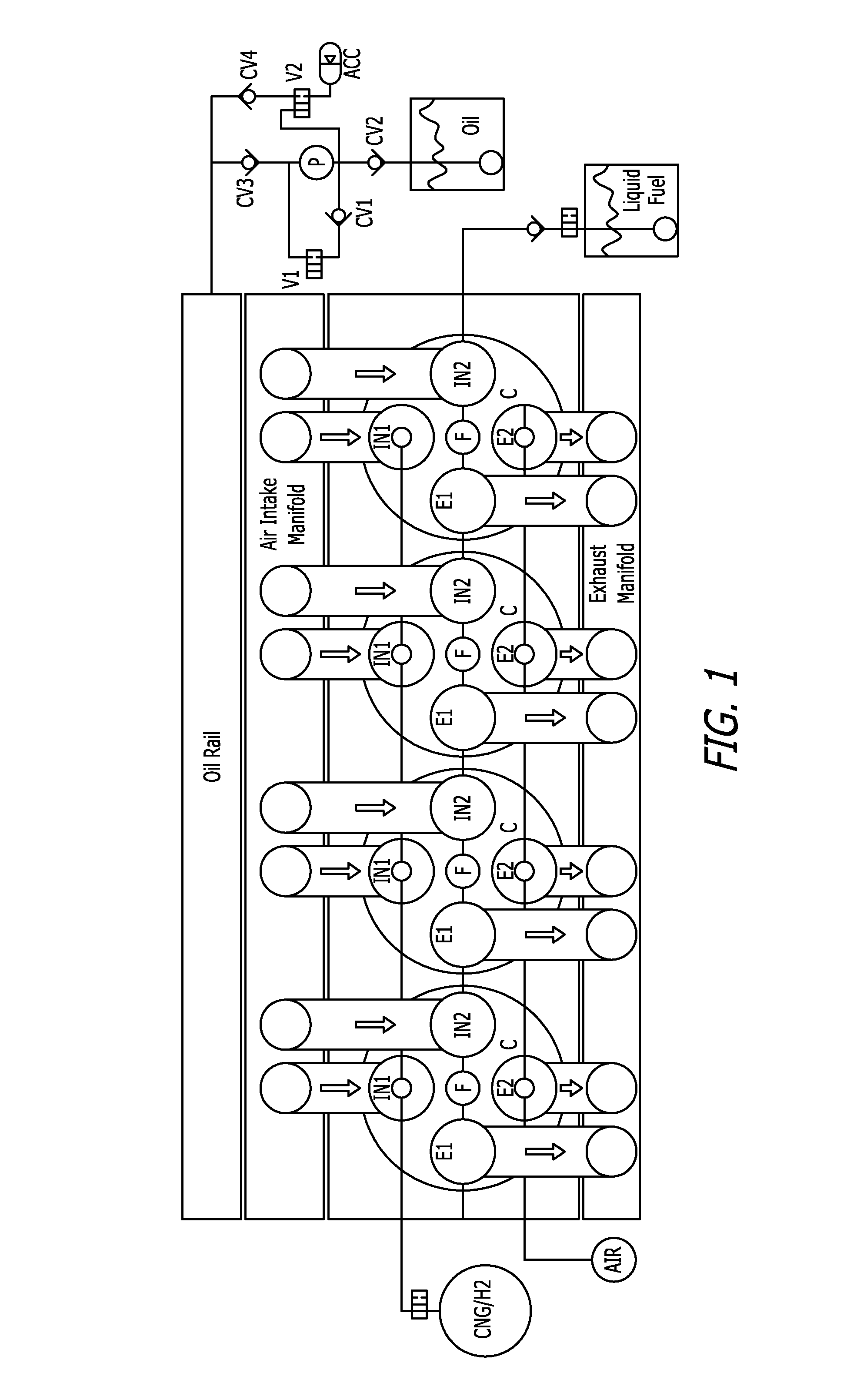

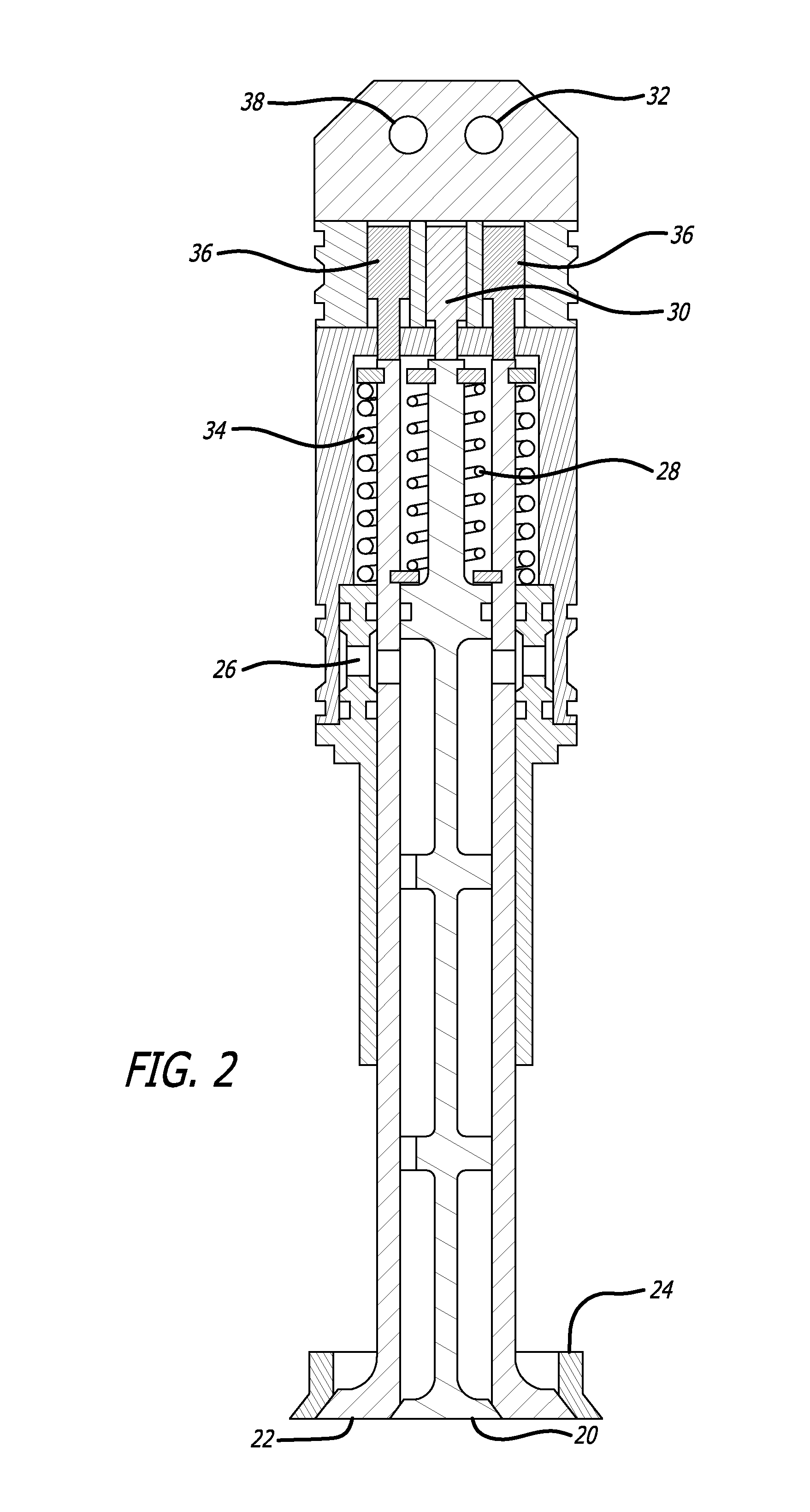

Dual Fuel Compression Ignition Engines and Methods

ActiveUS20100229838A1Non-fuel substance addition to fuelInternal combustion piston enginesHydrogenCompressed natural gas

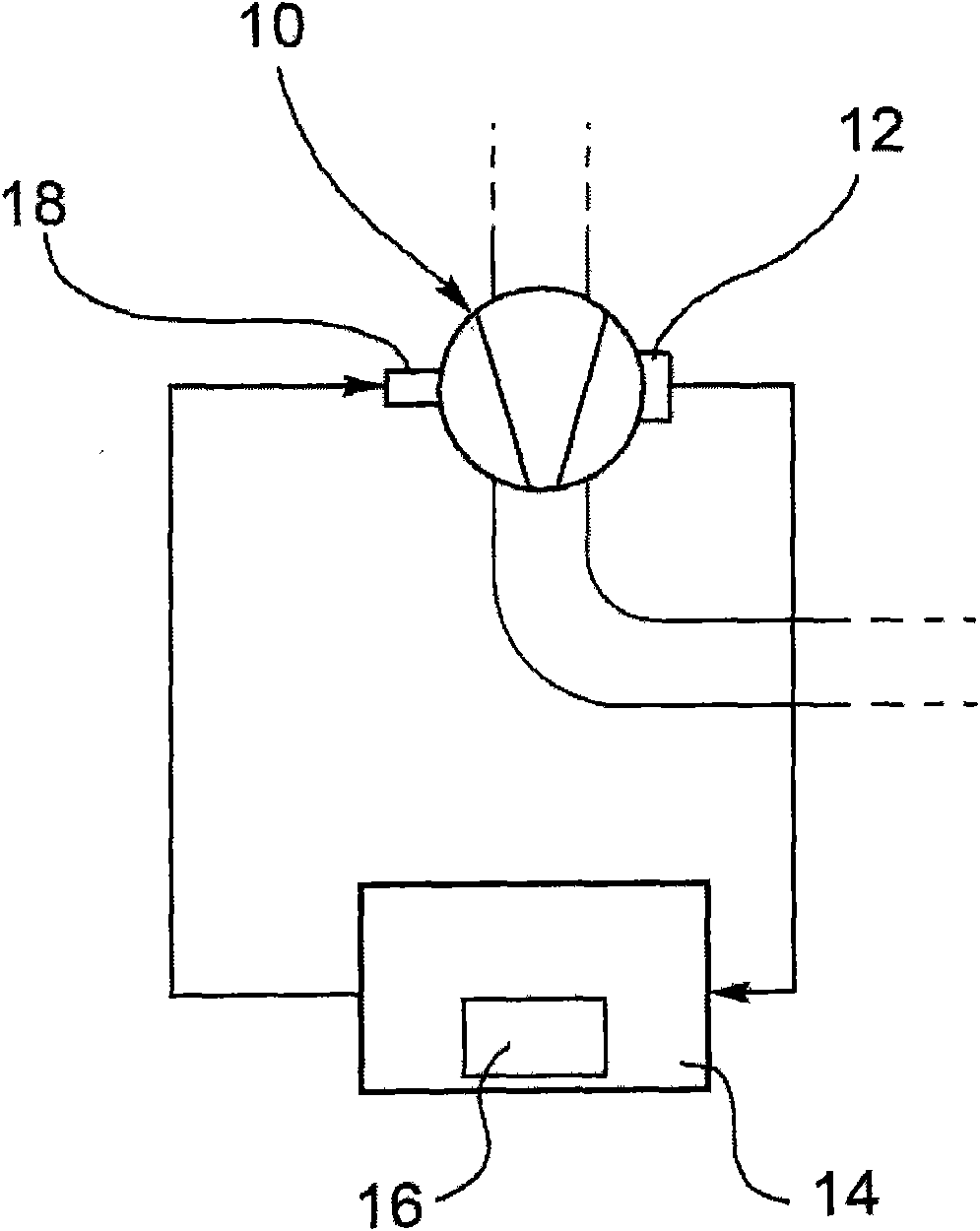

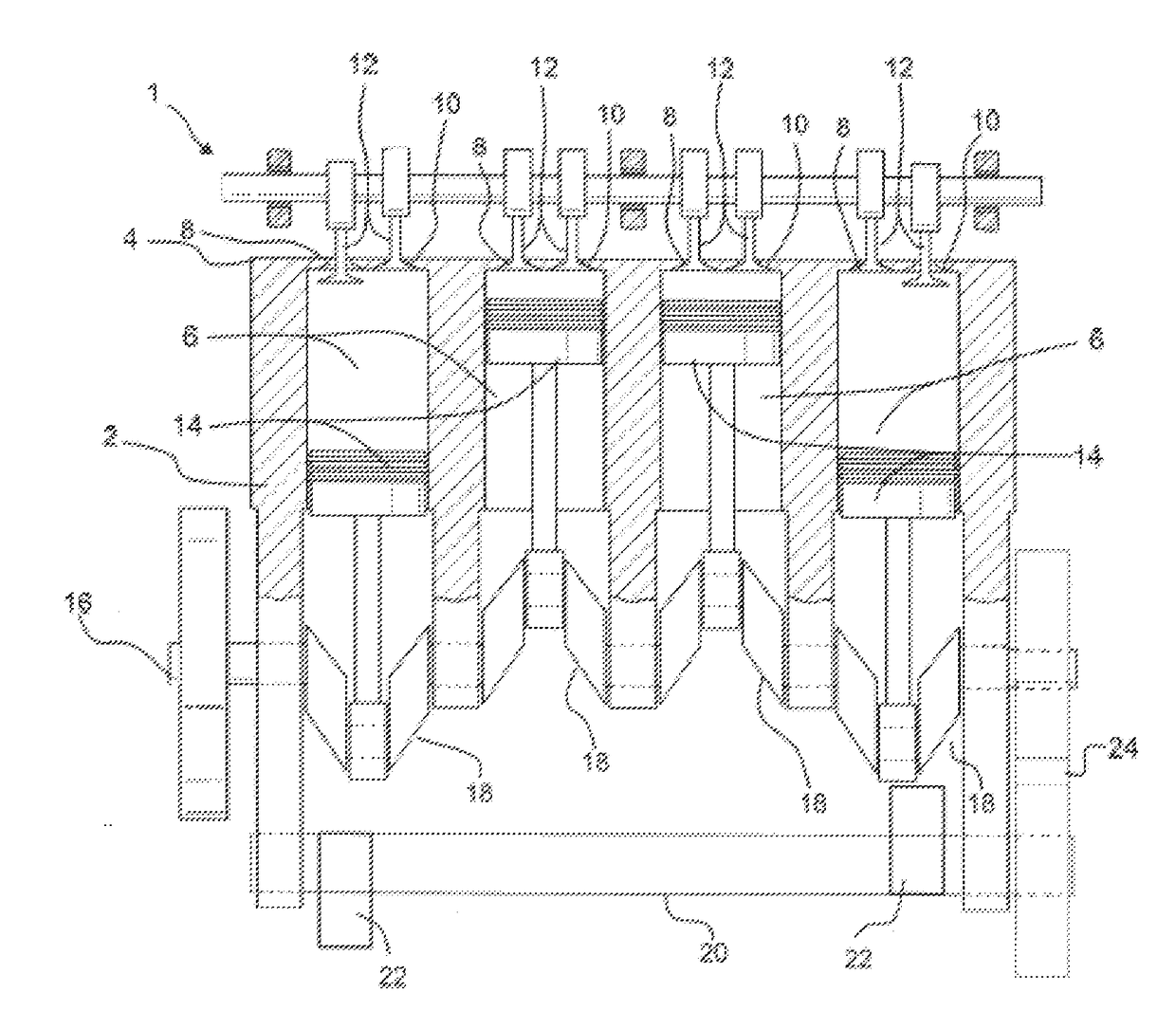

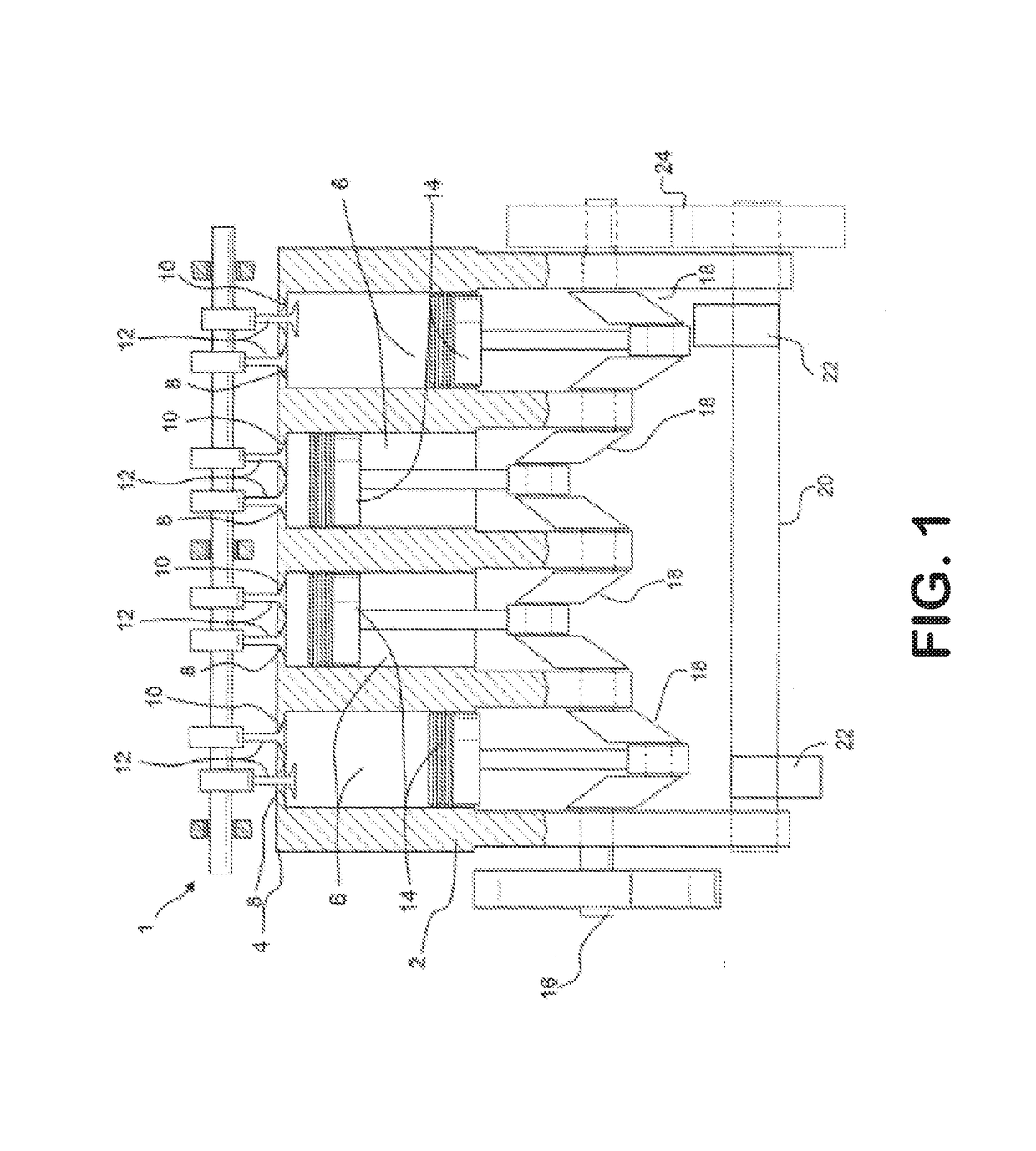

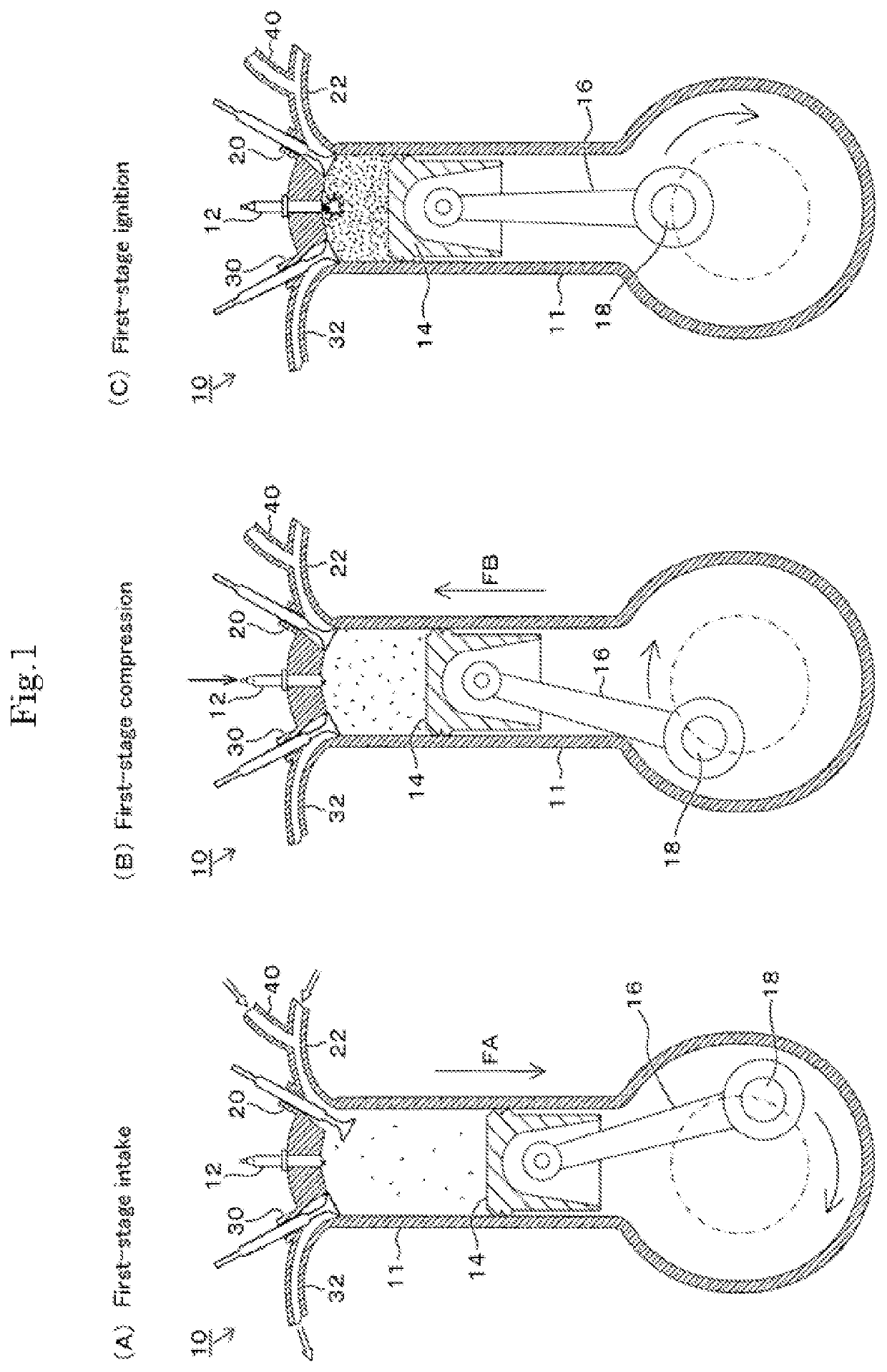

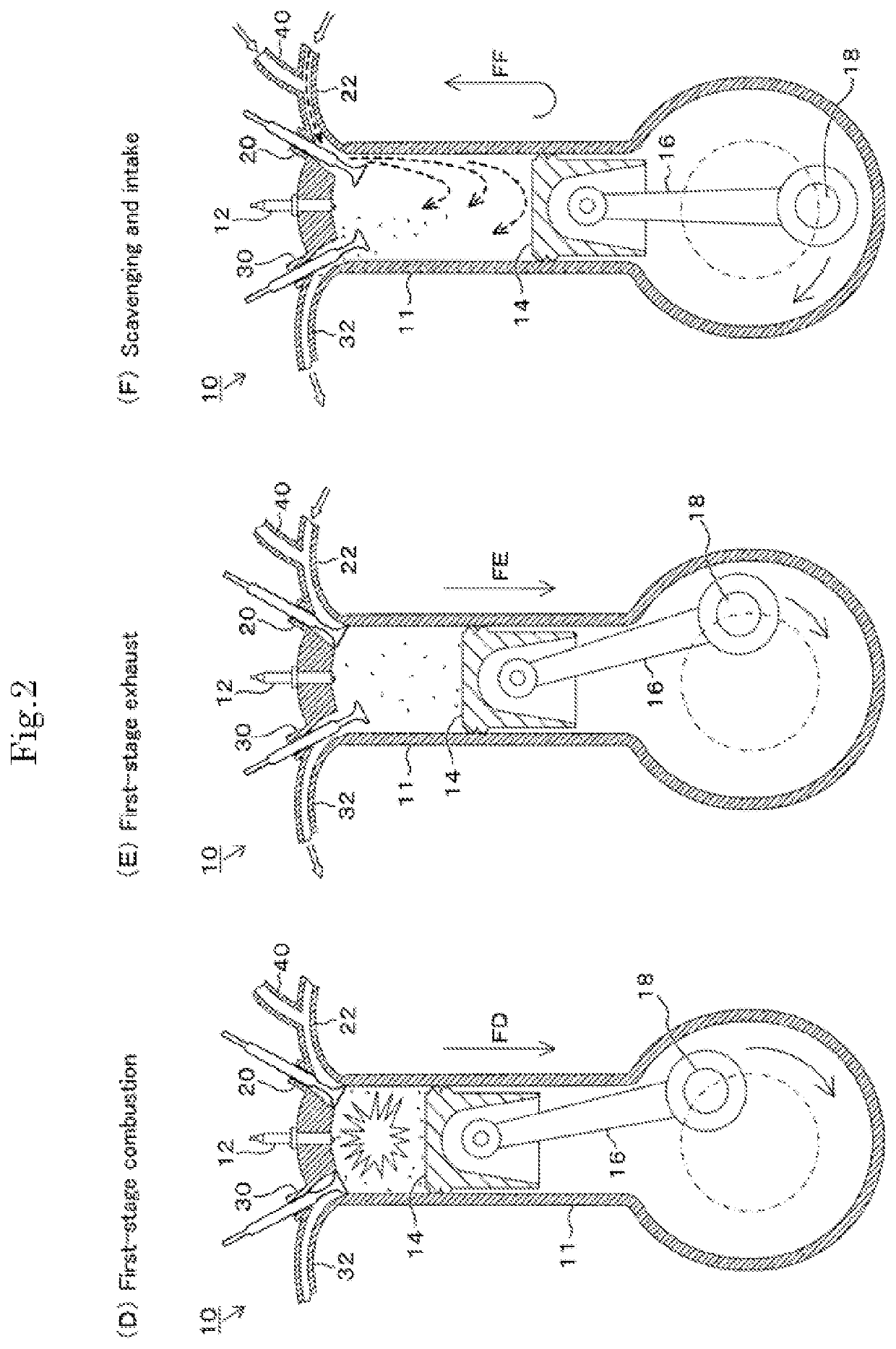

Dual fuel compression ignition engines and methods that allow compression ignition on gaseous fuels like compressed natural gas, hydrogen and ammonia, yet will run on liquid fuels, including diesel fuels for such purposes as starting or when the gaseous fuel is not available or has been consumed and greater range or operating time is needed. Ignition of fuels having a high self ignition temperature is assured by recirculating high temperature exhaust gas back into the intake charge before compression. Existing engines may be converted to run as a dual fuel engine by replacement of the engine head or heads. Various embodiments are disclosed.

