Patents

Literature

121results about "Drum steam boilers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

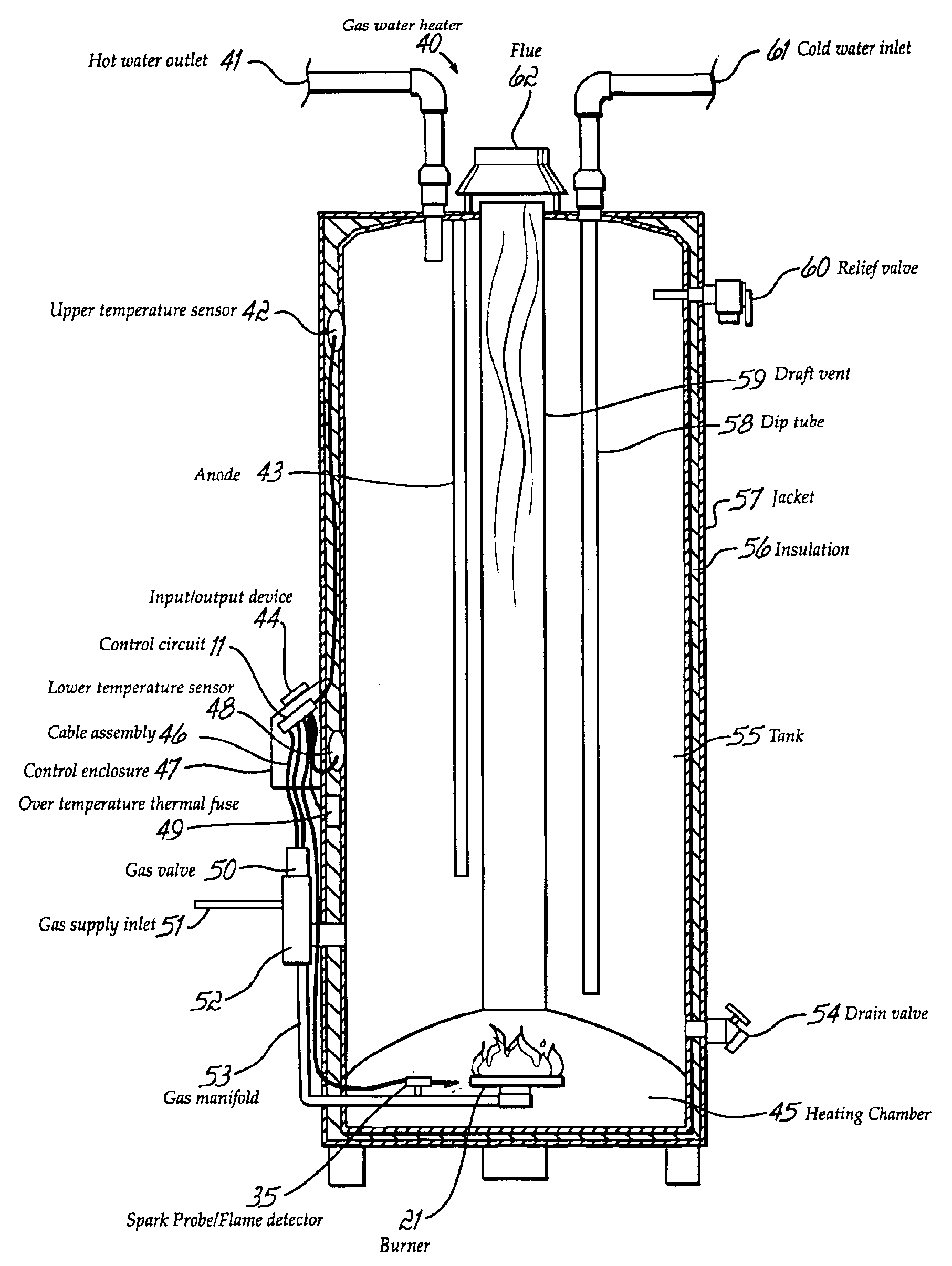

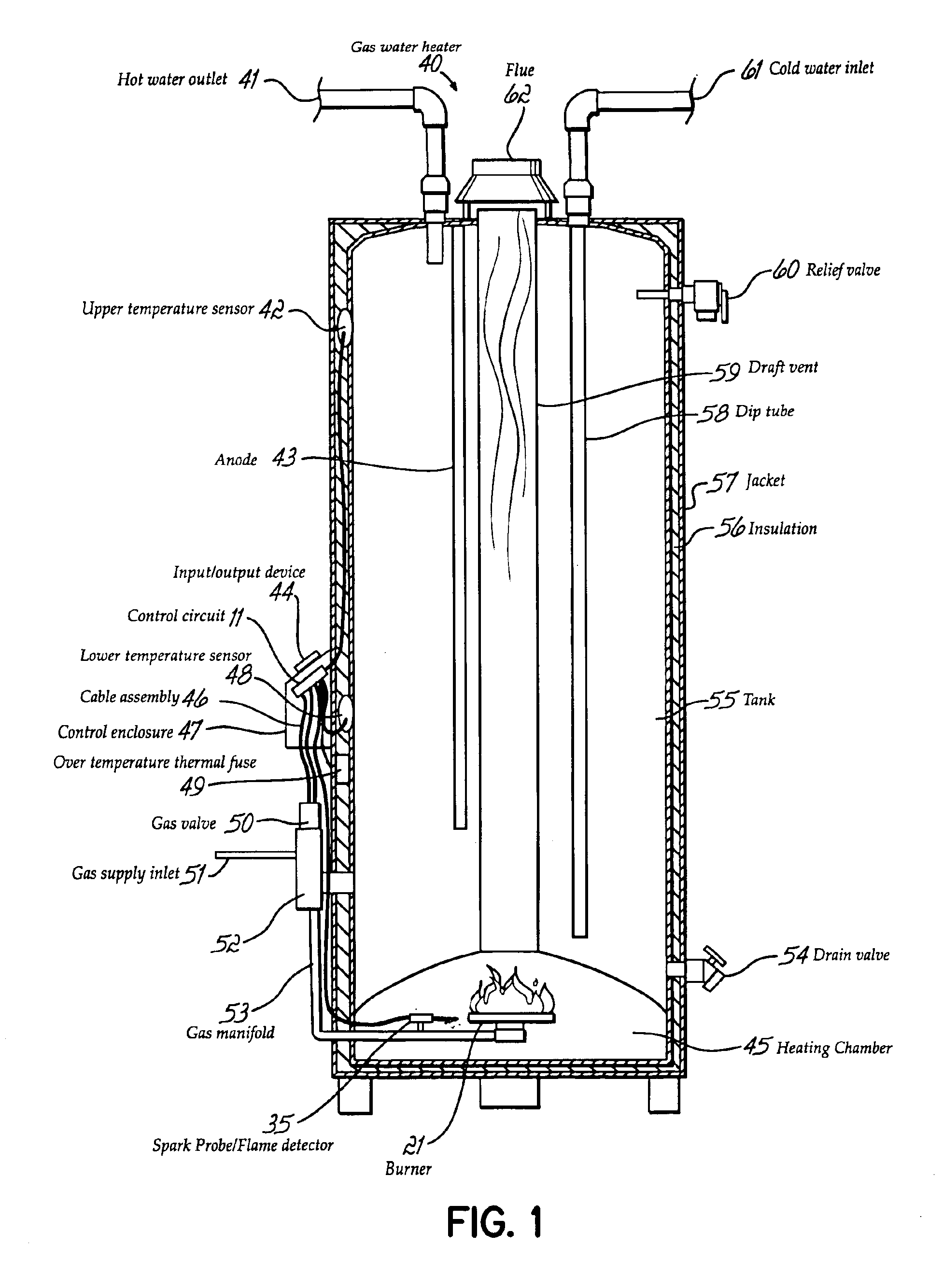

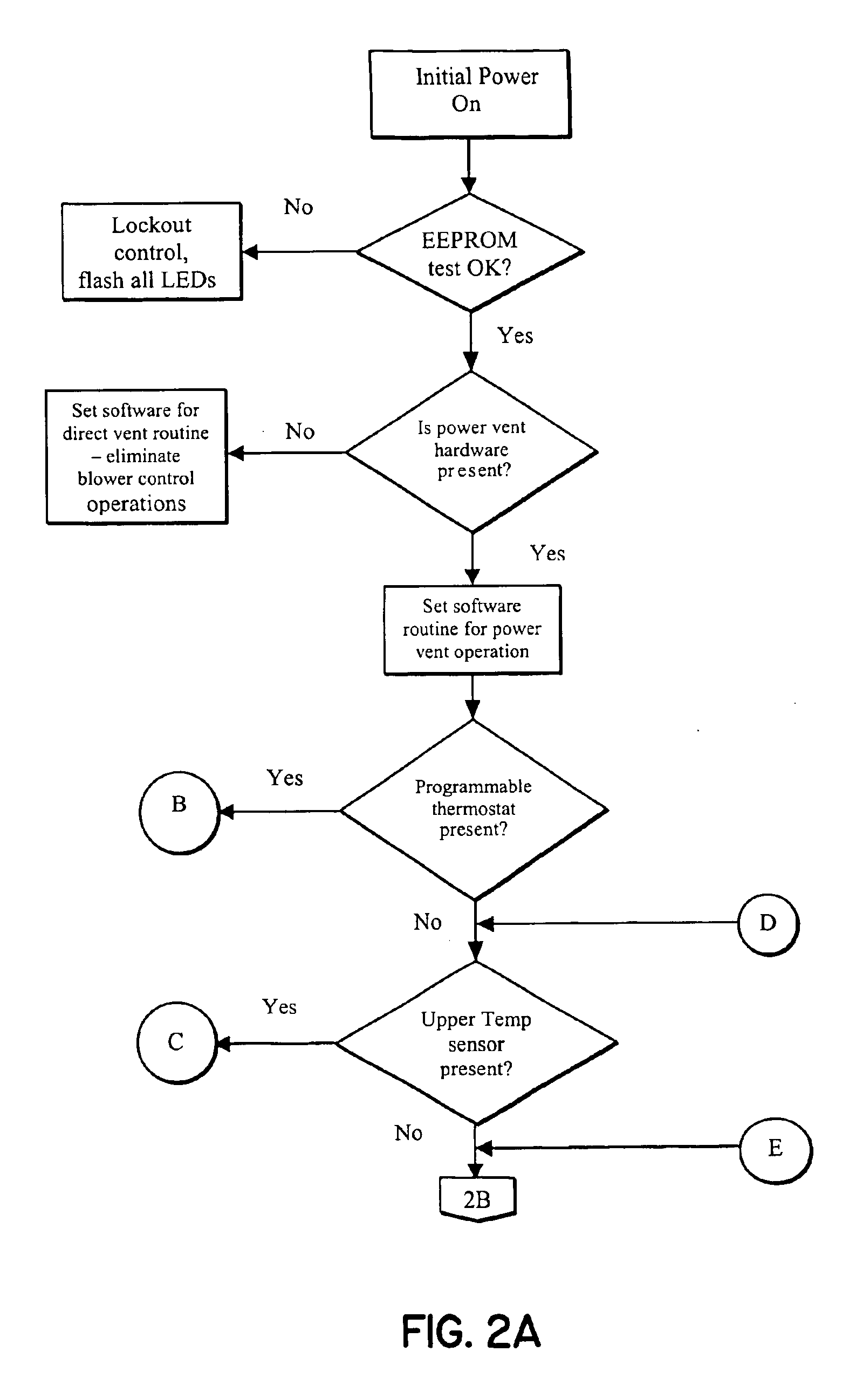

Gas water heater and method of operation

InactiveUS6880493B2Improve performanceStable temperatureFuel supply regulationElectric spark ignitersEngineeringProduct gas

A gas water heater with a tank for holding water including a gas valve mounted below the tank and in fluid communication with a supply of gas. A gas burner is fluidly connected to the gas valve. A first temperature sensor is mounted adjacent a lower portion of the tank and detects a temperature of the water in the lower portion of the tank, and a second temperature sensor is mounted adjacent an upper portion of the tank and detects a temperature of water in the upper portion of the tank. A control has inputs connected to the first and second temperature sensors and outputs connected to the gas valve. The control operates the gas valve in response to reading signals from the first and second temperature sensors such that water in the top and bottom portions of the tank stays within a desired temperature range.

