Internal combustion engine, operation method of internal combustion engine, cylinder, cylinder liner and sealing plate of internal combustion engine

A technology for internal combustion engines and cylinders, which is applied to the sealing device of engines, combustion engines, machines/engines, etc. It can solve problems such as high cost and complex systems, and achieve the effect of improving engine efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

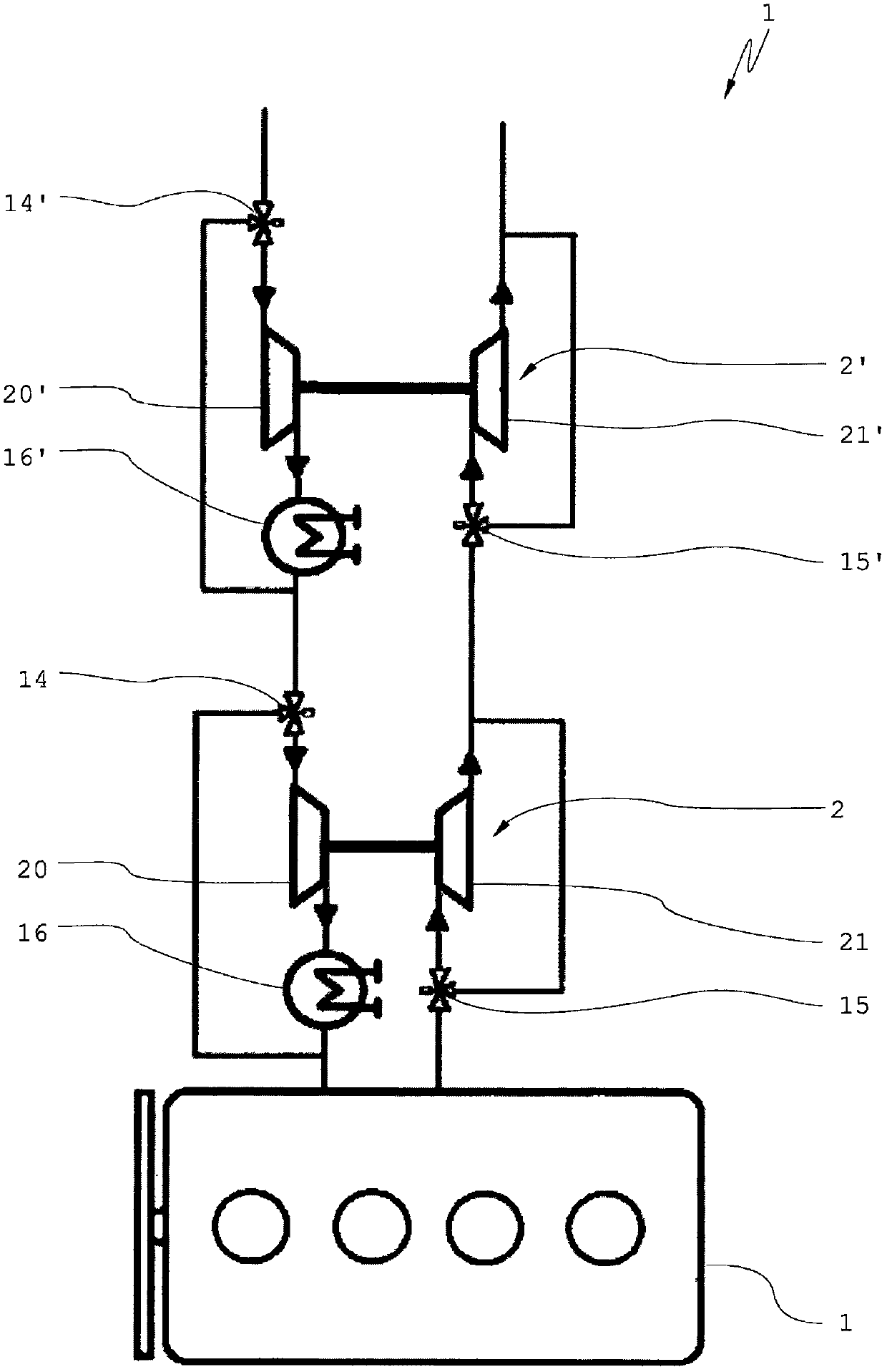

[0073] figure 1 A schematic diagram of an internal combustion engine 1 is shown. The internal combustion engine 1 is connected to two turbochargers 2 and 2' arranged in series. Each turbocharger comprises a compressor 20, 20' and a turbine 21, 21'. A separate air cooler 16, 16' is