Owner:STURMAN DIGITAL SYST

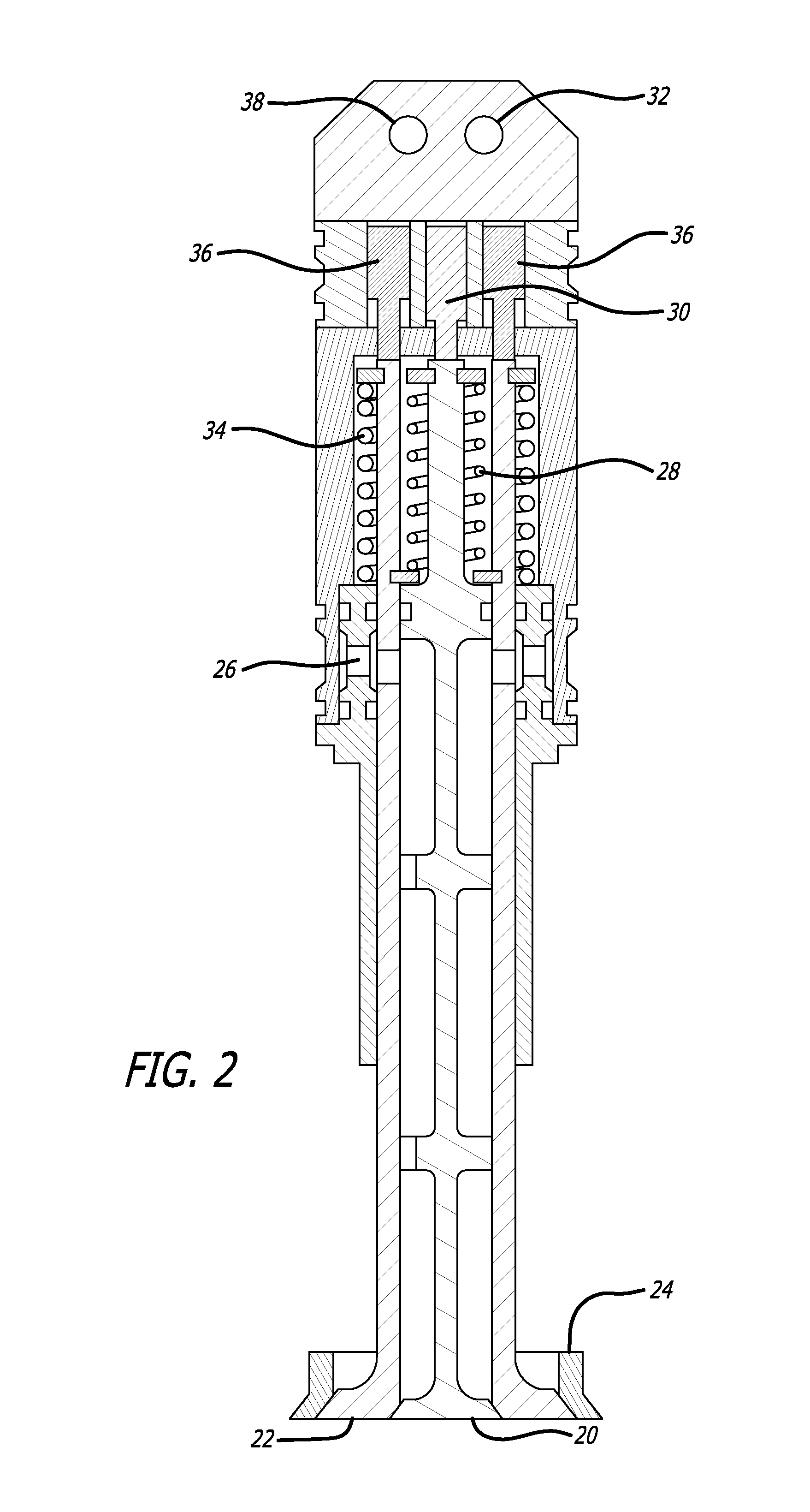

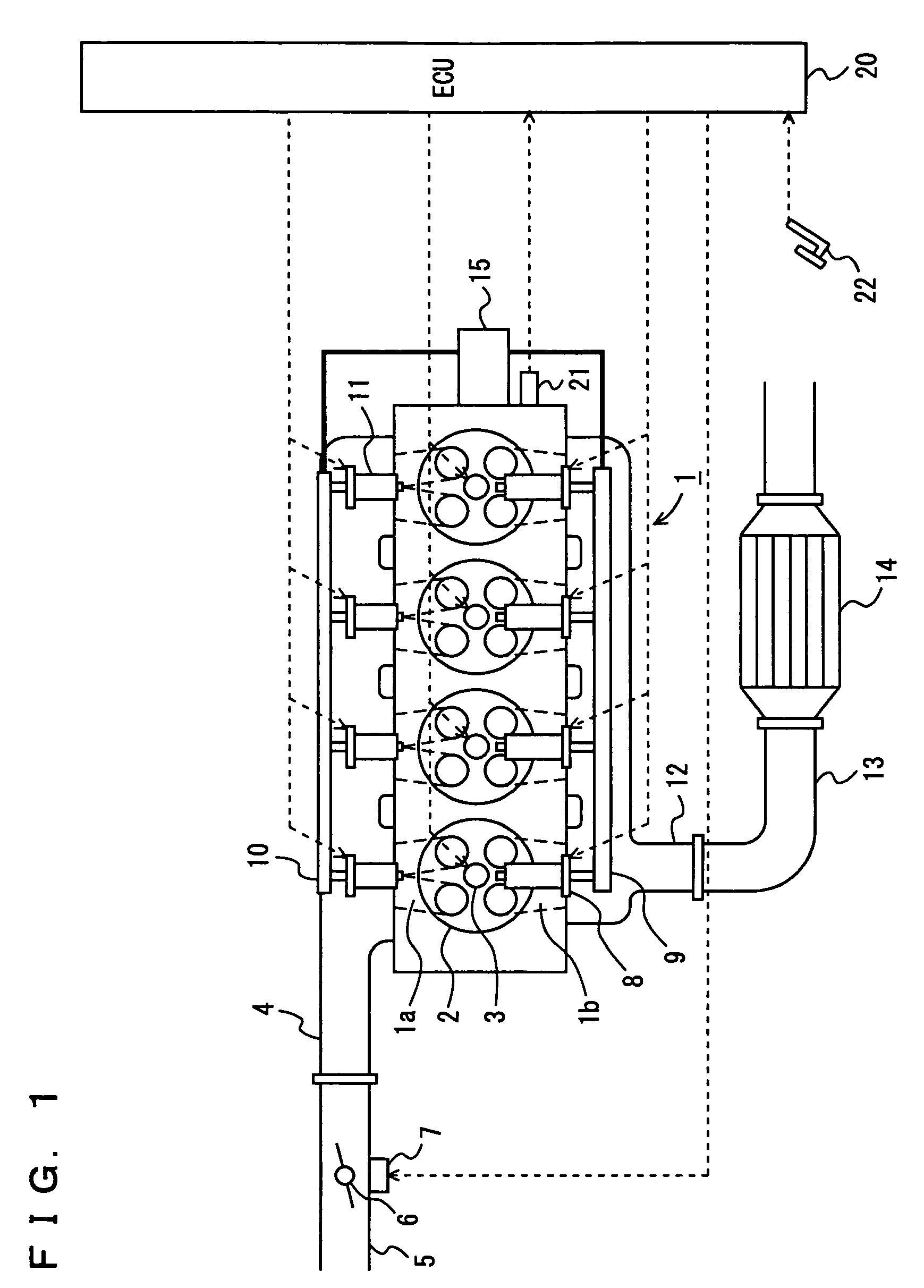

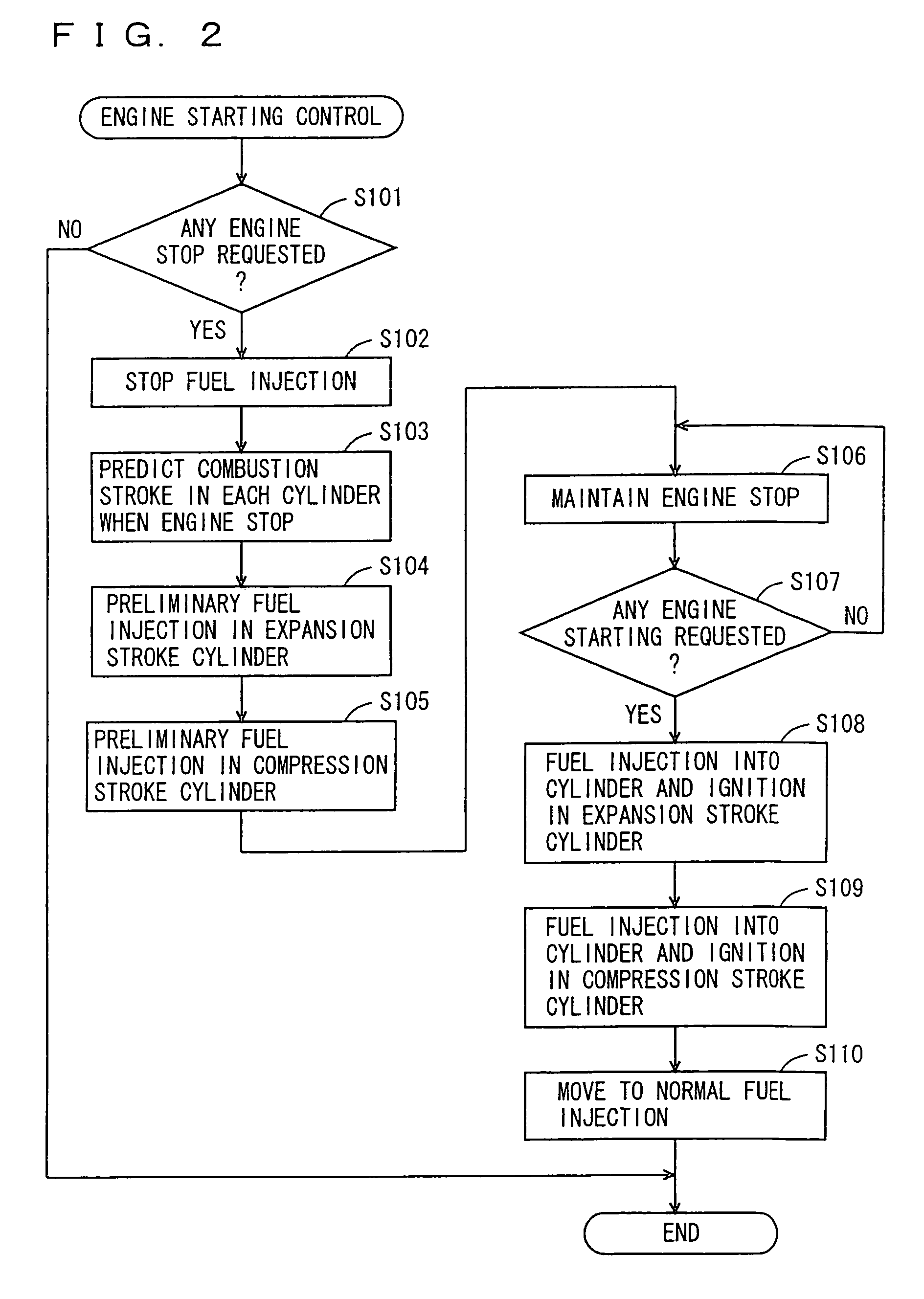

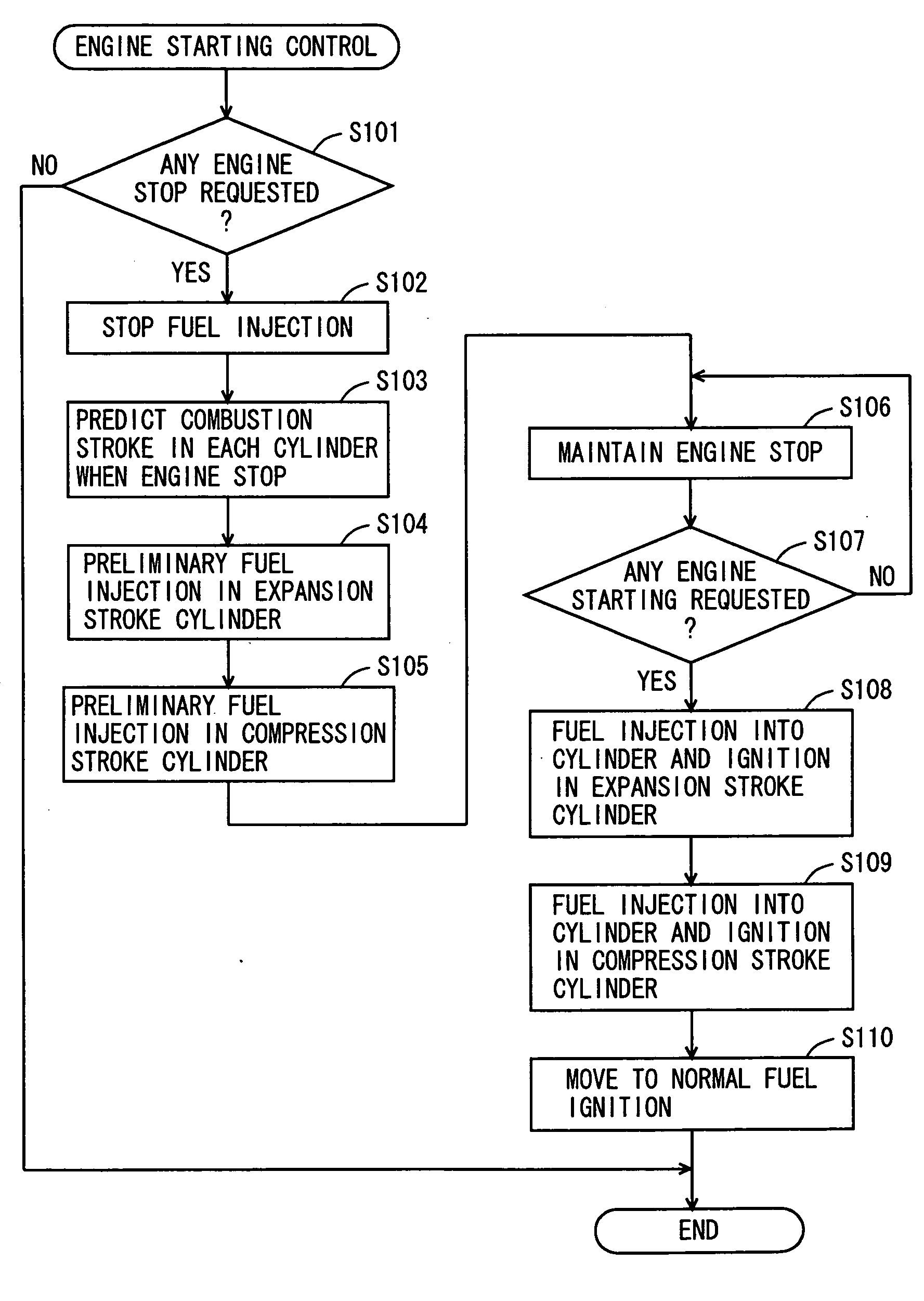

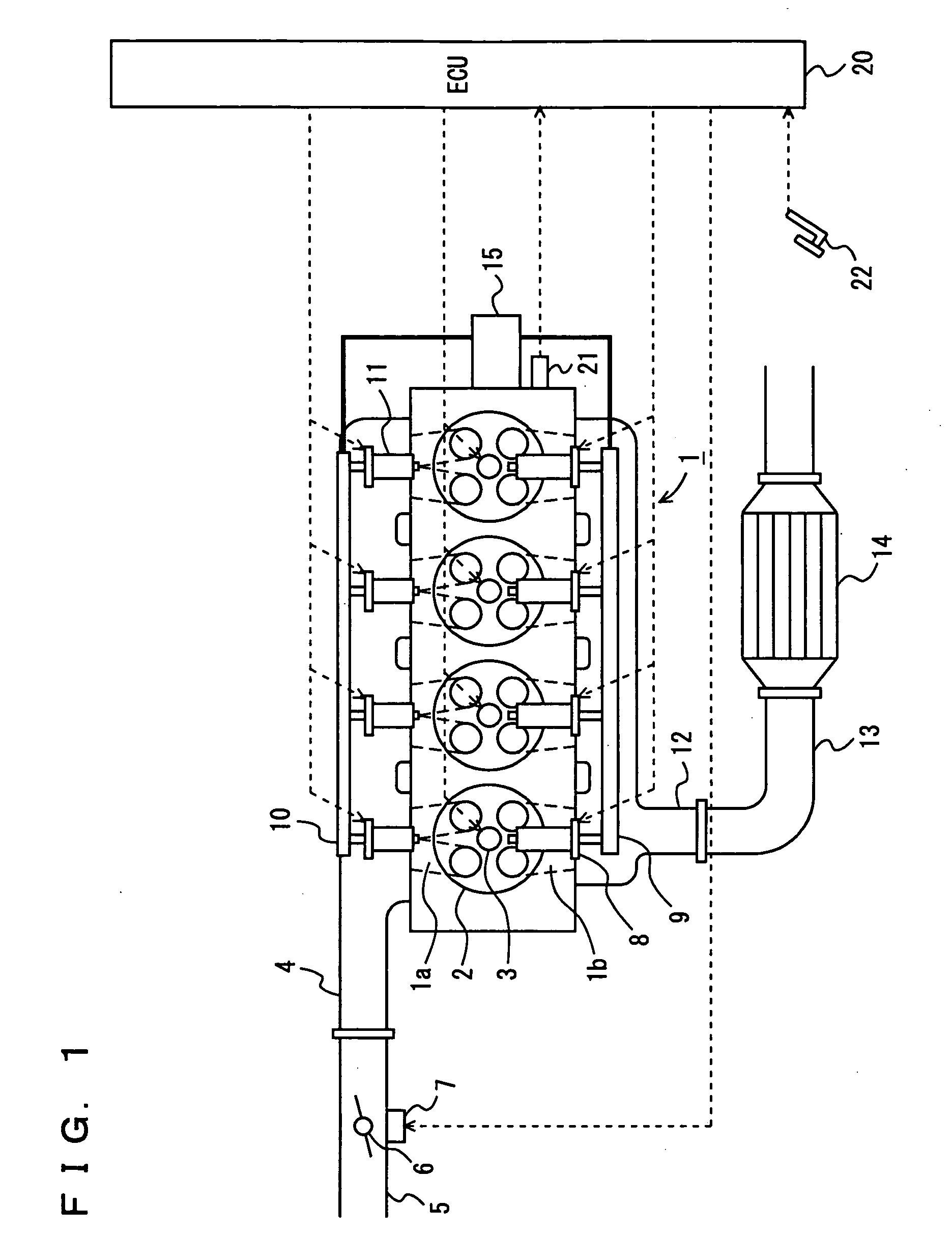

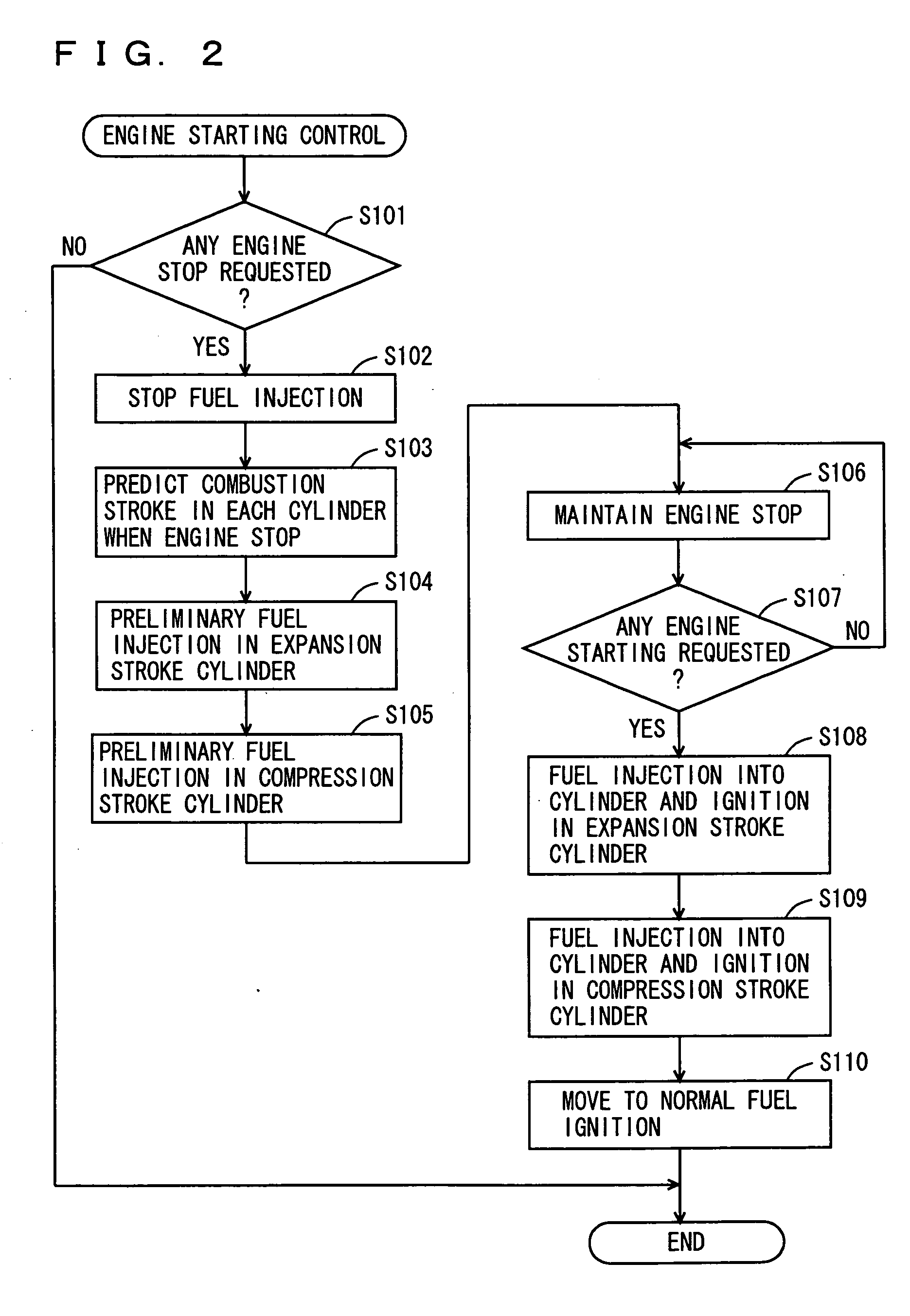

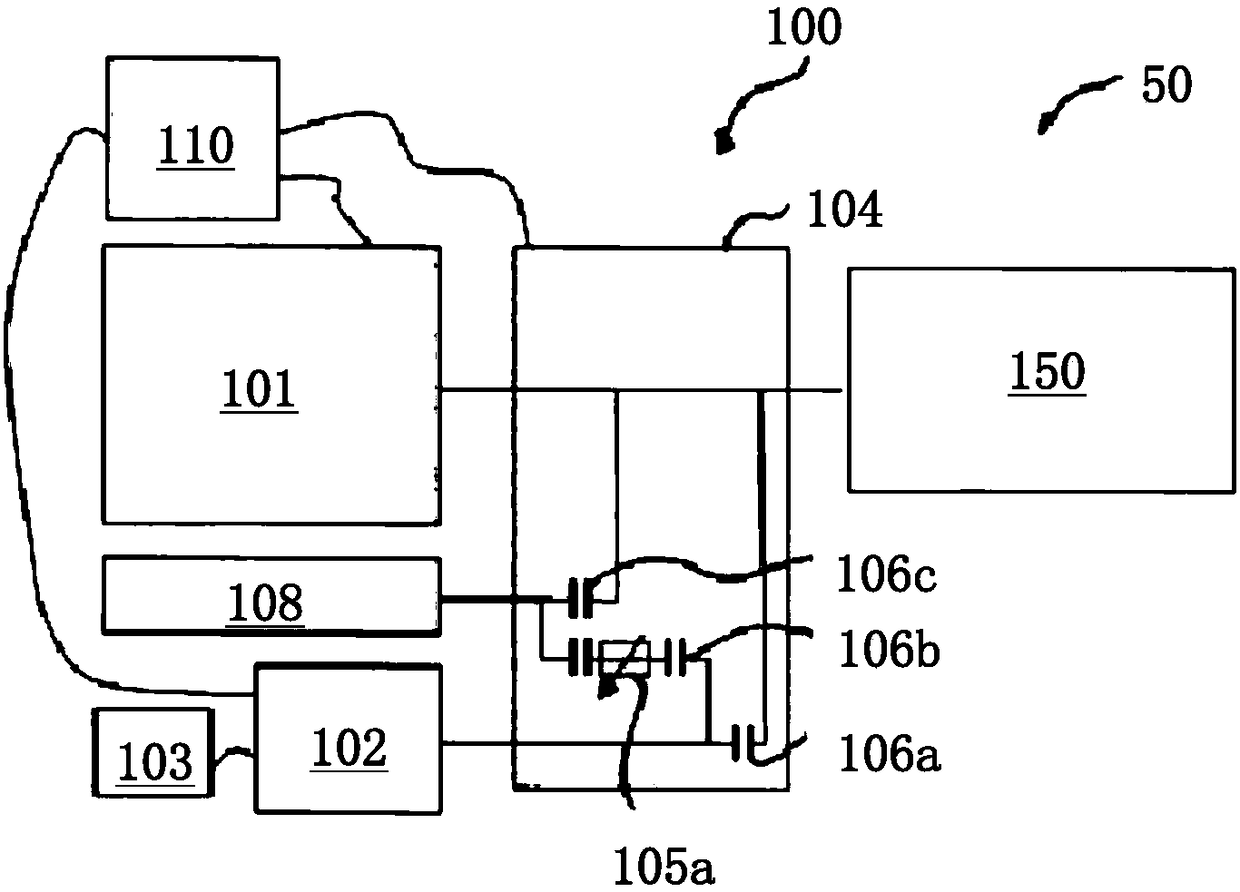

Engine starting control system of internal combustion engine

InactiveUS7377248B2Inhibit deteriorationRapid engine startPower operated startersElectrical controlCombustionExternal combustion engine

In an engine starting control system of an internal combustion engine in which an eco-run control is performed, a combustion stroke that each cylinder reaches when the internal combustion engine comes to an engine stopped state by the eco-run control is predicted, and in an expansion stroke cylinder that the predicted combustion stroke is an expansion stroke, fuel of a predetermined amount is injected from an intake passage injection valve into an intake passage just before the internal combustion engine comes to an engine stopped state, and in the expansion stroke cylinder, an engine start of the internal combustion engine in an engine stopped state is performed by injecting fuel from the cylinder injection valve into the cylinder and igniting the air-fuel mixture in the cylinder by an ignition plug.

Owner:TOYOTA JIDOSHA KK

Engine starting control system of internal combustion engine

InactiveUS20070131188A1Inhibit deteriorationRapid engine startPower operated startersElectrical controlCombustionControl system

In an engine starting control system of an internal combustion engine in which an eco-run control is performed, a combustion stroke that each cylinder reaches when the internal combustion engine comes to an engine stopped state by the eco-run control is predicted, and in an expansion stroke cylinder that the predicted combustion stroke is an expansion stroke, fuel of a predetermined amount is injected from an intake passage injection valve into an intake passage just before the internal combustion engine comes to an engine stopped state, and in the expansion stroke cylinder, an engine start of the internal combustion engine in an engine stopped state is performed by injecting fuel from the cylinder injection valve into the cylinder and igniting the air-fuel mixture in the cylinder by an ignition plug.

Owner:TOYOTA JIDOSHA KK

Dual fuel compression ignition engines and methods

ActiveUS8327831B2Non-fuel substance addition to fuelInternal combustion piston enginesHydrogenCompressed natural gas

Dual fuel compression ignition engines and methods that allow compression ignition on gaseous fuels like compressed natural gas, hydrogen and ammonia, yet will run on liquid fuels, including diesel fuels for such purposes as starting or when the gaseous fuel is not available or has been consumed and greater range or operating time is needed. Ignition of fuels having a high self ignition temperature is assured by recirculating high temperature exhaust gas back into the intake charge before compression. Existing engines may be converted to run as a dual fuel engine by replacement of the engine head or heads. Various embodiments are disclosed.