Owner:CLIFFORD TODD W

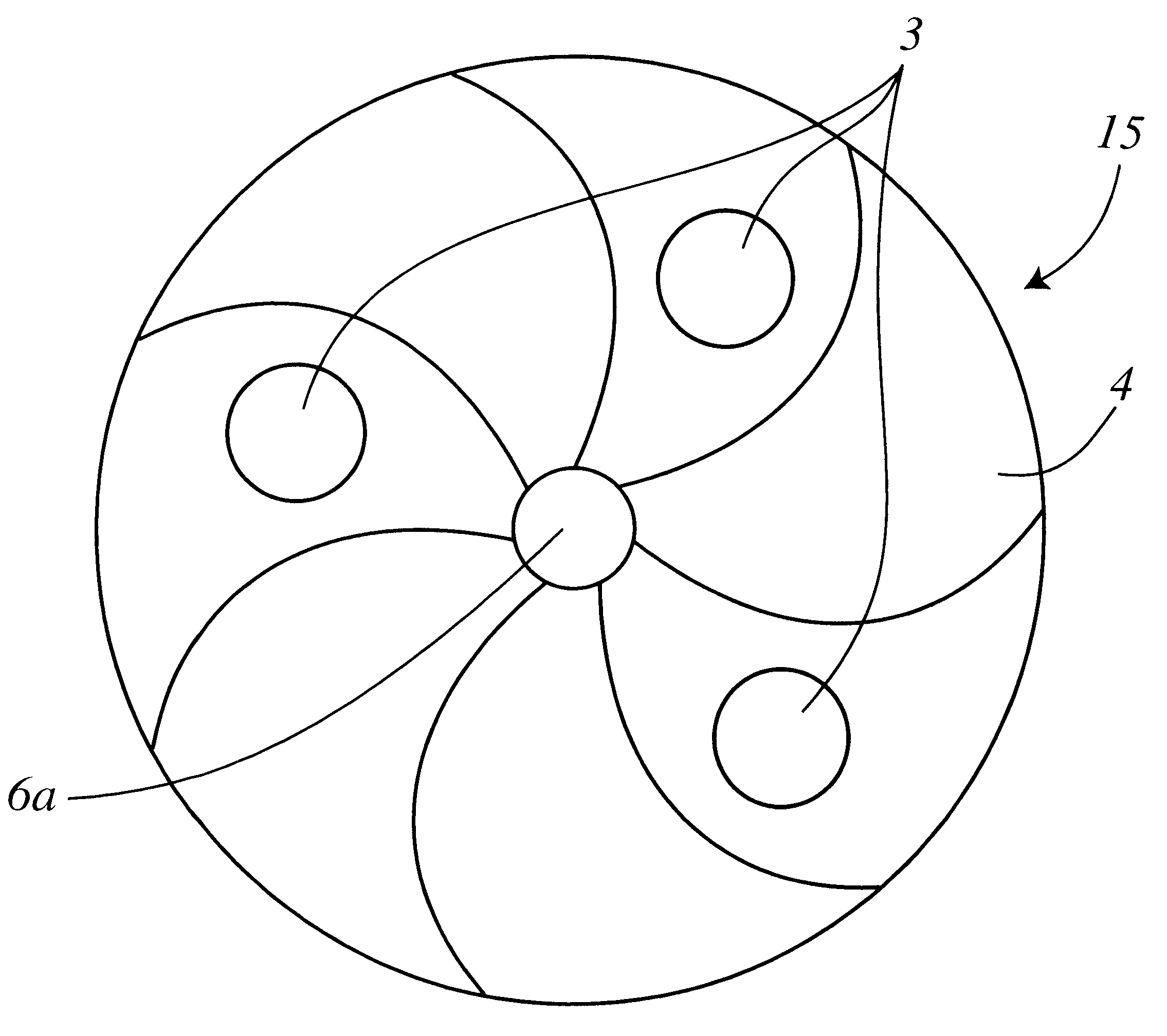

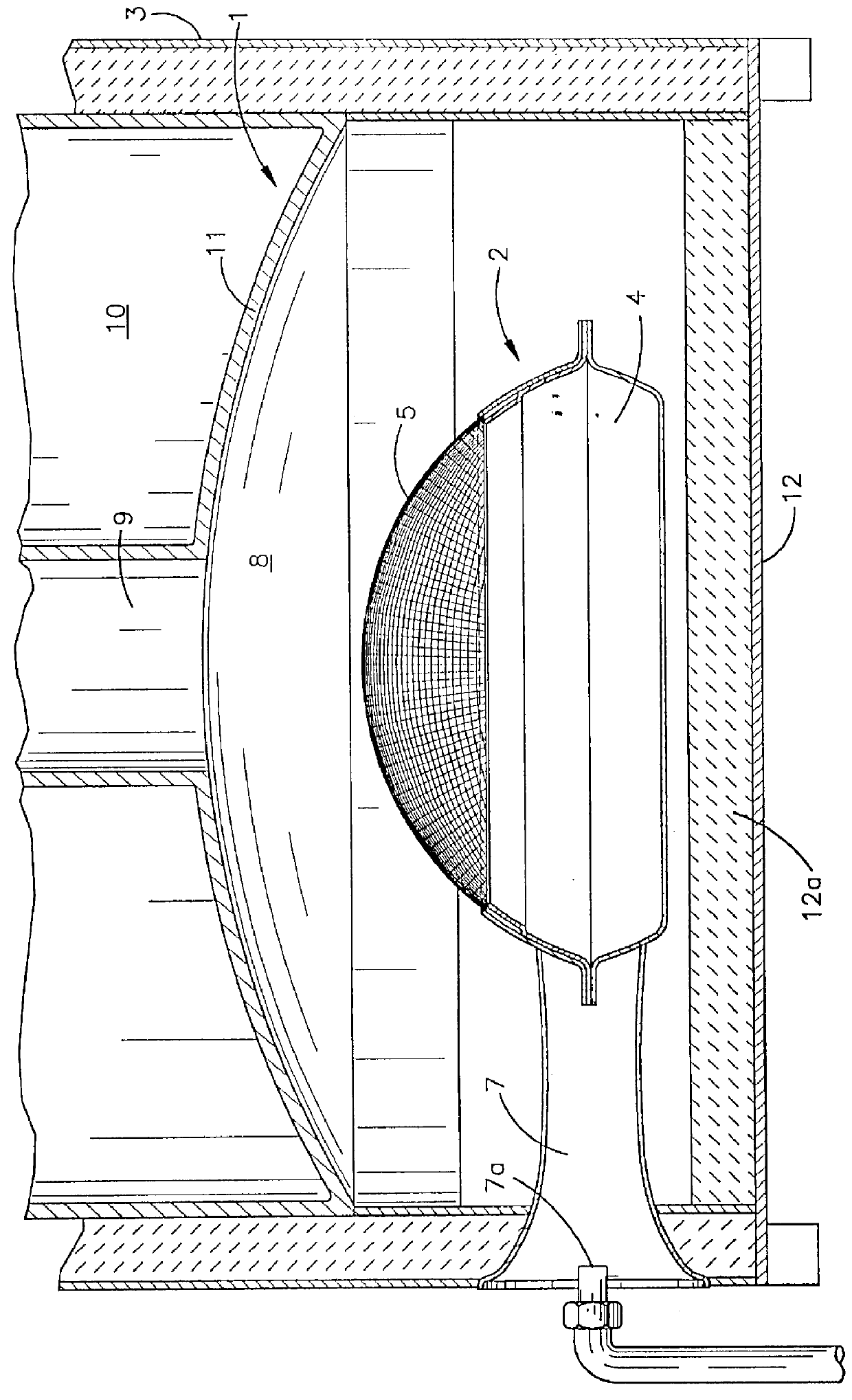

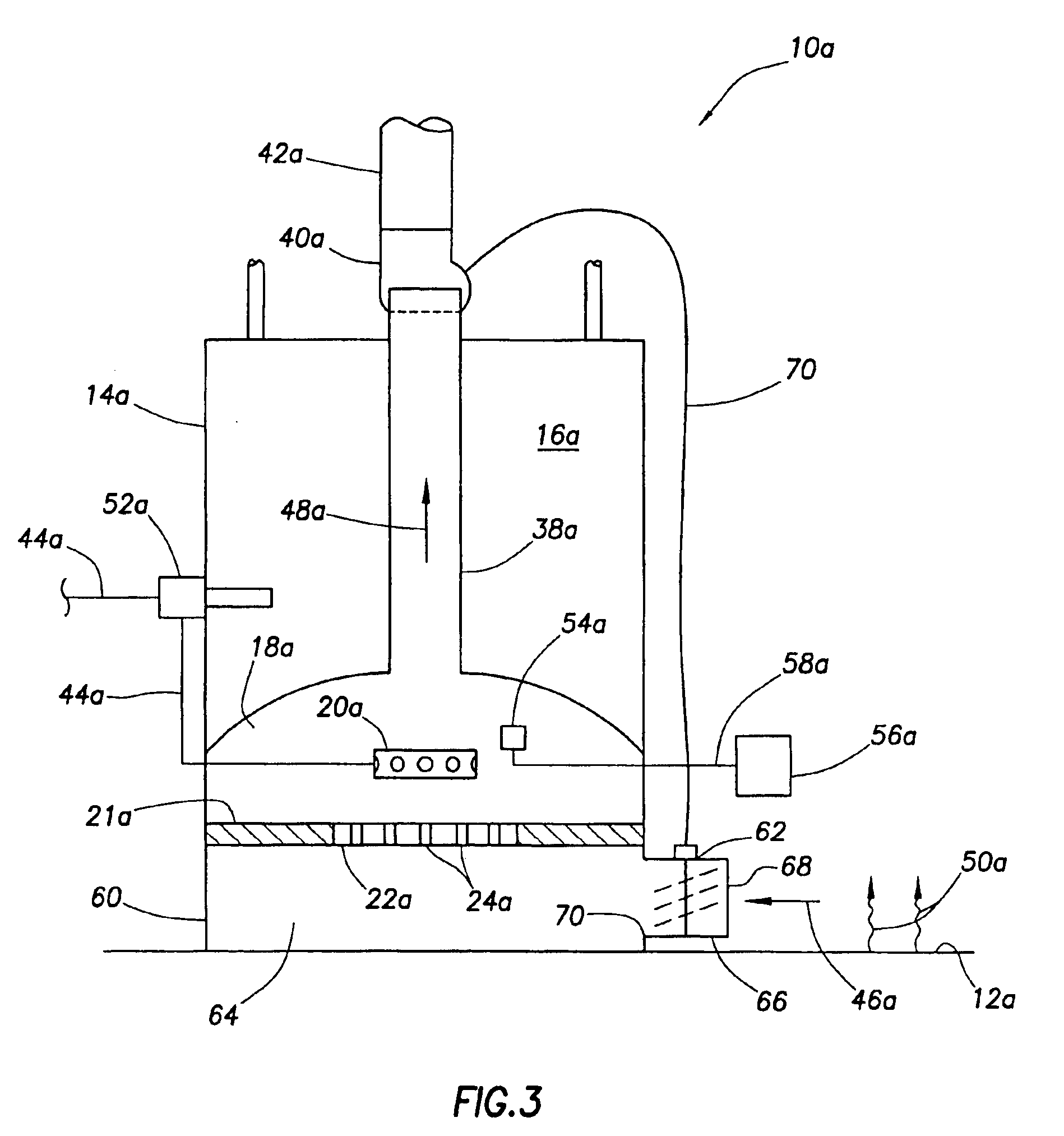

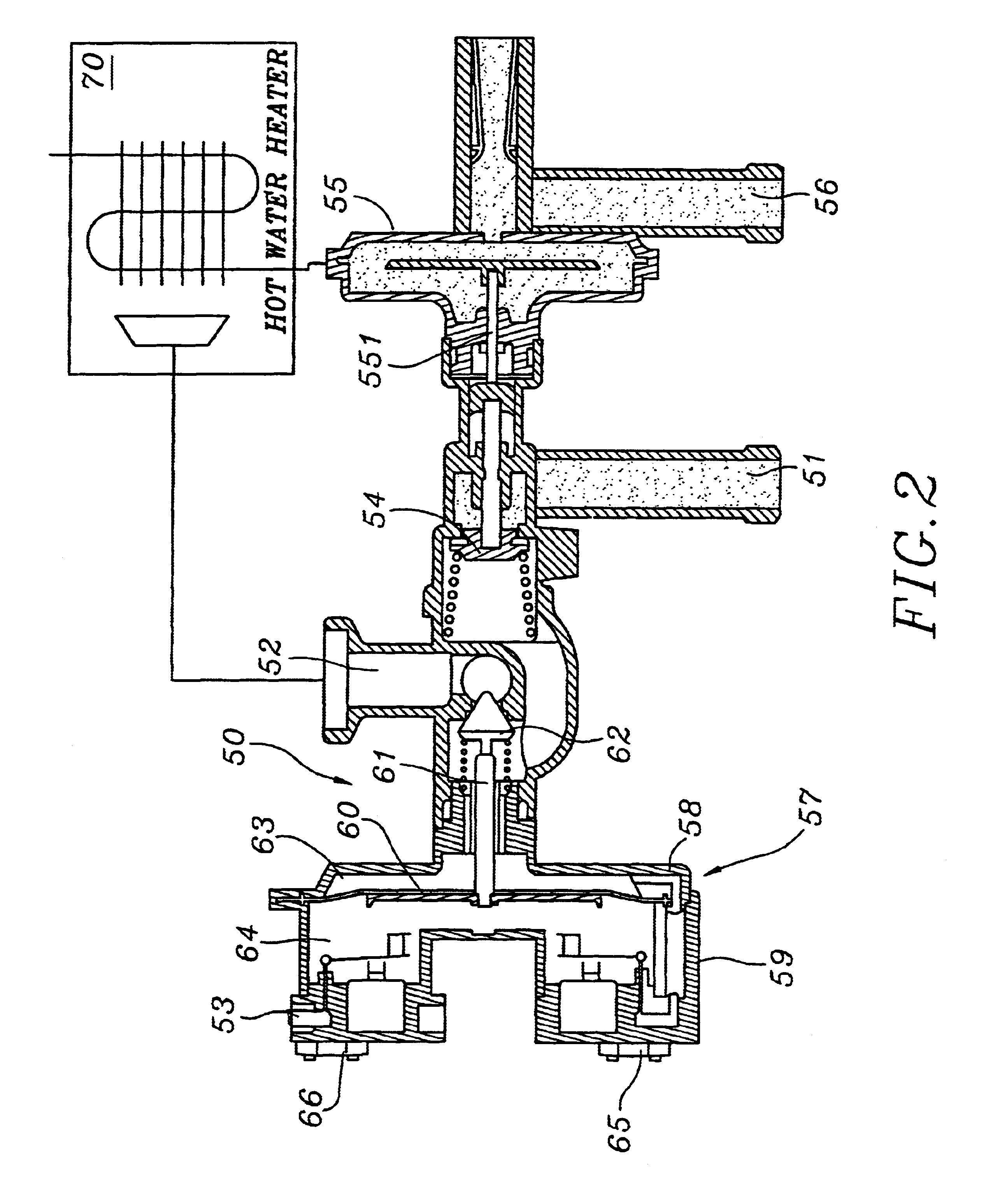

Method and apparatus for providing dilution air to a blower motor

A blower is disclosed which has a housing that provides a means for drawing dilution air into a combined motor and impeller housing. The dilution air is drawn into a first chamber which houses the blower motor and is then drawn into the impeller chamber where the dilution air mixes with hot exhaust gases from a hot water heater to which the blower is attached. Apertures on a back plate of the impeller provide fluid communication between the motor chamber and the impeller chamber. The housing has walls which extend beyond a housing cover to form a skirt so that the attachment of the blower to a water heater top results in a third chamber being formed within which the water heat flue is situated.The combination of the skirt section, the housing cover and the top of the hot water heater comprise the third chamber which has at least one slot provided therein for drawing dilution air into the third chamber where the dilution air is mixed with the exhaust gases exiting the water heater flue. The mixed air and exhaust gas is drawn into the second chamber by the operating impeller where the mixture is further mixed with the dilution air drawn from the motor chamber into the housing. The mixed gases are then channeled out an outlet port formed in the blower housing.The invention eliminates the need for fans dedicated to cool the blower motor while providing the means for more effectively reducing the temperatures of the exhaust gases which exit the blower.