assigned to each turbocharger 2, 2'. The compressor 20, 20' of each turbocharger 2, 2' may be bypassed using a compressor bypass valve 14, 14'. Furthermore, each turbine can be bypassed using a turbine bypass valve 15, 15'. Thus, one of the turbochargers 2 , 2 ′, for example the second turbocharger 2 ′, can be bypassed and the internal combustion engine 1 can be operated using only the first turbocharger 2 . This may be useful if one of the turbochargers fails. The bypass valves 14, 15, 14', 15' can also be partially opened or closed depending on the desired mode of operation.

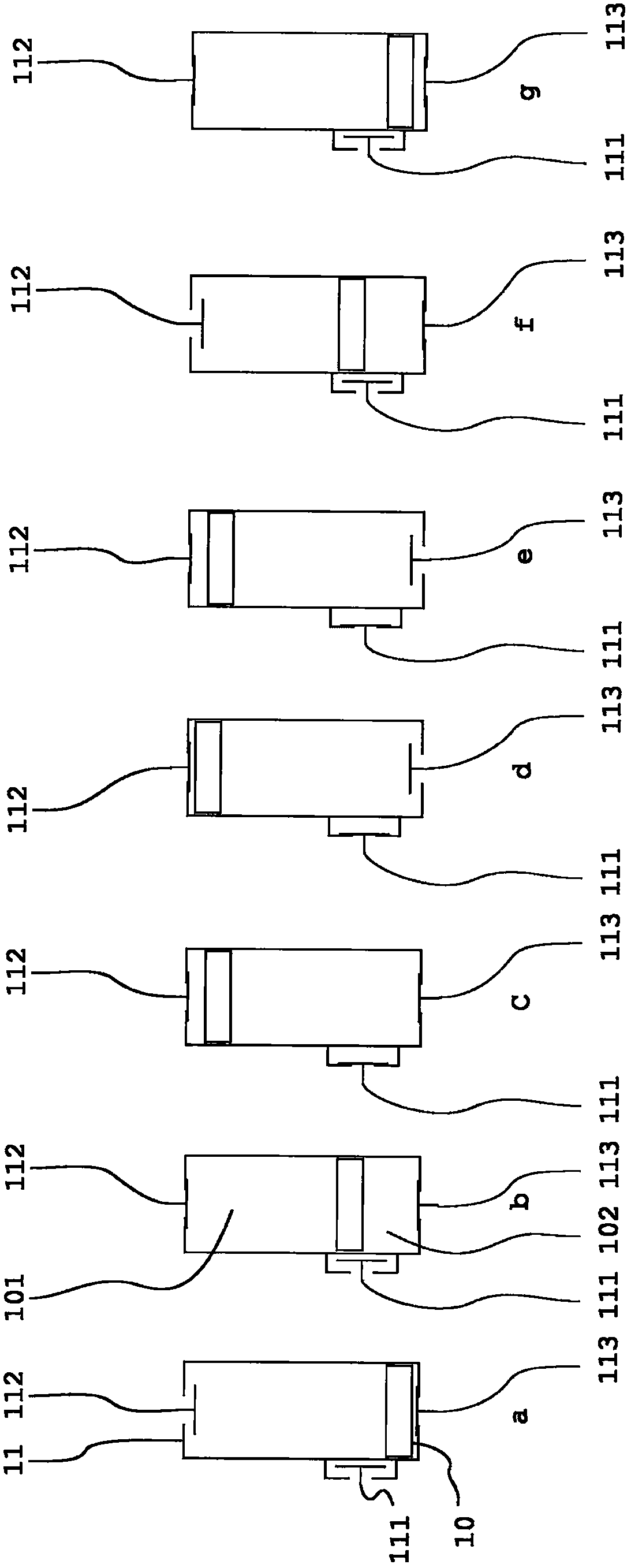

[0074] figure 2 Several stages of the working cycle of an internal combustion engine are schematically shown. exis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com