Owner:STURMAN DIGITAL SYST

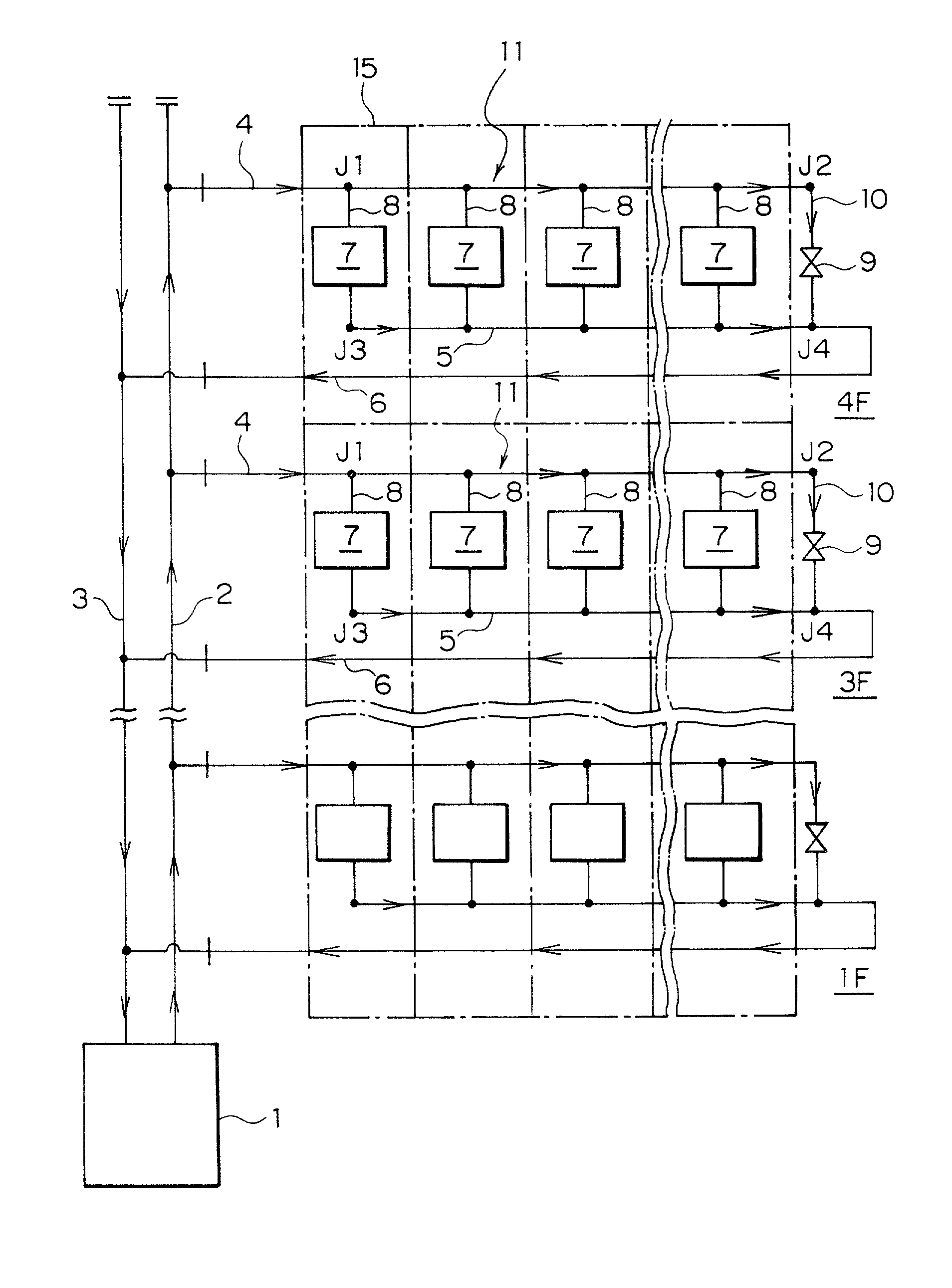

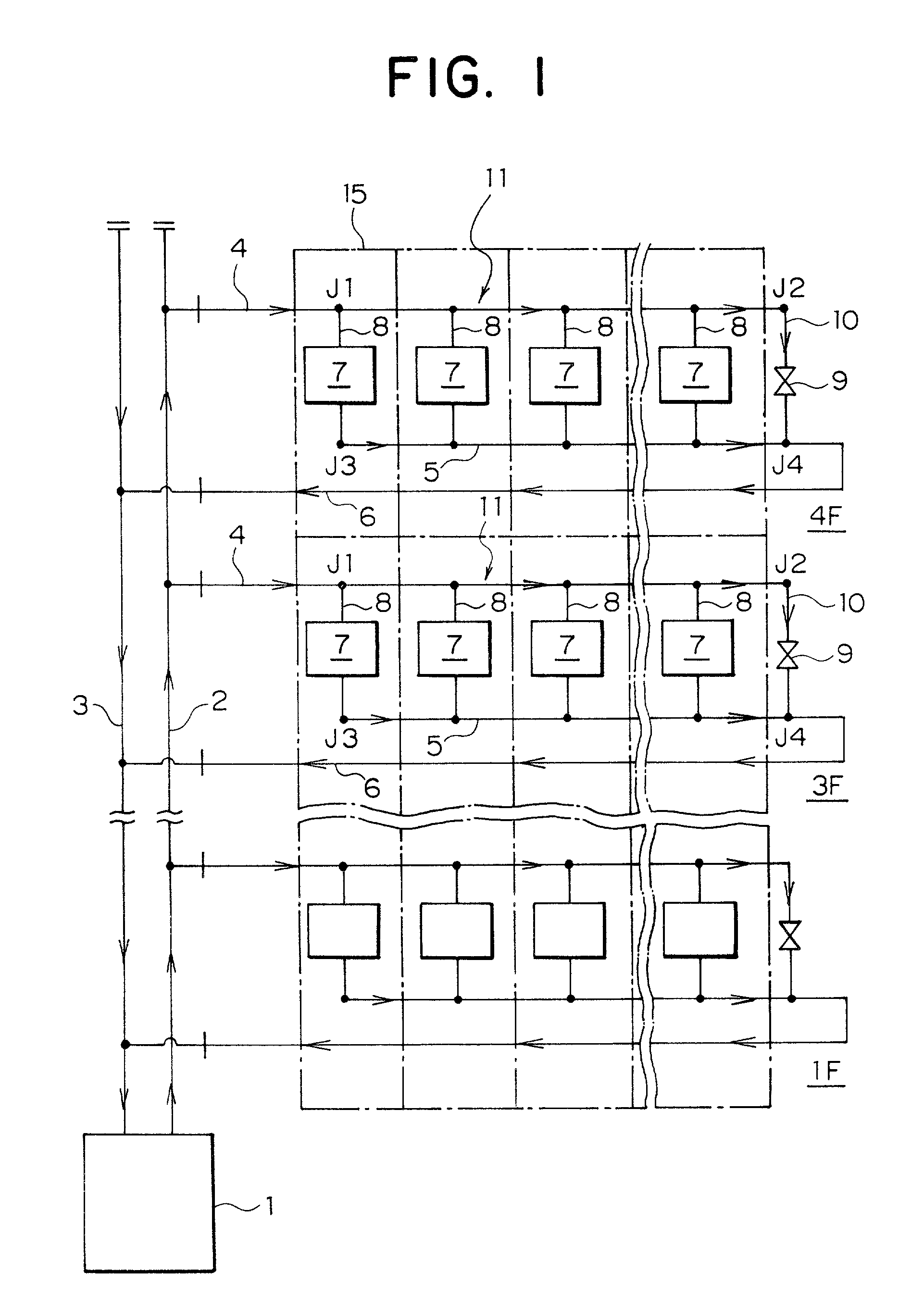

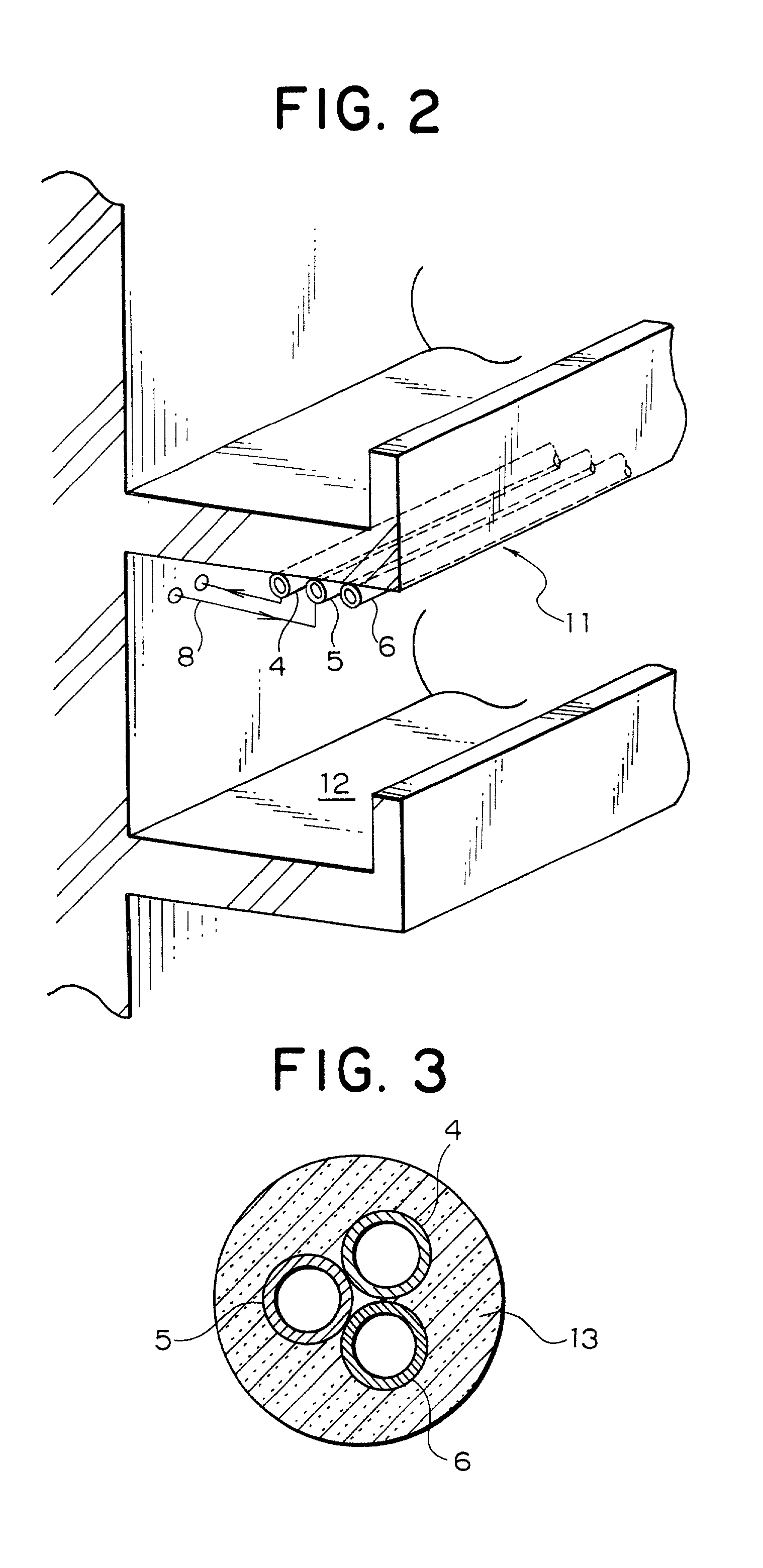

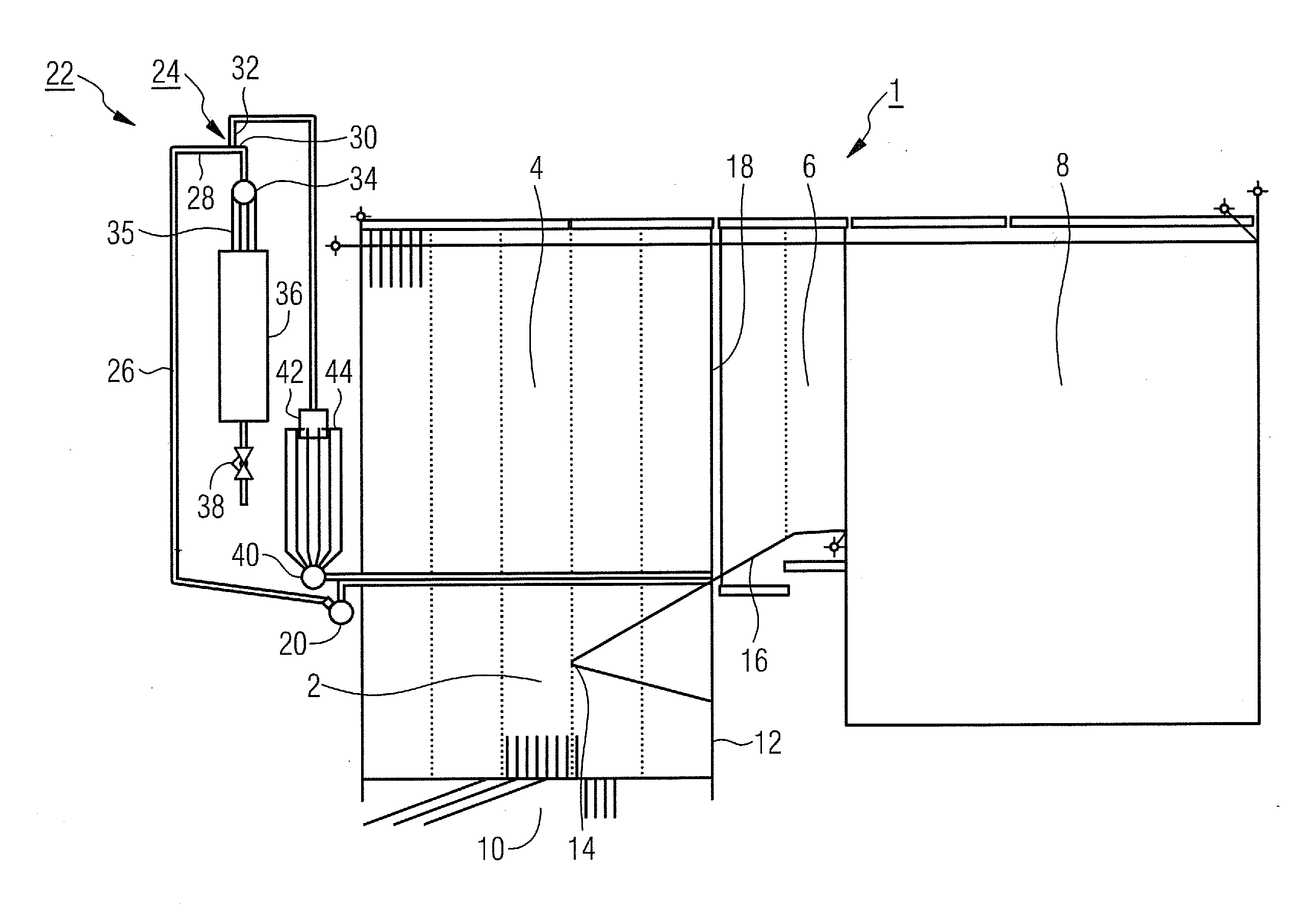

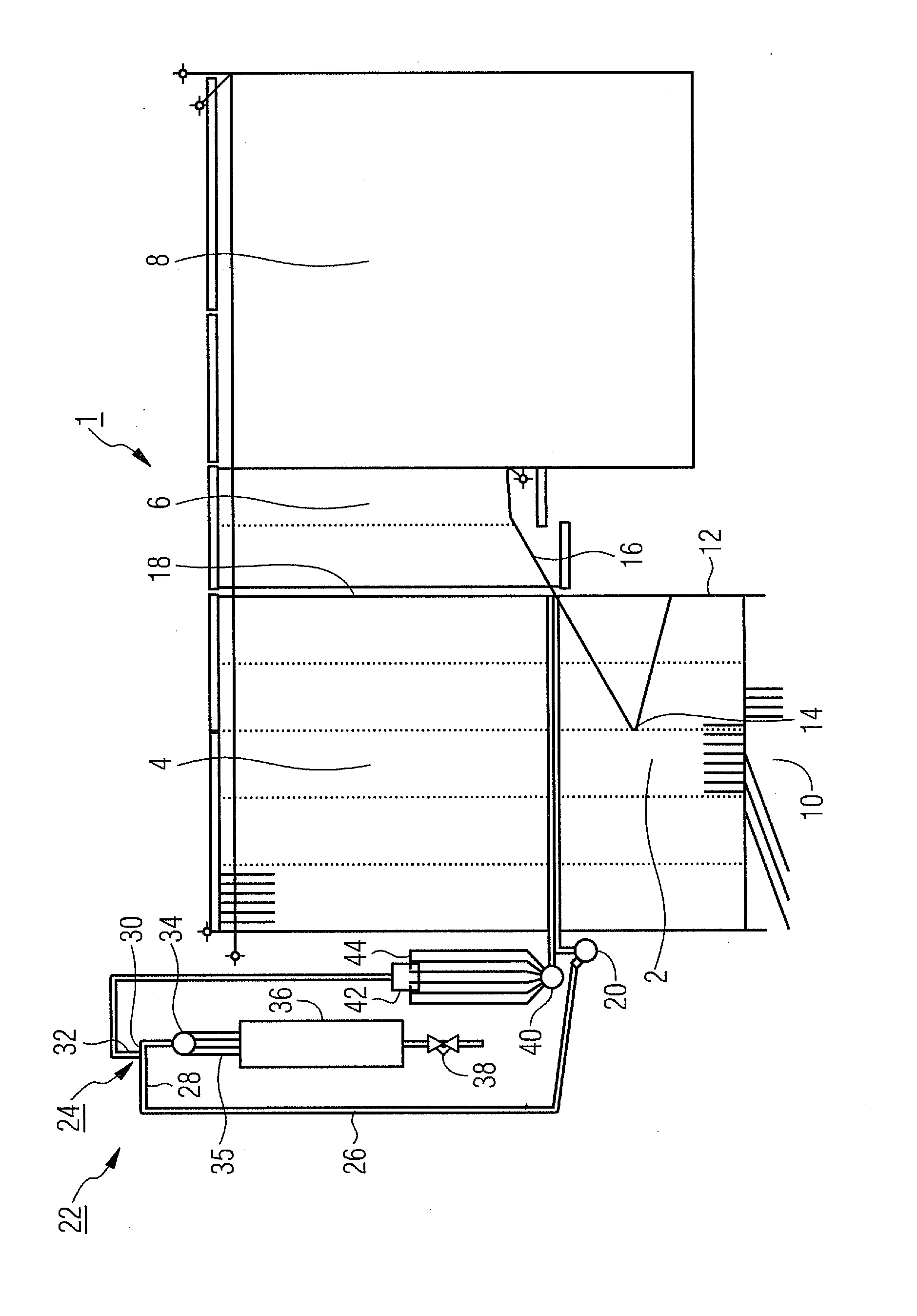

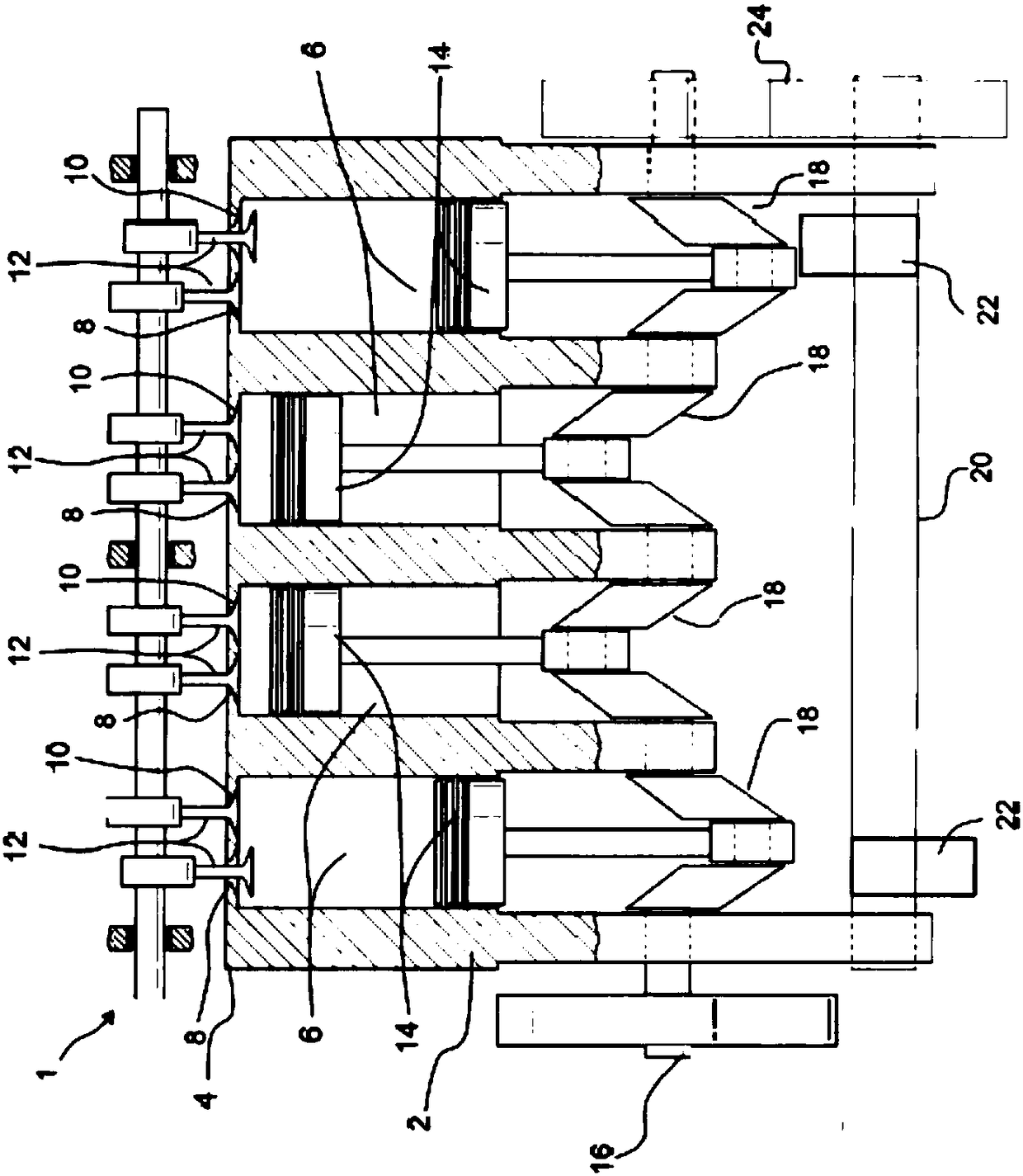

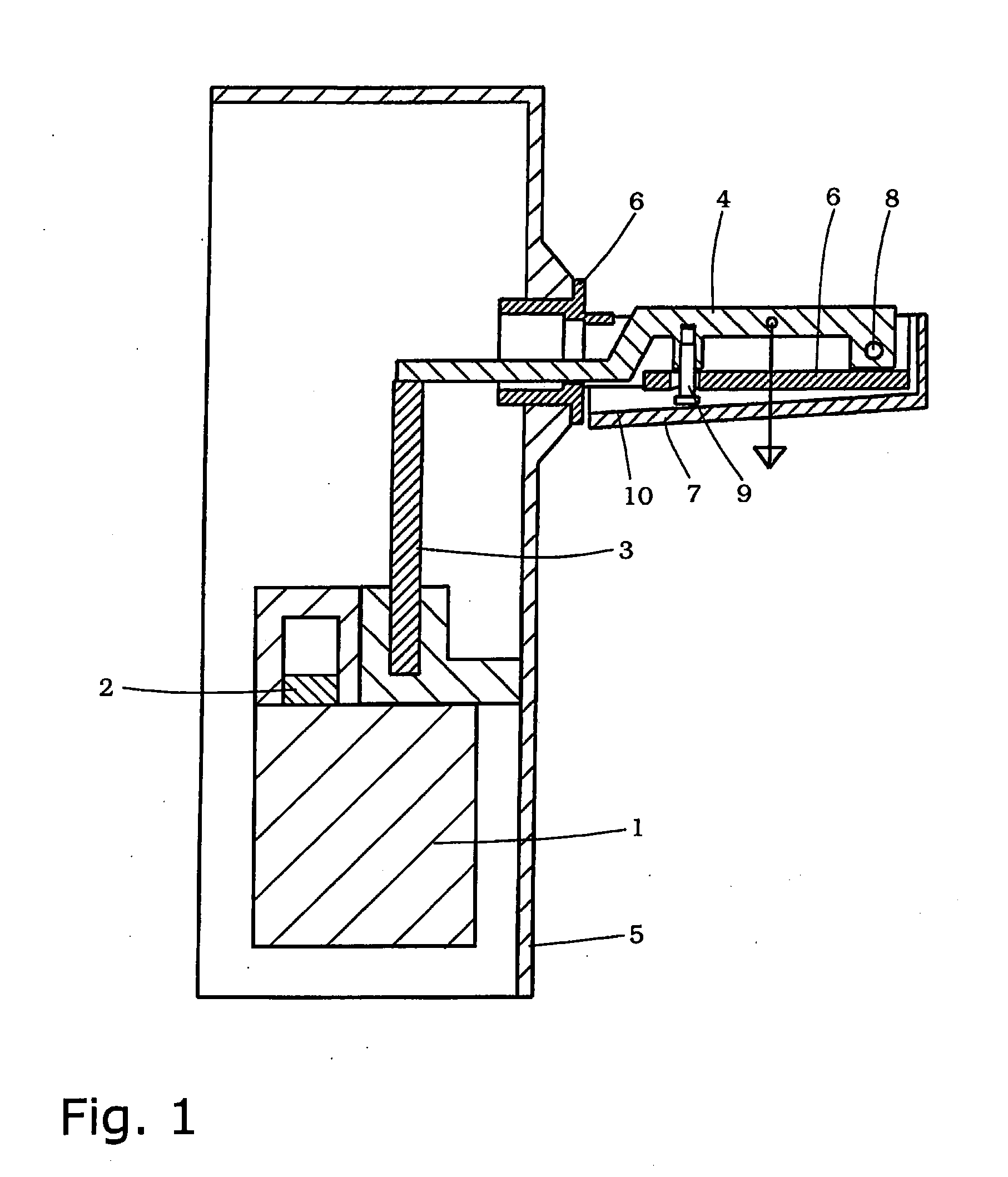

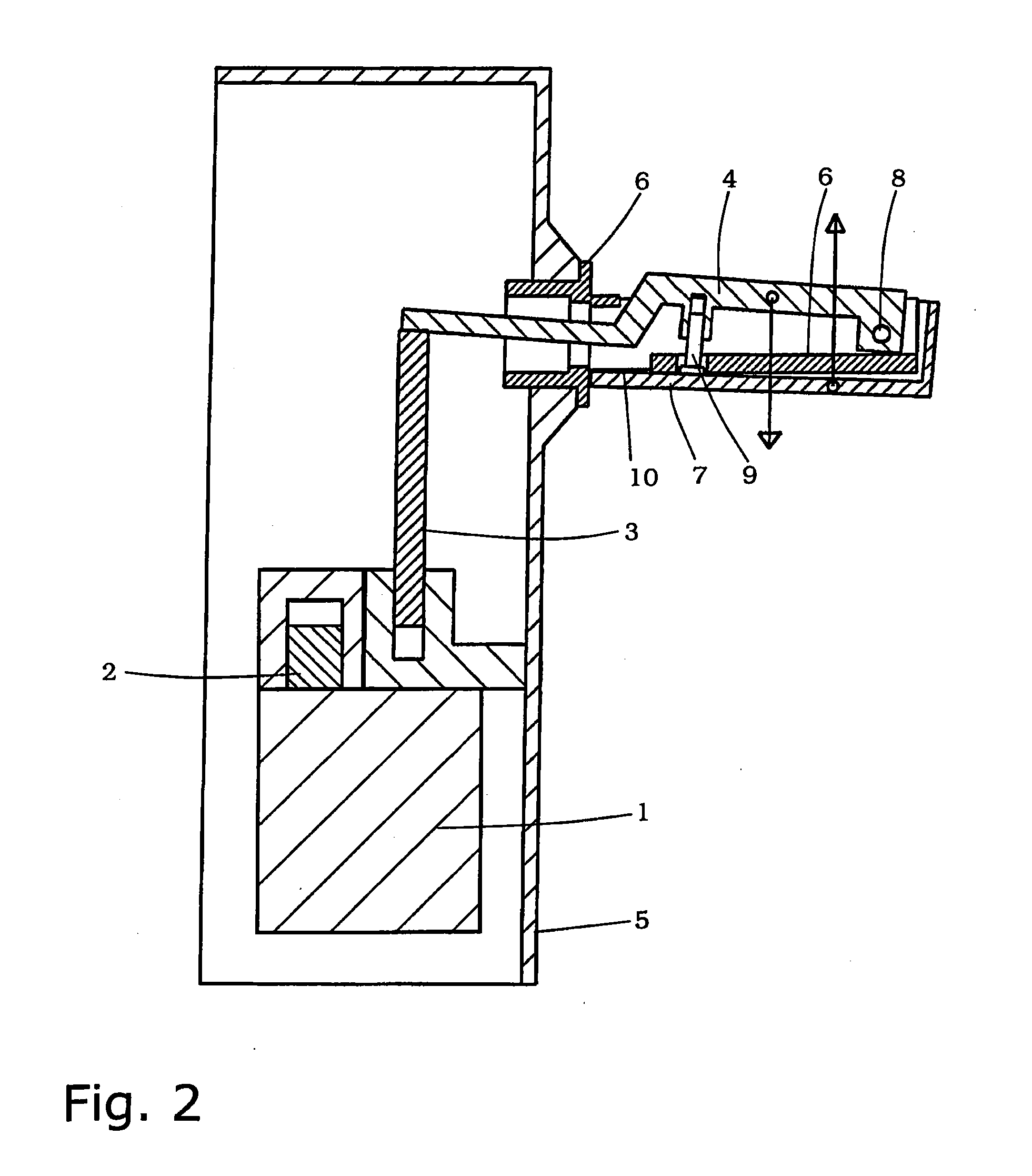

Heat supply system

InactiveUS20020026904A1Equally distributedBoiler flue tubes/fire tubesBoiler water tubesProcess engineeringHeat exchanger

A heat supply system is provided which enables use of small pipes with the same diameter for both feed branch pipes and return branch pipes, thus reducing the initial cost and also suppressing heat emission loss. The heat supply system comprises a heat exchanger 1, a feed main pipe 2, a return main pipe 3, a feed branch pipe 4 connected to the feed main pipe 2, a first return branch pipe 5 for directing the flow of a heat medium to an edge section in the downstream side of the feed branch pipe 4, a plurality of load pipes connected in parallel to a section between the feed branch pipe 4 and the first return branch pipe 5 each having a load member 7 provided thereon, and a second return branch pipe 6 connected to a section between an edge section in the downstream side of the first return branch pipe 5 and the return main pipe 3, said heat supply system having a plurality of branch pipe paths 11 including therein the feed branch pipe 4, first return branch pipe 5, load pipe 8, and second branch pipe 6.

Owner:MARUYAMA NOBORU

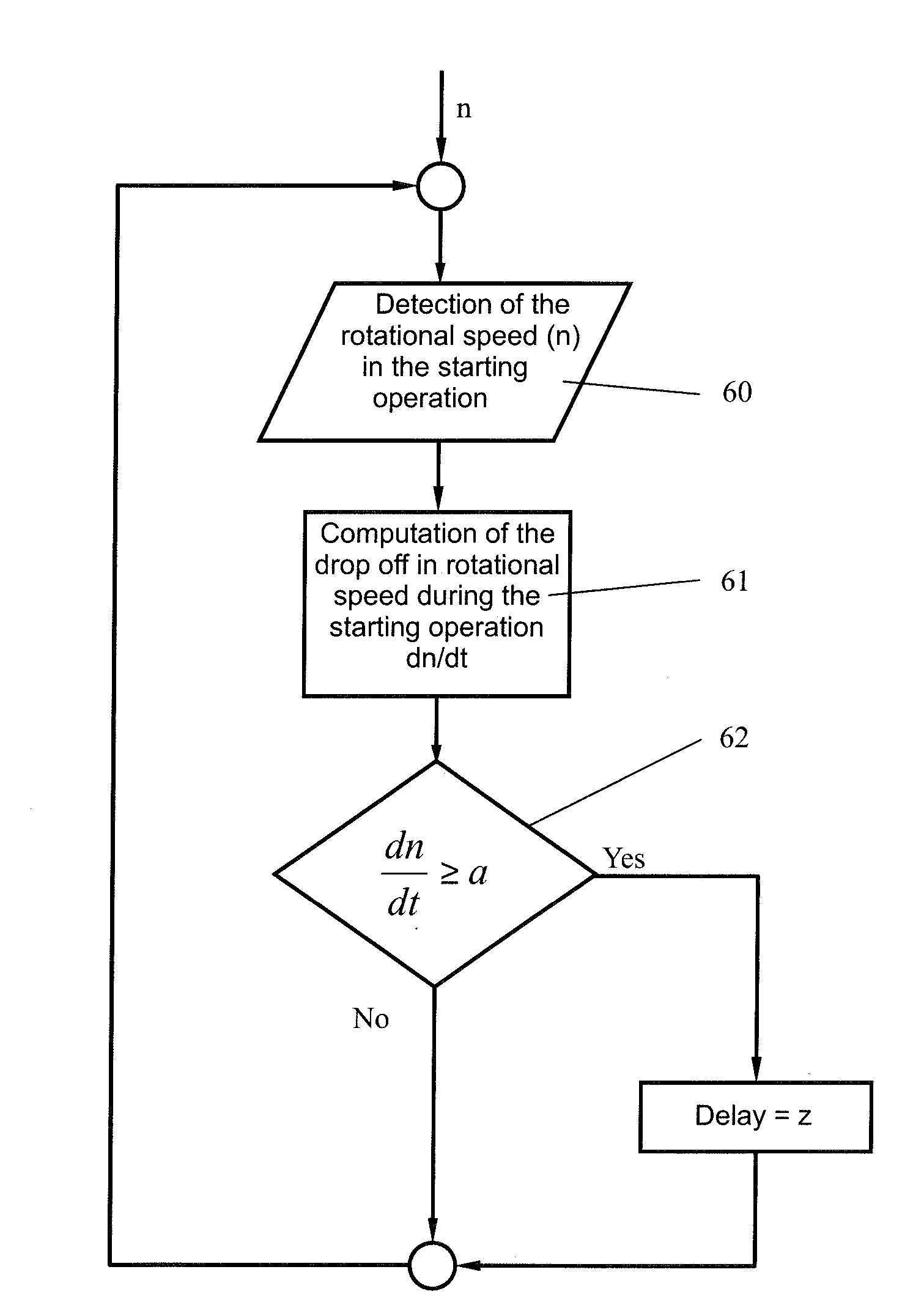

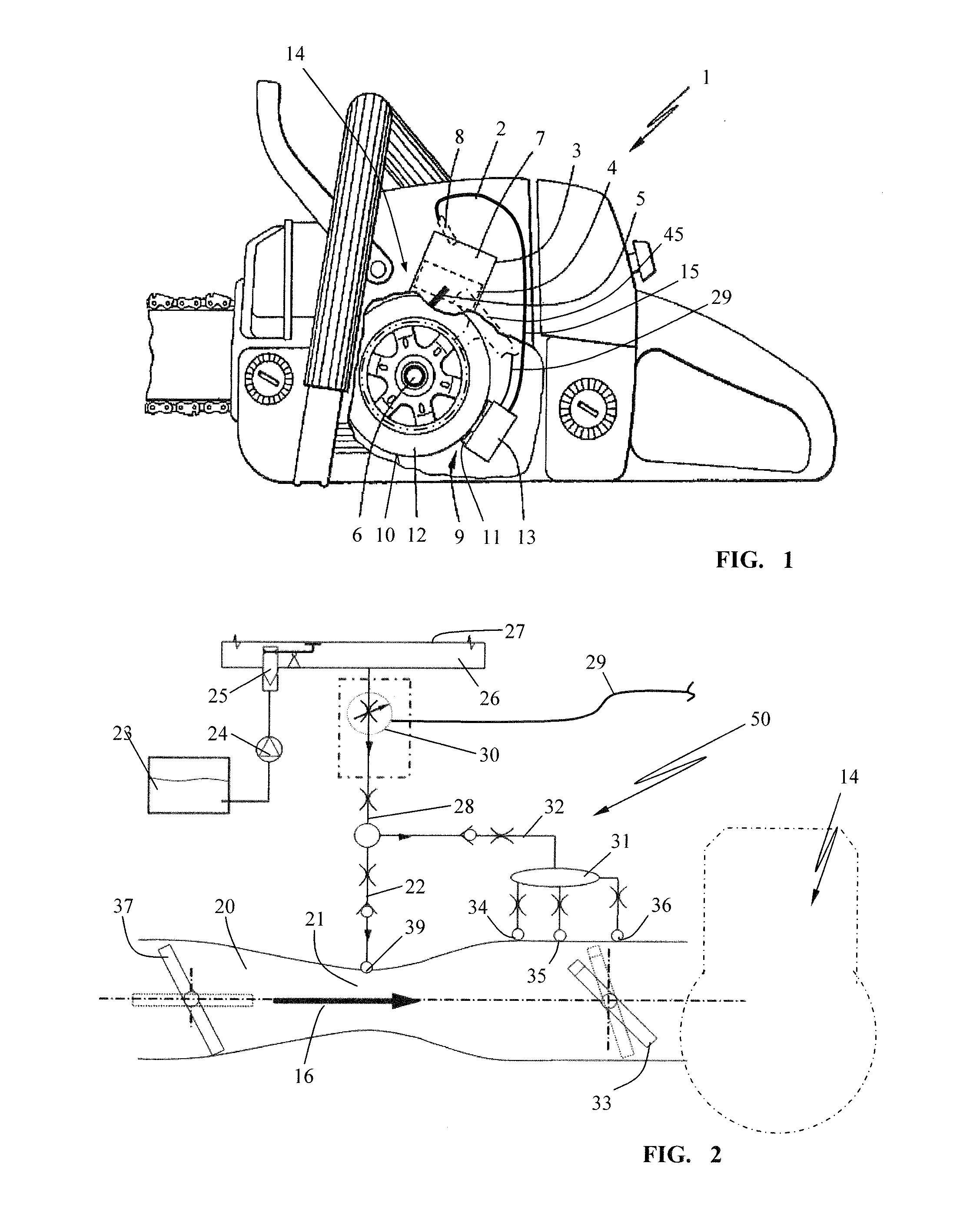

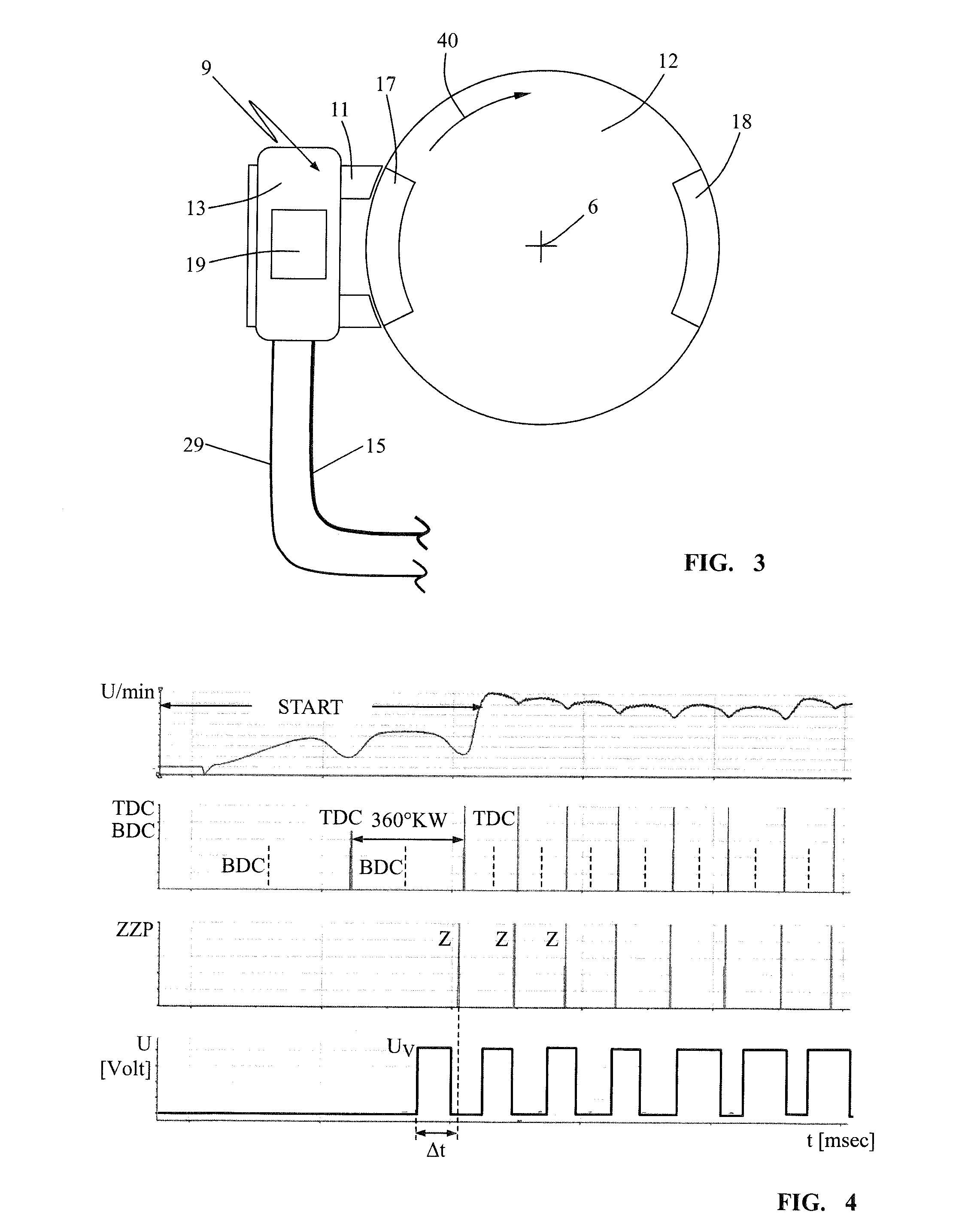

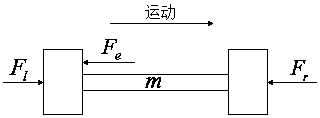

Method for starting a combustion engine having a starter apparatus

InactiveUS20150047593A1Increase frictionReduce lubricationElectrical controlInternal combustion piston enginesCombustionInternal combustion engine

A method is for starting a combustion engine having a pull-rope starter. A fuel / air mixture is fed to the engine via an intake channel. The mixture is ignited by a spark plug. The combustion drives the piston downward and drives a crankshaft rotationally. The fuel system has a fuel channel opening into the intake channel. An electric fuel valve is open in its currentless state and closes a fuel channel only when an operating voltage is applied. An electronic control unit actuates the fuel valve and triggers an ignition spark and is utilized by a generator to supply energy to the control unit, the fuel valve and the ignition device. To prevent excessive enriching of the fuel / air mixture during starting, the energy, which is generated at the beginning of the rotation of the crankshaft, is used to first close the fuel valve before the control unit triggers an ignition spark.

Owner:ANDREAS STIHL AG & CO KG

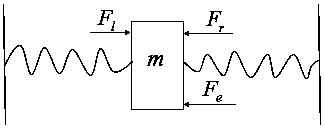

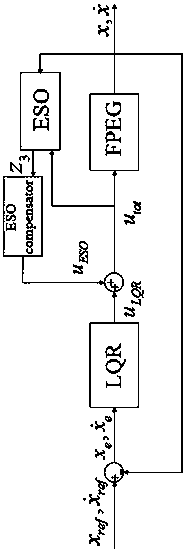

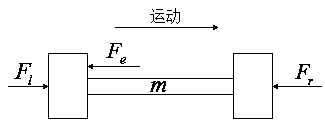

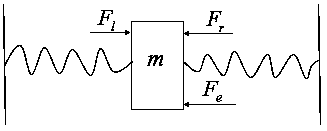

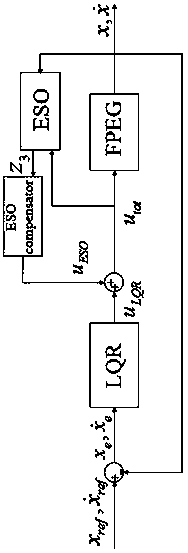

Control method for piston motion track of free piston engine

ActiveCN107288751AGuaranteed uptimeGood piston trajectory tracking performanceNon-electrical controlFree piston enginesFree-piston engineControl oriented

The invention discloses a control method for piston motion track of a free piston engine, and belongs to the technical field of control. The invention aims to provide the control method for the piston motion track of the free piston engine, and the control method establishes a free piston internal combustion engine generator mechanism model system under an MATLAB environment according to the working mechanism of the free piston internal combustion engine generator, can effectively compensate interferences and keeps stable operation of the free piston internal combustion engine generator. The control method comprises the following steps of: establishing a free piston electric generator simulation model; controlling piston track of the free piston electric generator; enabling track of the piston to trace reference track, wherein the reference track is that a FPEG works under load needed for a driver; establishing a control-oriented model; designing a quadric-form secondary optimal controller; expanding design of a state observer; and performing uncertainty compensation. According to the control method disclosed by the invention, a control-oriented simplified model of the system is established, a piston motion control method based on linear quadratic type (LRQ) and extended state observer (ESO) is disclosed, and piston motion track of EPEG is controlled by regulating circulating oil spray amount.