Owner:RBC MFG COPORATION

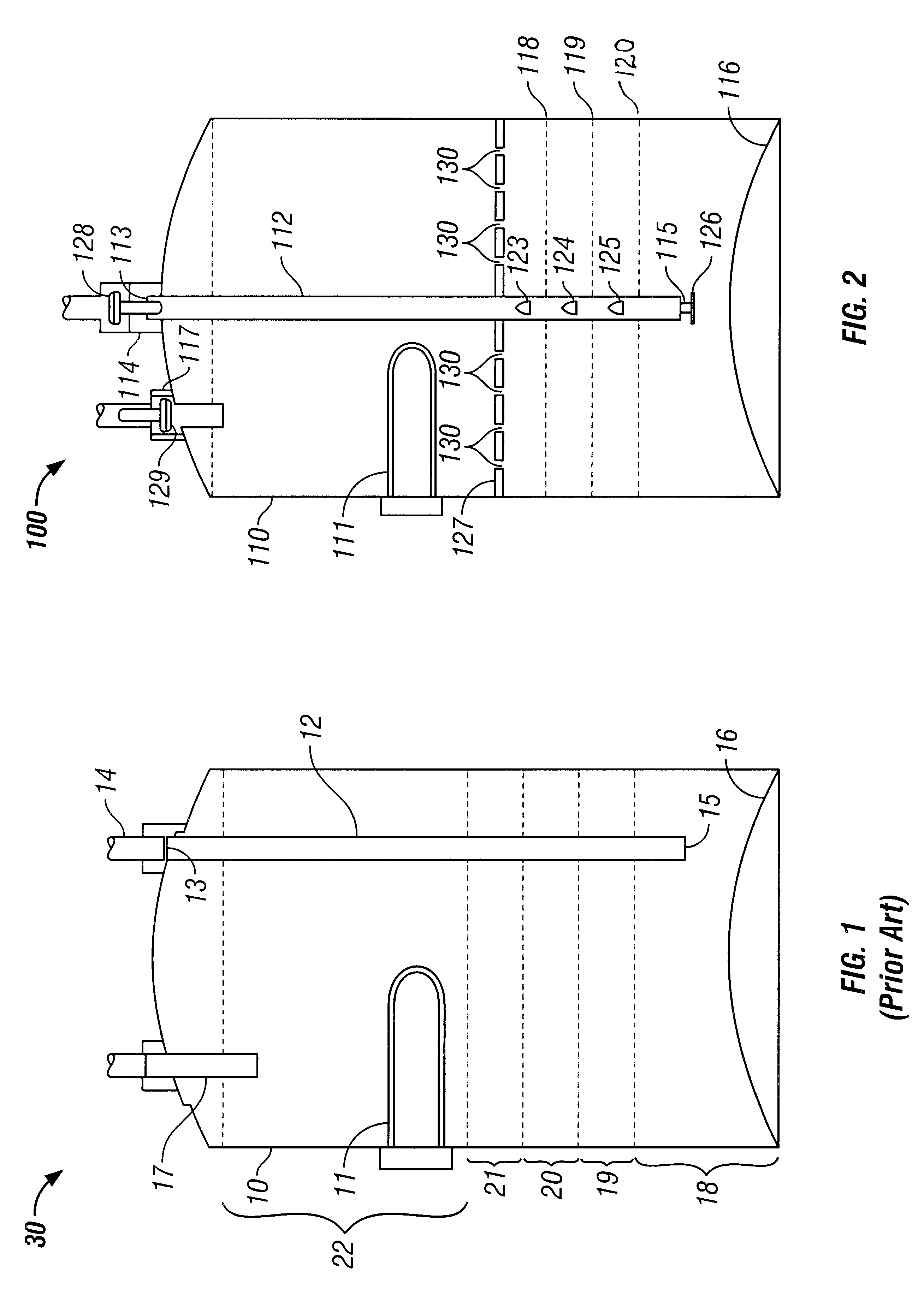

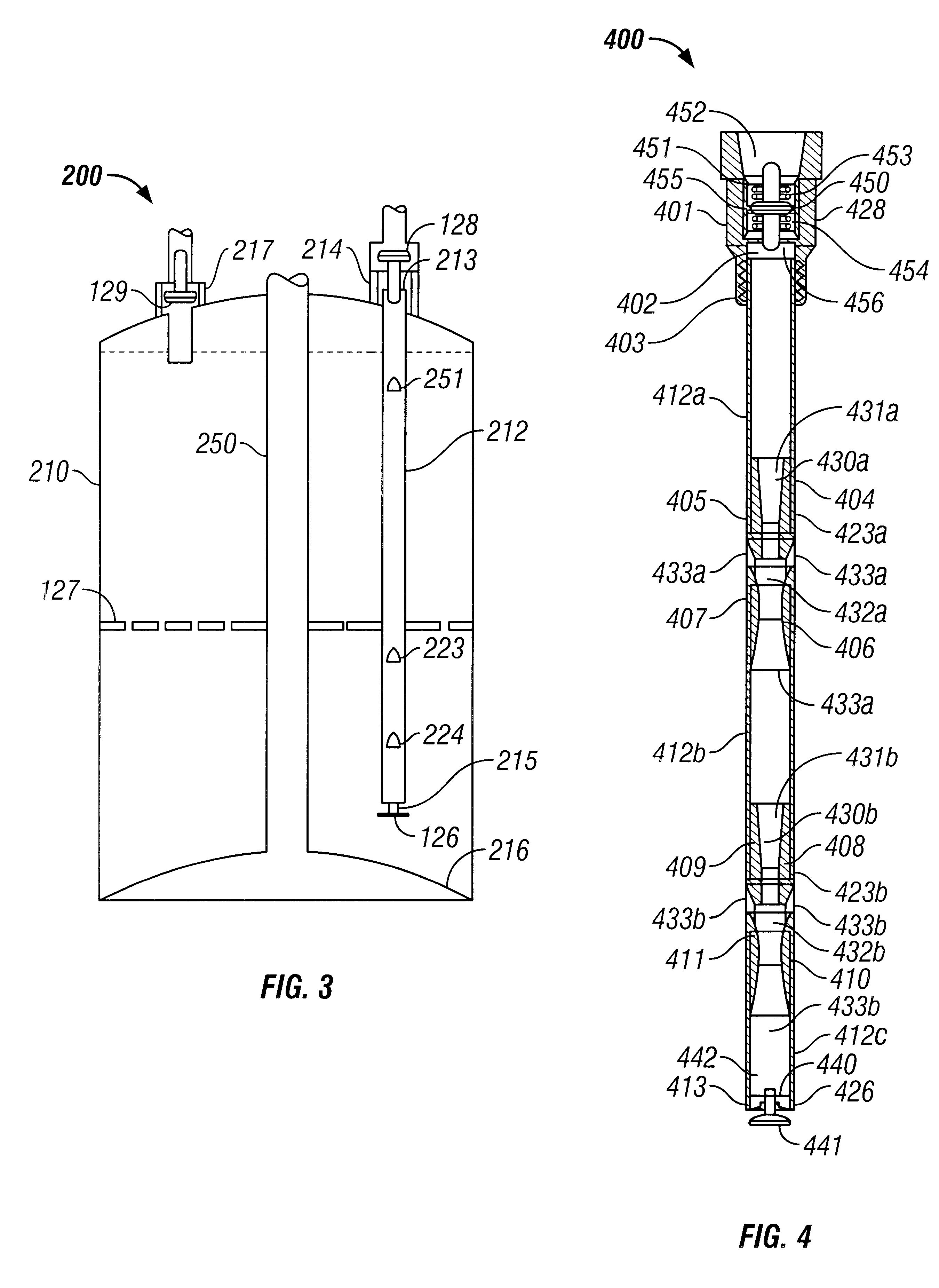

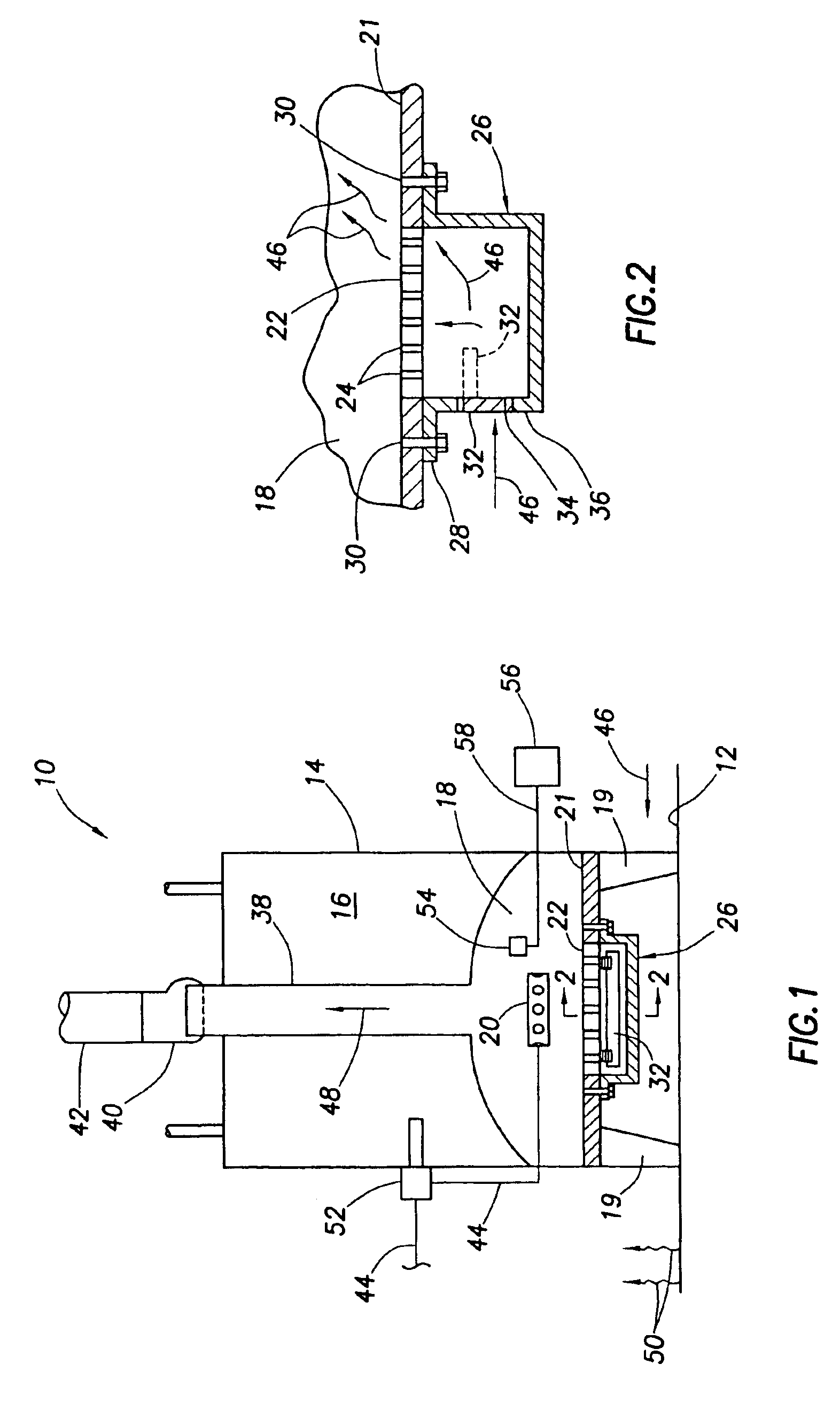

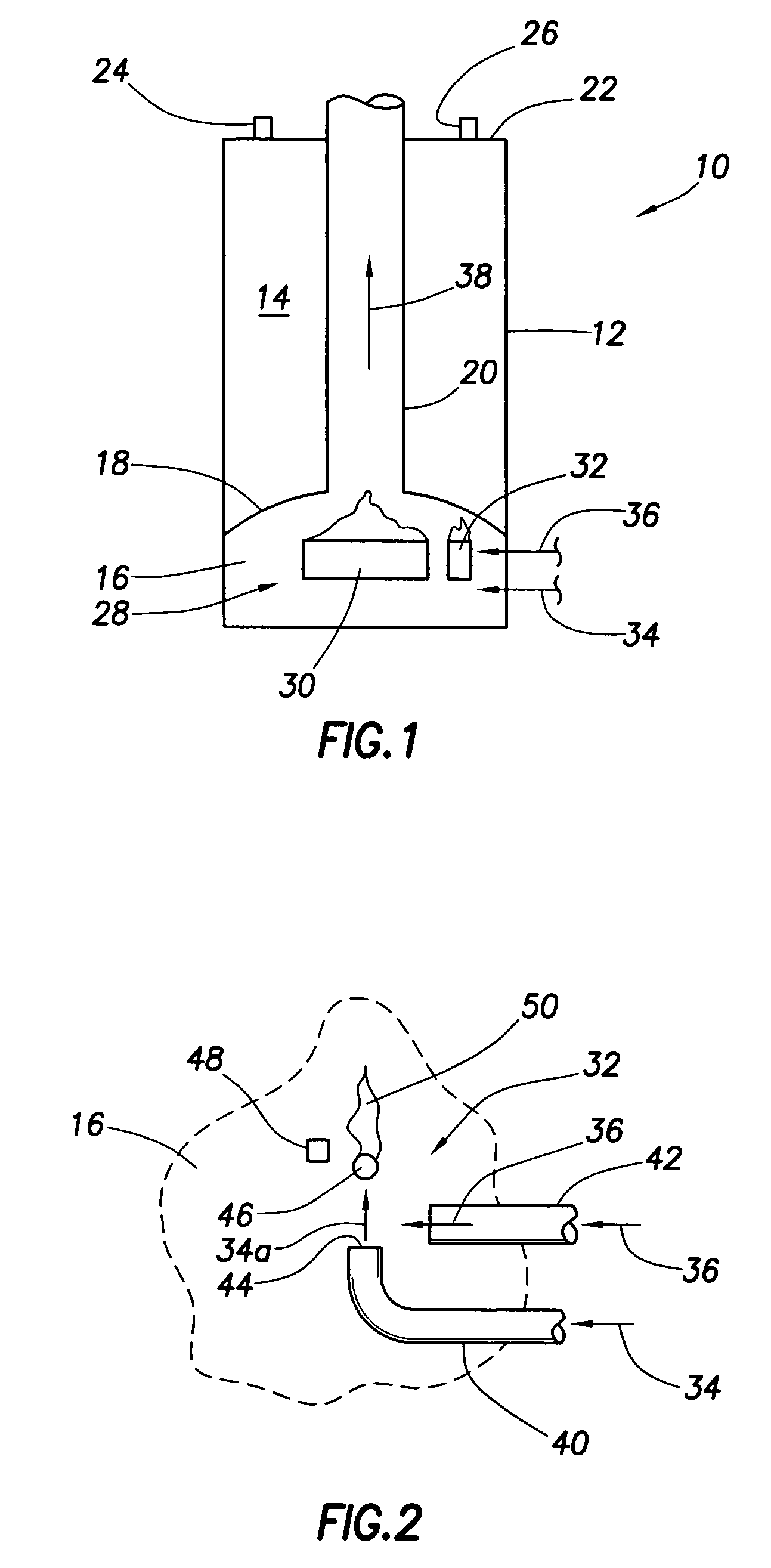

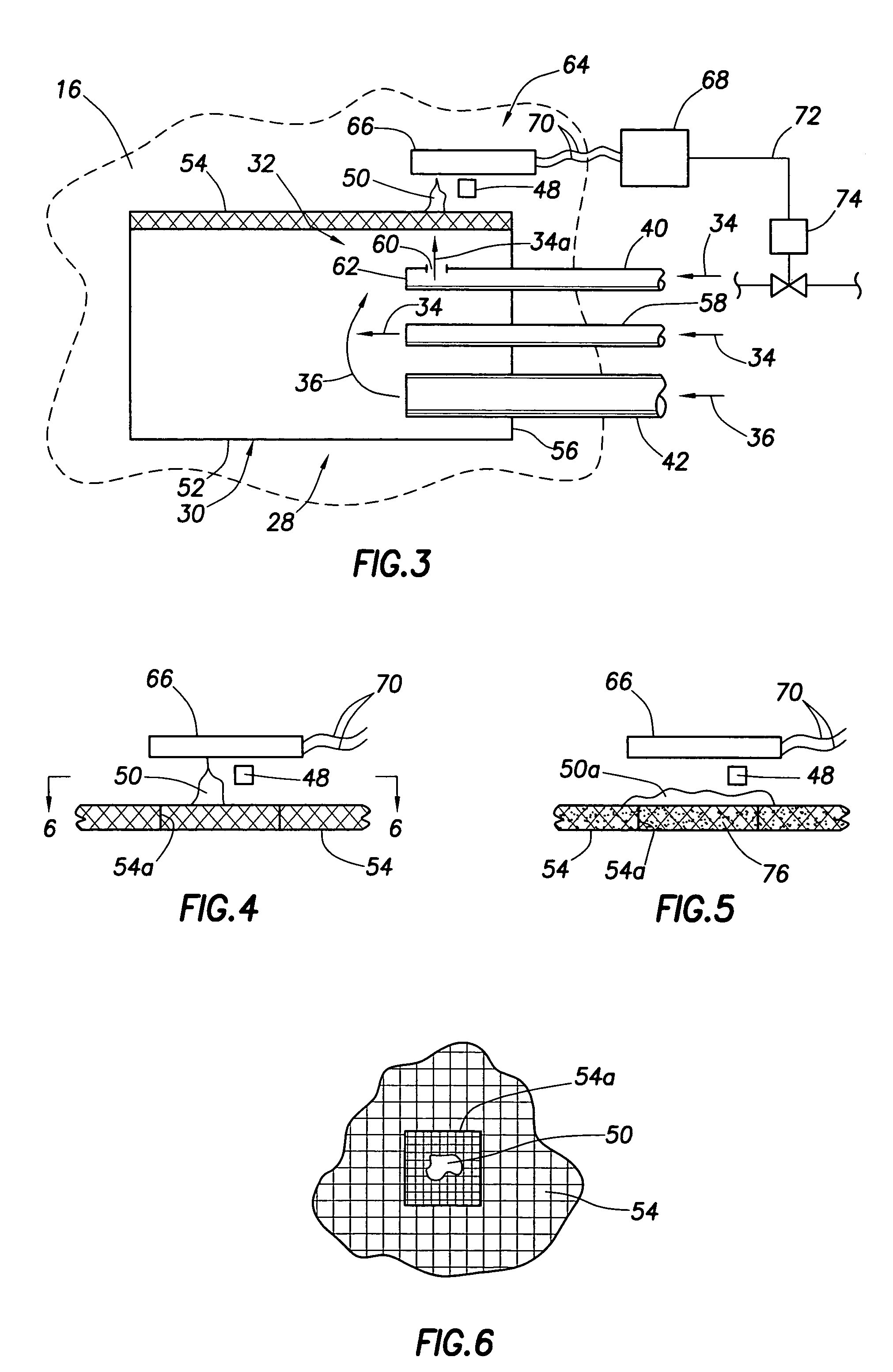

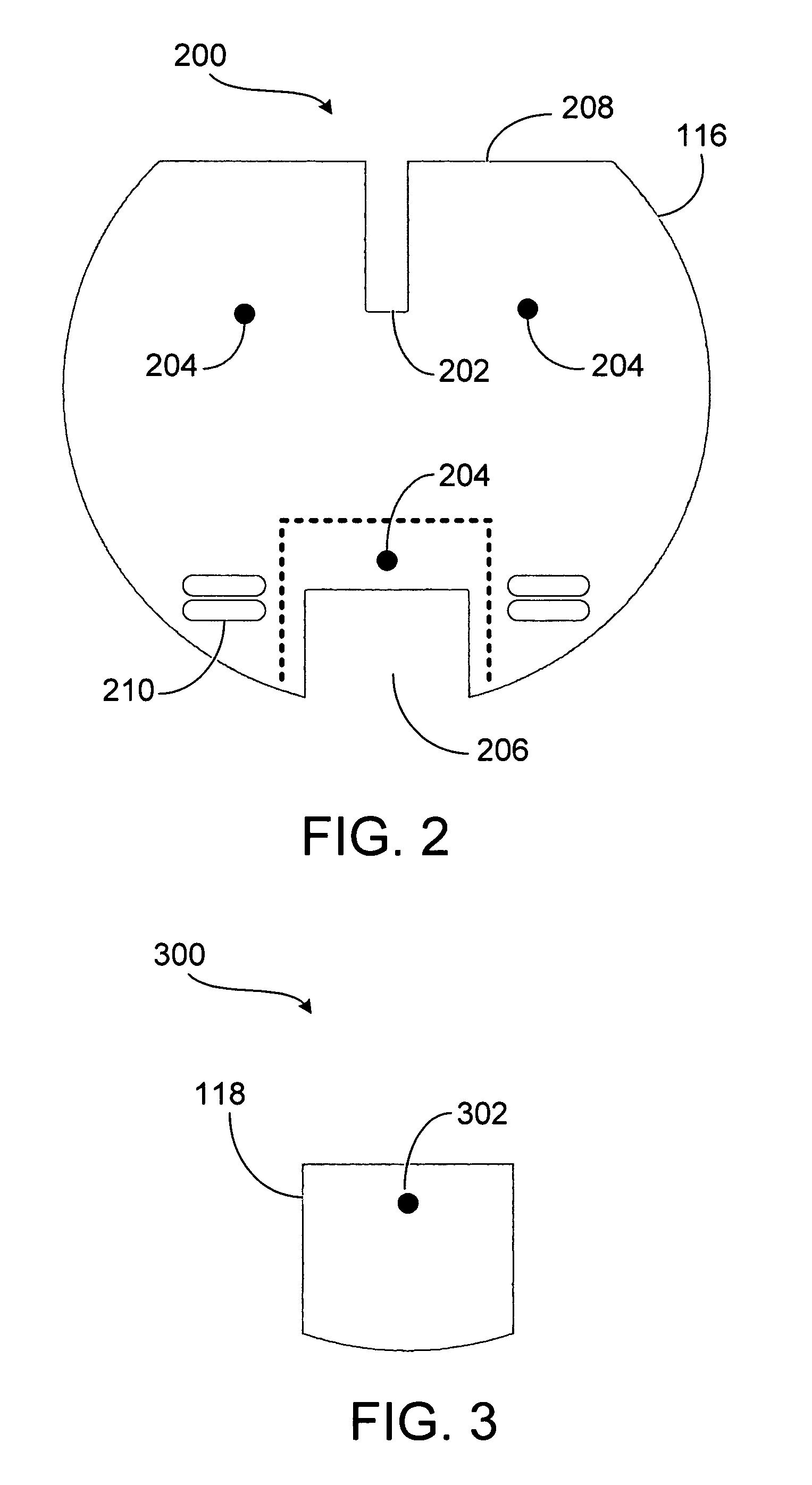

Water mixing system for water heaters

InactiveUS6553947B2Temperature control without auxillary powerSteam generation heating methodsEngineeringStorage type

Disclosed herein are storage type water heaters having means for improved mixing of cold water supply with water stored in the water tank of a water heater, means for limiting surges of water into and out of a water tank, and means for disrupting formation and propagation of convection currents and water streamers in a water tank.

Owner:BRADENBAUGH KENNETH A

Condensing gas boiler having structure of preventing corrosion caused by using heterogeneous metal