Owner:JILIN UNIV

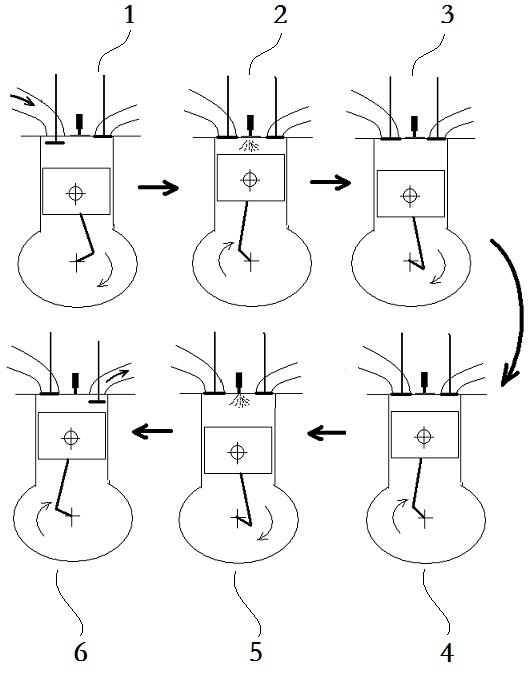

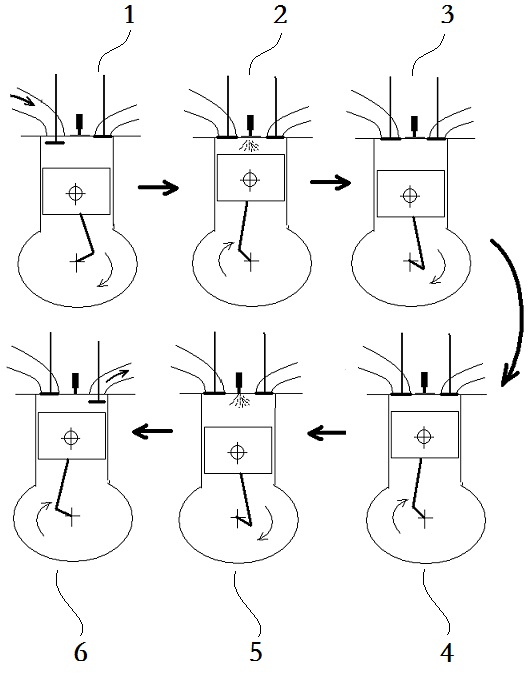

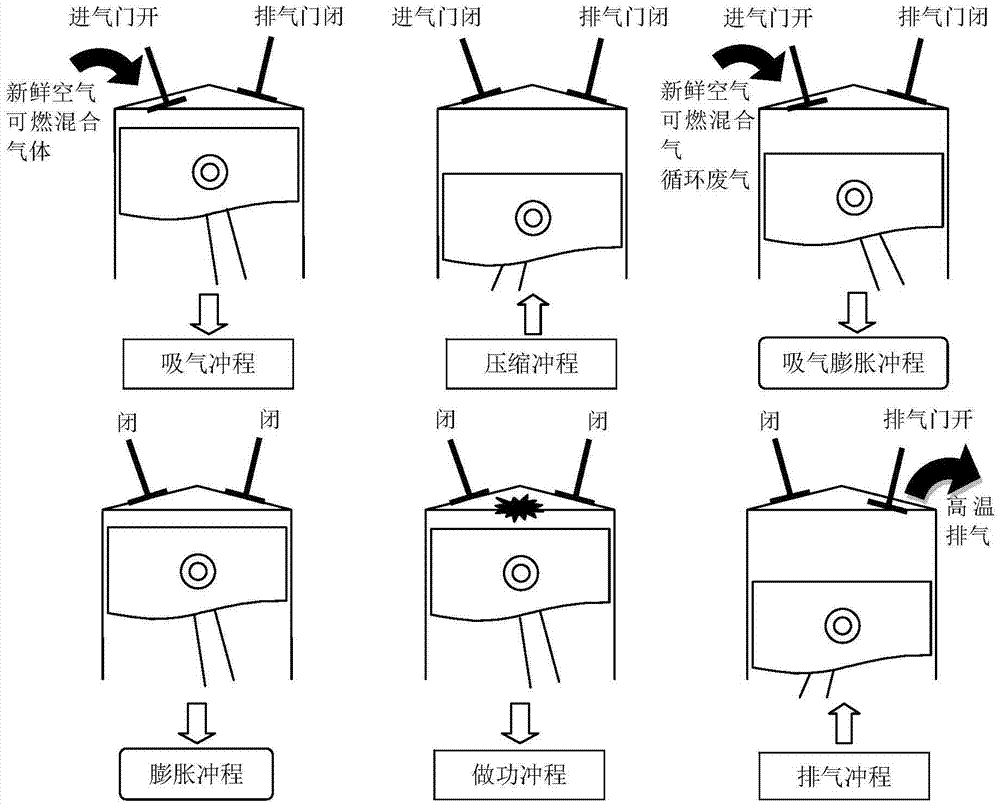

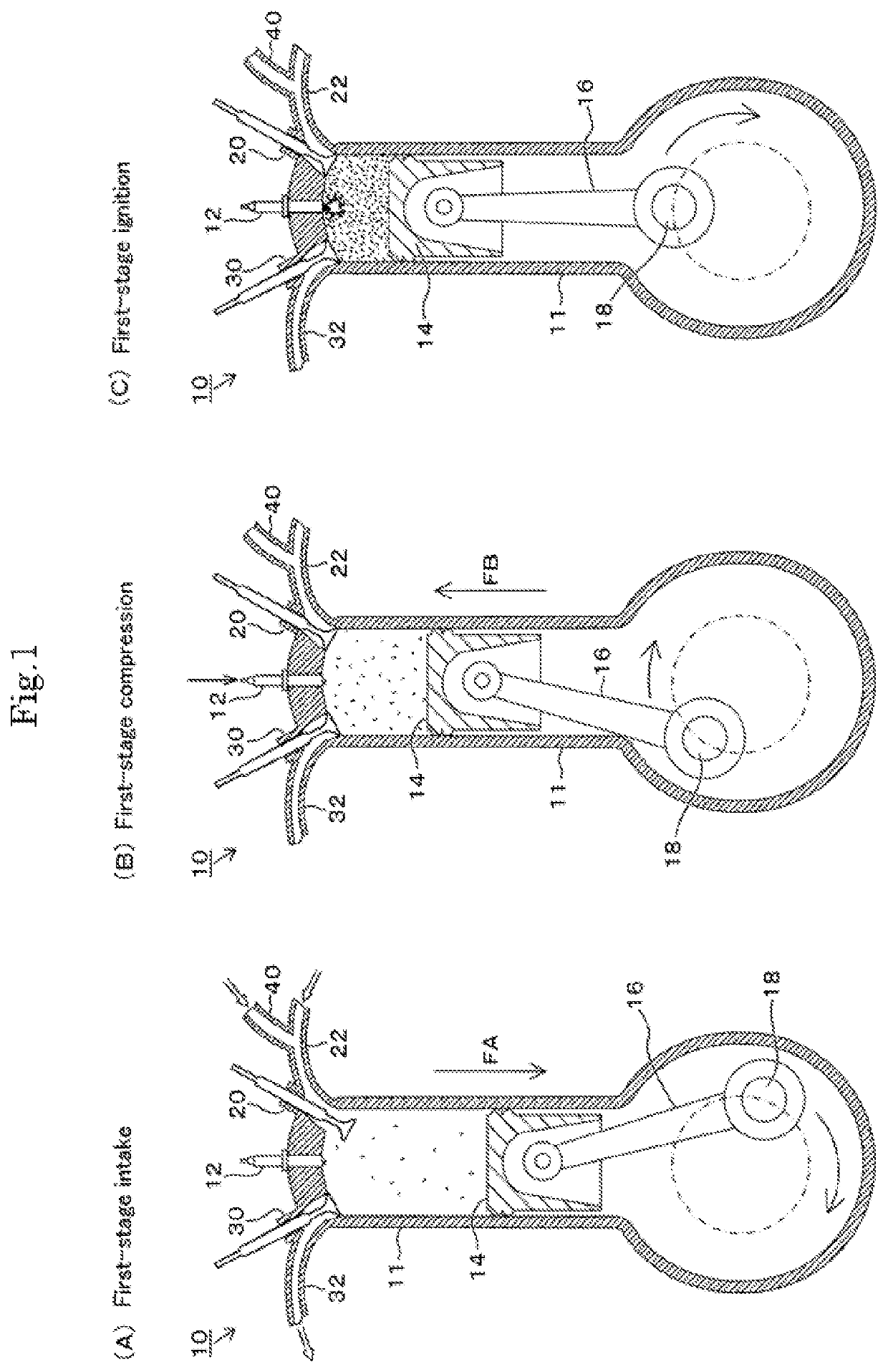

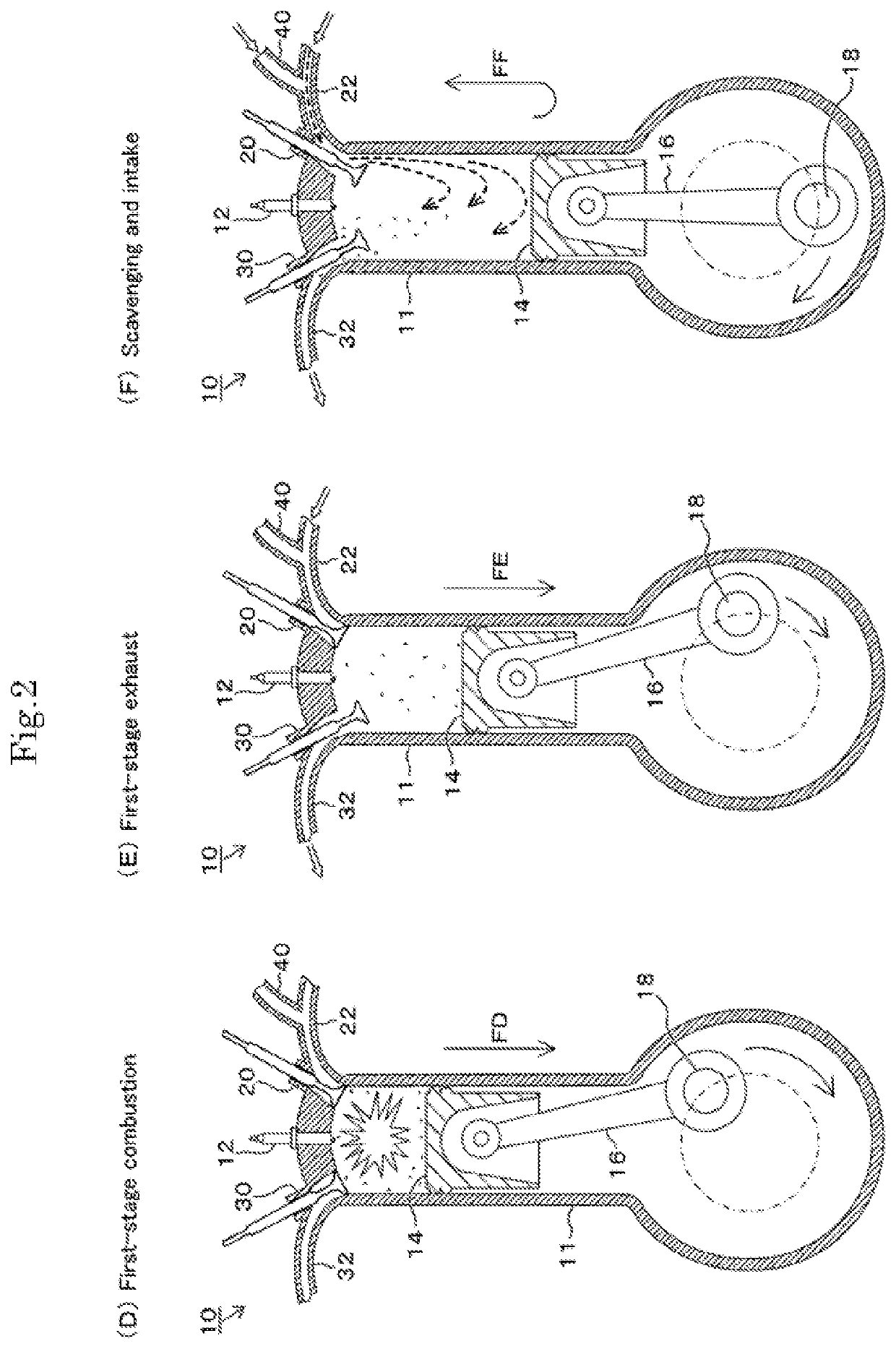

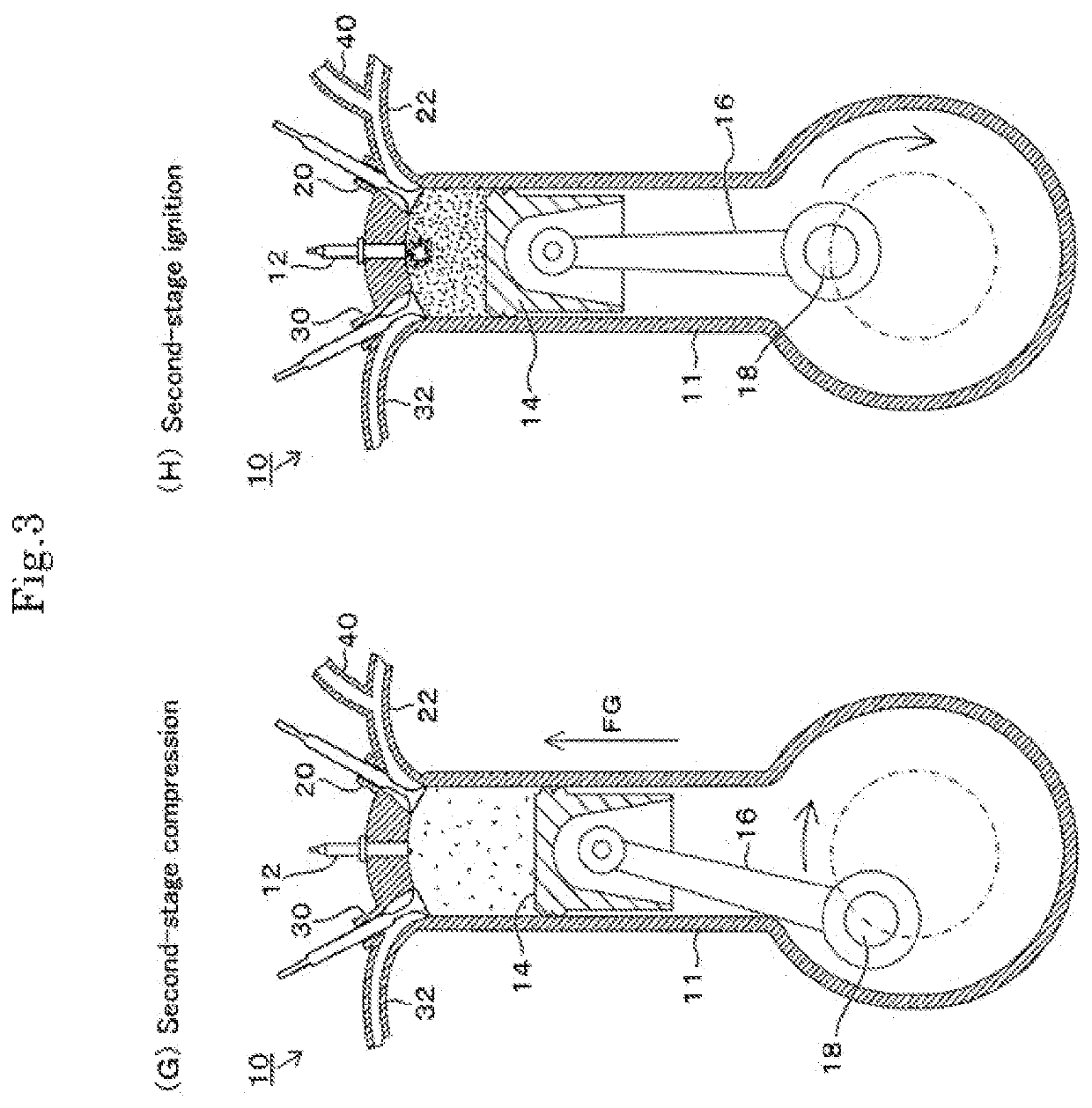

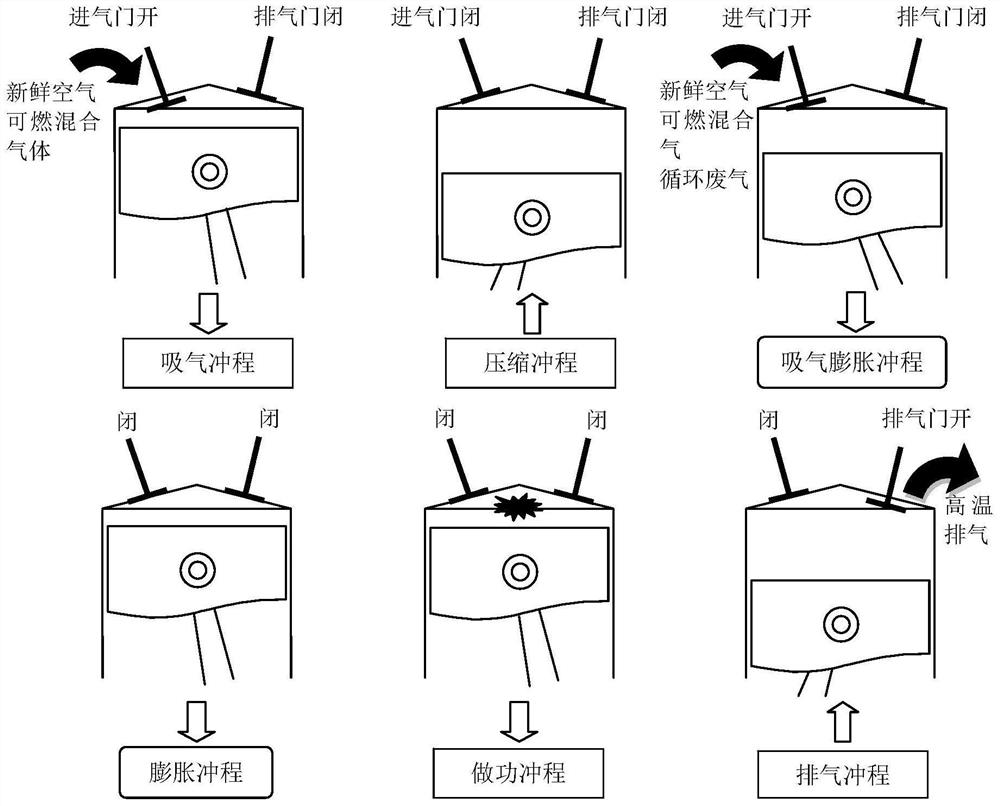

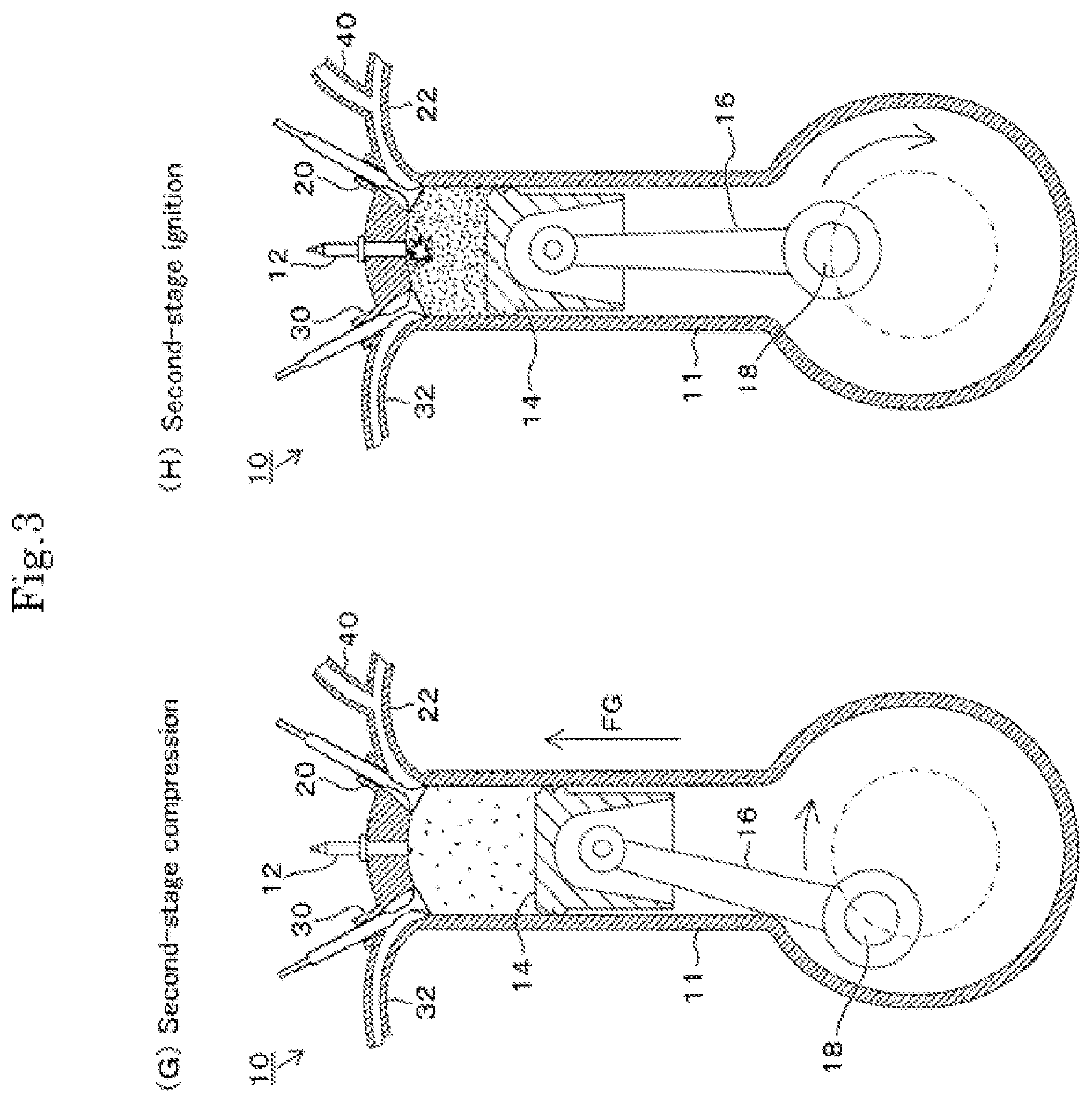

Secondary combustion working method of six-stroke internal-combustion engine

InactiveCN102155311AImprove combustion efficiencySolve the problem of poor combustion performanceNon-electrical controlMachines/enginesCombustionTop dead center

The invention relates to a secondary combustion working method of a six-stroke internal-combustion engine. In the method, one working cycle of the internal-combustion engine can be divided into an air intake stroke, a primary compression stroke, a primary combustion stroke, a secondary compression stroke, a secondary combustion stroke and an exhaust stroke in sequence by the movement of a piston of the internal-combustion engine, wherein in the primary combustion stroke, primary fuel is used for combustion, and in the secondary combustion stroke, secondary fuel is used for combustion; the primary fuel is sprayed in a cylinder body of the internal-combustion engine in the primary compression stroke, the secondary fuel is sprayed in the cylinder body of the internal-combustion engine at the moment that the piston of the internal-combustion engine gets away a top dead center of the secondary combustion stroke or in the secondary combustion stroke. In the method, the fuel air ratio of the sum of the primary fuel and the secondary fuel, and the intake air of the air intake stroke is not more than the fuel air ratio in theory of the fuel mixed by the primary fuel and the secondary fuel. In the secondary combustion working method of the six-stroke internal-combustion engine, the problem that the internal-combustion engine has poor consumption performance under high-load working condition is solved, and simultaneously the discharge of harmful tail gas of the internal-combustion engine is greatly reduced.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

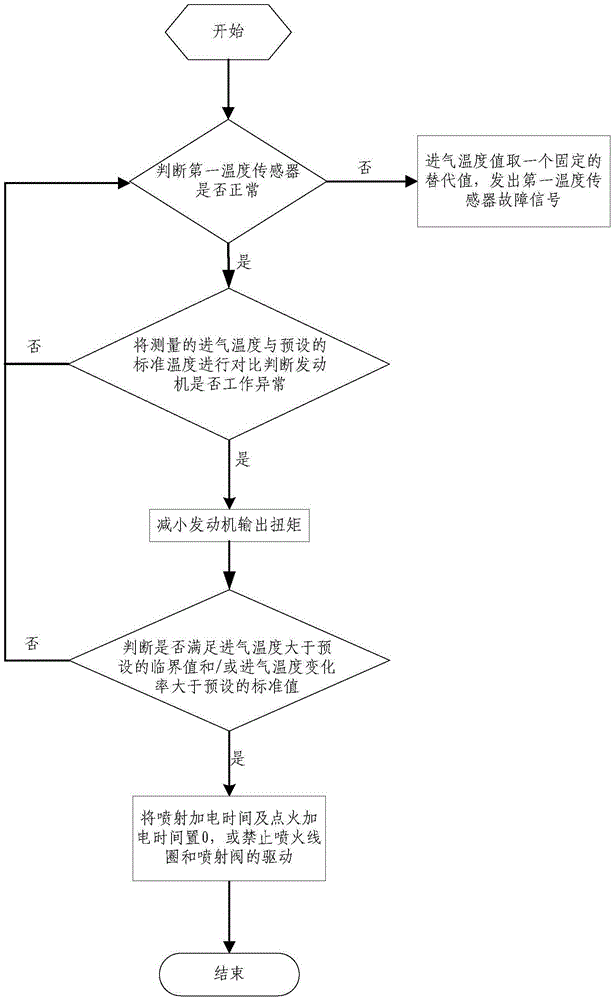

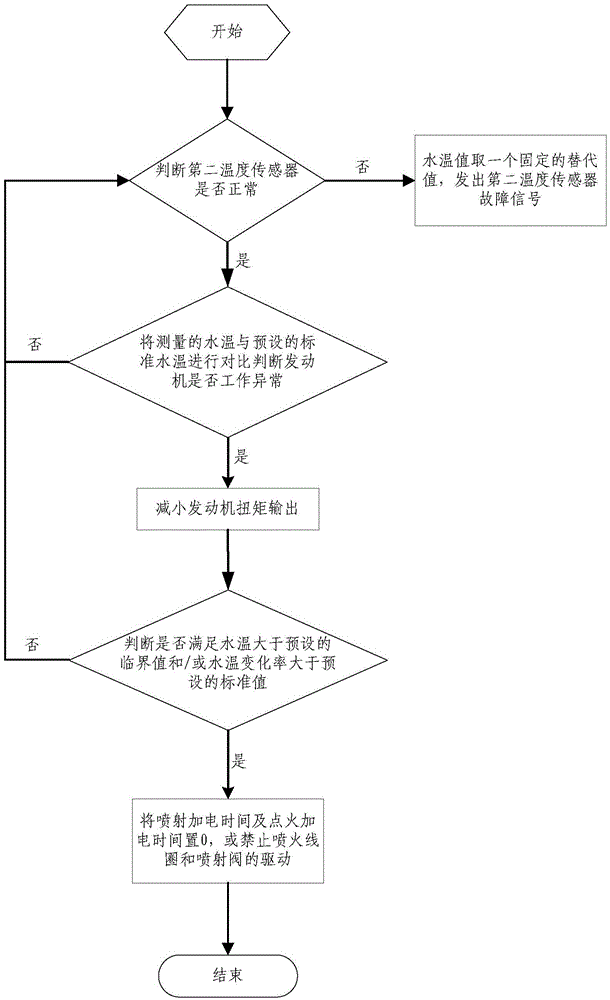

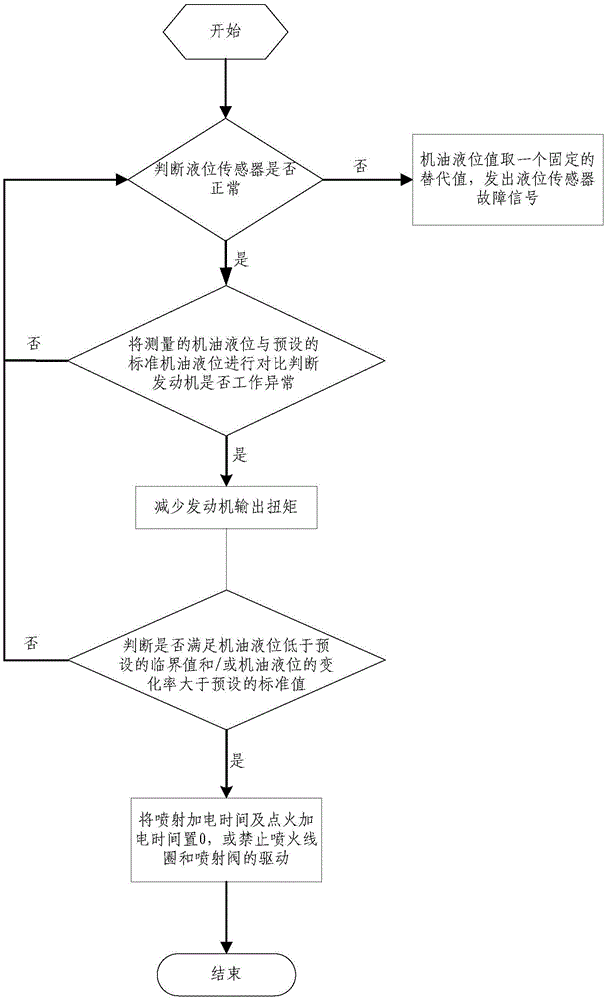

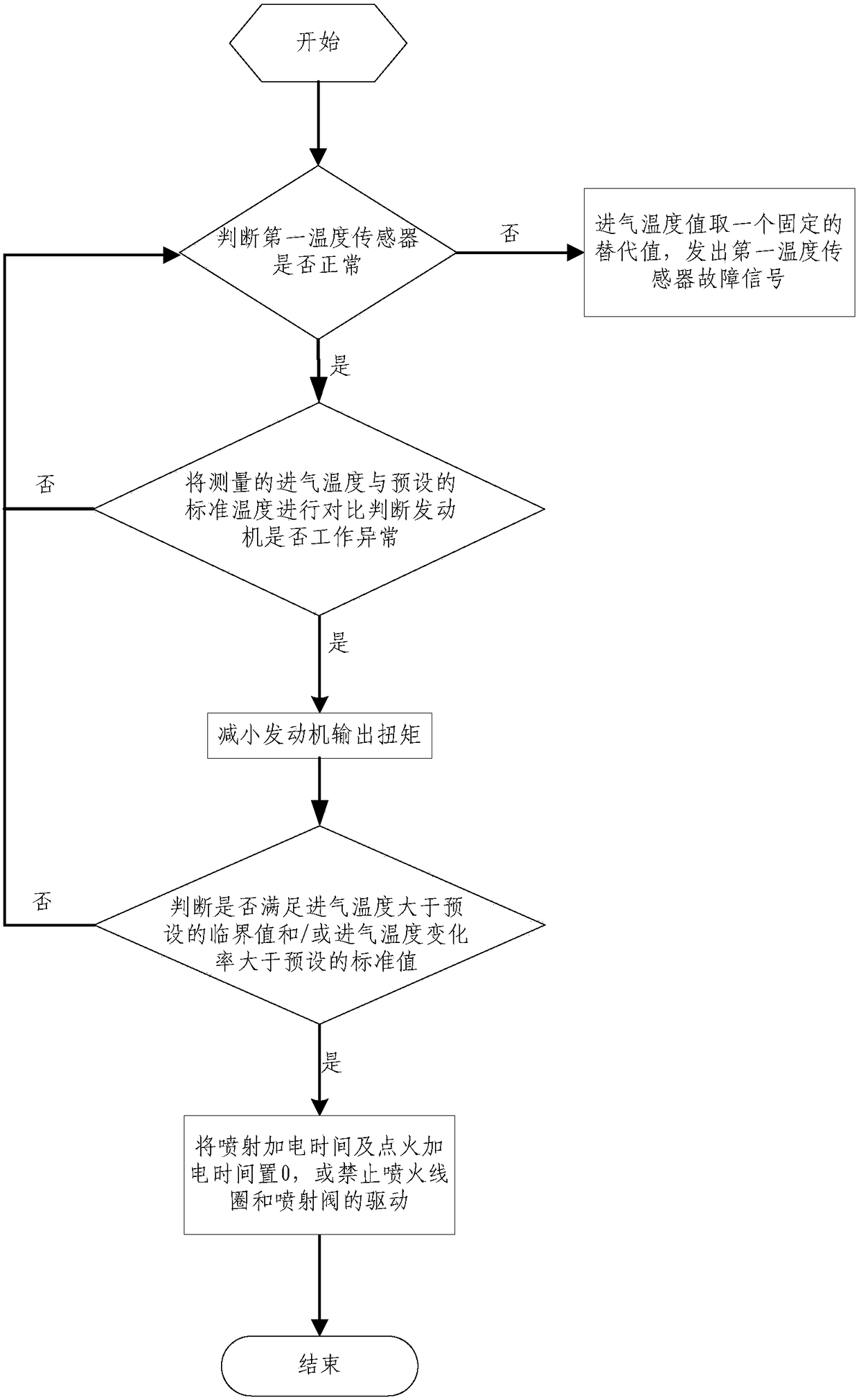

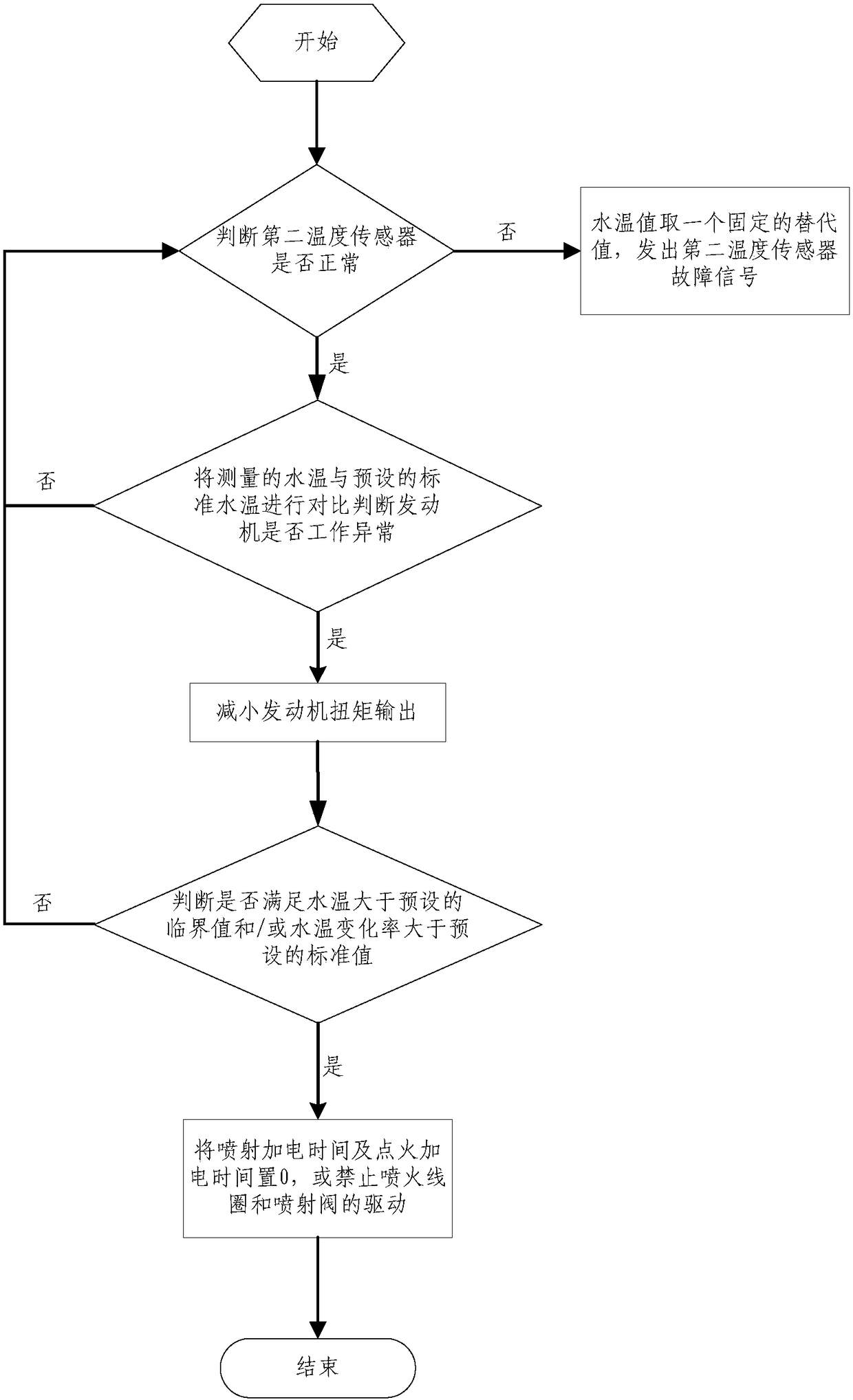

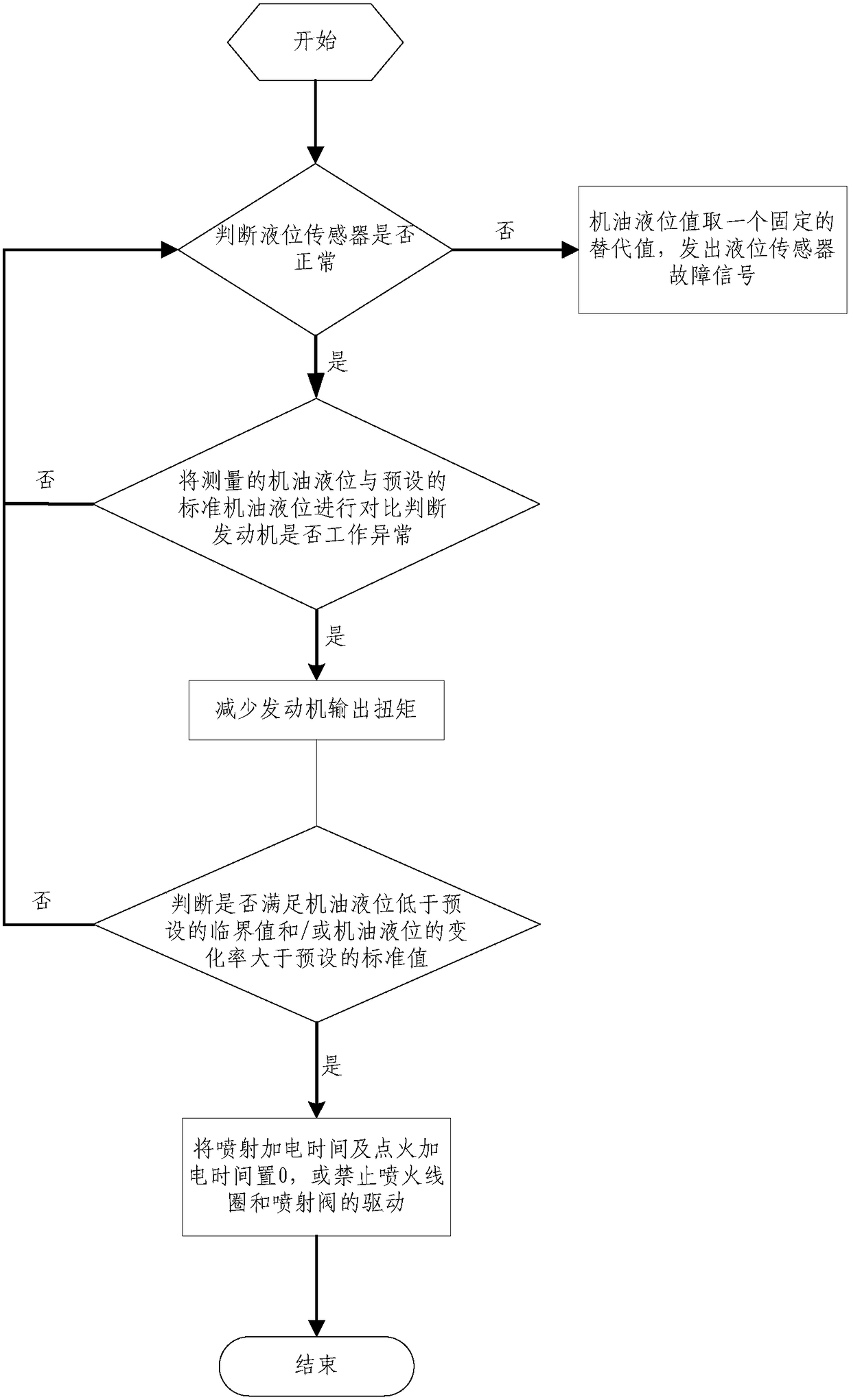

Method for preventing engine cylinder scoring

The invention relates to the technical field of automobiles, in particular to a method for preventing engine cylinder scoring. According to the method for preventing engine cylinder scoring, whether an engine fails or not is judged by measuring performance parameters of the engine; when it is judged that the engine fails according to the performance parameters of the engine, the output torque of the engine is limited first; and after the output torque of the engine is reduced, when the abnormal situation of the engine is still not improved or eliminated, the engine is directly turned off. According to the method, the situation that the gas inlet temperature, water temperature and lubrication situations of the engine become abnormal within a short period of time due to burst problems such as intercooler and throttle valve blockage, fan faults and engine oil leakage is considered, and it is effectively avoided that cylinder scoring happens when this type of situations happen to the engine.