InactiveUS6907846B2Increased durabilityImprove product reliabilityMechanical apparatusEnergy efficient heating/coolingElectricityCombustion chamber

Owner:KYUNGDONG NAVIEN

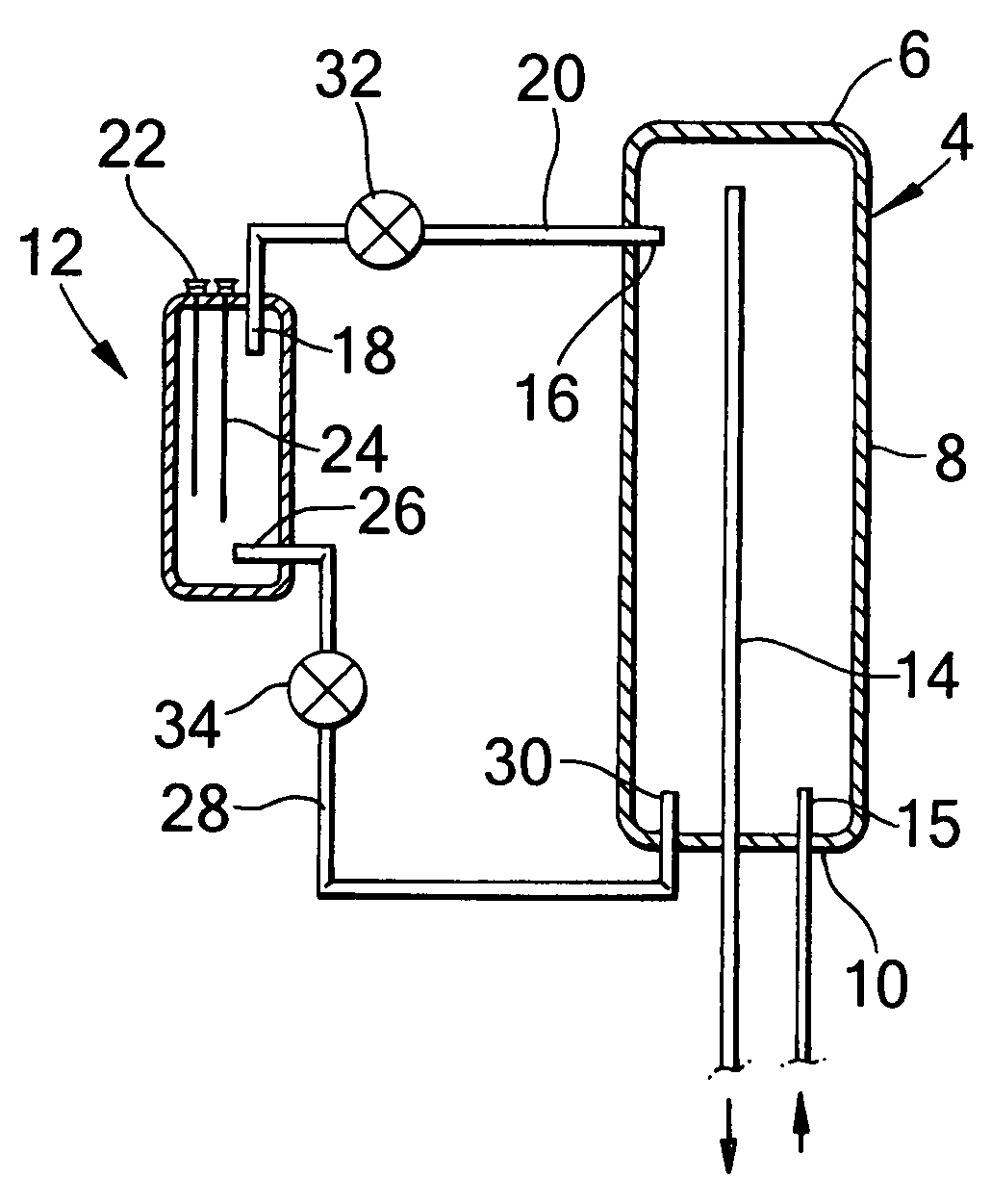

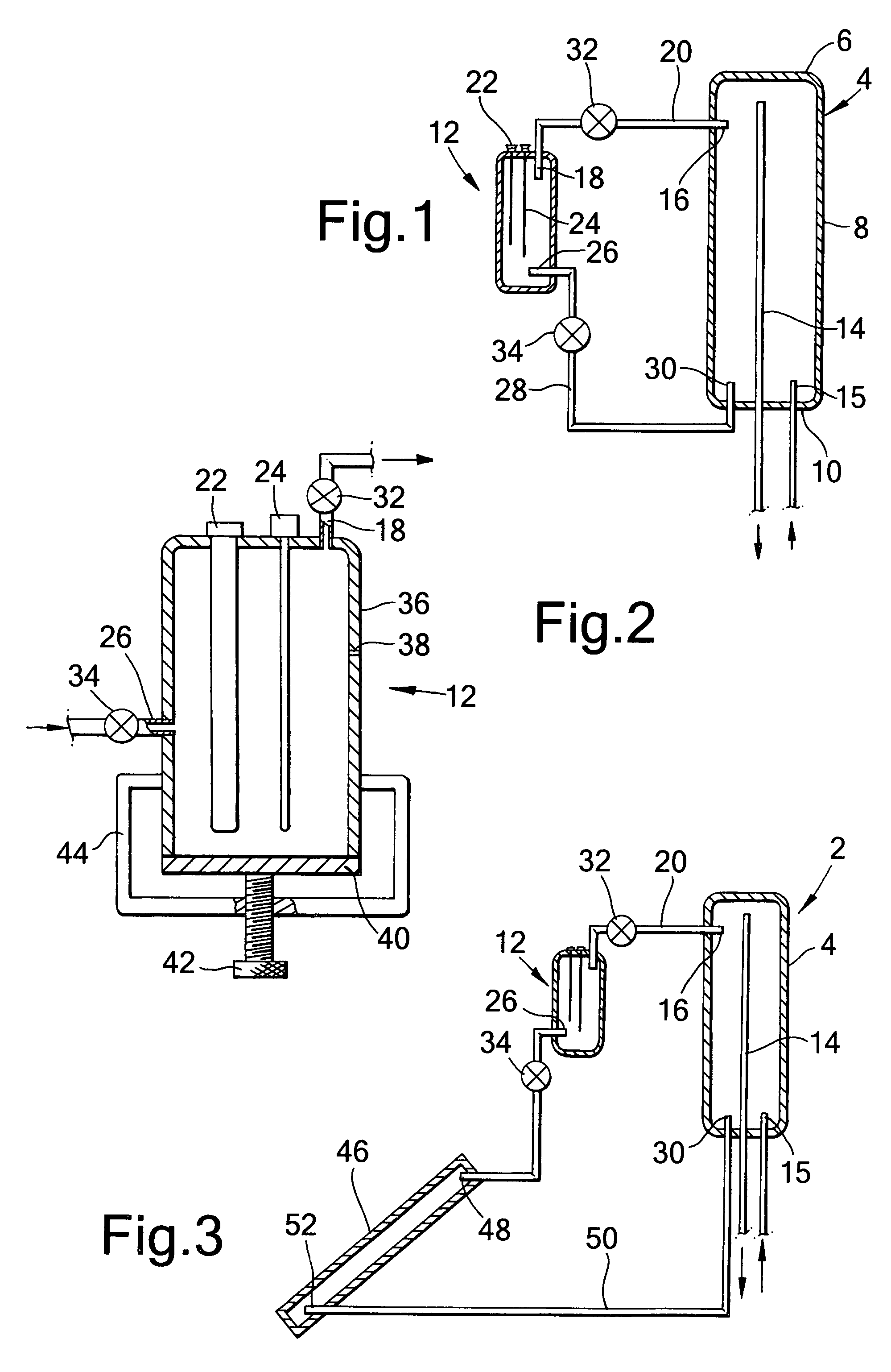

Heat exchanger having a counterflow evaporator

An evaporator including a lower drum, an upper drum, and at least one tube extending between the lower drum and the upper drum. The plurality of tubes have fluid passageways therein extending from the lower drum to the upper drum. A duct is provided having a heating gas passageway provided therein. The at least one tube extends through the heating gas passageway. The fluid passageways define an overall flow path from the lower drum to the upper drum extending in a direction substantially counter-current to an overall flow path defined by the heating gas passageway extending from a gas inlet of the heating gas passageway to a gas outlet thereof.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