Owner:WEICHAI POWER CO LTD

Continuous steam generator

ActiveUS20110197830A1Low costEasy to operateWater circulationDrum steam boilersCombustorCombustion chamber

A continuous steam generator including a combustion chamber with a plurality of burners for fossil fuel is provided. A vertical gas duct is connected downstream of the combustion chamber on the hot gas side, in an upper region via a horizontal gas duct. The outside wall of the combustion chamber is formed from evaporation pipes which are welded together in a gas-tight manner and mounted upstream of a water separator system on the flow medium side and from superheater pipes which are welded together in a gas-tight manner and mounted downstream of the water separator system. The water separator system includes a plurality of water separation elements, each element includes an inlet tube which is connected to the respective upstream evaporation for tubes, which extend into a water evacuation tube. A distributer element is arranged on the evaporator side between the respective water separator element and the inlet collector.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

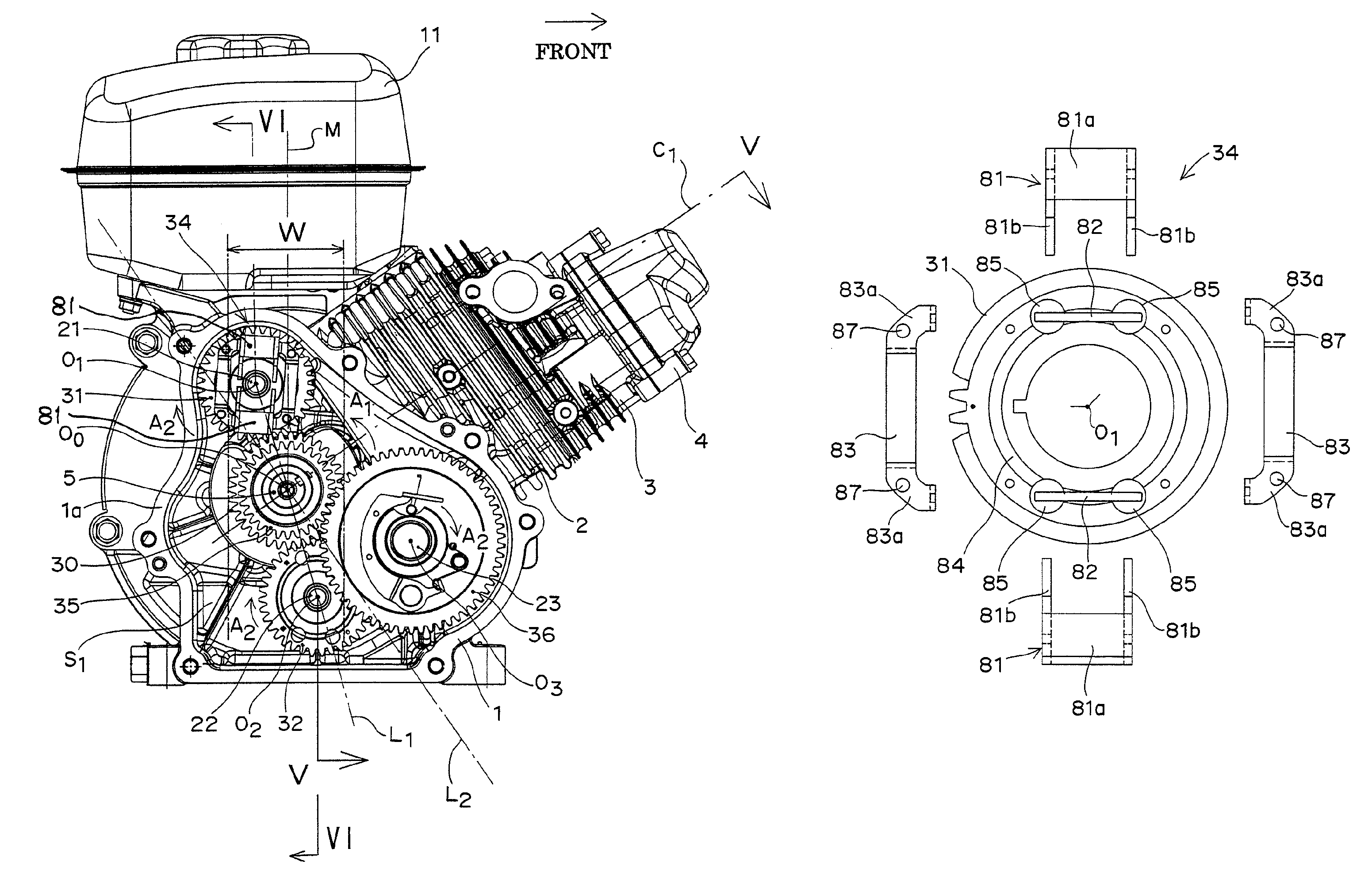

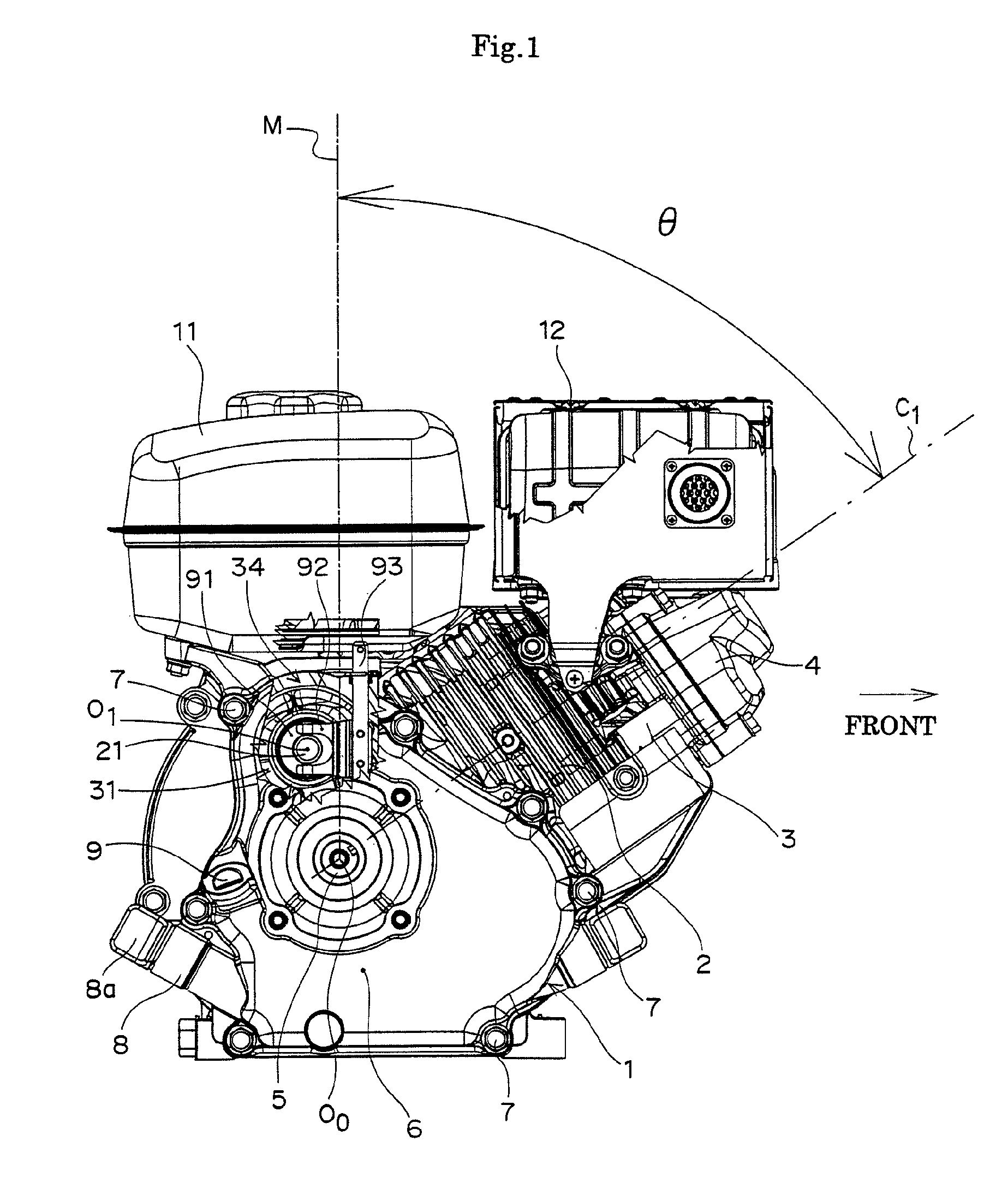

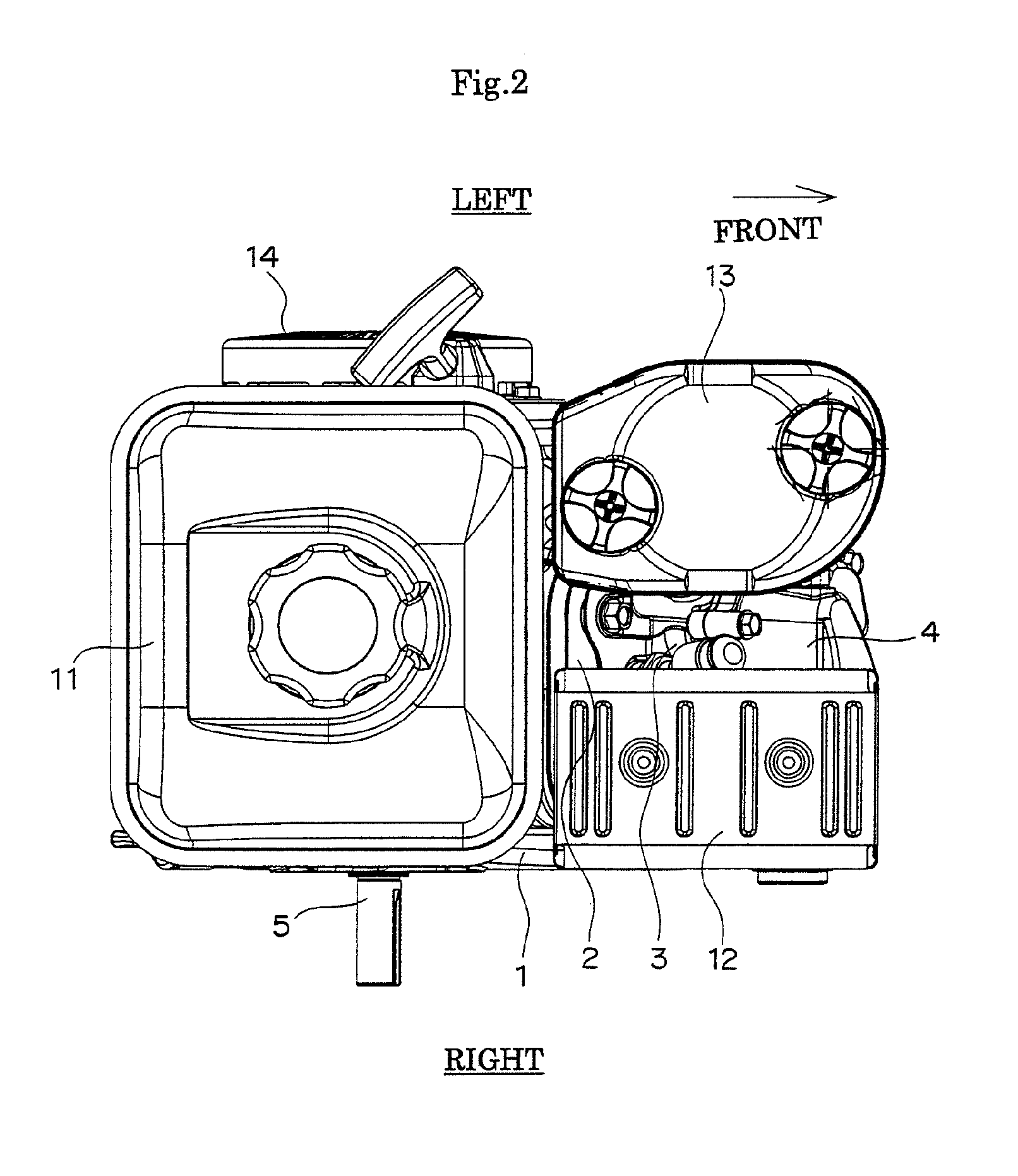

Speed governor of engine

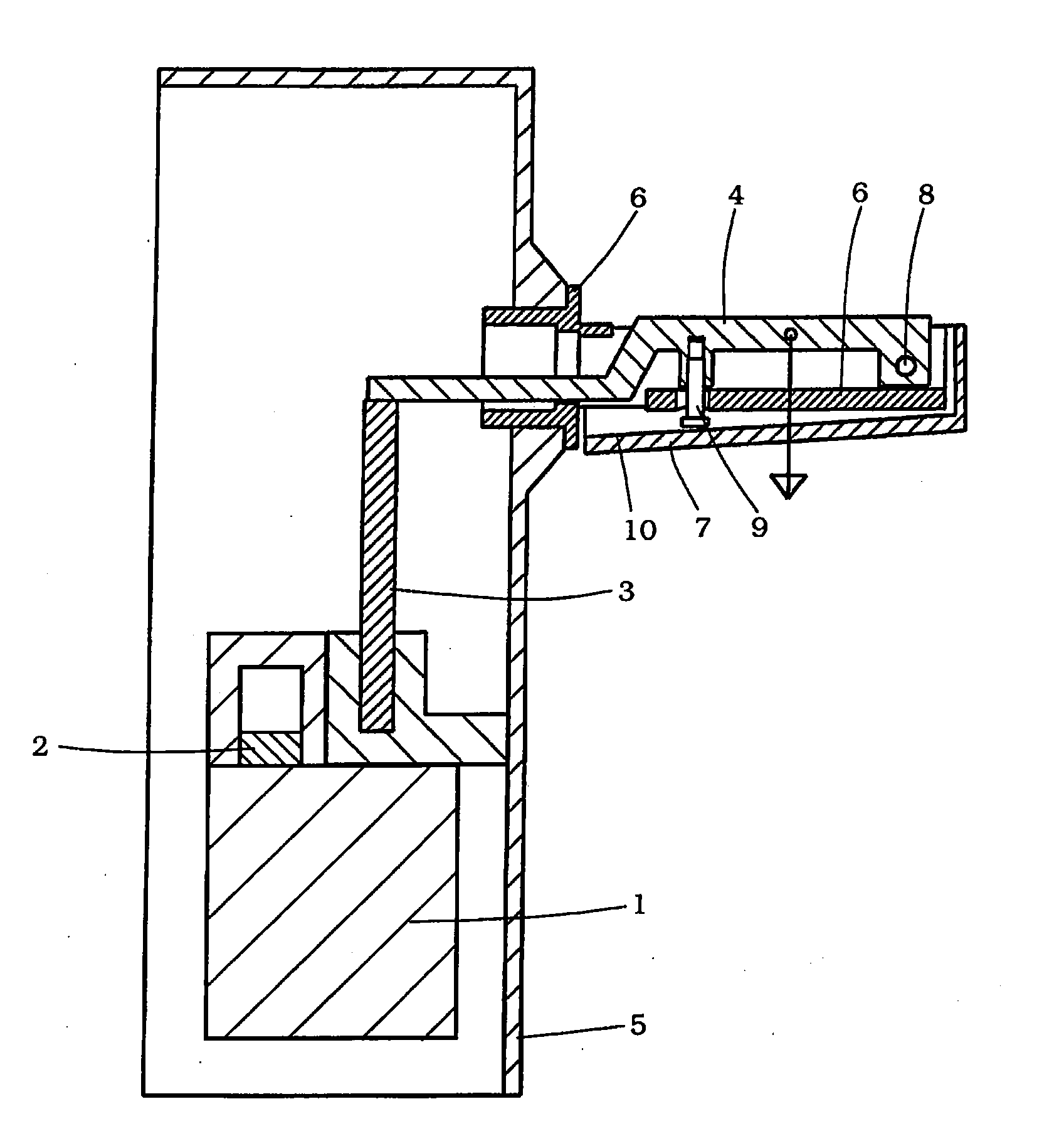

ActiveUS8590509B2Small sizeReduce the number of partsLow pressure fuel injectionNon-electrical controlGear wheelEngineering

Owner:KAWASAKI MOTORS LTD

Engine assembly

ActiveCN108087116AHybrid vehiclesInertia force compensationInternal combustion engineMotorized vehicle

The disclosure relates to an engine assembly, and an internal combustion engine assembly for a motor vehicle is provided. The engine assembly comprising: an engine; an electric motor; and a balance shaft comprising an eccentric mass, wherein the electric motor is configured to selectively rotate the balance shaft in order to balance a vibration characteristic of the engine. A method of operating the engine assembly is also provided.

Owner:FORD GLOBAL TECH LLC

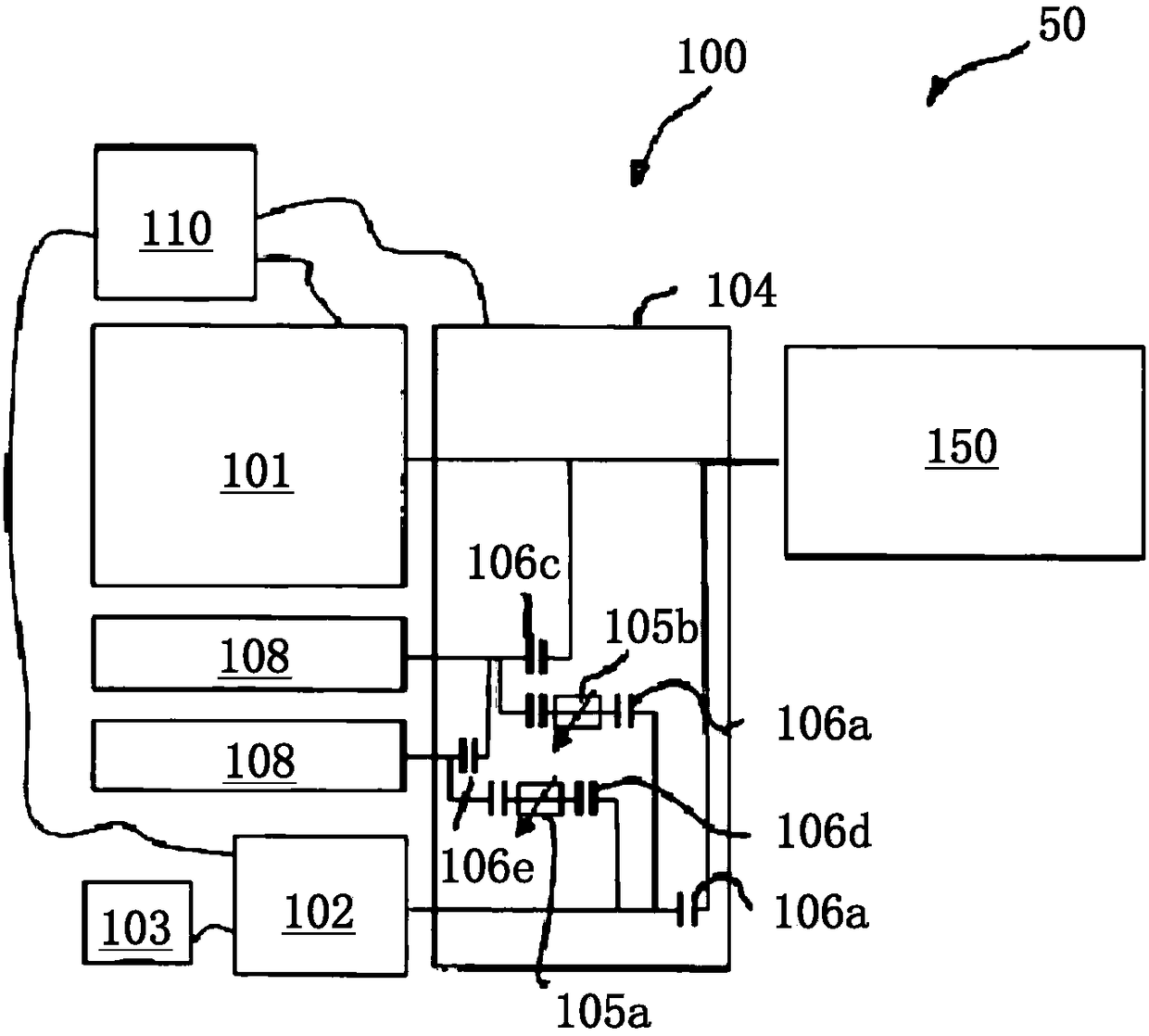

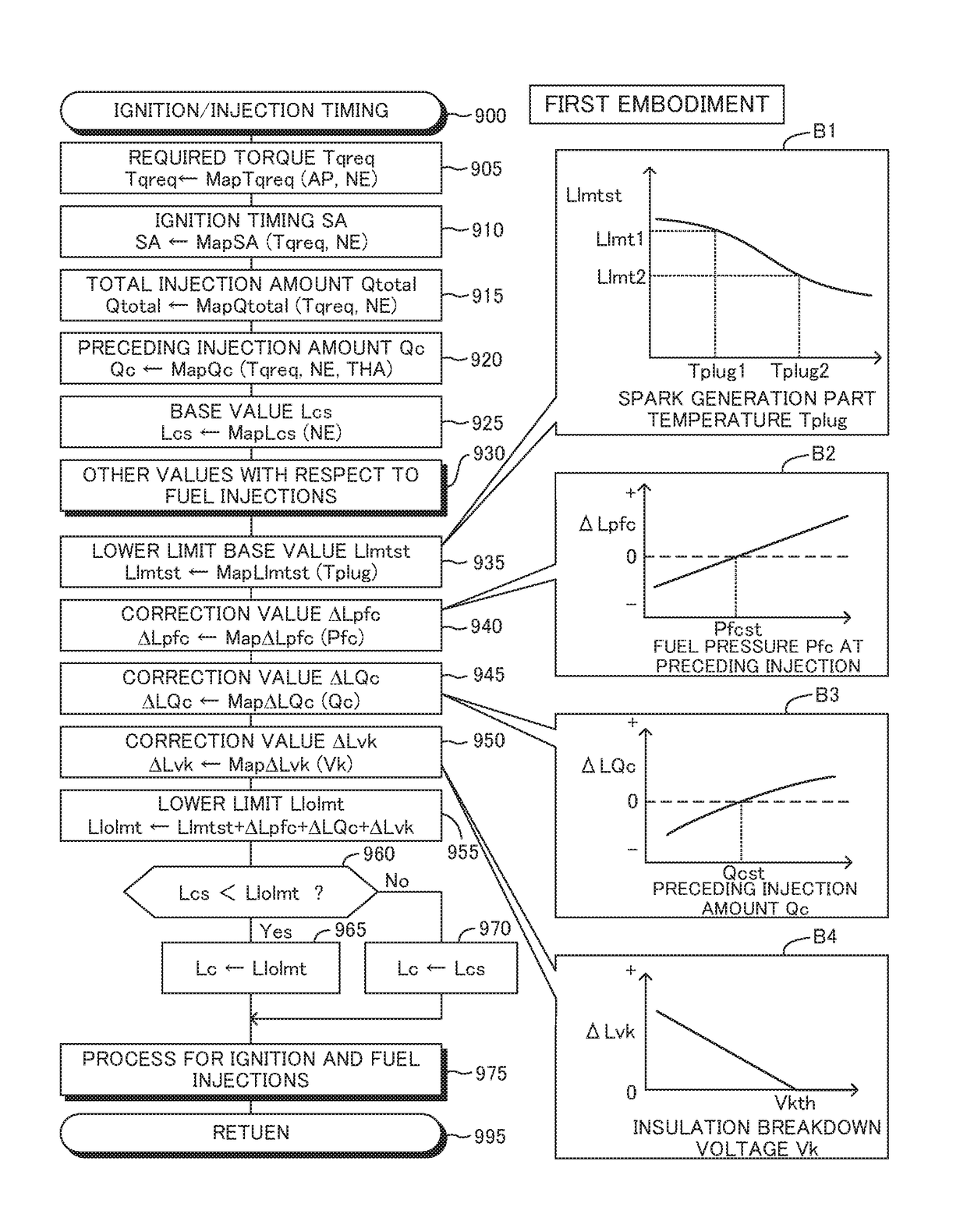

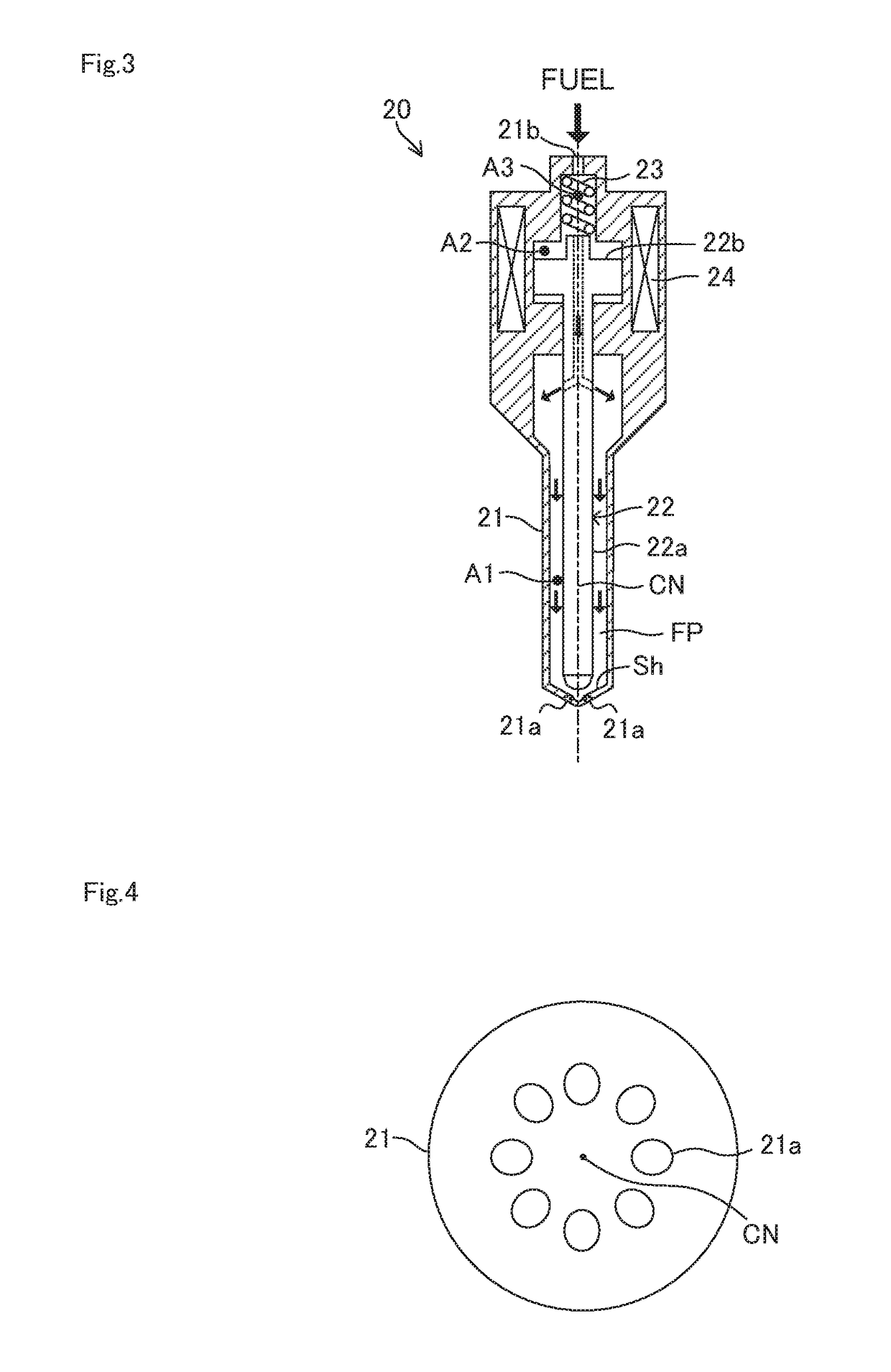

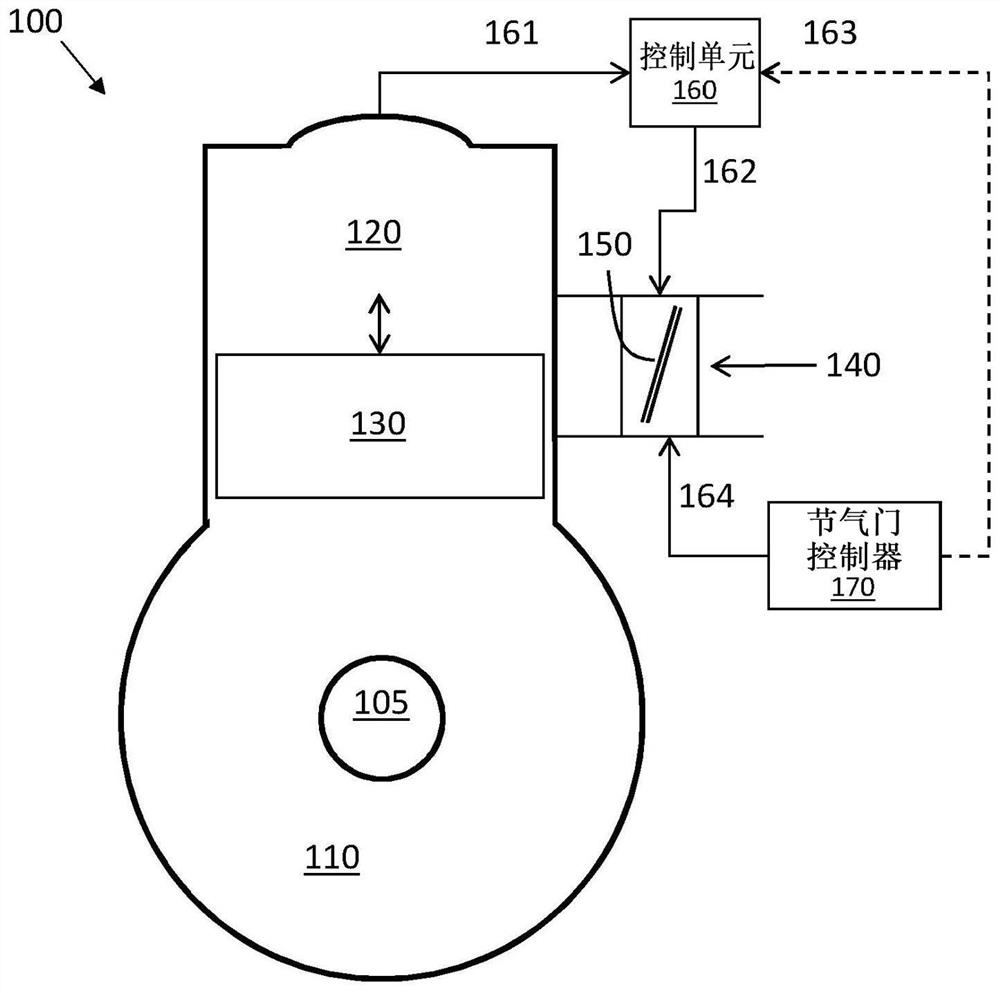

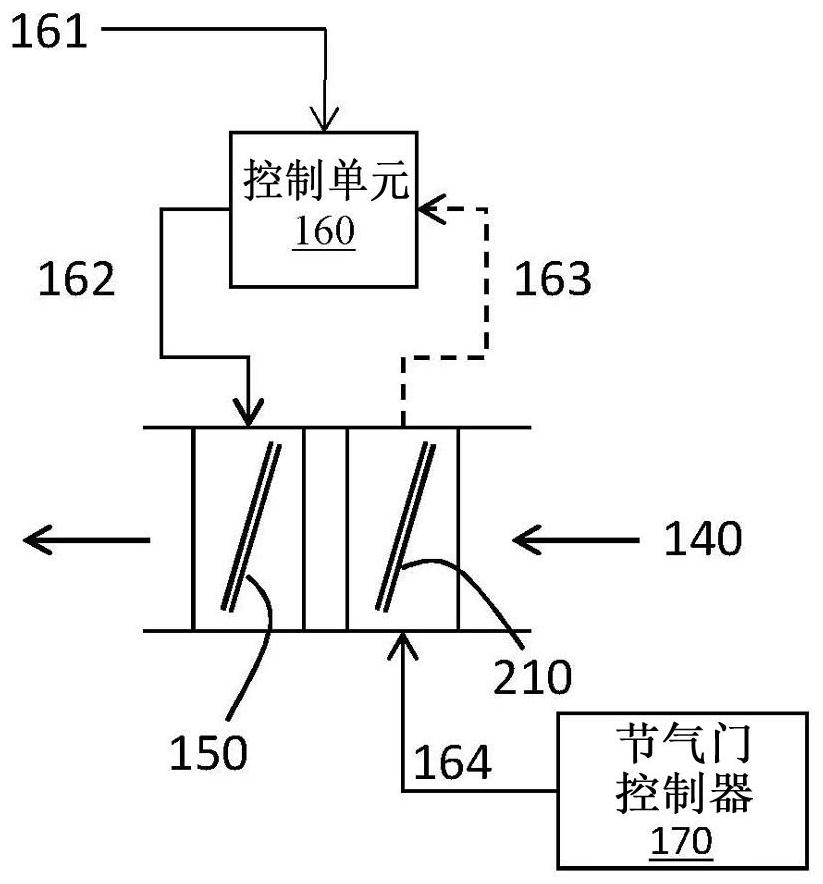

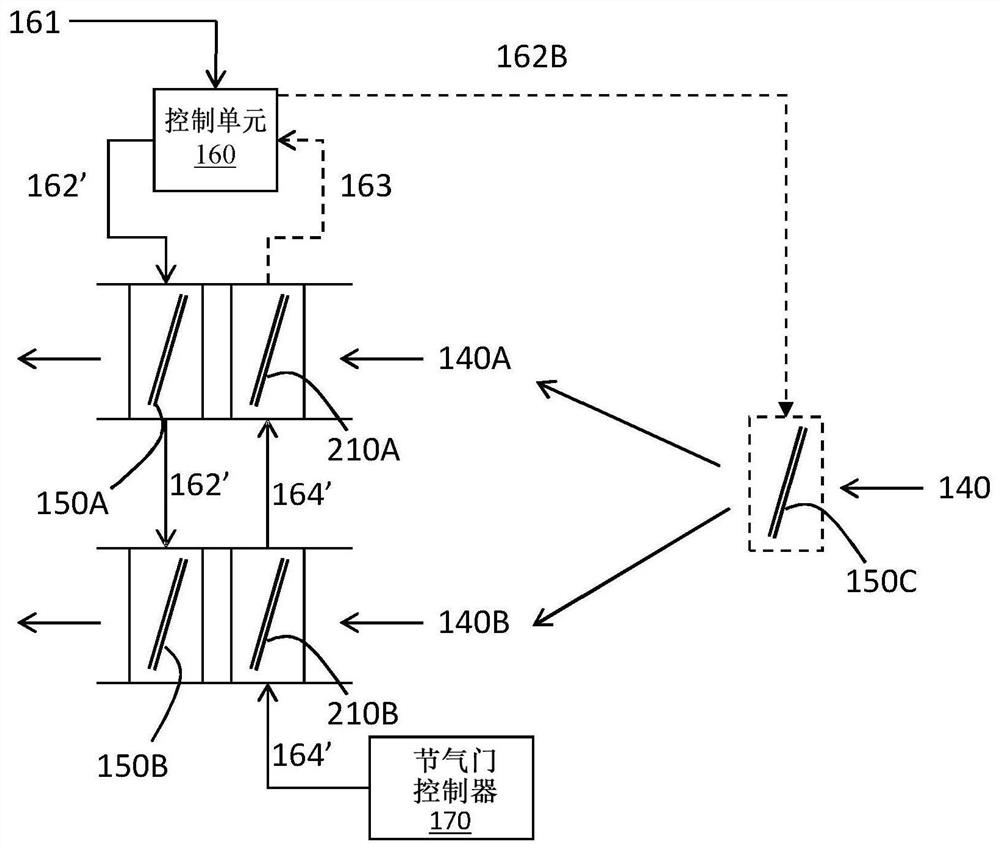

Control device for internal combustion engine

ActiveUS20170191441A1Fast increasing of degree of smolder can be preventedIncreasing degree of spreadingElectrical controlInternal combustion piston enginesExternal combustion engineIgnition timing

The invention relates to a control device applied to a cylinder injection type of an internal combustion engine (10). The control device control a disperse parameter for changing a degree of a spread of the fuel spray injected from the injector (20) such that the maximum degree of the spread of the fuel spray under a state where an amount of the fuel adhering to the spark generation part (31a) of the spark plug (30) at the ignition timing corresponds to a first amount, is smaller than the maximum degree of the spread of the fuel spray under a state where the amount of the fuel adhering to the spark generation part at the ignition timing corresponds to a second amount smaller than said first amount.