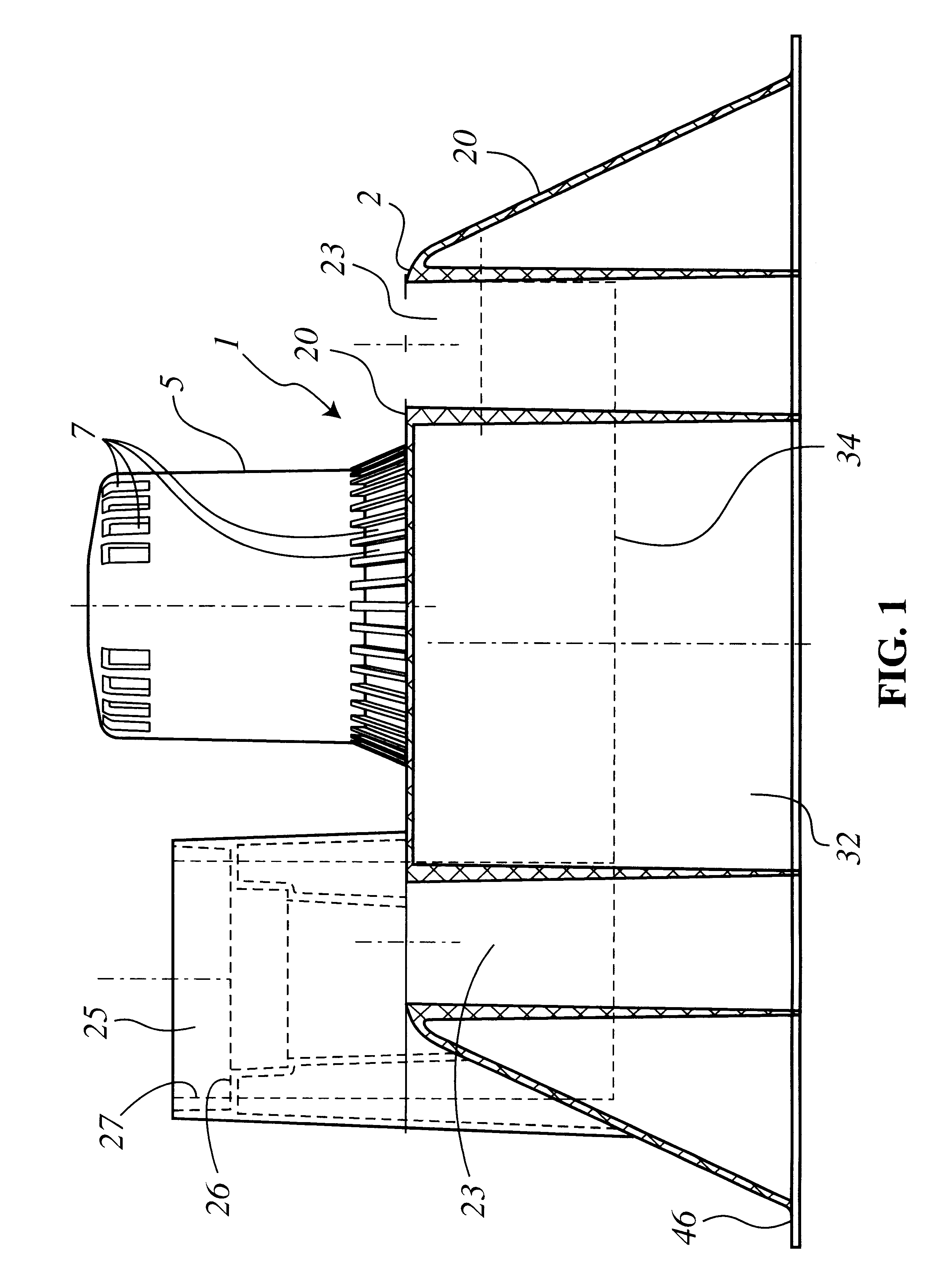

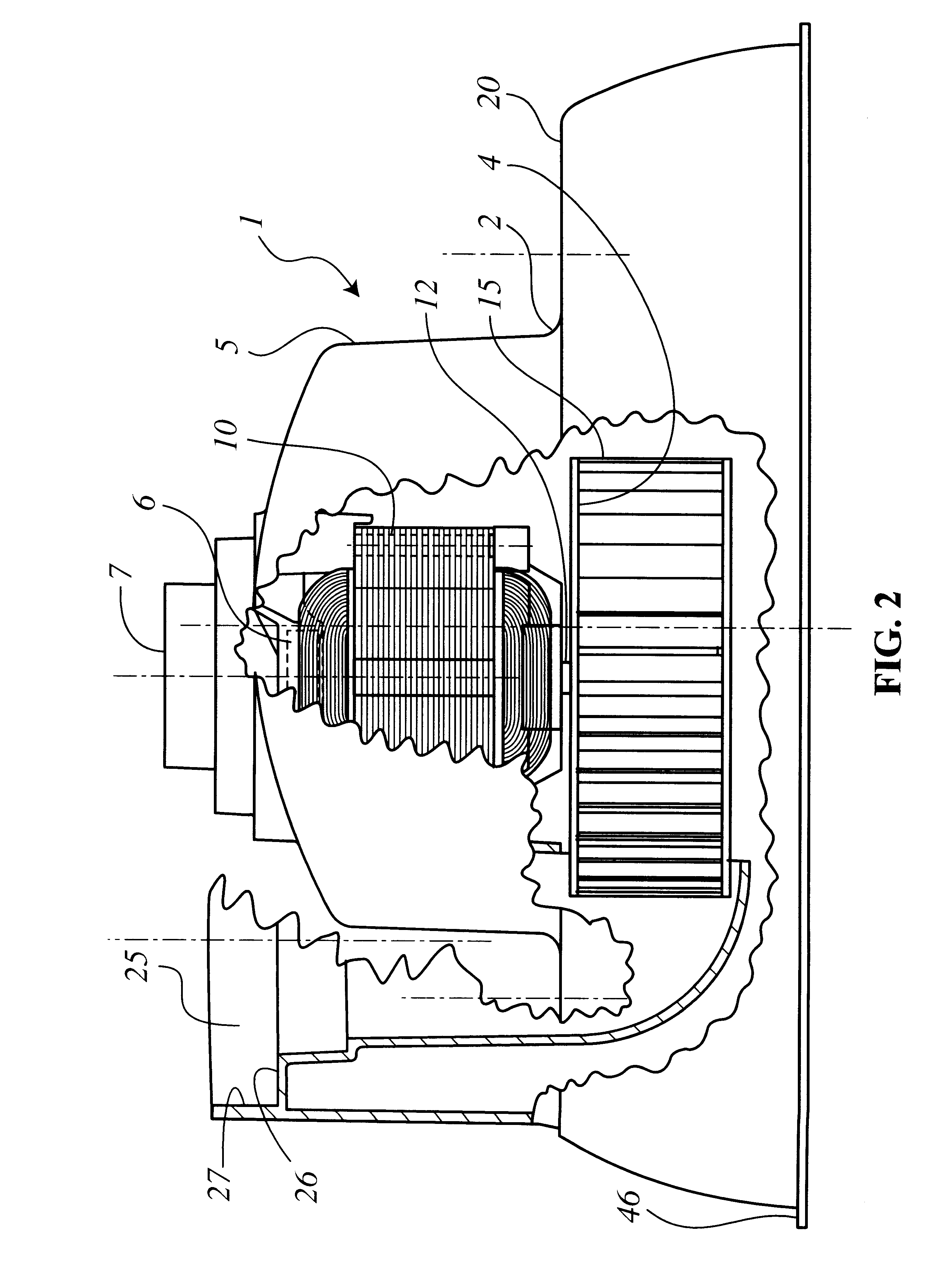

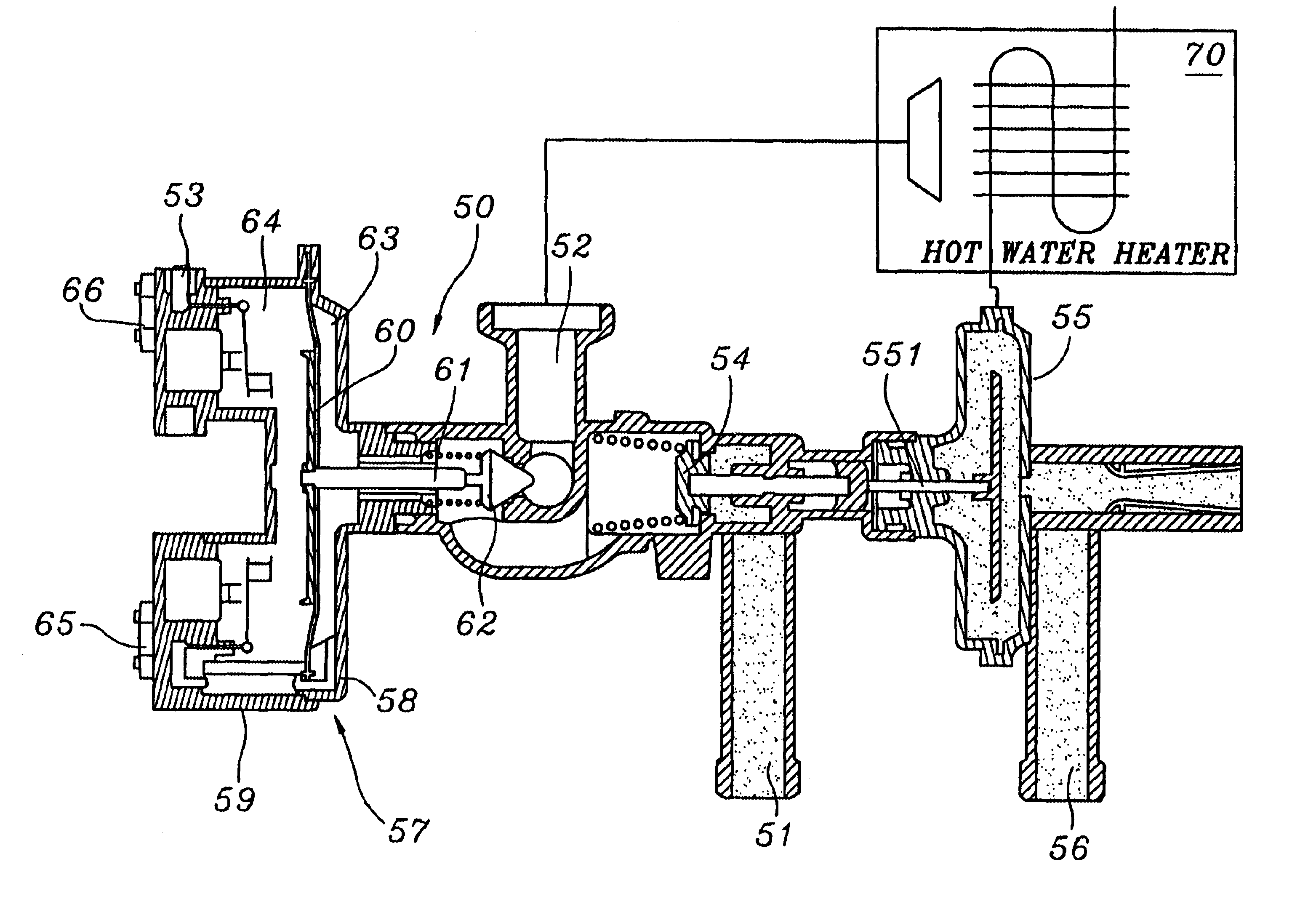

Vehicle supplemental heating system

A preferred embodiment supplemental heating system is fluidly connectable to a vehicle cooling system and includes a liquid heat generator operable for heating a cooling fluid delivered to the supplemental heating system from the vehicle's cooling system. The liquid heat generator includes a discharge passage connectable to a heater core of the vehicle and a inlet passage connectable to the vehicle's cooling system. The supplemental heating system further includes a control valve having an inlet connectable to an exit passage of a heater core of the vehicle, a discharge passage fluidly connected to the liquid heat generator, and a second discharge passage connectable to the vehicle's cooling system. The control valve is operable for controlling the proportion of cooling fluid exiting the heater core that is returned to the vehicle's cooling system and recirculated back to the liquid heat generator.

Owner:WEBASTO AG

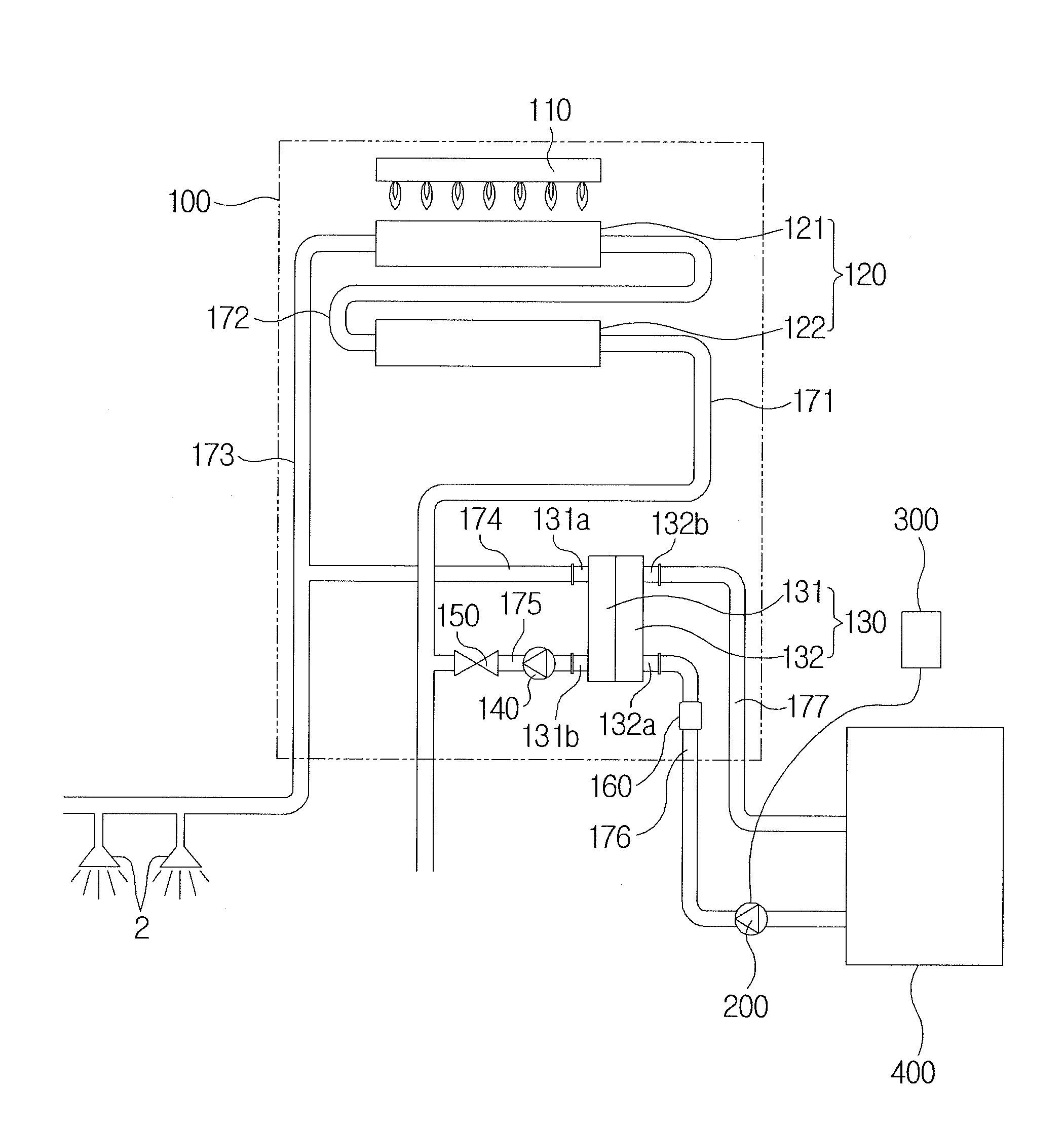

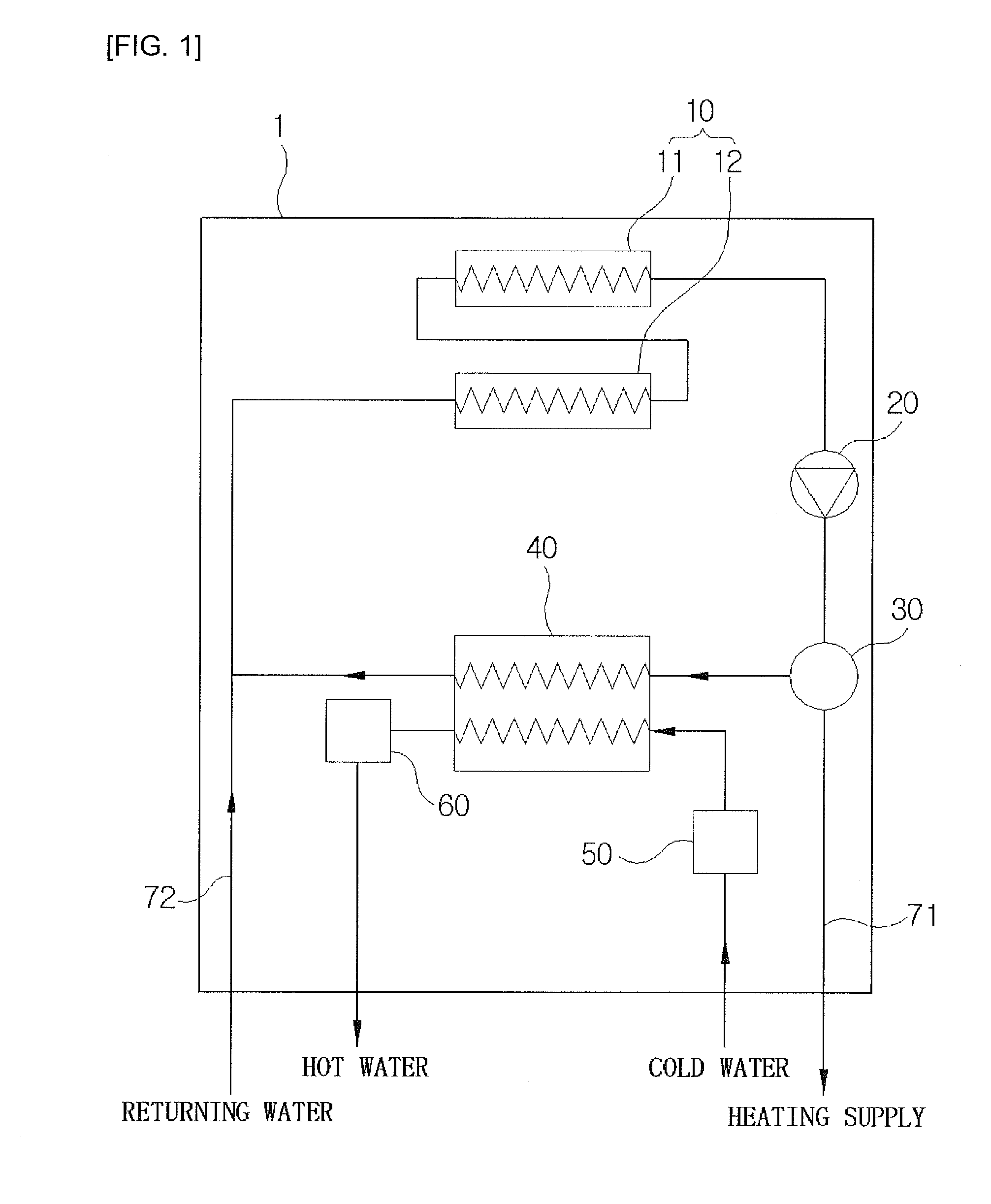

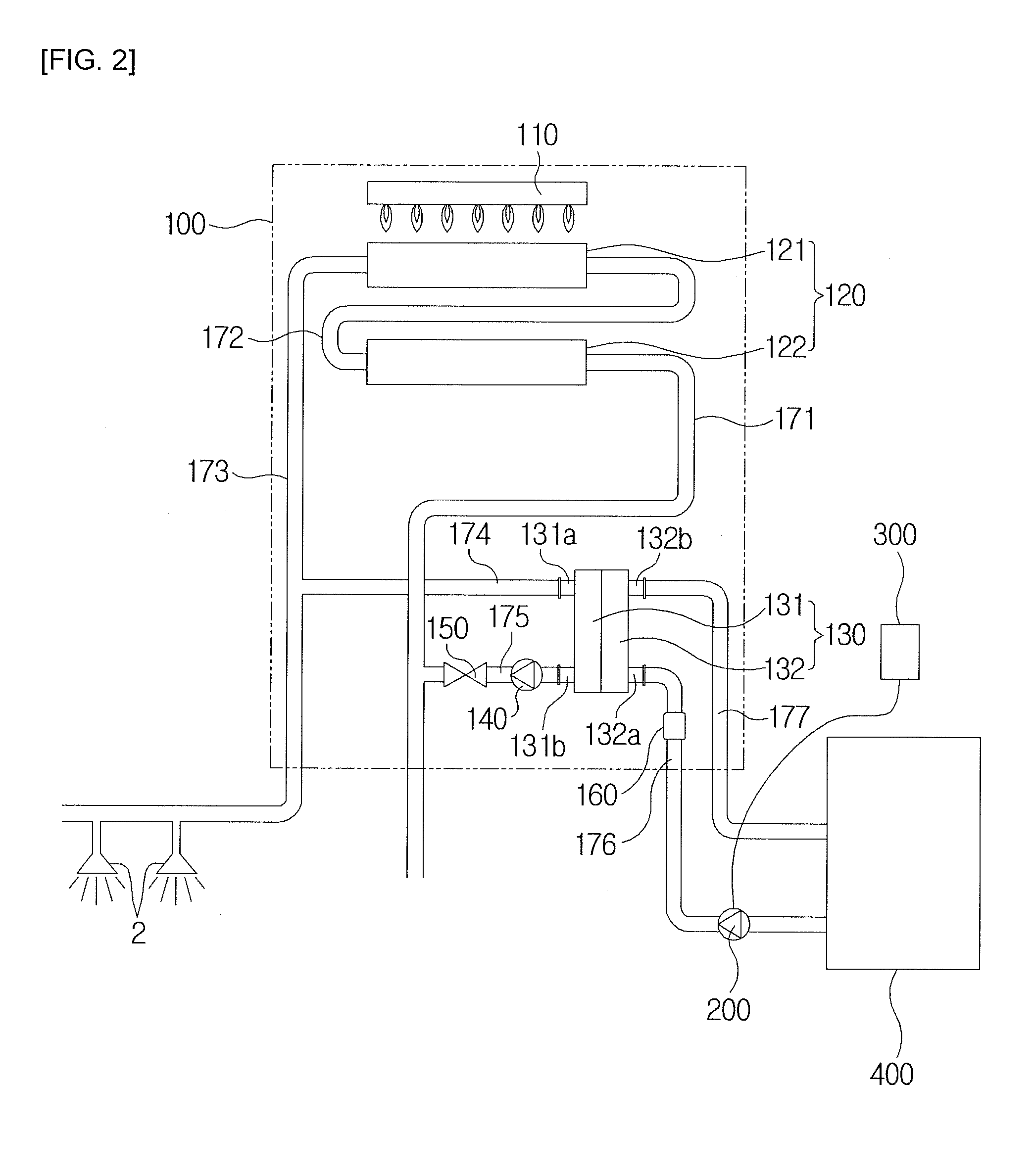

Hot water-centered combined hot water and heating boiler

The objective of the present invention is to provide a hot water-centered hot water and heating combination boiler, in which heat exchange for a hot water supply is performed in a main heat exchanger and heat exchange for a heating water supply is performed in an auxiliary heat exchanger so that the hot water supply can be accelerated, energy can be saved, and the temperature of the hot water can be controlled with ease. To achieve the abovementioned objective, the boiler of the present invention includes: a cold water inflow tube through which cold water flows in; a main heat exchanger which heats the cold water flowing in through the cold water inflow tube by using the combustion heat of a burner; a hot water discharge tube which discharges the hot water heated in the main heat exchanger; an auxiliary heat exchanger which supplies heating water during a heating mode, in which heating consumption place, and causes heat exchange to occur between the heated water in the main heat exchanger and the lowered temperature returning water, in which the heating consumption place; and a control part which controls the combustion of the burner during a hot water mode and heating mode.

Owner:KYUNGDONG NAVIEN

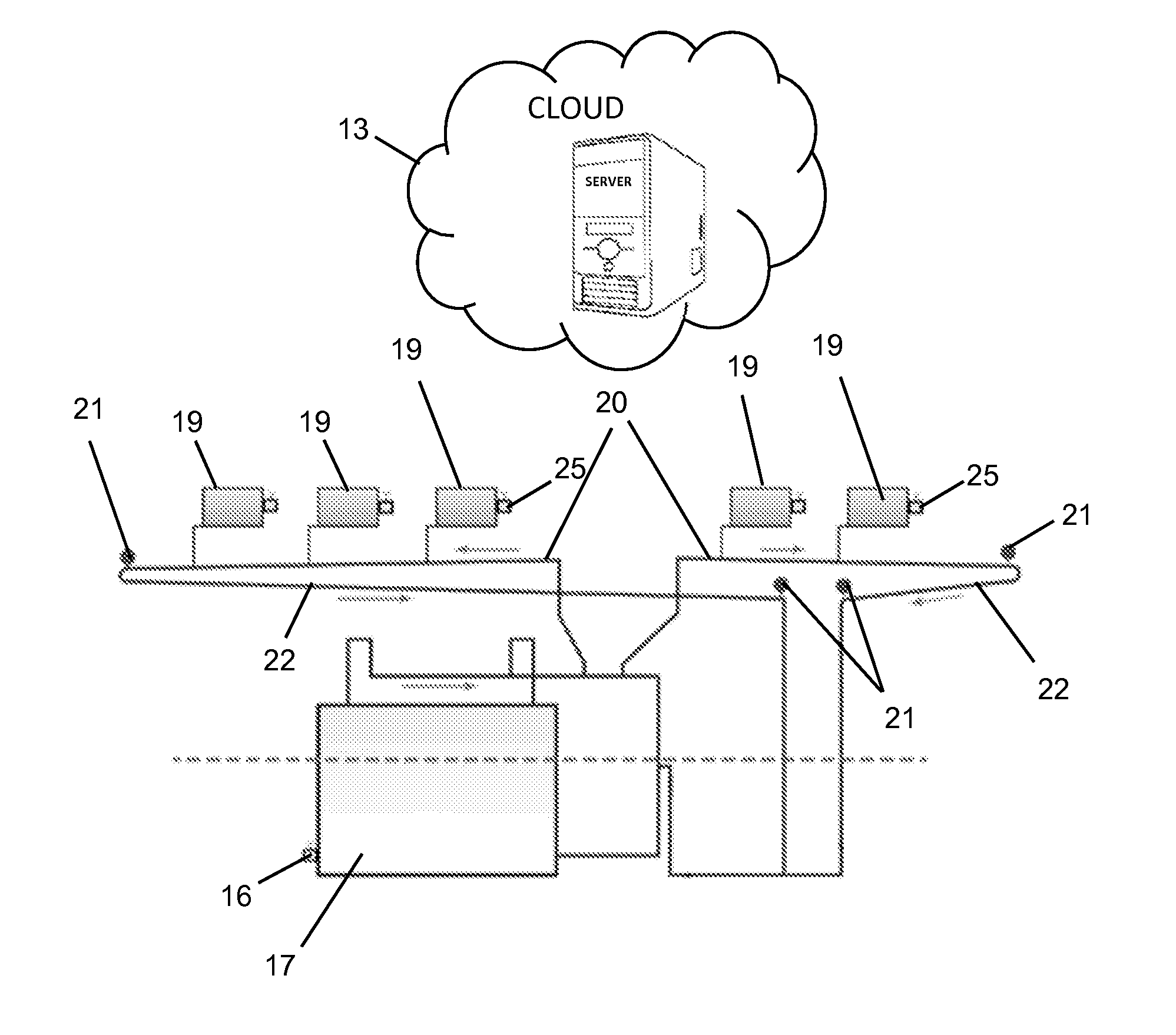

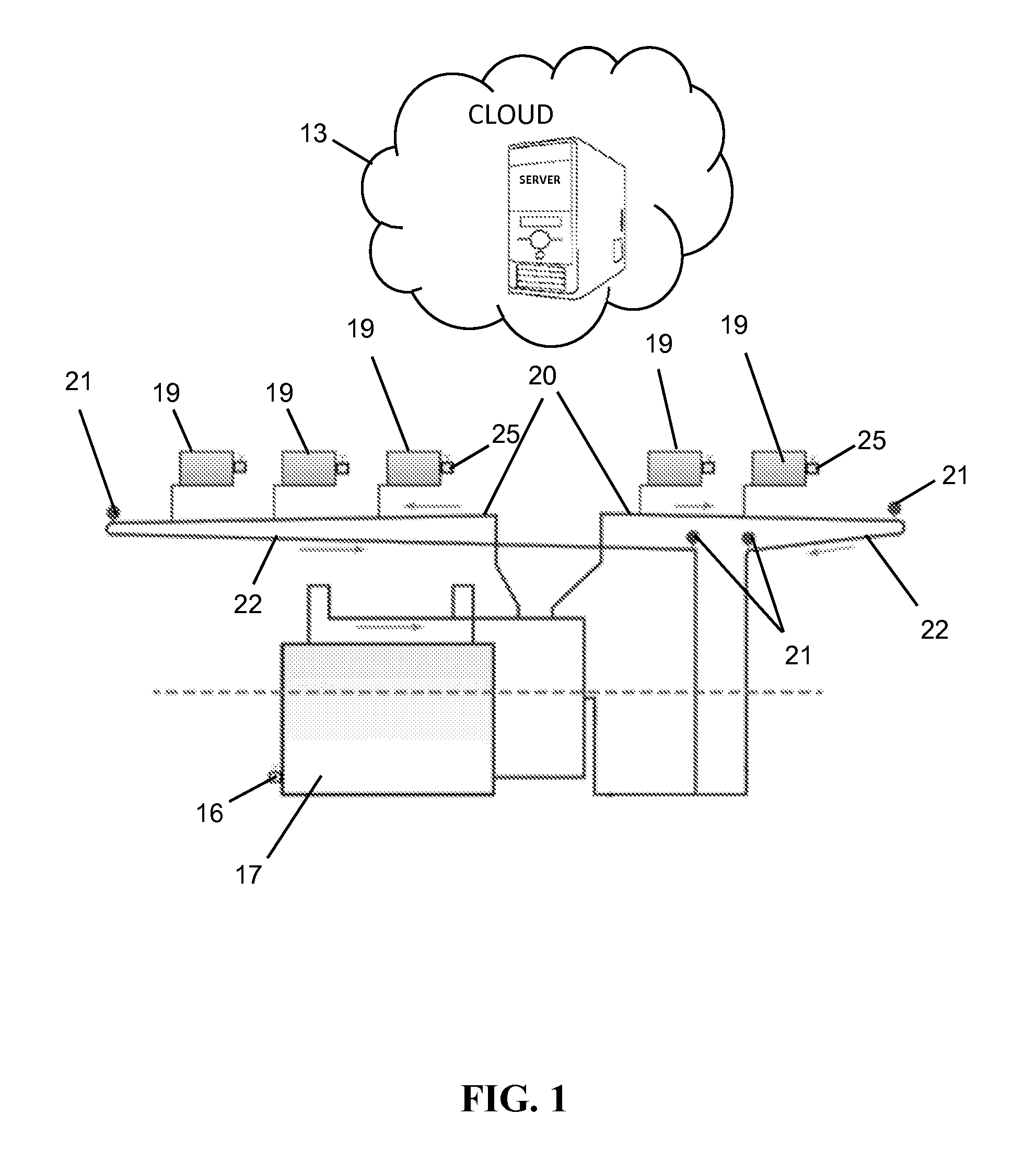

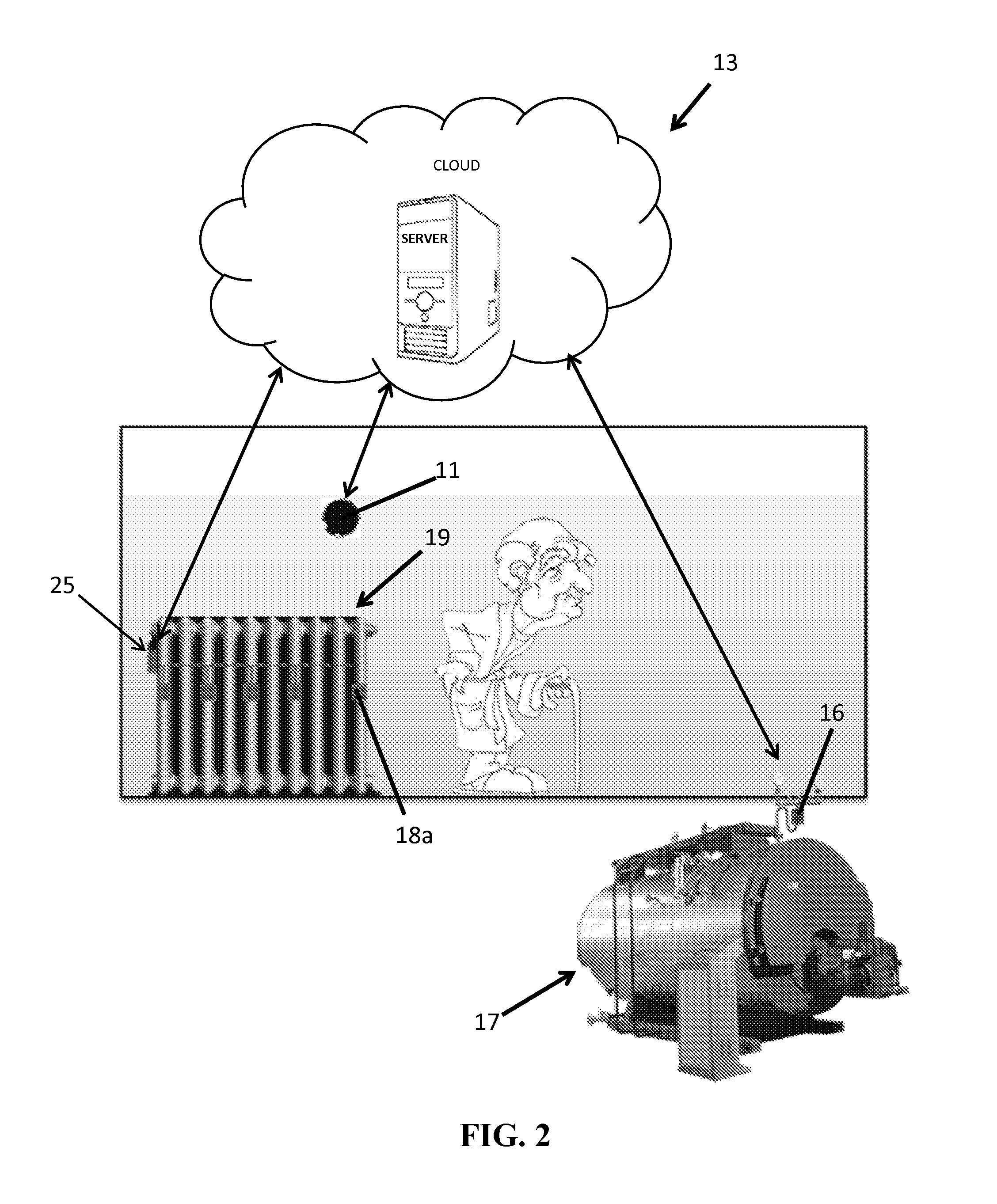

Systems and methods for controlling conditioned fluid systems in a built environment

ActiveUS20150323200A1Steam generation heating methodsHot-air central heatingRoom temperatureMultiple sensor

The systems and methods of this disclosure control the flow rate of conditioned fluid at thermal distribution devices and at a conditioned fluid source that supplies conditioned fluid to the thermal distribution devices. The systems include multiple thermal distribution devices disposed throughout multiple rooms of a building, a fluid flow control device in fluid communication with each of the thermal distribution devices, multiple sensors disposed on each of the thermal distribution devices, a room temperature sensor disposed in each of the rooms, a first controller coupled to each of the fluid flow control devices, and a second controller coupled to a source of conditioned fluid. The first controllers control respective fluid flow control devices based on the measurement data obtained from the sensors and the room temperature sensors and a second controller controls the conditioned fluid source based on the demand for conditioned fluid by the thermal distribution devices.

Owner:GLUCK JERRITT L

Method for cleaning combustion devices

InactiveUS6935281B2Short timeProcess can be minimizedLinings repairBoiler cleaning apparatusCombustionSlag

An on-line method and a device for cleaning of contamination such as caking or slag deposits from surfaces in vessels and combustion installations by means of blasting technology. An explosive gas mixture is made to detonate in the proximity of the deposits and thereby clean the deposits from the surfaces.