Owner:TOYOTA JIDOSHA KK

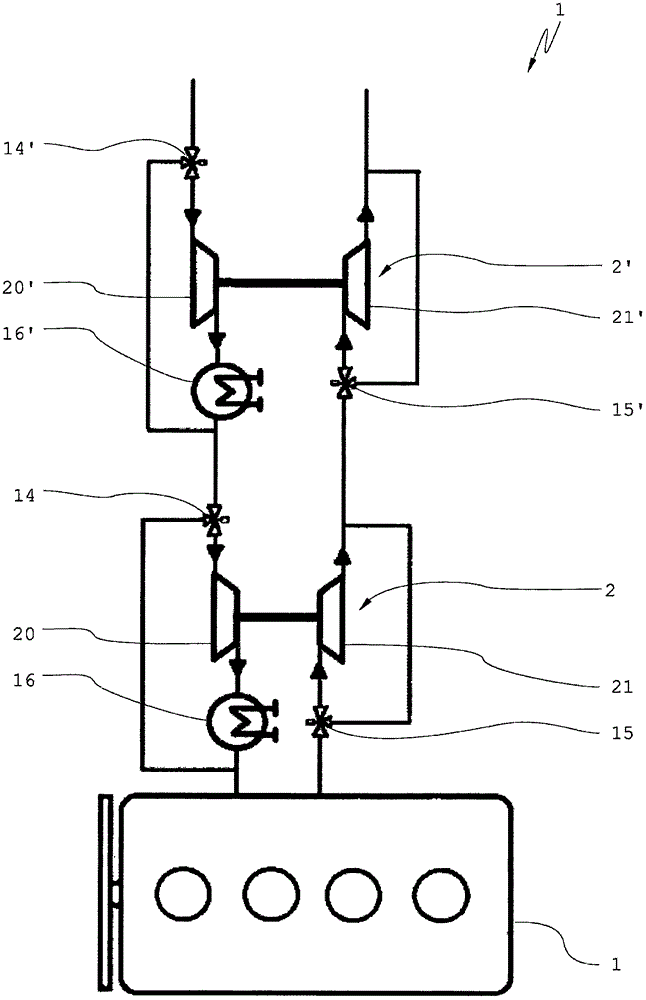

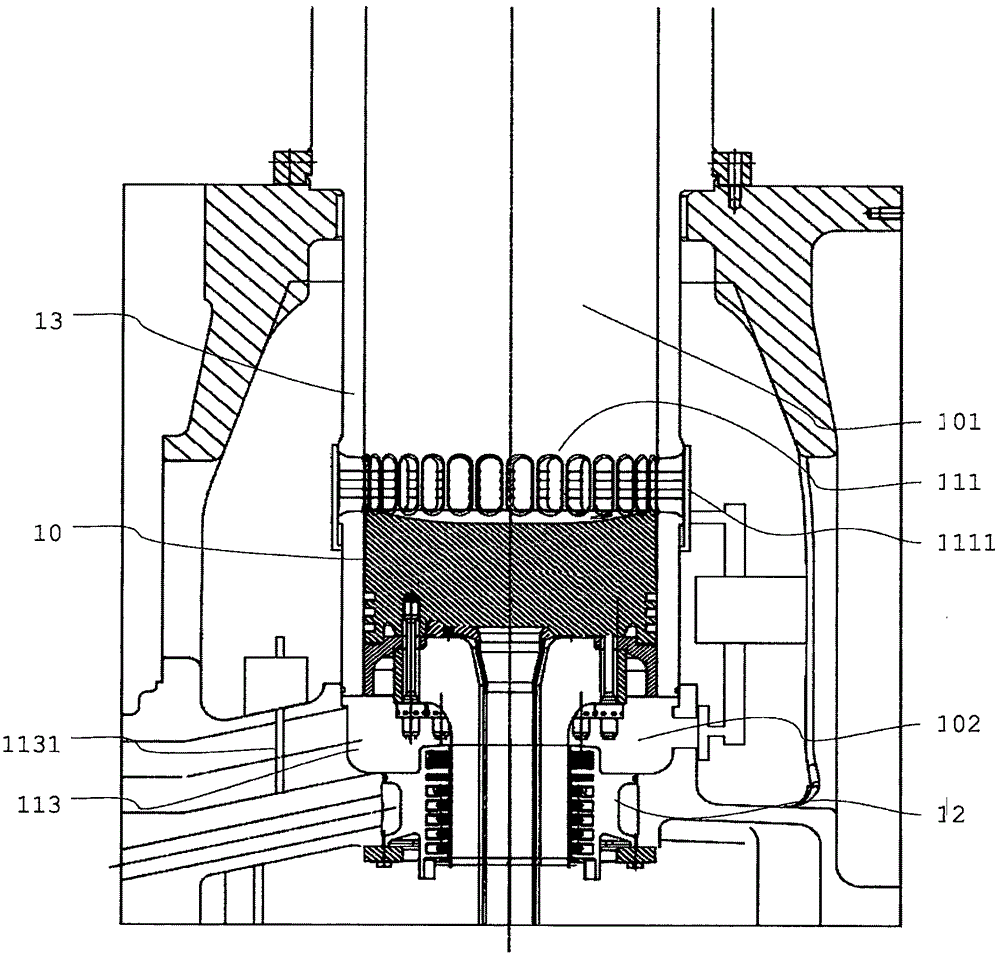

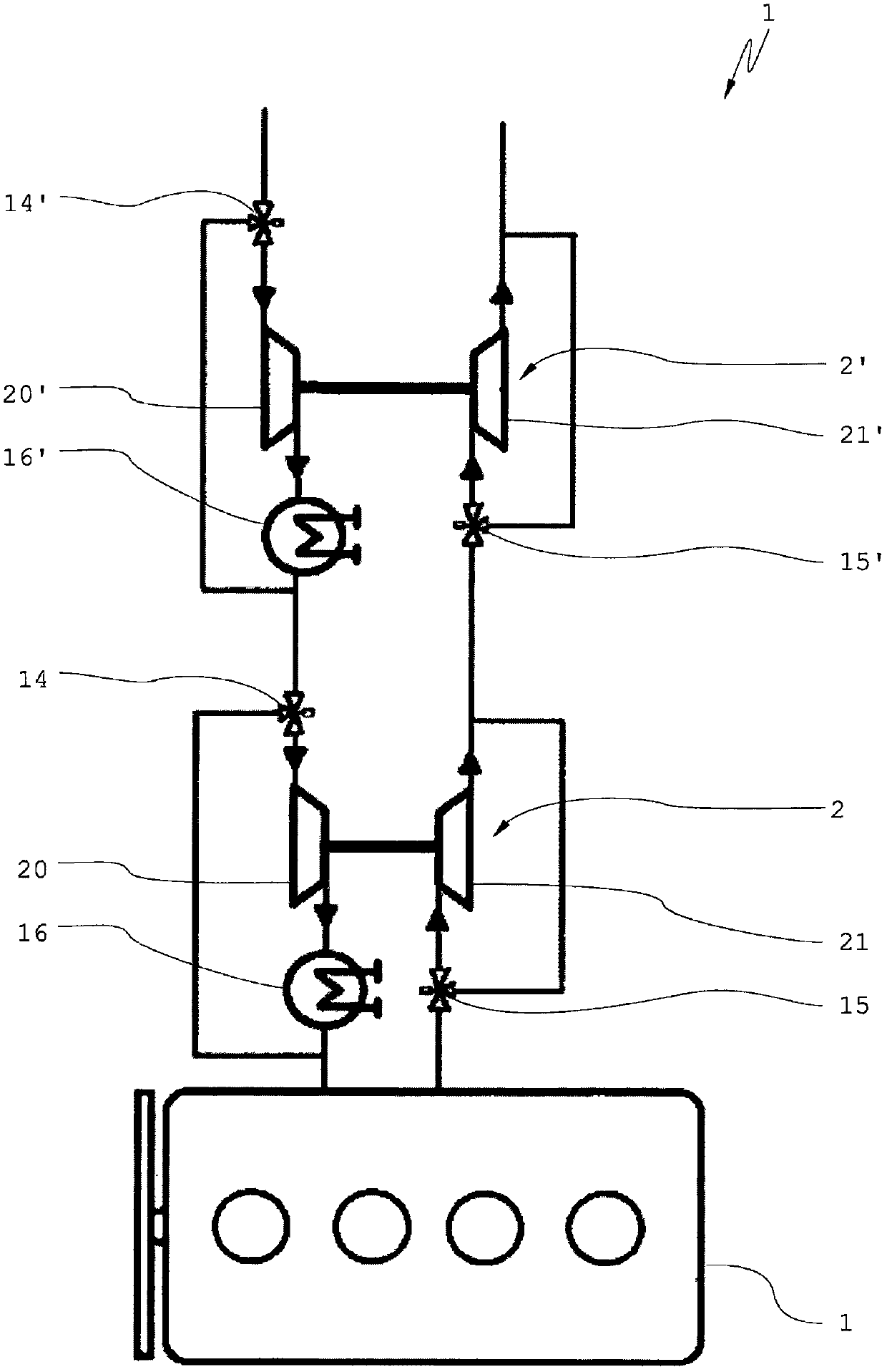

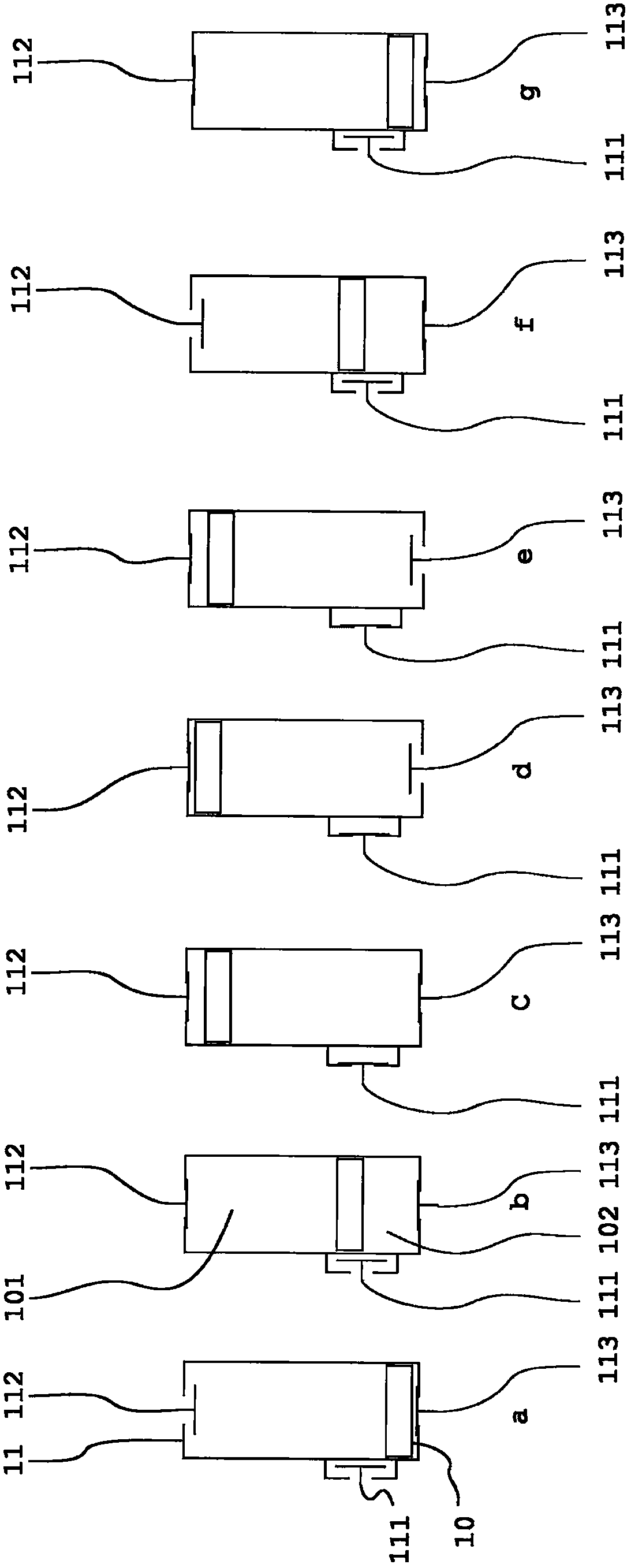

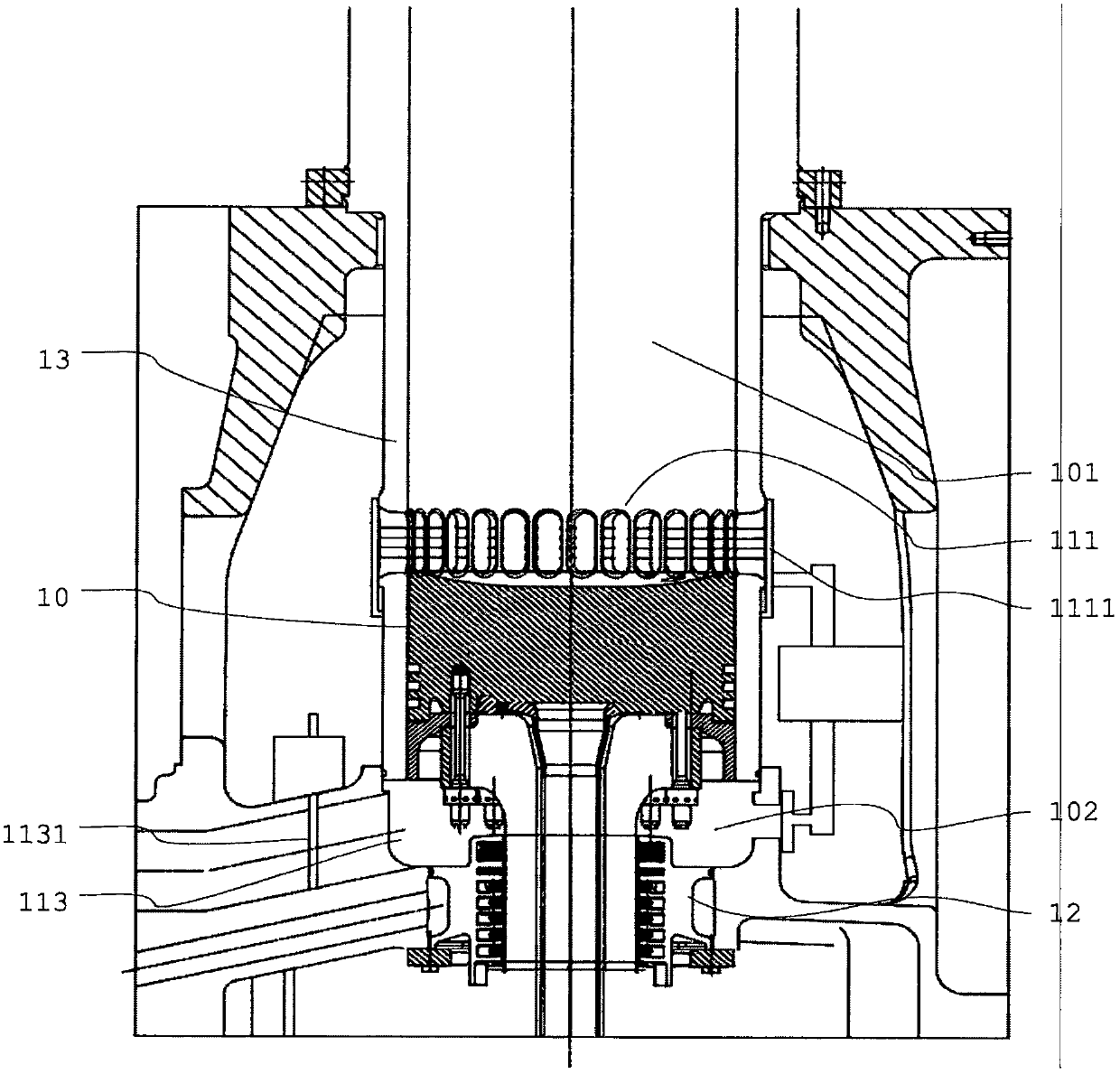

Internal combustion engine, method for operating the internal combustion engine, and cylinder, cylinder liner and closing plate for the internal combustion engine

InactiveCN105863821AAchieve expansionImprove efficiencyCylinder headsSealing arrangements for enginesCombustion chamberTurbocharger

The invention relates to an internal combustion engine, a method for operating the internal combustion engine, and a cylinder, a cylinder liner and a closing plate for the internal combustion engine. The internal combustion engine (1) is particularly a two-stroke engine, preferably a diesel two stroke engine, and comprises at least one piston (10) arranged in a cylinder (11). The piston (10) and the cylinder (11) define a variable combustion chamber (101) and a variable second chamber (102). The variable combustion chamber (101) is fluidly connectable to the compressor side of a turbocharger (2, 2') via at least one inlet opening (111) and to the turbine side of the turbo charger (2, 2') via an exhaust opening (112). The second chamber (102) is fluidly connectable to the compressor side of the turbocharger (2, 2') to introduce a compressed air flow into the second chamber (102).

Owner:WINTERTHUR GAS & DIESEL

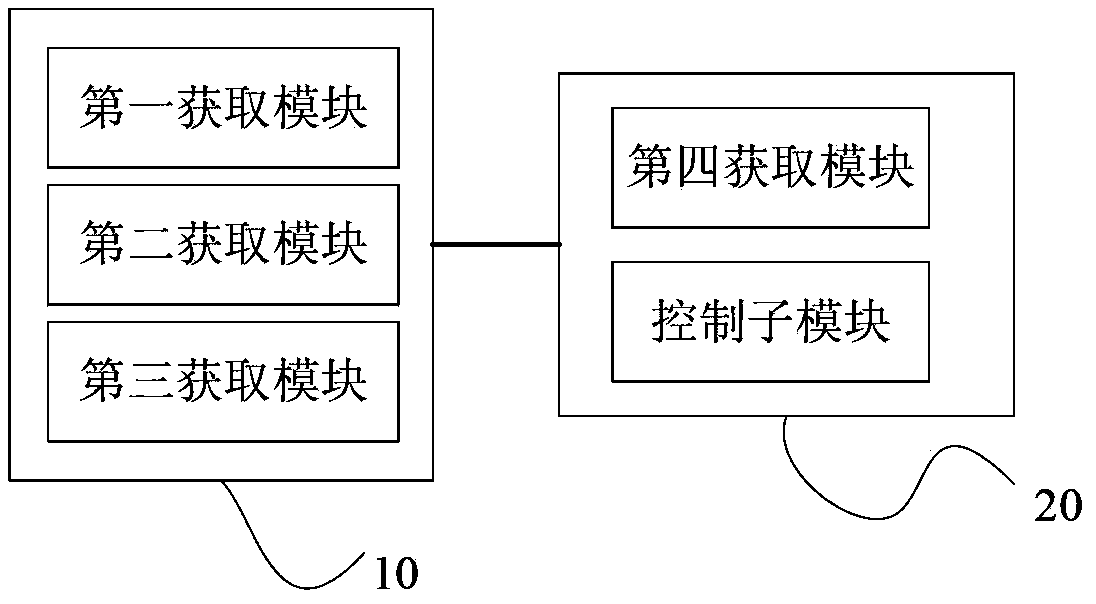

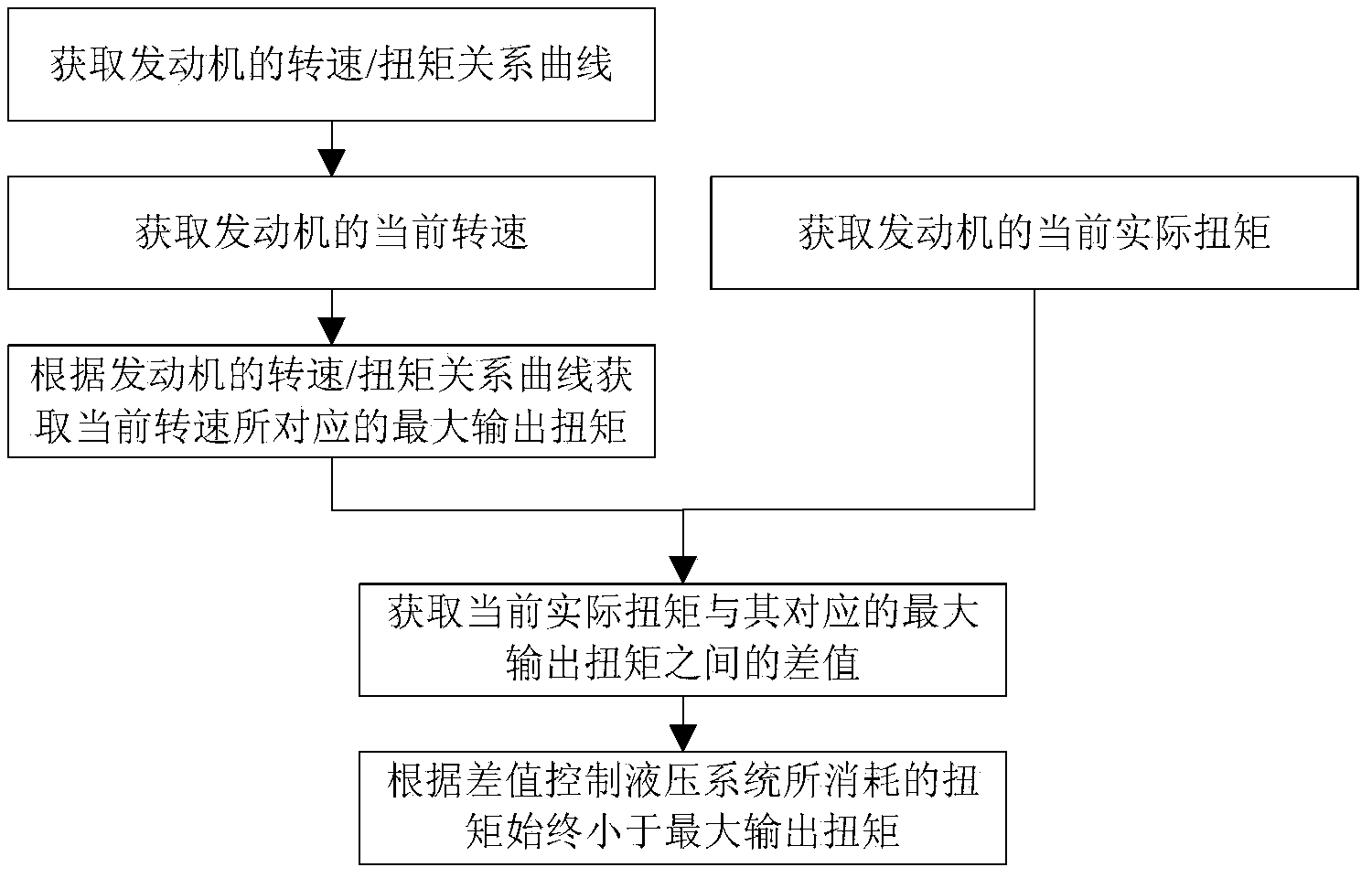

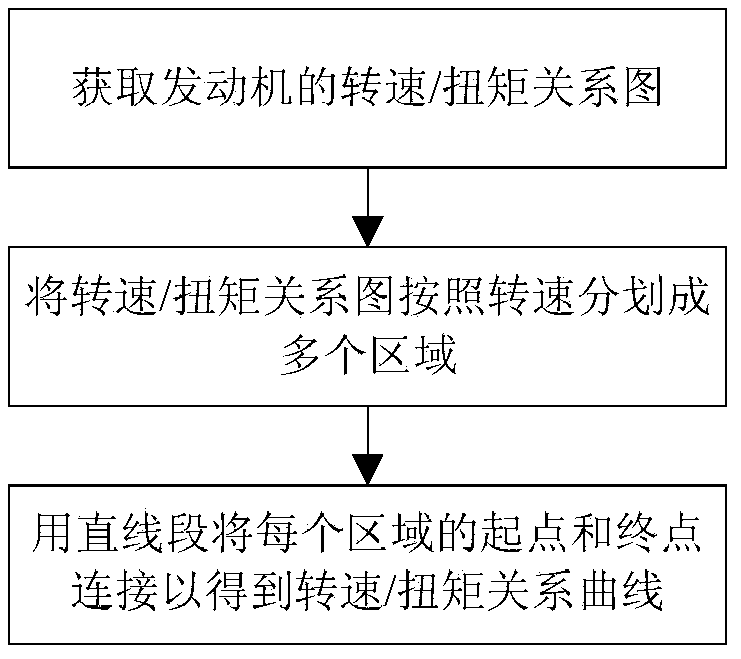

Engine limit load control method and device

ActiveCN103511097ASufficient powerWon't turn offNon-electrical controlMachines/enginesRelation graphControl theory

The invention provides an engine limit load control method and device. The engine limit load control method includes the steps of obtaining the current rotating speed of an engine, obtaining a rotating speed / torque relation graph of the engine, dividing the rotating speed / torque relation graph into multiple areas according to the rotating speeds, using a straight line section to connect a start point of each area with the end point of the area to obtain a rotating speed / torque relation curve of the engine, obtaining the largest output torque corresponding to the current rotating speed according to the rotating speed / torque relation curve, and controlling the torque consumed by a hydraulic system driven by the engine to be always smaller than the largest output torque. The largest output torque which can be supplied by the engine at some moment can be obtained in real time, meanwhile, the size of the torque consumed by the hydraulic system is controlled, and therefore the torque can be always smaller than the largest output torque which can be outputted by the engine, so that the engine can supply enough power for the hydraulic system, and the hydraulic system can not be shut down under various working conditions.