Owner:BANG & CLEAN

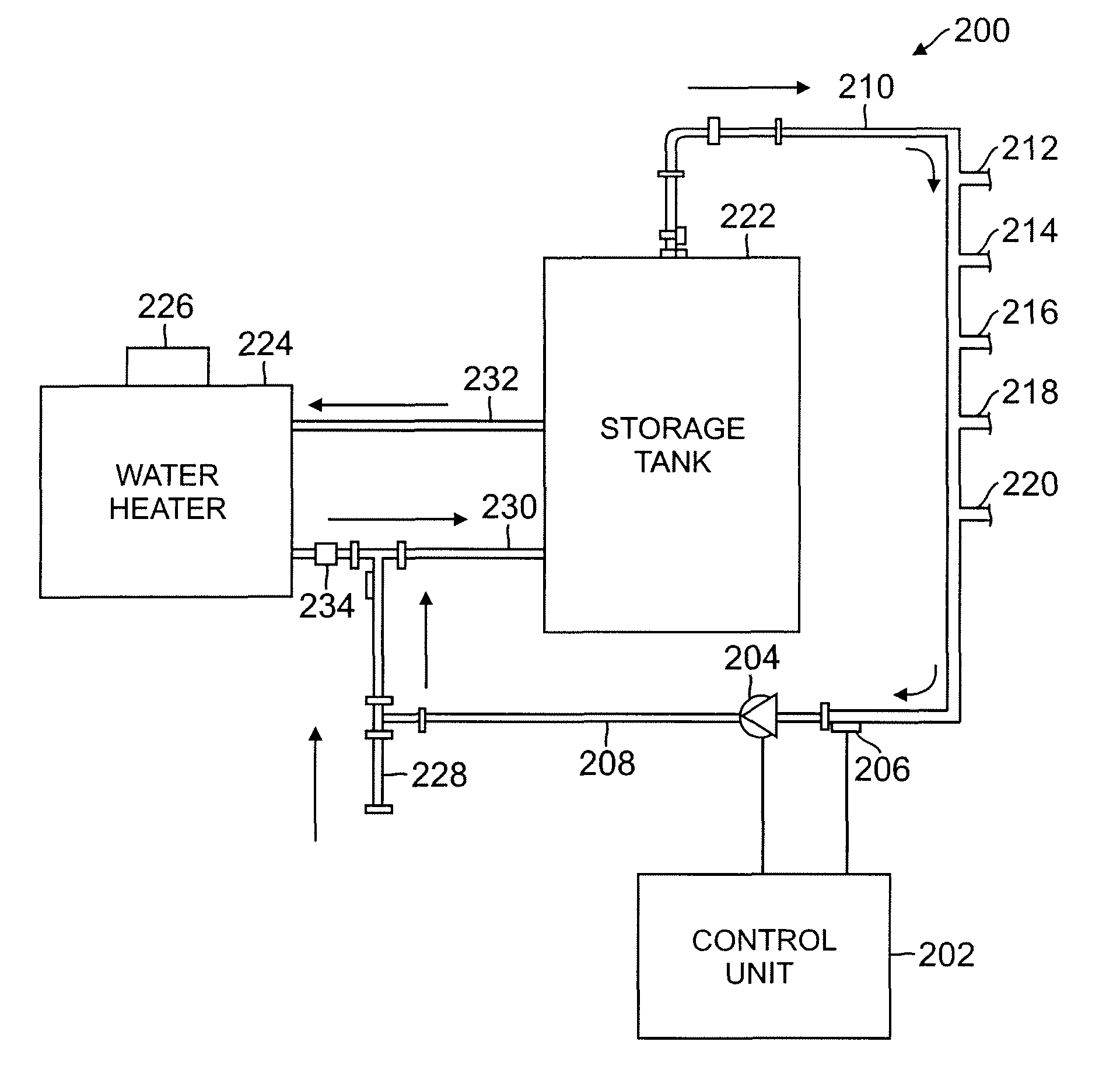

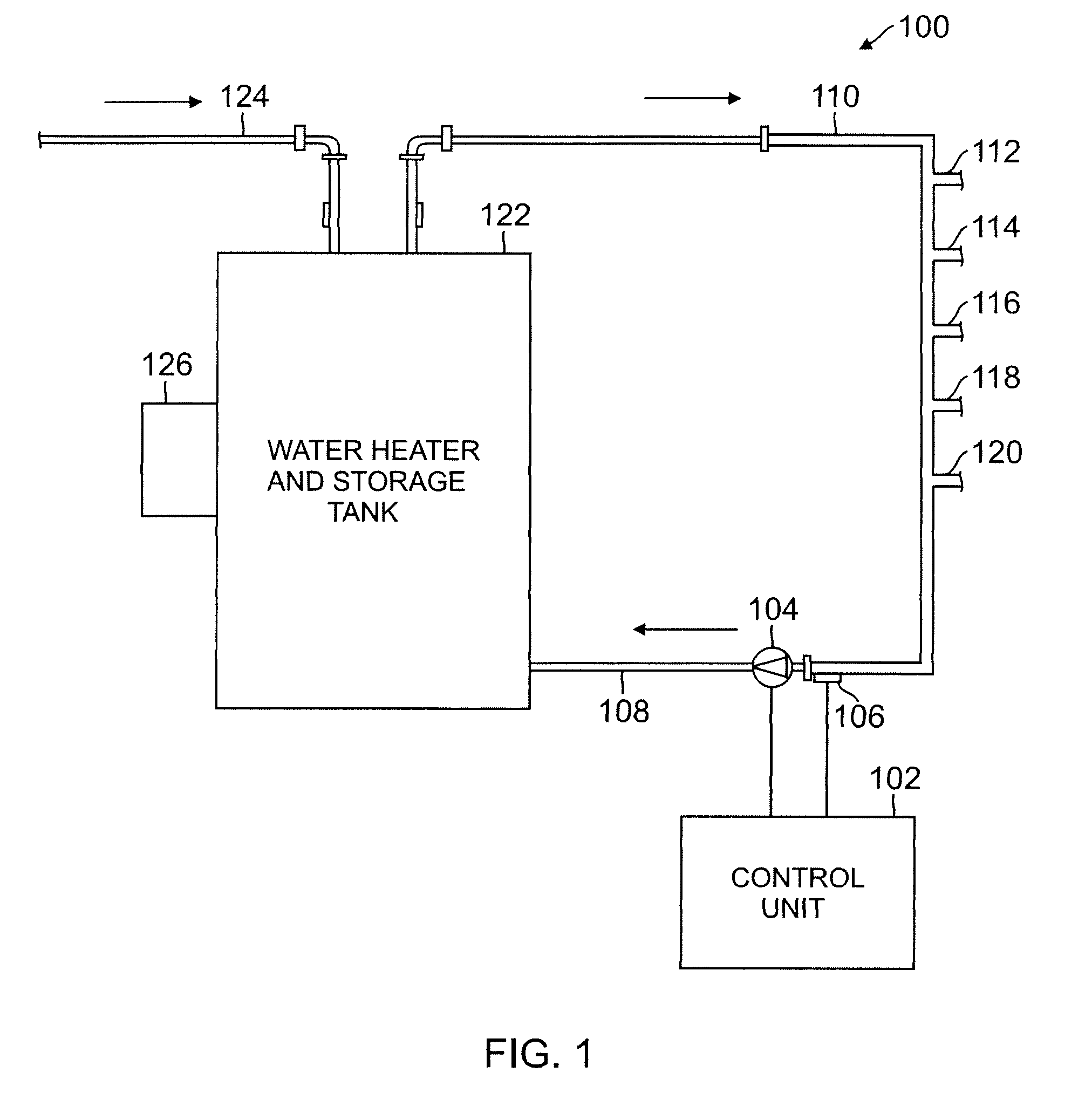

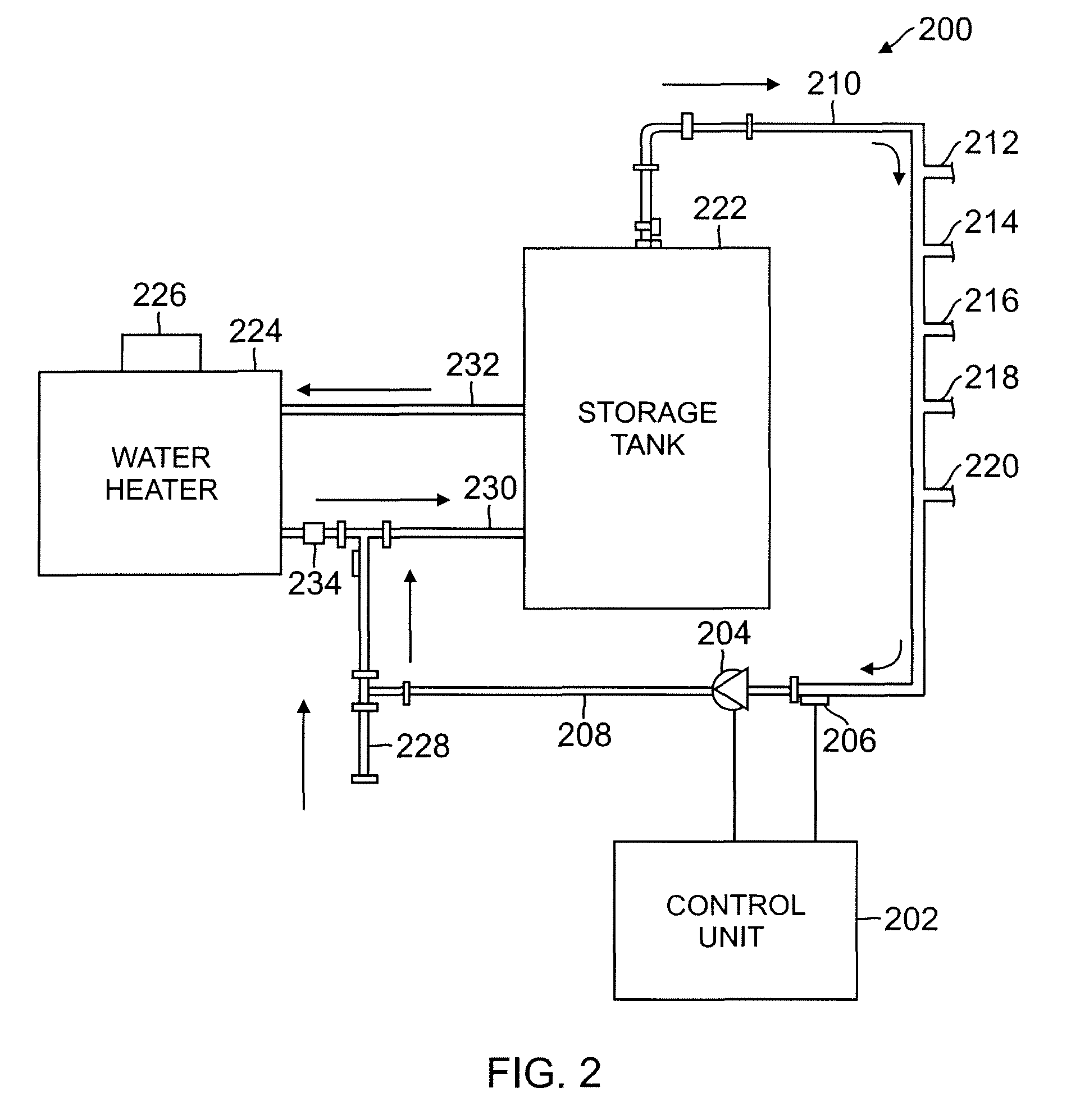

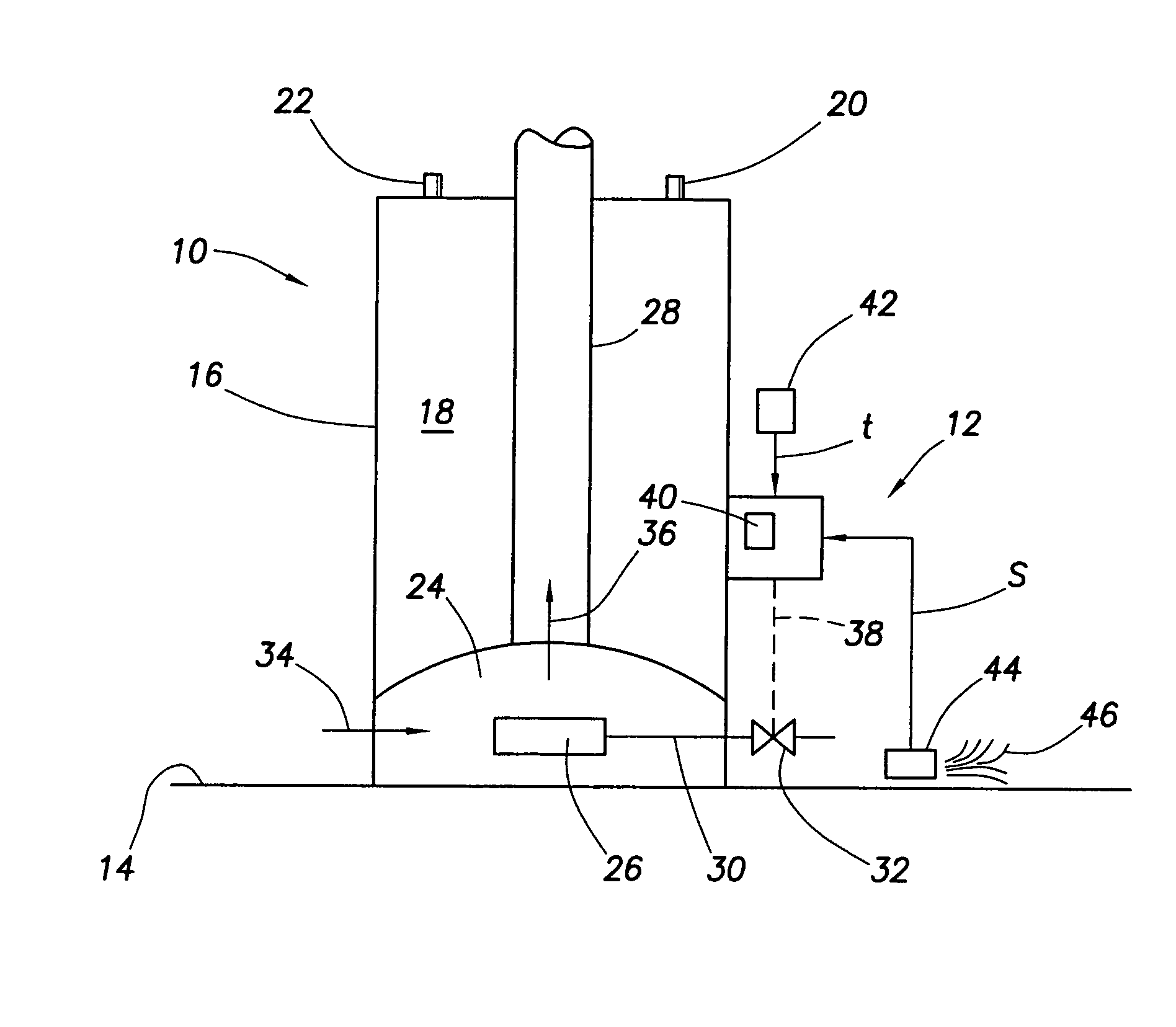

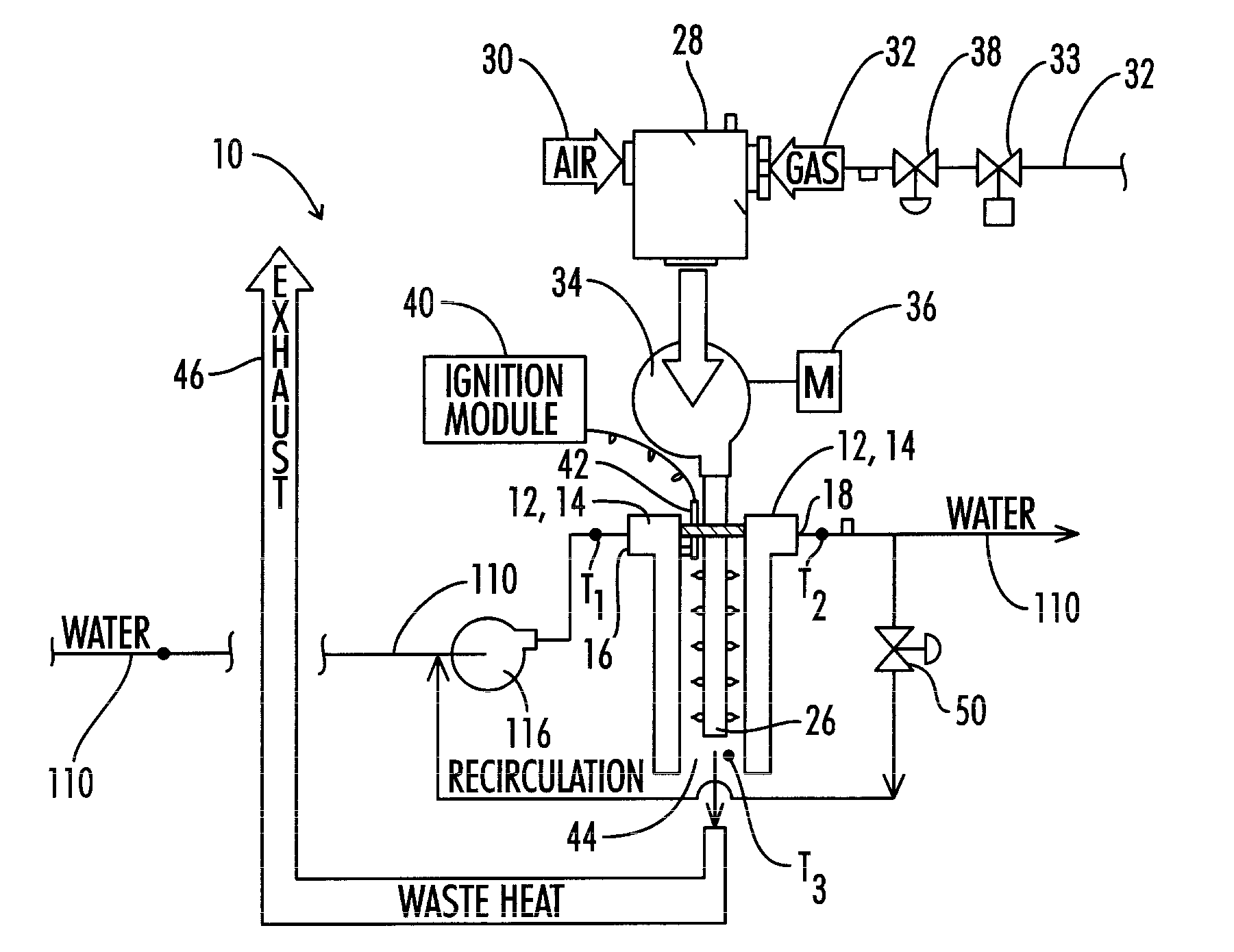

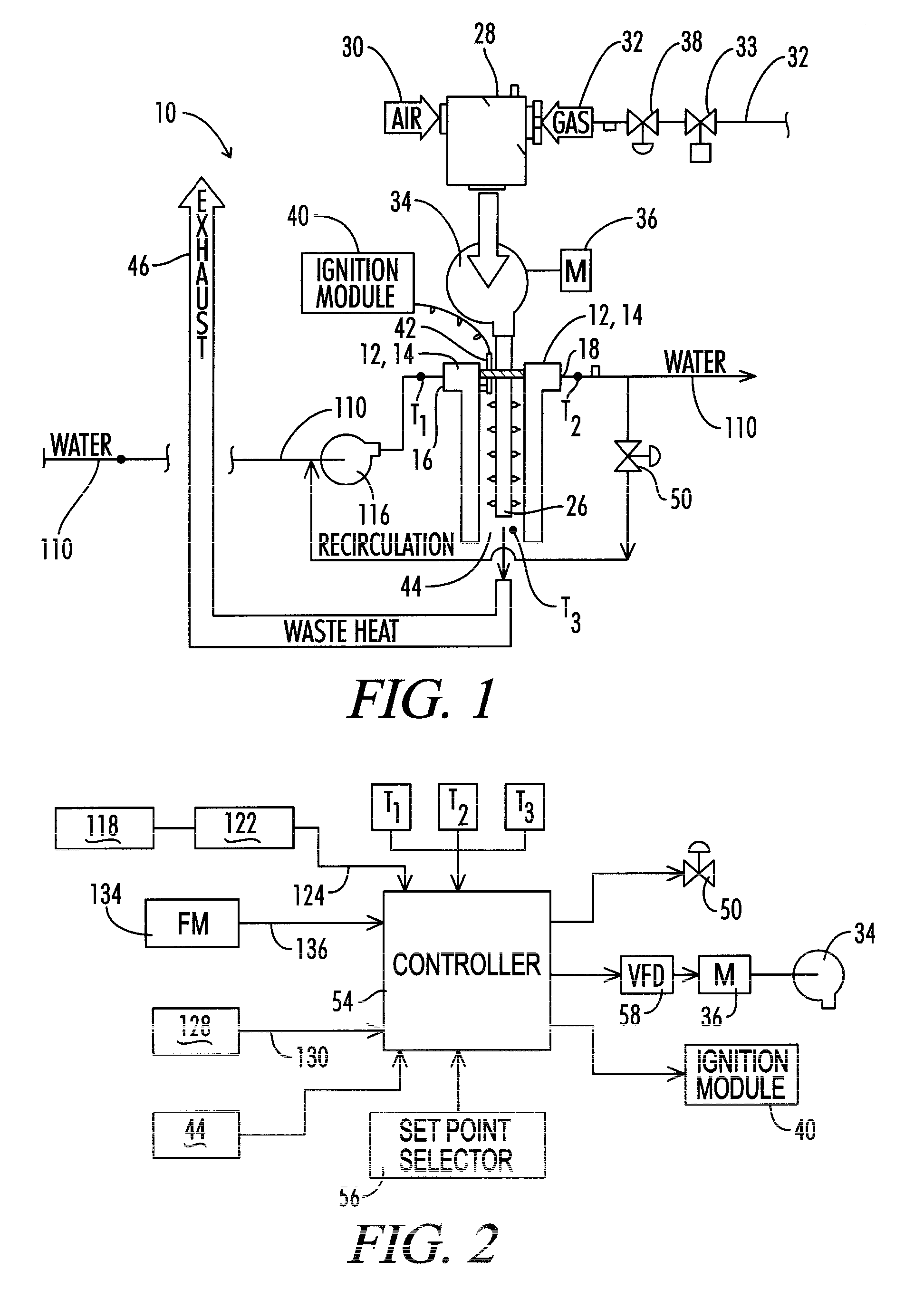

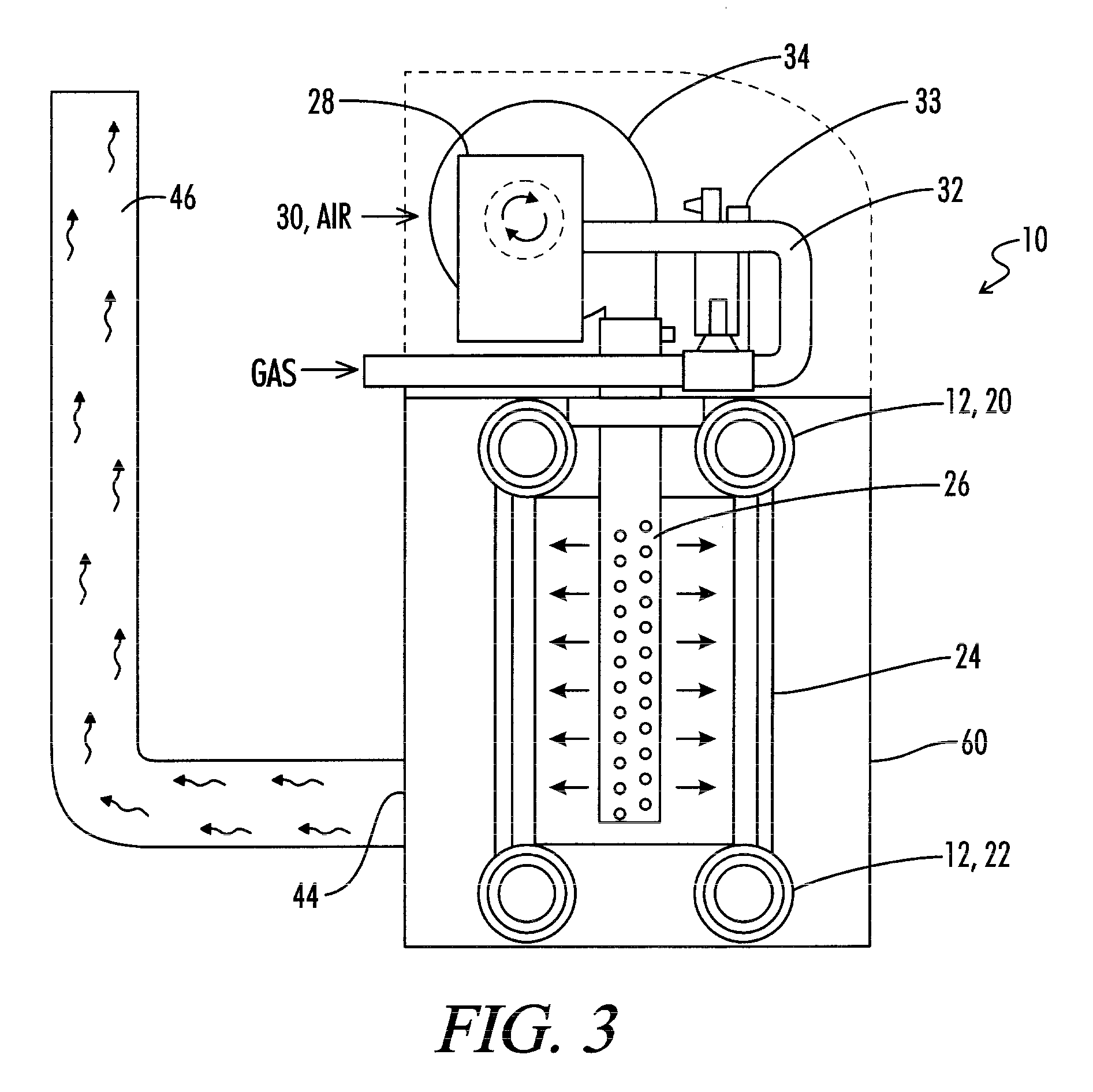

System and method for controlling a pump in a recirculating hot water system

InactiveUS8191513B2Efficient regulation technologiesMachines/enginesTemperature controlWater cycling

A system and a method for controlling a pump in a recirculating hot water system is provided. In one embodiment, the invention relates to a method for controlling a temperature of water in a recirculating hot water system including a storage tank for storing heated water, a recirculation conduit including a supply conduit for supplying the heated water to users via a plurality of outlets having a first outlet and a last outlet and a return conduit for returning an unused portion the heated water to the storage tank, a pump for circulating the heated water, the pump disposed along the return conduit, the method including measuring, at a point along the recirculation conduit, a temperature of the heated water provided from the storage tank, and controlling a speed of the pump, disposed along the return conduit, based on the measured temperature.