Owner:ZOOMLION HEAVY IND CO LTD

Systems and methods for engine

PendingCN113969832AReduce operation modeElectrical controlExhaust apparatusInternal combustion engineDiesel engine

Owner:POWERHOUSE ENGINE SOLUTIONS SWITZERLAND IP HLDG GMBH

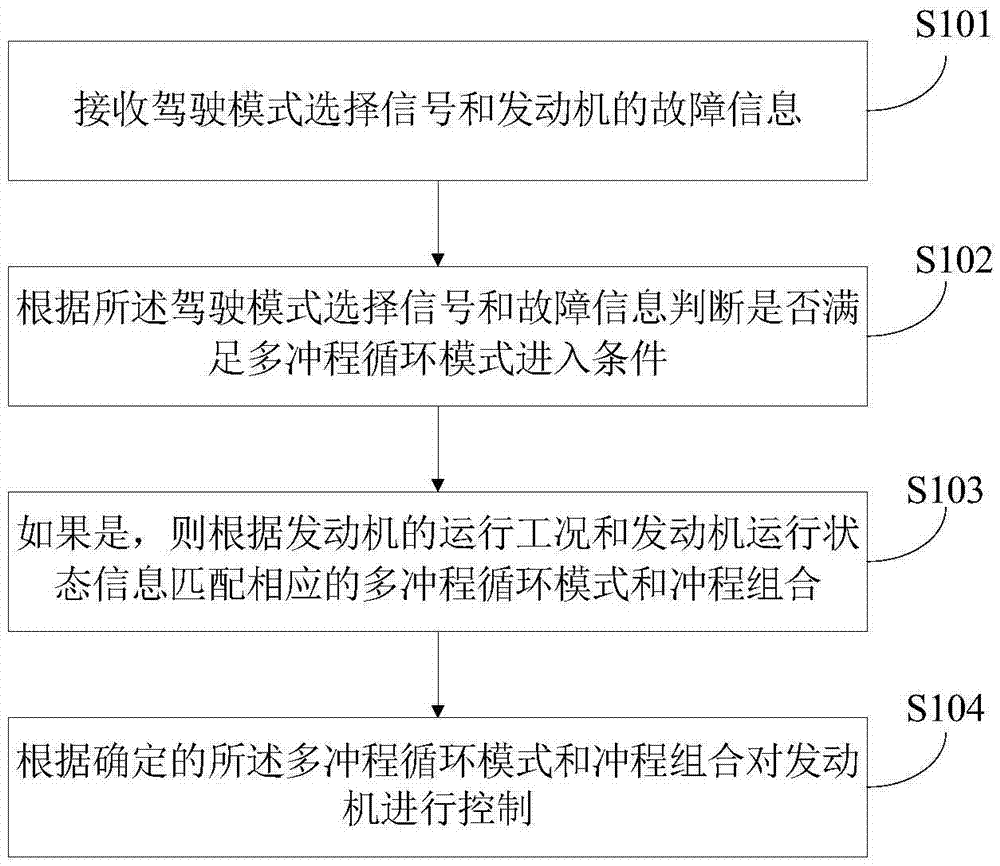

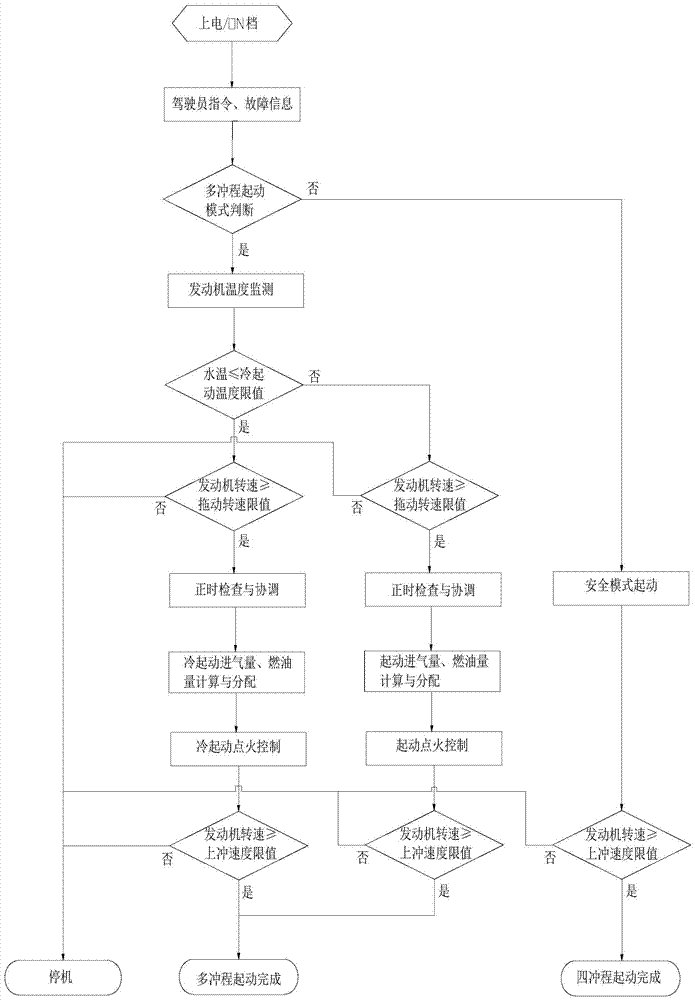

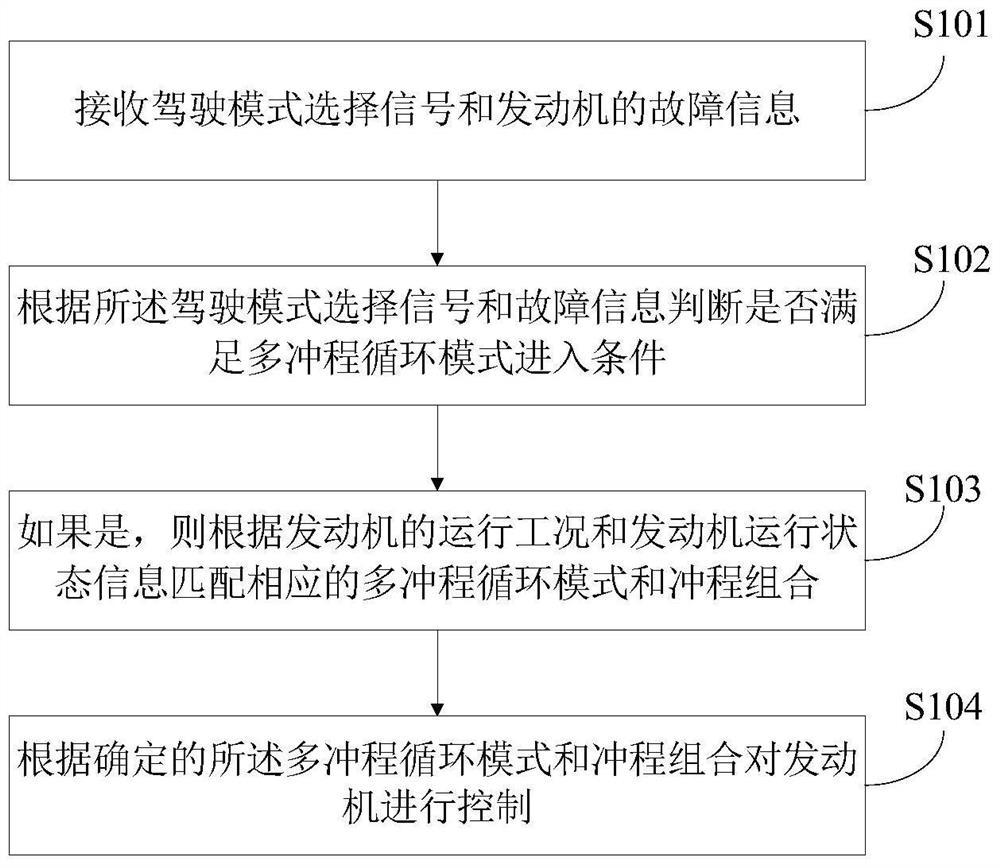

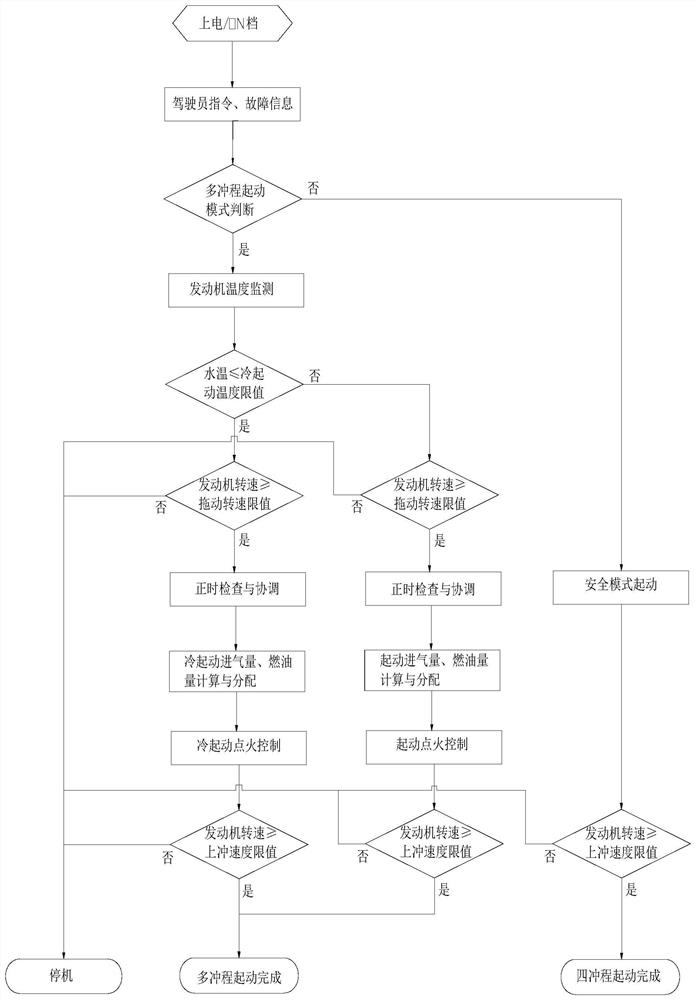

Control method and system for multi-stroke circulation gasoline engine and vehicle

ActiveCN106930851AControl Method AdvantagesImprove fuel economyElectrical controlNon-electrical controlCombustion chamberGasoline fuel

The invention provides a control method and system for a multi-stroke circulation gasoline engine and a vehicle. The control method comprises the steps that if the engine is a multi-stroke circulation direct-injection gasoline engine, gasoline fuel is provided for a combustion chamber from the end section of an induction stroke and / or a compression stroke to the front section of an expansion stroke in a current multi-stroke circulation mode; ignition time is determined according to finishing temperature, a mixed gas average air-fuel ratio, a gasoline fuel injection amount around a compression upper dead center and injection timing, and ignition is performed at the ignition time; if the engine is a multi-stroke circulation port injection gasoline engine, the gasoline fuel is provided for a port at the induction stroke and / or an exhaust stroke in the current multi-stroke circulation mode; and ignition timing is determined during a period from the end section of the compression stroke to the front section the expansion stroke, and ignition is performed at the ignition timing. By adopting the method, fuel economy of the engine in multiple operation conditions can be effectively improved; and emission of tail gas pollutants is lowered.

Owner:GREAT WALL MOTOR CO LTD

Six-stroke engine

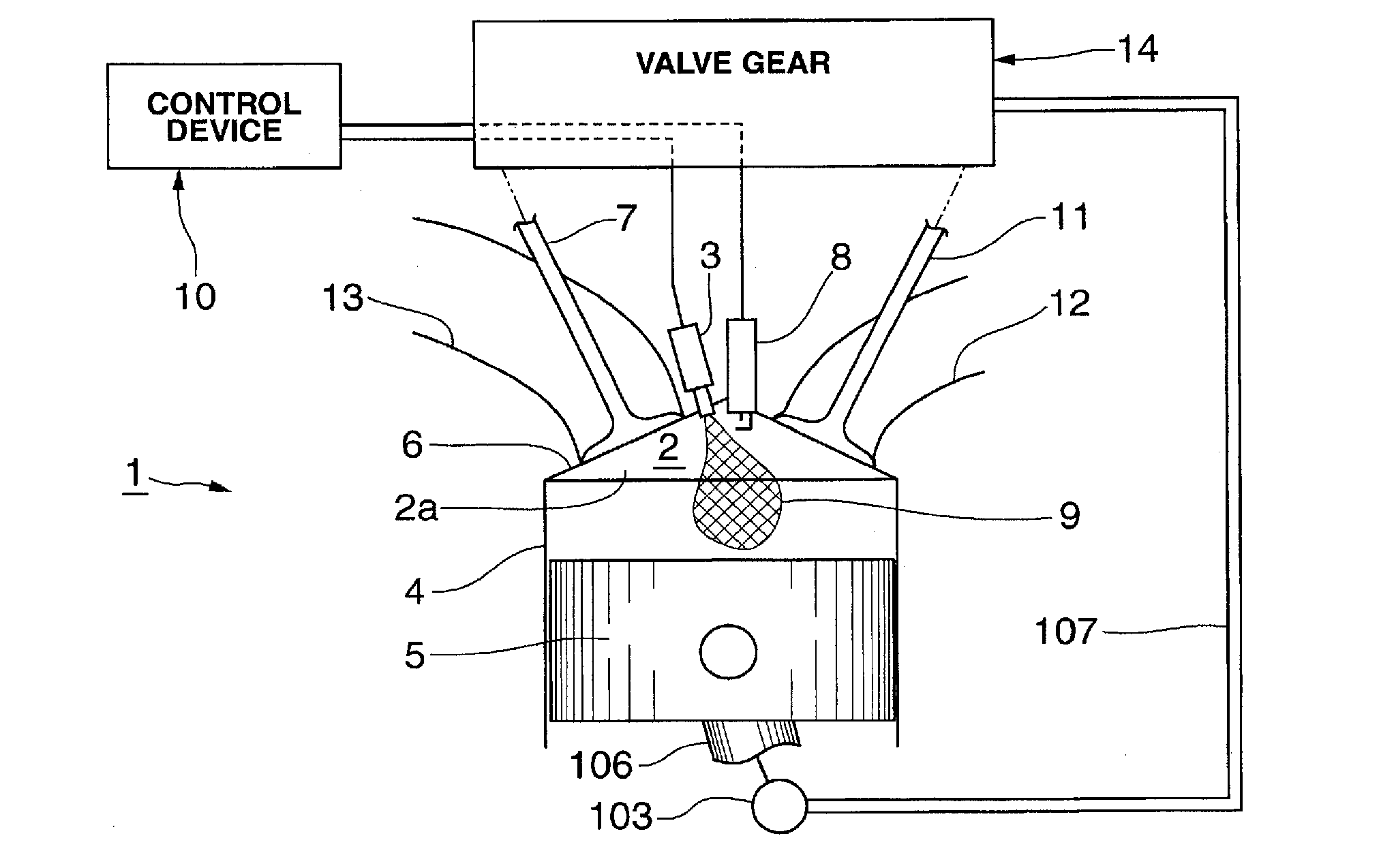

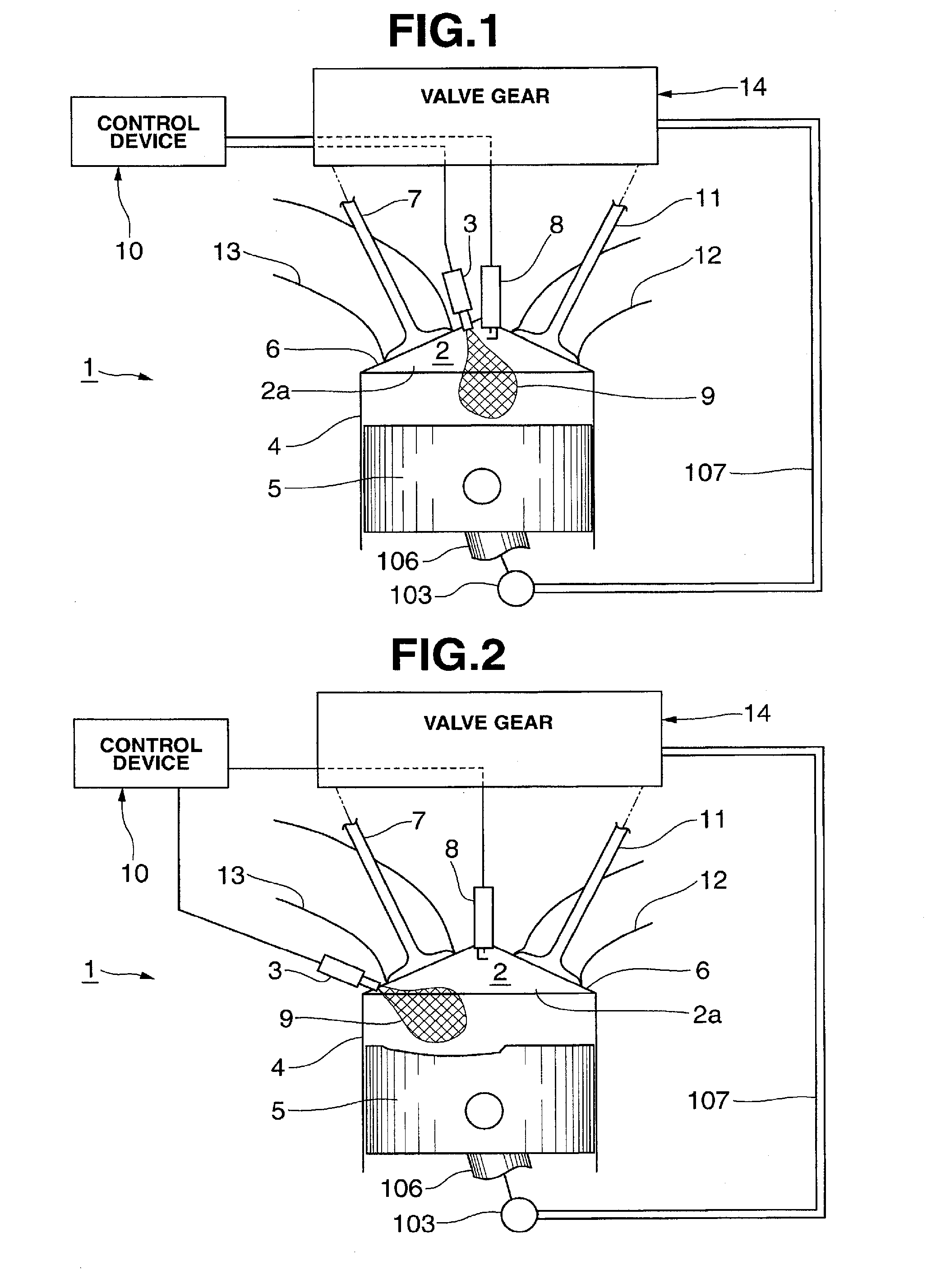

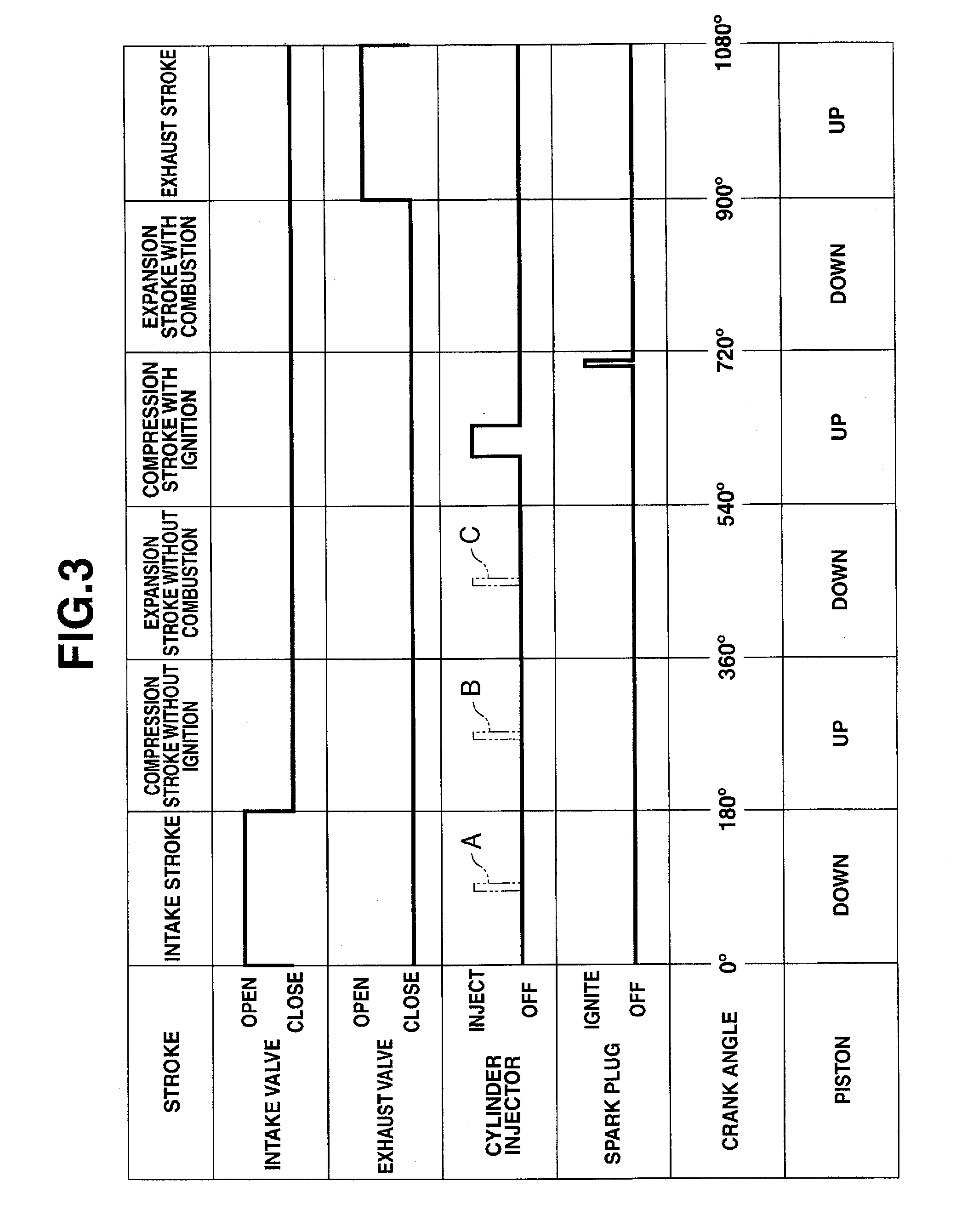

InactiveUS20140224195A1Increase volumeAccurate supplyValve arrangementsElectrical controlCylinder headInlet valve

A six-stroke engine includes a cylinder, a piston, a cylinder head, a combustion chamber, cylinder injector, a spark plug, an intake port, an exhaust port, an intake valve, an exhaust valve, a valve gear, and a control device. The valve gear operates the intake valve and the exhaust valve to execute six strokes including an intake stroke, a compression stroke without ignition, an expansion stroke without combustion, a compression stroke with ignition, an expansion stroke with combustion, and an exhaust stroke in this order. The control device is programmed to cause the cylinder injector to inject fuel and to energize the spark plug in the compression stroke with ignition.

Owner:YAMAHA MOTOR CO LTD

A control method and system for a turbocharger, based on position sensor learning

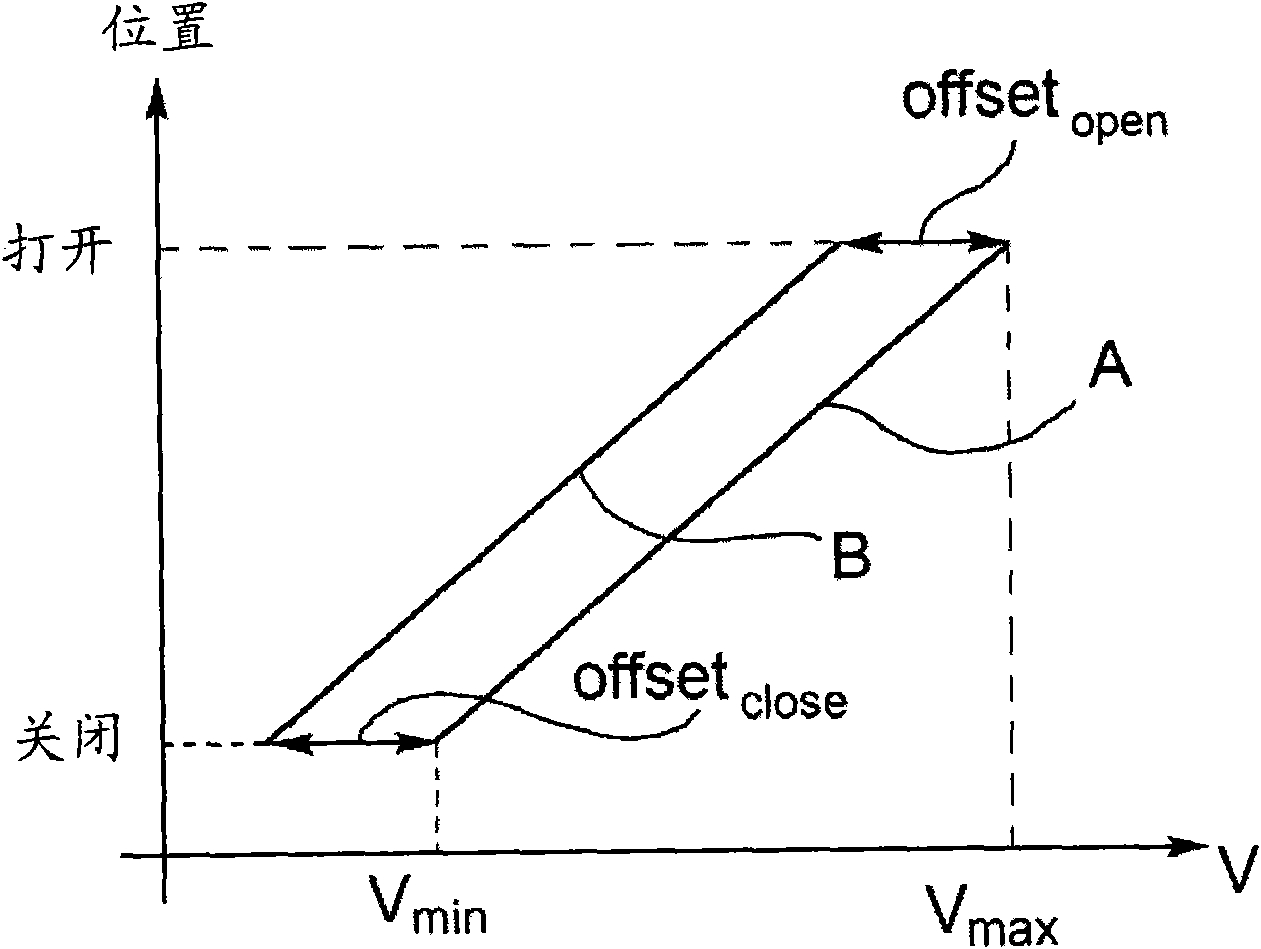

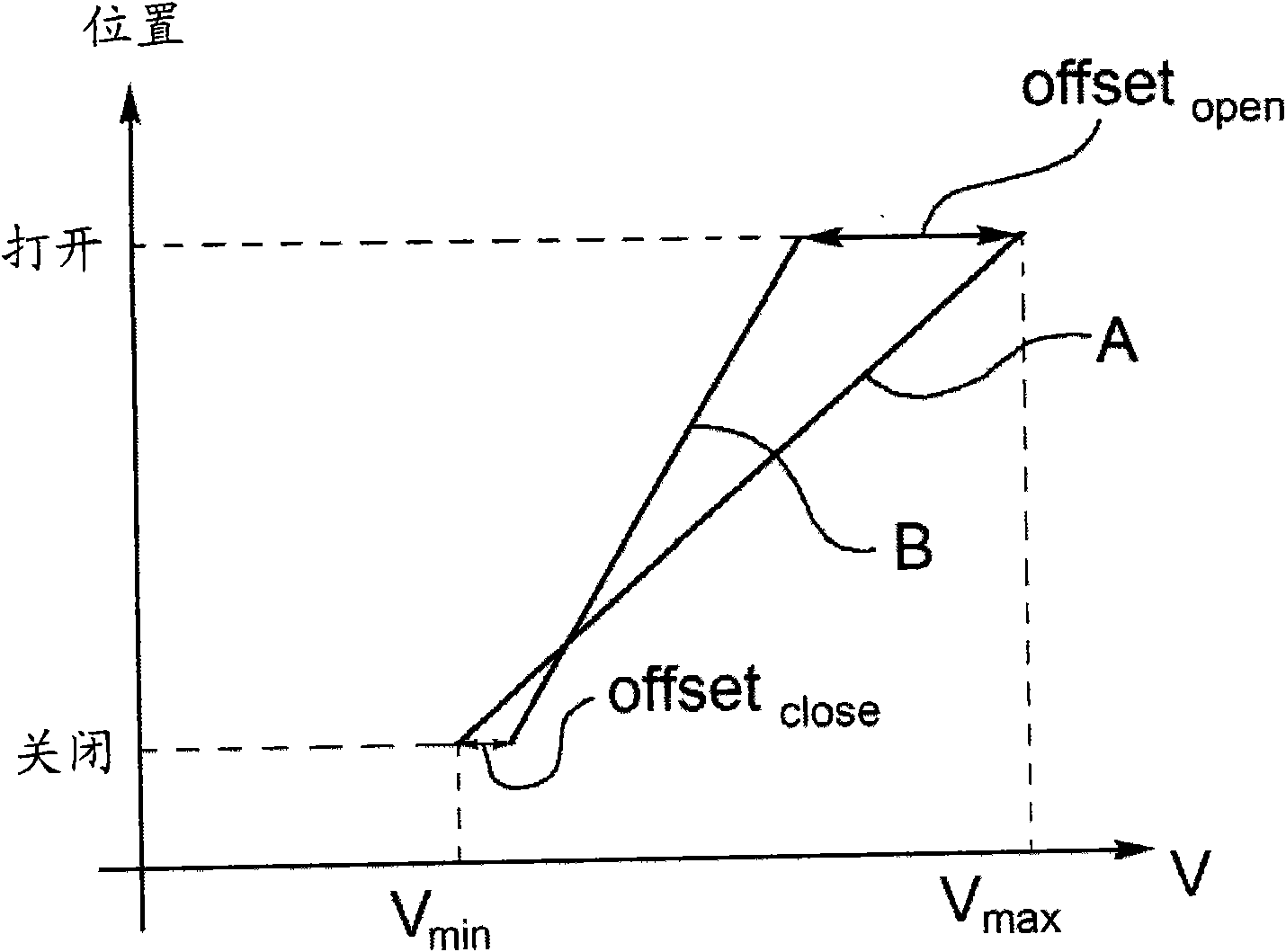

The invention discloses a control method of a fluid control device 10 such as a turbocharger, particularly for an internal combustion engine equipped with a position sensor 12 for measuring the position of the variable geometry turbocharger blades. The position sensor has a nominal characteristic curve (A) representative of a predetermined relationship between an admissible range of position values and a corresponding range of return electric signal values. The method comprises the steps of: determining an offset between a returned signal related to at least one defined position of the device 10 and an expected signal related to said defined position of the device according to the nominal characteristic curve (A); estimating an updated characteristic curve (B) of the sensor by applying said offset to the nominal characteristic curve (A); and applying a predetermined control strategy of the fluid control device 10 according to the updated characteristic curve (B).

Owner:GM GLOBAL TECH OPERATIONS LLC

Implement having rotational speed reduction and operating method therefor

InactiveUS20110220060A1Controlling membersNon-electrical controlExternal combustion engineEngineering

An implement comprises an internal combustion engine having a throttle valve. At least one handle, the inside of which is provided with a gas lever likewise in a pivotal manner, is attached to a housing surrounding the internal combustion engine. The minimum distance between the gas lever and the handle is defined by a stop. When the operator lifts the implement by the handle, the position of the gas lever also changes. Even when the gas lever is fully depressed, only a part-load position is achieved at the throttle valve. In this way, effective rotational speed limitation is achieved.

Owner:WACKER NEUSON SE

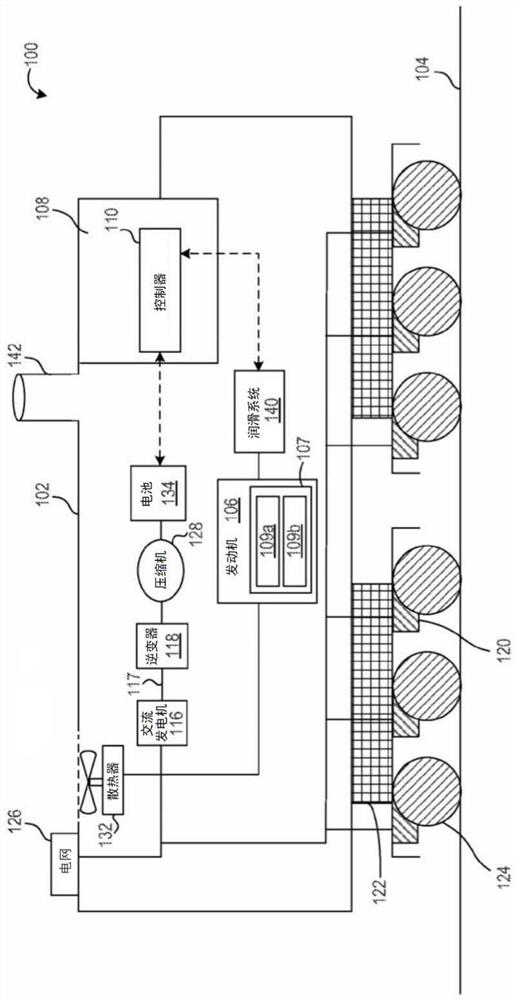

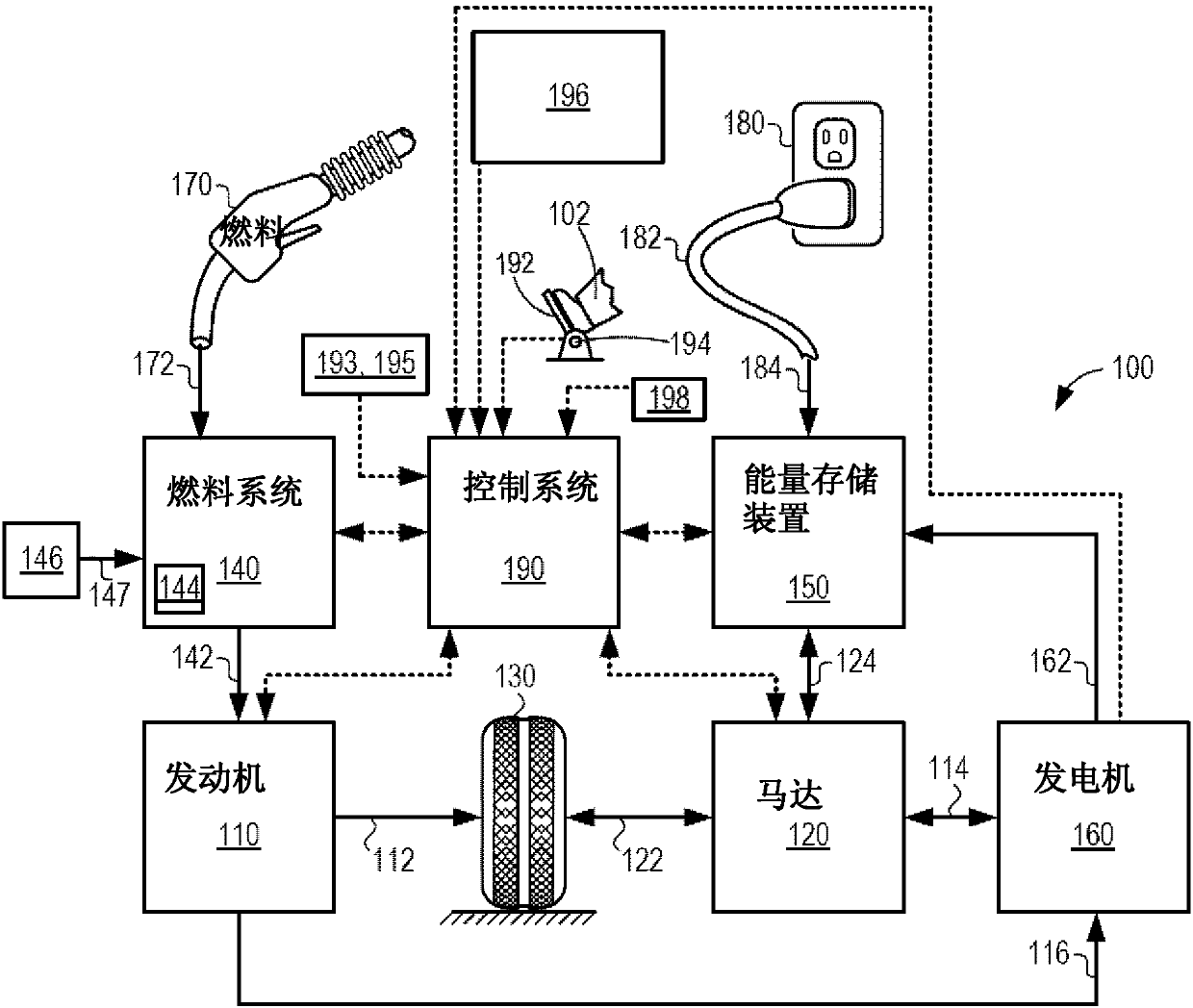

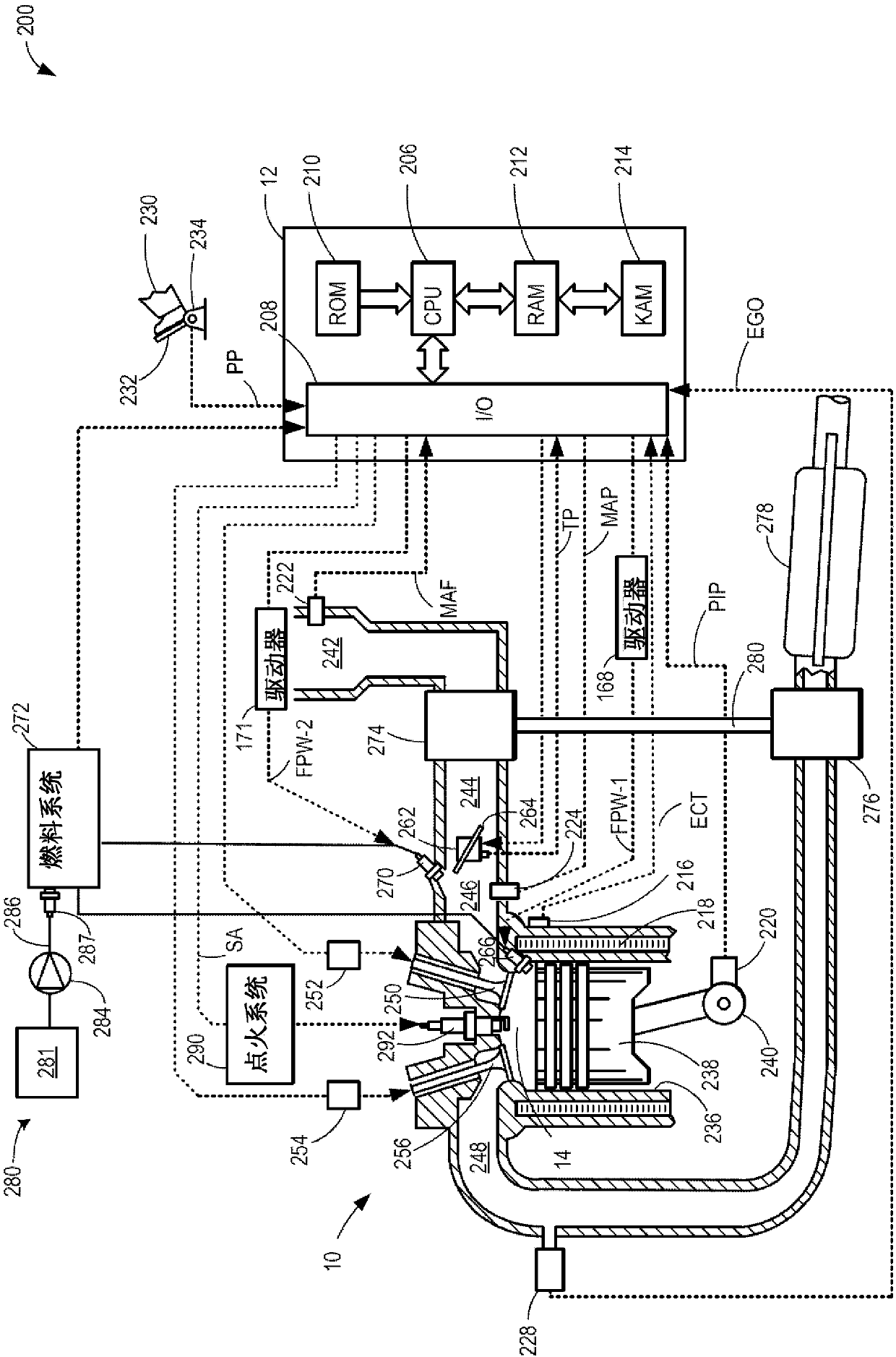

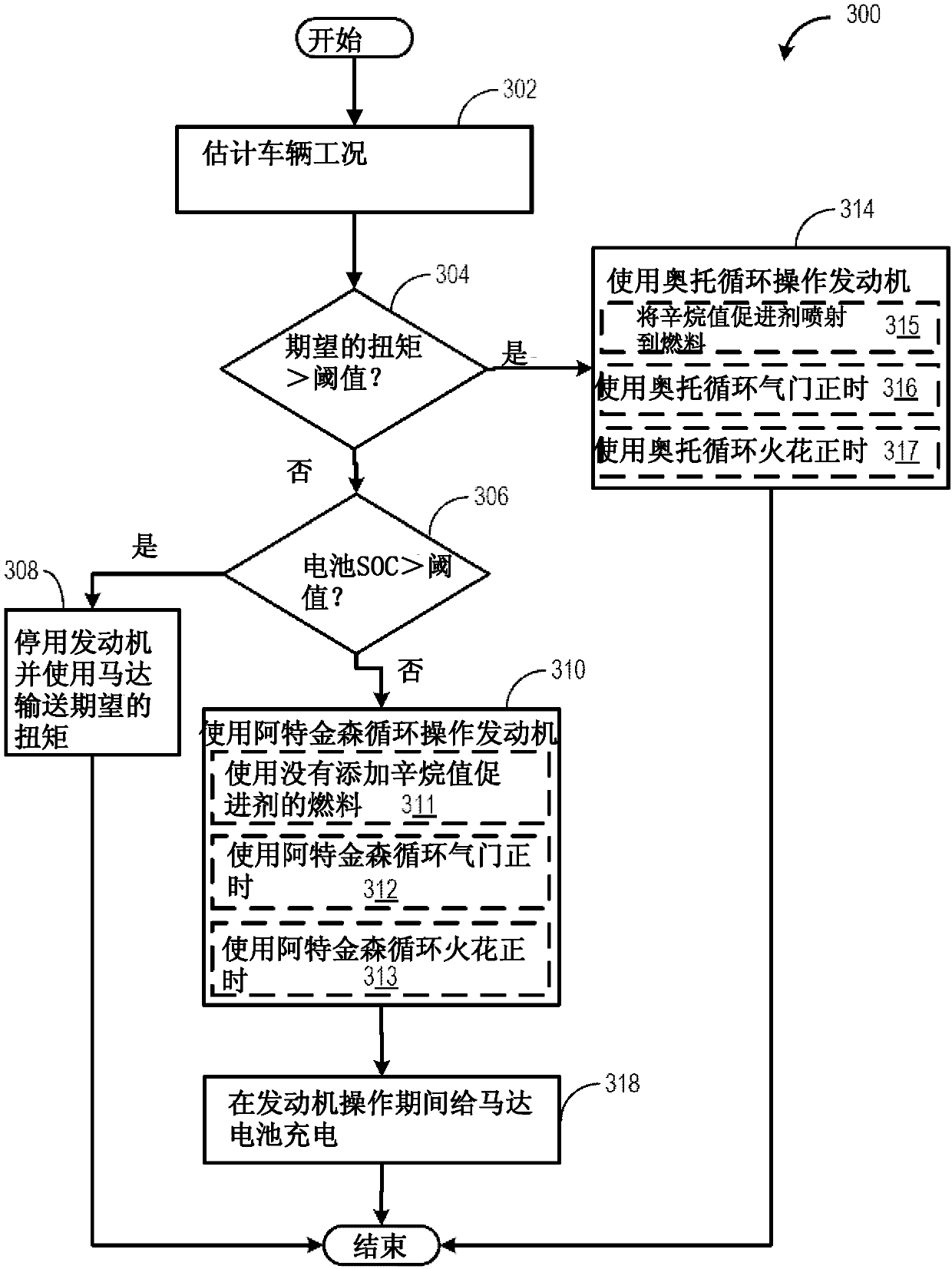

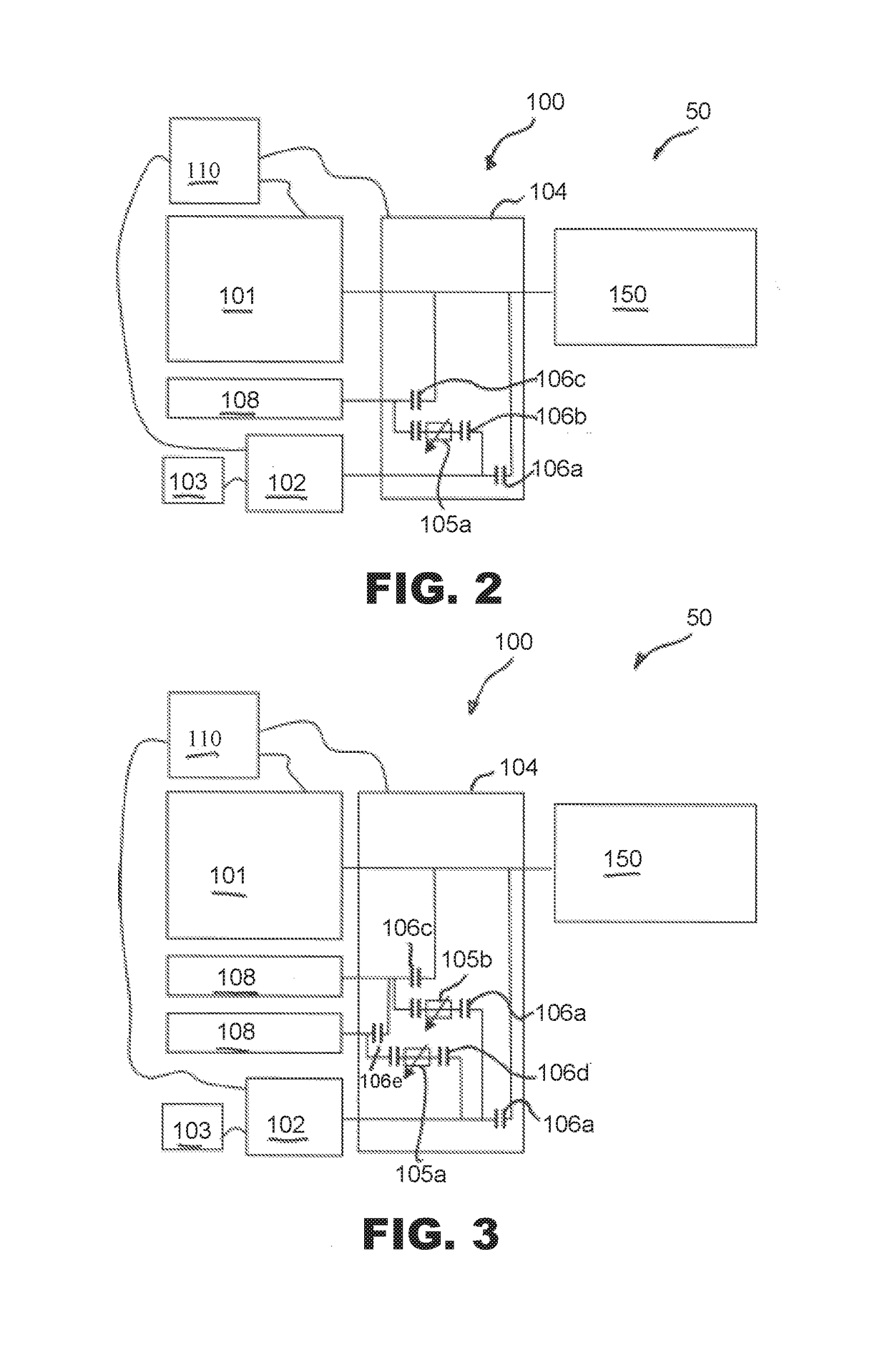

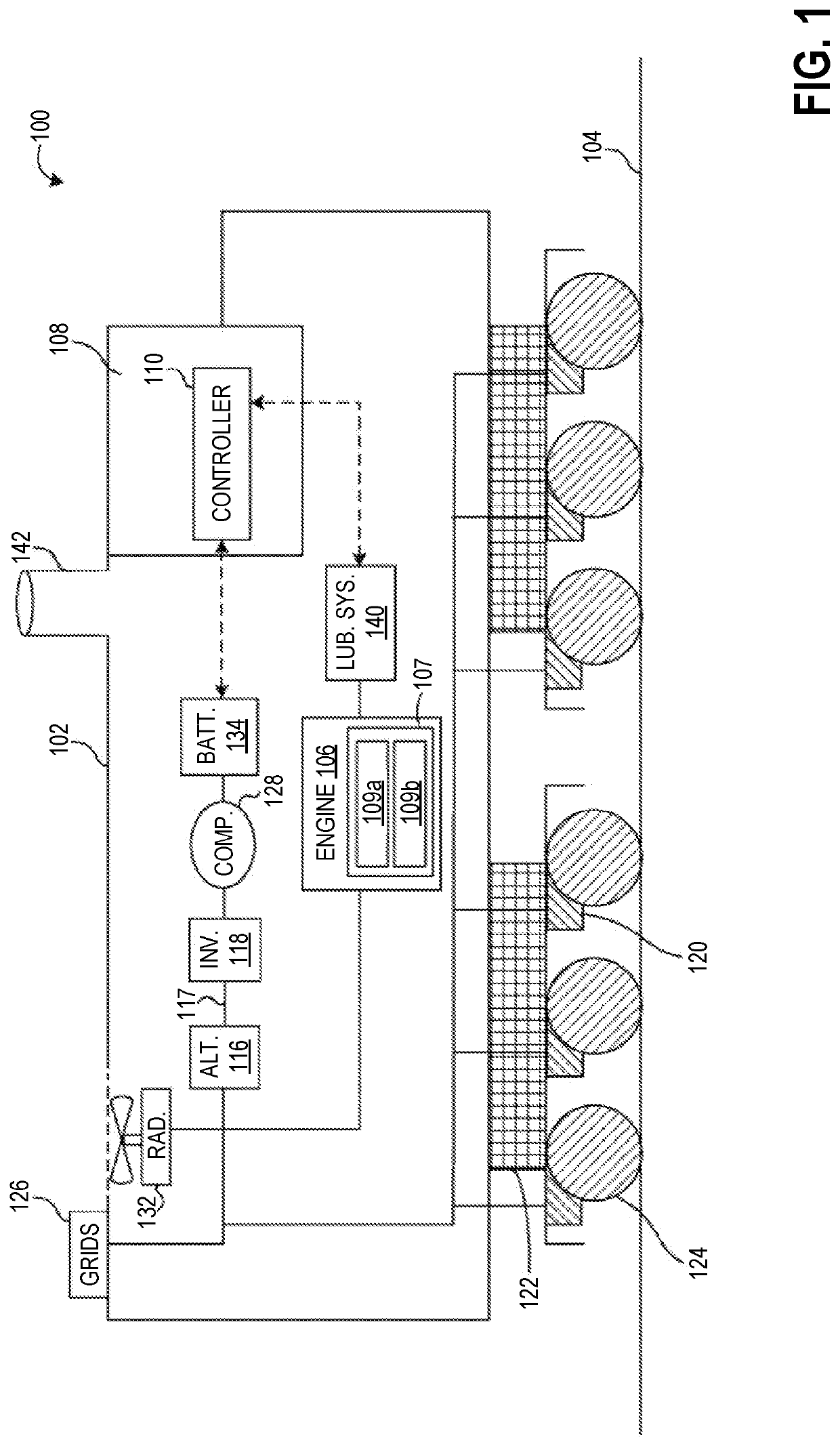

Methods and systems for hybrid vehicle power delivery

ethods and systems are provided for adjusting engine operation of a hybrid vehicle to increase power output, and fuel efficiency. In one example, a method may include operating the engine using an Atkinson cycle during a lower than threshold engine torque demand, and a lower than threshold battery state of charge, and operating the engine using an Otto cycle during a higher than threshold torque demand. During operating in the Otto cycle, an octane booster may be injected to the fuel line to increase the octane level in the fuel.

Owner:FORD GLOBAL TECH LLC

Engine assembly

ActiveUS20180141536A1Unnecessary of repetitionHybrid vehiclesElectrical controlInternal combustion engineBalance shaft

An internal combustion engine assembly for a motor vehicle is provided. The engine assembly comprising: an engine; an electric motor; and a balance shaft comprising an eccentric mass, wherein the electric motor is configured to selectively rotate the balance shaft in order to balance a vibration characteristic of the engine. A method of operating the engine assembly is also provided.

Owner:FORD GLOBAL TECH LLC

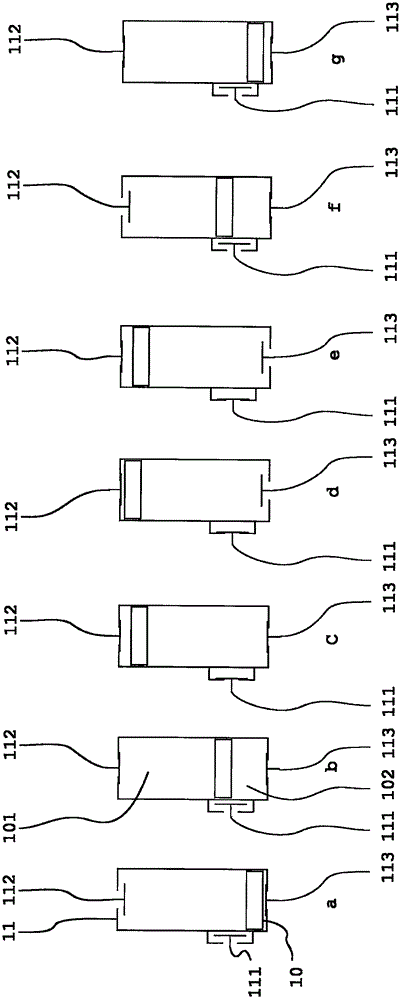

Internal-combustion engine and drive system

ActiveUS11225904B2Pumping loss is reducedIncrease productionInternal combustion piston enginesValve drivesReciprocating motionInternal combustion engine

In an exemplary embodiment, an internal combustion engine, in which a valve is opened and closed when a piston reciprocates in a cylinder, has a configuration to perform repeatedly the following combined strokes: an intake stroke→a compression stroke→a combustion stroke→an exhaust stroke in a four-cycle internal combustion engine are combined with an intake and compression stroke→a combustion and exhaust stroke in a two-cycle internal combustion engine. The internal combustion engine can reduce pumping loss in a six-cycle internal combustion engine and increase the output.

Owner:SAWADA FUKUEI +1

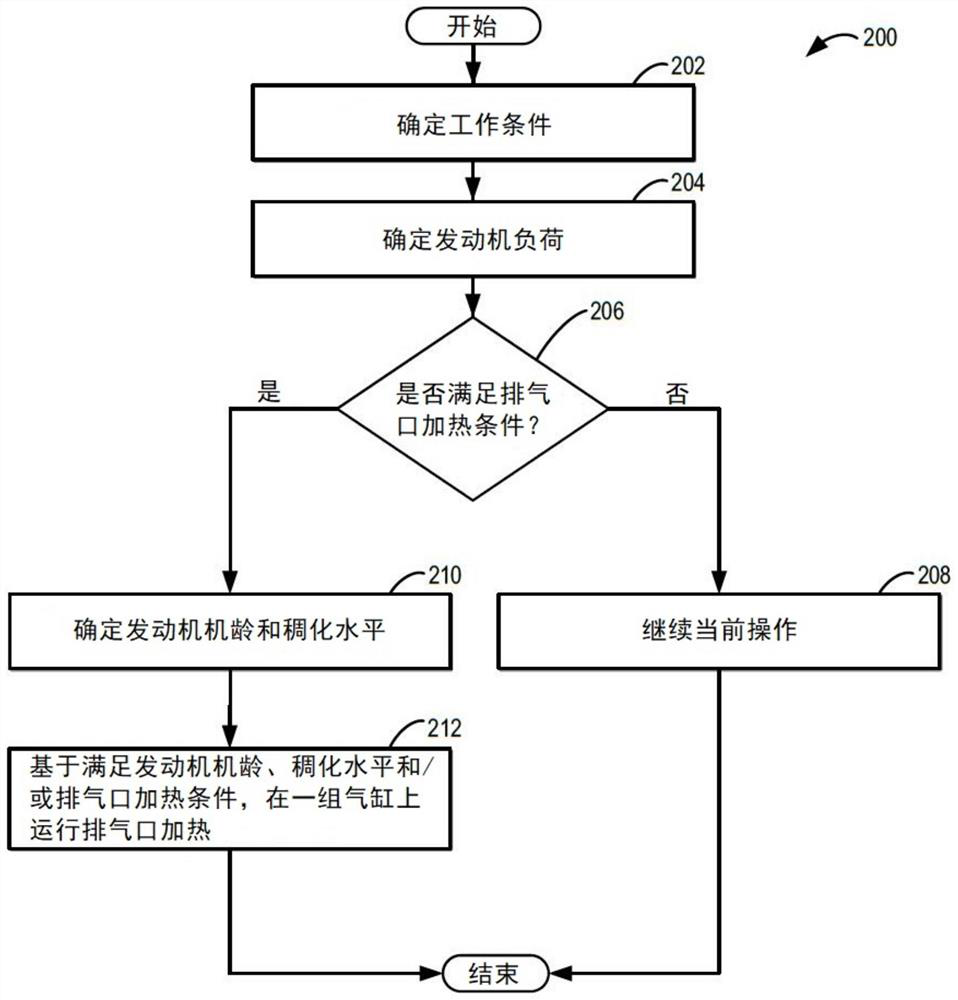

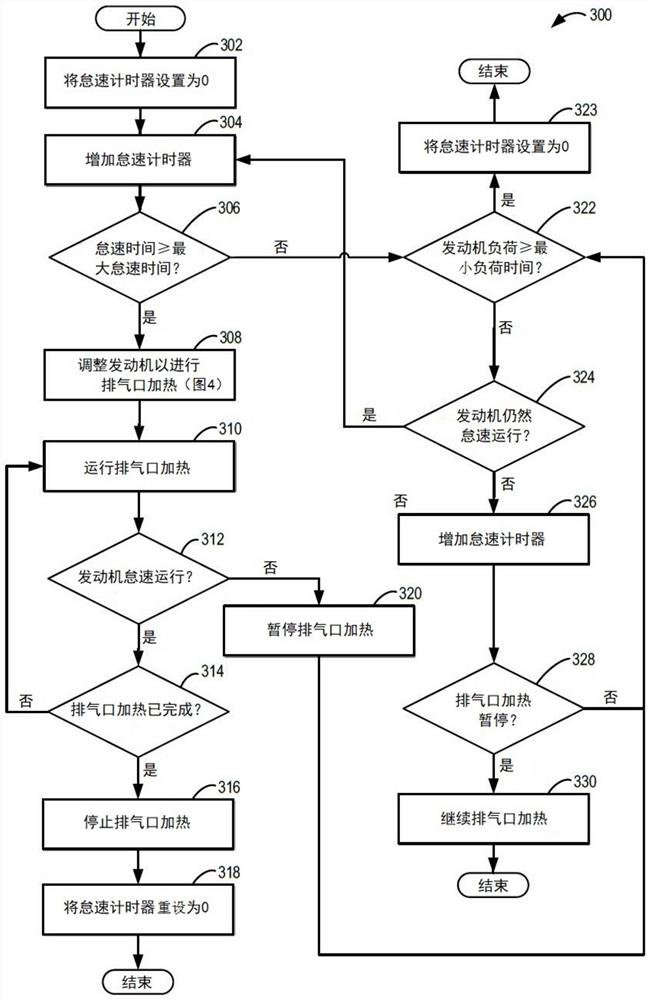

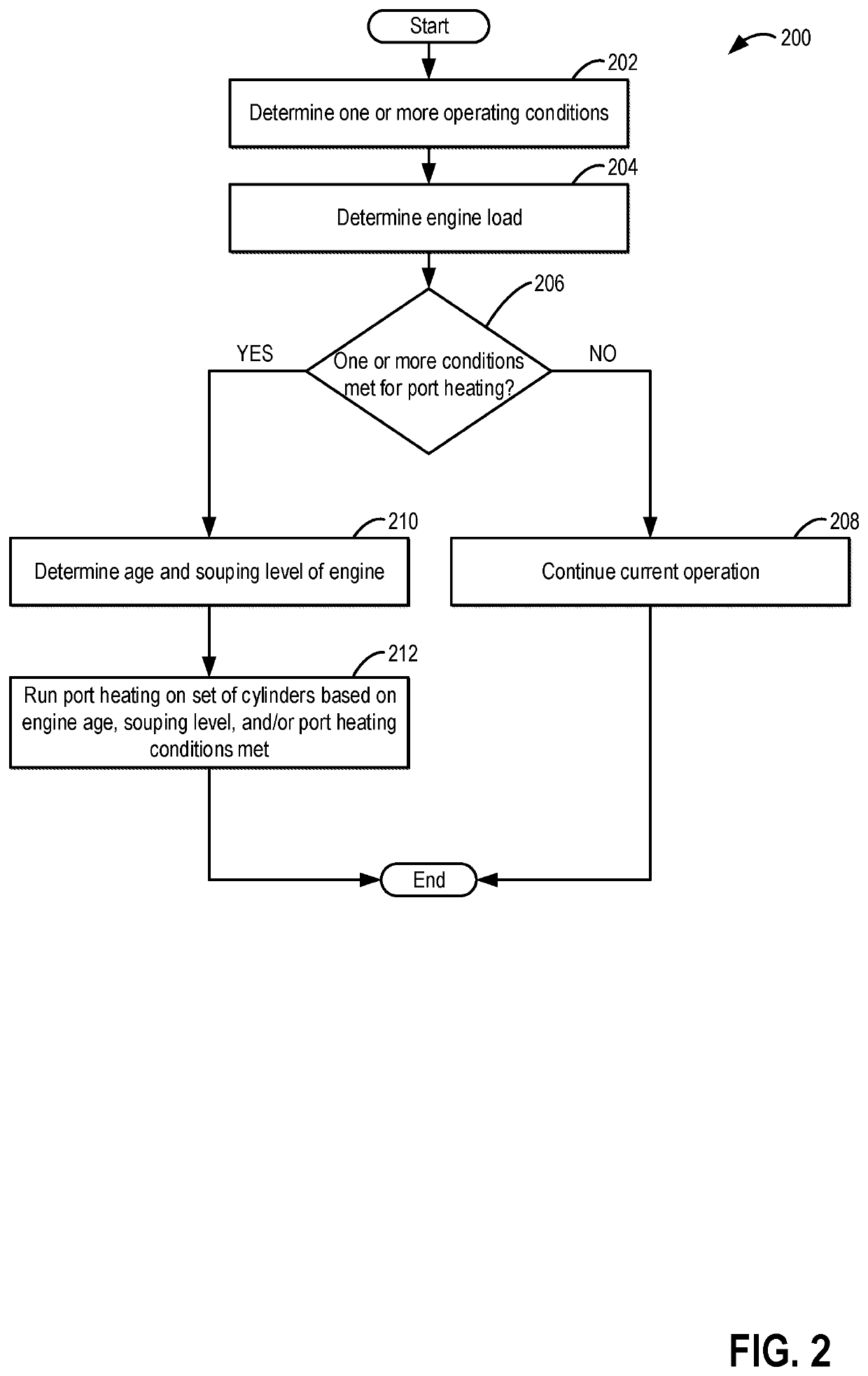

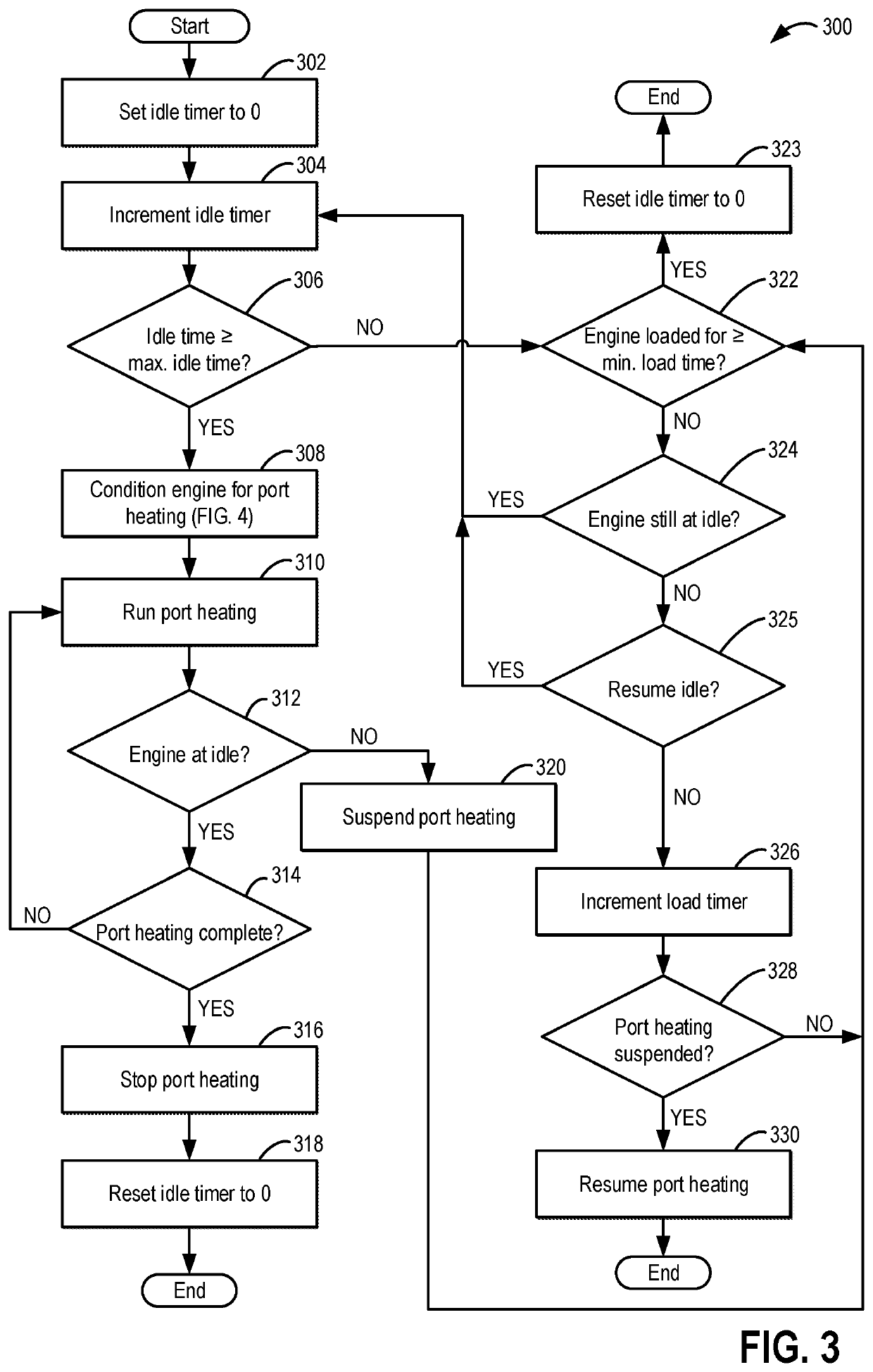

Port heating system and method

PendingUS20220025828A1Reduce fuel consumption penaltyReduce stepsElectrical controlExhaust apparatusMechanical engineeringDiesel engine

Methods and systems are provided for operating an engine having a plurality of cylinders that utilize oil for lubrication purposes. In one embodiment, a method for the engine may include determining if one or more conditions have been met for port heating based on one or more operating conditions of the engine, continuing current operation if the one or more conditions for port heating have not been met, and determining a souping level of the engine if the one or more conditions for port heating have been met and subsequently running port heating on a set of cylinders of the engine based on the souping level of the engine and / or the one or more conditions for port heating. The engine may be a non-EGR engine and / or a high speed diesel engine. Each cylinder of the set of cylinders may have at least one port.

Owner:POWERHOUSE ENGINE SOLUTIONS SWITZERLAND IP HLDG GMBH

Control Method of Piston Trajectory in Free Piston Engine

ActiveCN107288751BGuaranteed uptimeGood piston trajectory tracking performanceNon-electrical controlFree piston enginesControl orientedFree-piston engine

The invention discloses a control method for piston motion track of a free piston engine, and belongs to the technical field of control. The invention aims to provide the control method for the piston motion track of the free piston engine, and the control method establishes a free piston internal combustion engine generator mechanism model system under an MATLAB environment according to the working mechanism of the free piston internal combustion engine generator, can effectively compensate interferences and keeps stable operation of the free piston internal combustion engine generator. The control method comprises the following steps of: establishing a free piston electric generator simulation model; controlling piston track of the free piston electric generator; enabling track of the piston to trace reference track, wherein the reference track is that a FPEG works under load needed for a driver; establishing a control-oriented model; designing a quadric-form secondary optimal controller; expanding design of a state observer; and performing uncertainty compensation. According to the control method disclosed by the invention, a control-oriented simplified model of the system is established, a piston motion control method based on linear quadratic type (LRQ) and extended state observer (ESO) is disclosed, and piston motion track of EPEG is controlled by regulating circulating oil spray amount.

Owner:JILIN UNIV

Control method, system and vehicle of multi-stroke cycle gasoline engine

ActiveCN106930851BImprove fuel economyEmission reductionElectrical controlNon-electrical controlCombustion chamberGasoline fuel

The invention provides a control method and system for a multi-stroke circulation gasoline engine and a vehicle. The control method comprises the steps that if the engine is a multi-stroke circulation direct-injection gasoline engine, gasoline fuel is provided for a combustion chamber from the end section of an induction stroke and / or a compression stroke to the front section of an expansion stroke in a current multi-stroke circulation mode; ignition time is determined according to finishing temperature, a mixed gas average air-fuel ratio, a gasoline fuel injection amount around a compression upper dead center and injection timing, and ignition is performed at the ignition time; if the engine is a multi-stroke circulation port injection gasoline engine, the gasoline fuel is provided for a port at the induction stroke and / or an exhaust stroke in the current multi-stroke circulation mode; and ignition timing is determined during a period from the end section of the compression stroke to the front section the expansion stroke, and ignition is performed at the ignition timing. By adopting the method, fuel economy of the engine in multiple operation conditions can be effectively improved; and emission of tail gas pollutants is lowered.

Owner:GREAT WALL MOTOR CO LTD

Internal combustion engine, operation method of internal combustion engine, cylinder, cylinder liner and sealing plate of internal combustion engine

An internal combustion engine (1) and corresponding method, cylinder, closing plate, cylinder and kit of parts, in particular a two-stroke engine, preferably a diesel two stroke engine, which comprises at least one piston (10) arranged in a cylinder (11). Said piston (10) and said cylinder (11) define a variable combustion chamber (101) and a variable second chamber (102). The variable combustion chamber (101) is fluidly connectable to the compressor side of a turbocharger (2,2') via at least one inlet opening (111) and to the turbine side of the turbo charger (2,2') via an exhaust opening (112). The second chamber (102) is fluidly connectable to the compressor side of the turbocharger (2,2') to introduce a compressed air flow into the second chamber (102). The compressed air flow is interruptible such that the second chamber (102) is disconnected from the turbocharger (2, 2') and the second chamber (102) comprises an outlet opening (113) for reducing a pressure of the second chamber (102). The outlet opening (113) preferably comprises a controllable chamber valve.

Owner:WINTERTHUR GAS & DIESEL

A method for preventing engine from scuffing

The invention relates to the technical field of automobiles, in particular to a method for preventing engine cylinder scoring. According to the method for preventing engine cylinder scoring, whether an engine fails or not is judged by measuring performance parameters of the engine; when it is judged that the engine fails according to the performance parameters of the engine, the output torque of the engine is limited first; and after the output torque of the engine is reduced, when the abnormal situation of the engine is still not improved or eliminated, the engine is directly turned off. According to the method, the situation that the gas inlet temperature, water temperature and lubrication situations of the engine become abnormal within a short period of time due to burst problems such as intercooler and throttle valve blockage, fan faults and engine oil leakage is considered, and it is effectively avoided that cylinder scoring happens when this type of situations happen to the engine.

Owner:WEICHAI POWER CO LTD

Camshaft for internal-combustion engine

ActiveUS20220082048A1Pumping loss is reducedIncrease productionInternal combustion piston enginesValve drivesExhaust valveInlet valve

A camshaft includes, as a cam that opens and closes an exhaust valve and an intake valve, a ball cam whose protrusion amount changes according to rotation of the camshaft, wherein the camshaft has a double structure consisting of an inner shaft and an outer shaft provided in a manner that the inner shaft is helically displaced with respect to the outer shaft around an axis of the camshaft according to a rotation speed of the camshaft, and the ball cam is accommodated movably in a guide groove provided in the inner shaft and protrudes from the outer shaft, and a protrusion amount of the ball cam from the outer shaft changes when the ball cam moves in the guide groove due to the helical displacement of the inner shaft with respect to the outer shaft.

Owner:SAWADA FUKUEI +1

Two-stroke engine control

ActiveCN112368471AReduce stepsLow costMetal sawing devicesElectrical controlThrottle controlInternal combustion engine

A two-stroke combustion engine comprising a user-operated throttle control, an adjustable valve arranged to control one or more air intakes of the combustion engine, and a control unit arranged to control a state of the adjustable valve, wherein the combustion engine is arranged to operate in a first idle mode at an idle engine speed below a clutch engagement engine speed when the user-operated throttle control is not engaged, wherein the combustion engine is arranged to operate in a second idle mode at a target engine speed above the clutch engagement engine speed when the user-operated throttle control is engaged and when the engine is not subject to an external load, the control unit being arranged to control the state of the adjustable valve to maintain engine speed at the target engine speed when the engine operates in the second idle mode.

Owner:HUSQVARNA AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com