Owner:TDK FAMILY PARTNERSHIP

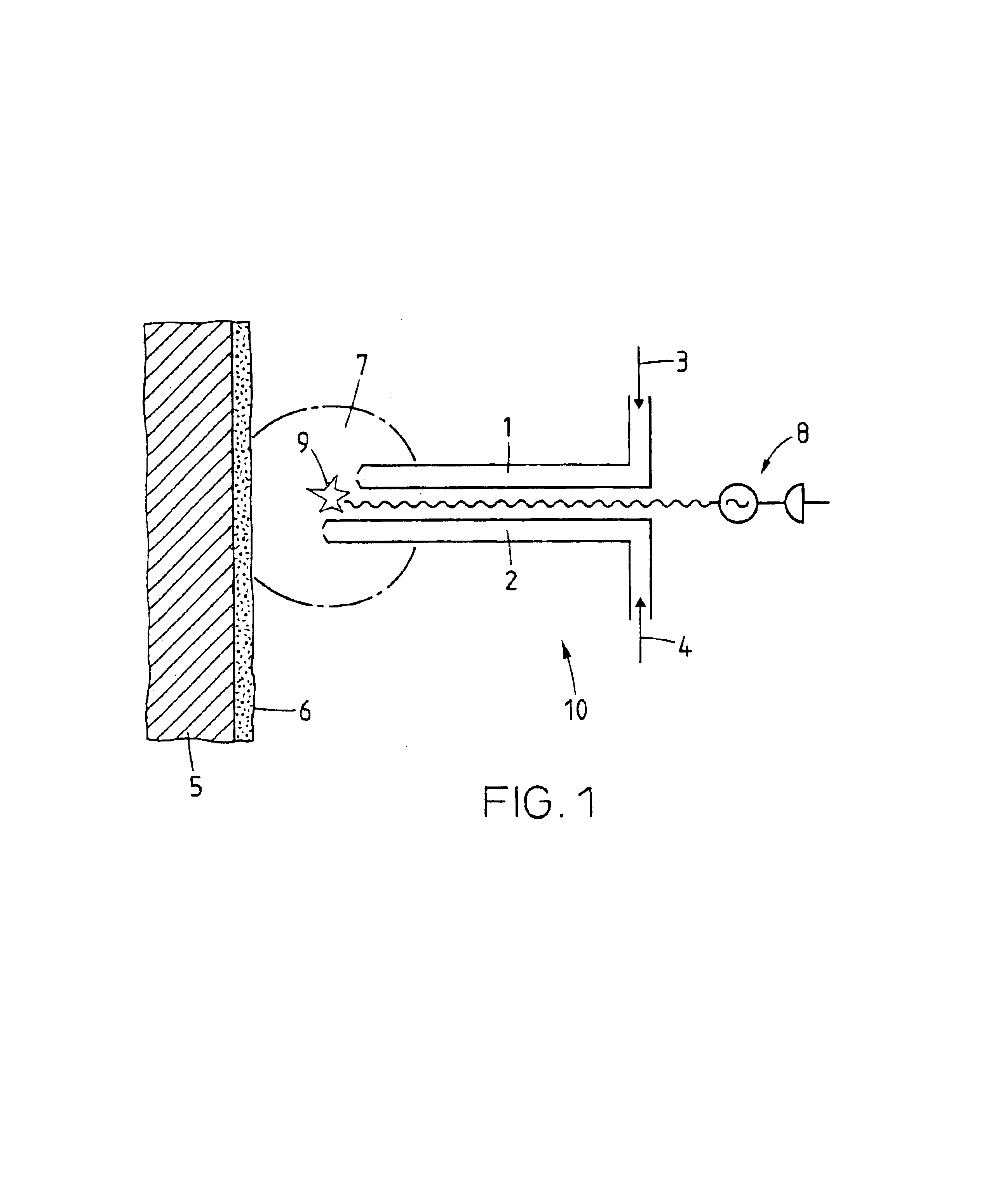

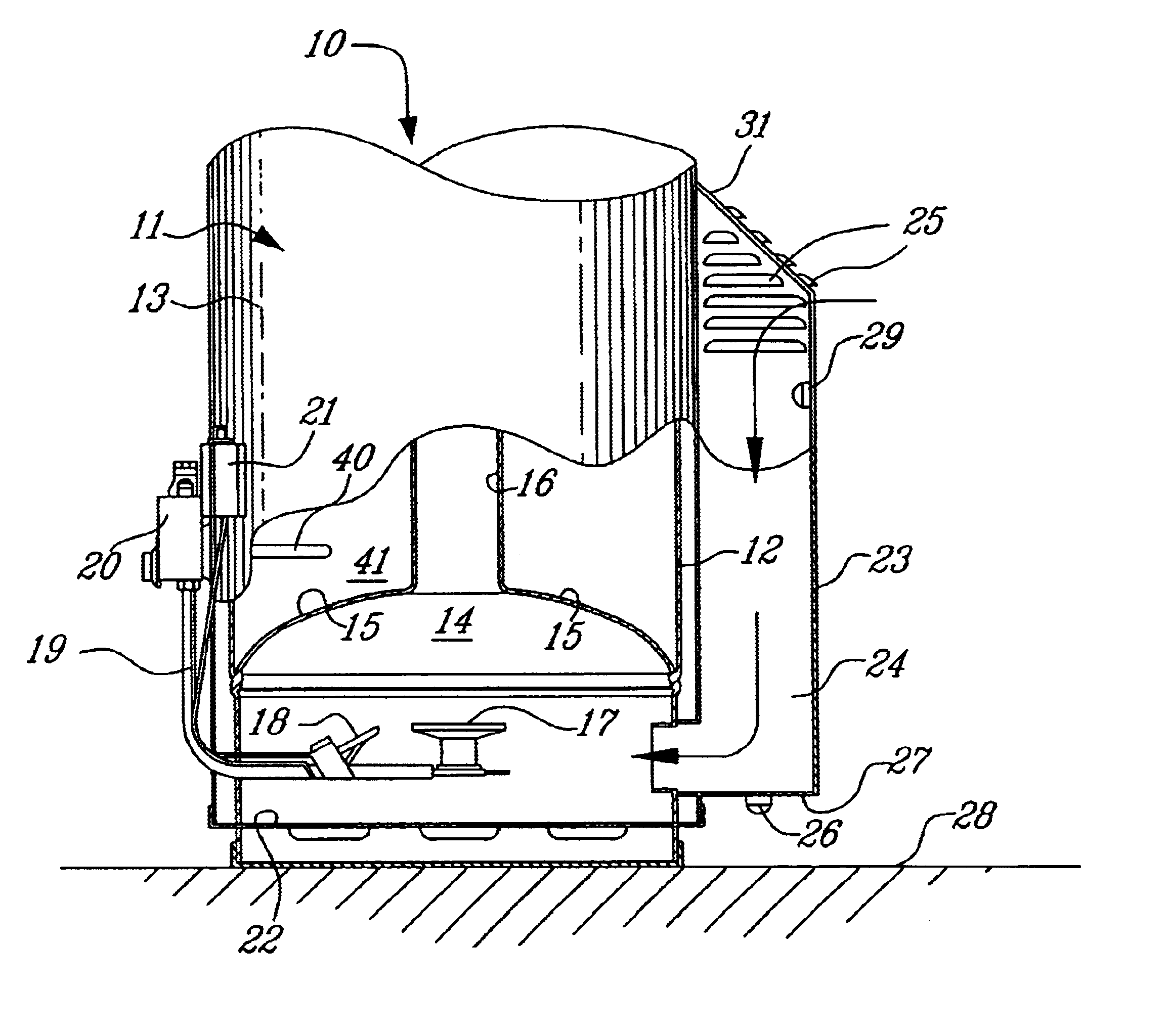

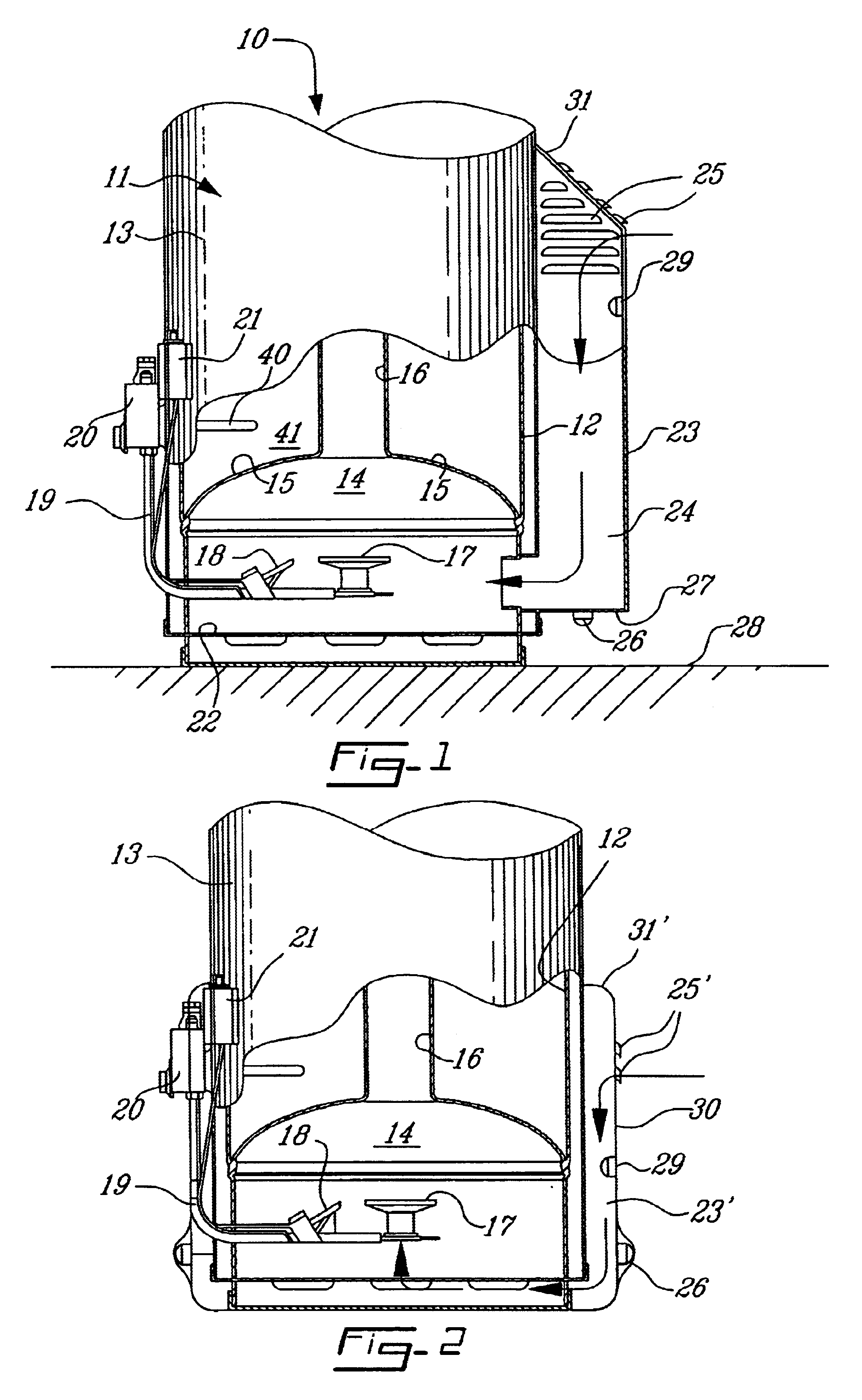

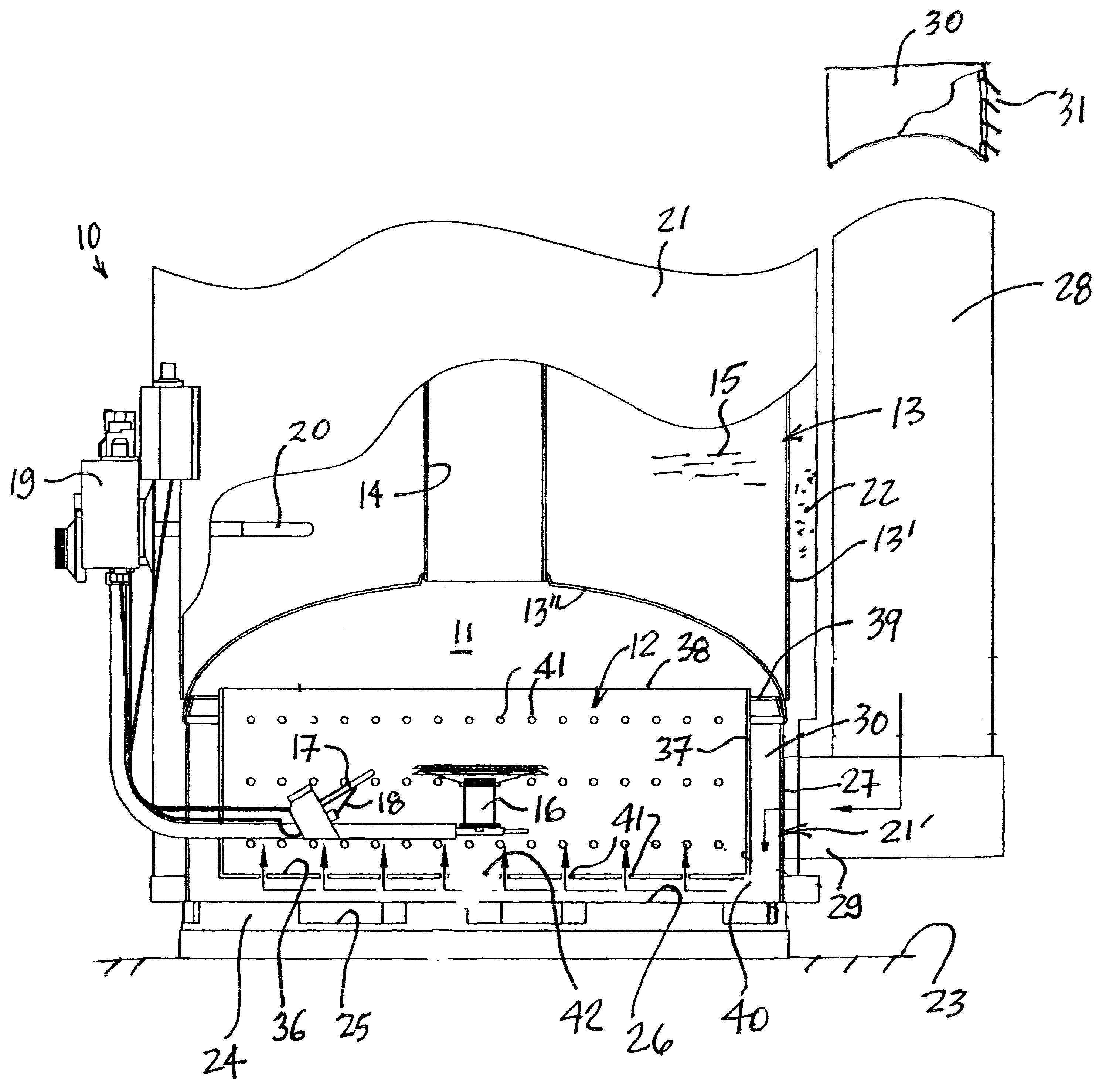

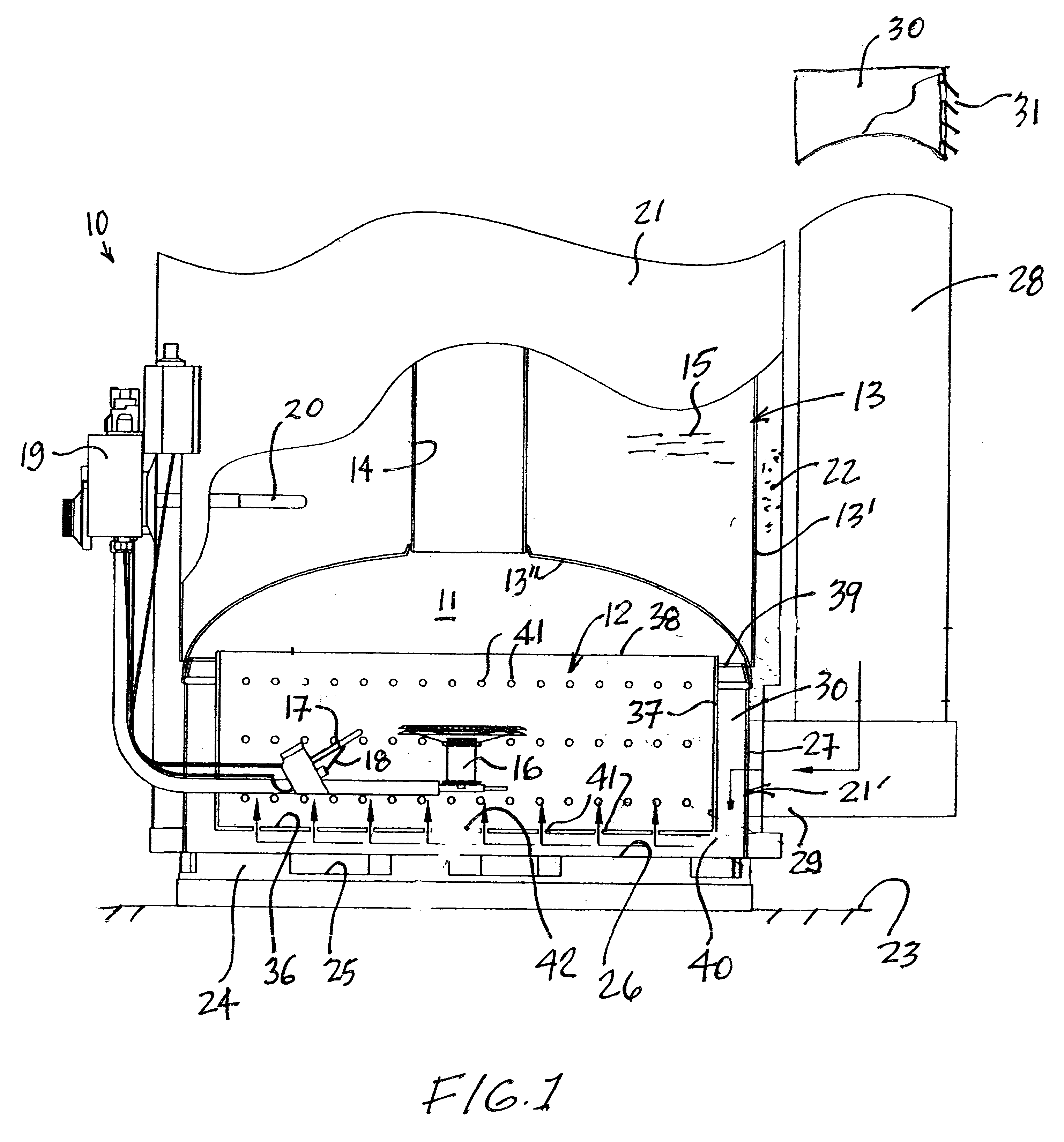

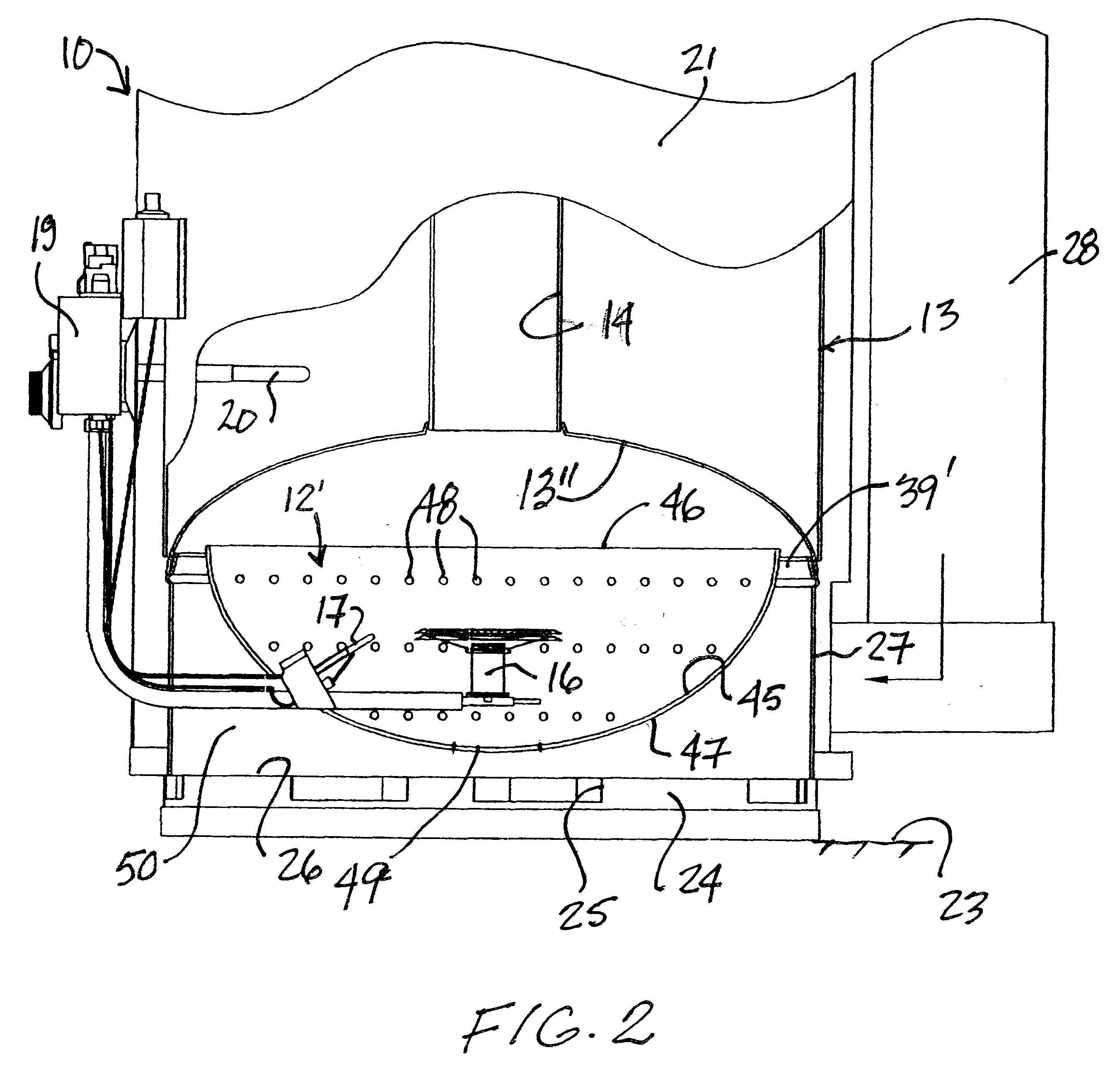

Gas-fired heaters with burners which operate without secondary air and have a substantially sealed combustion chamber

InactiveUS6019069AVelocity increasesSmall sizeDomestic stoves or rangesWater heatersCombustion chamberCombustor

A gas-fired burner apparatus includes a porous combustion surface disposed in a combustion chamber substantially sealed to prevent entry of secondary air. A subatmospheric pressure is maintained in the combustion chamber by a natural or aspirated draft. The subatmospheric pressure cooperates with an aspirating flow of fuel to the burner apparatus to provide an increased flow of primary combustion air which reduces the combustion temperature and the emission of pollutants. Alternatively, the subatmospheric pressure may be used to achieve a given flow of primary combustion air with a reduced combustion surface area. Water heater and room heater applications of the burner apparatus are illustrated.

Owner:BOWIN TECH

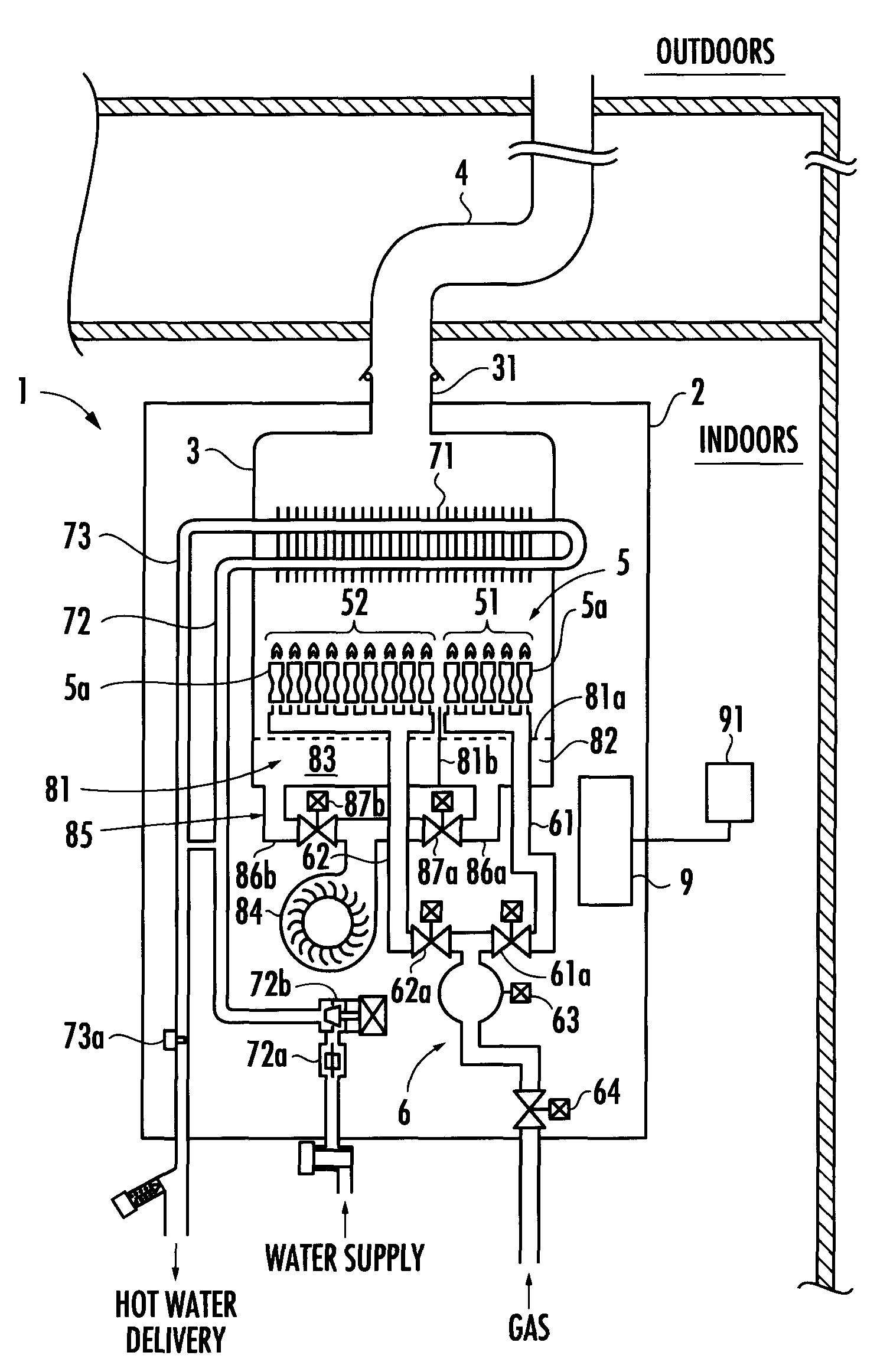

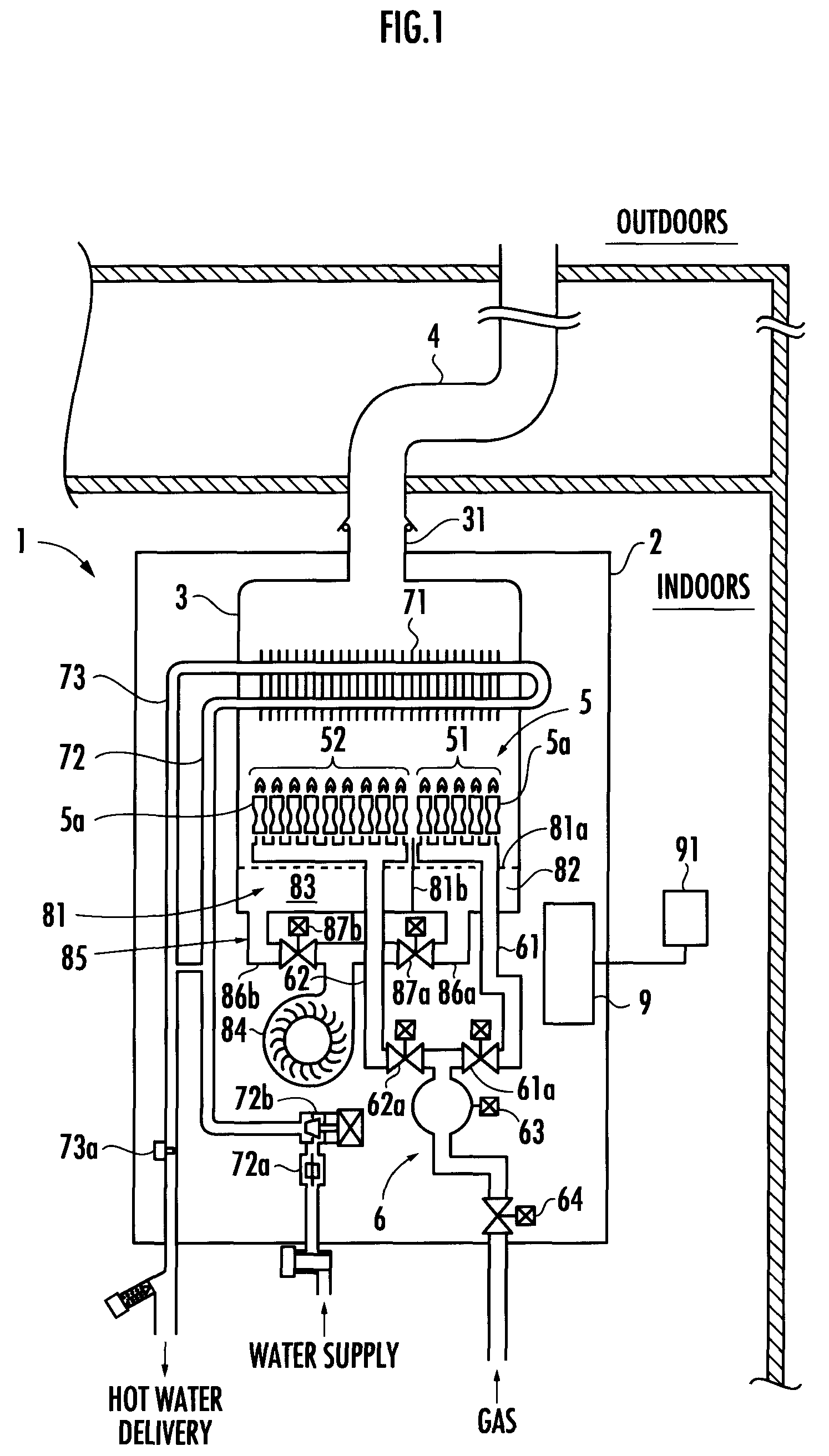

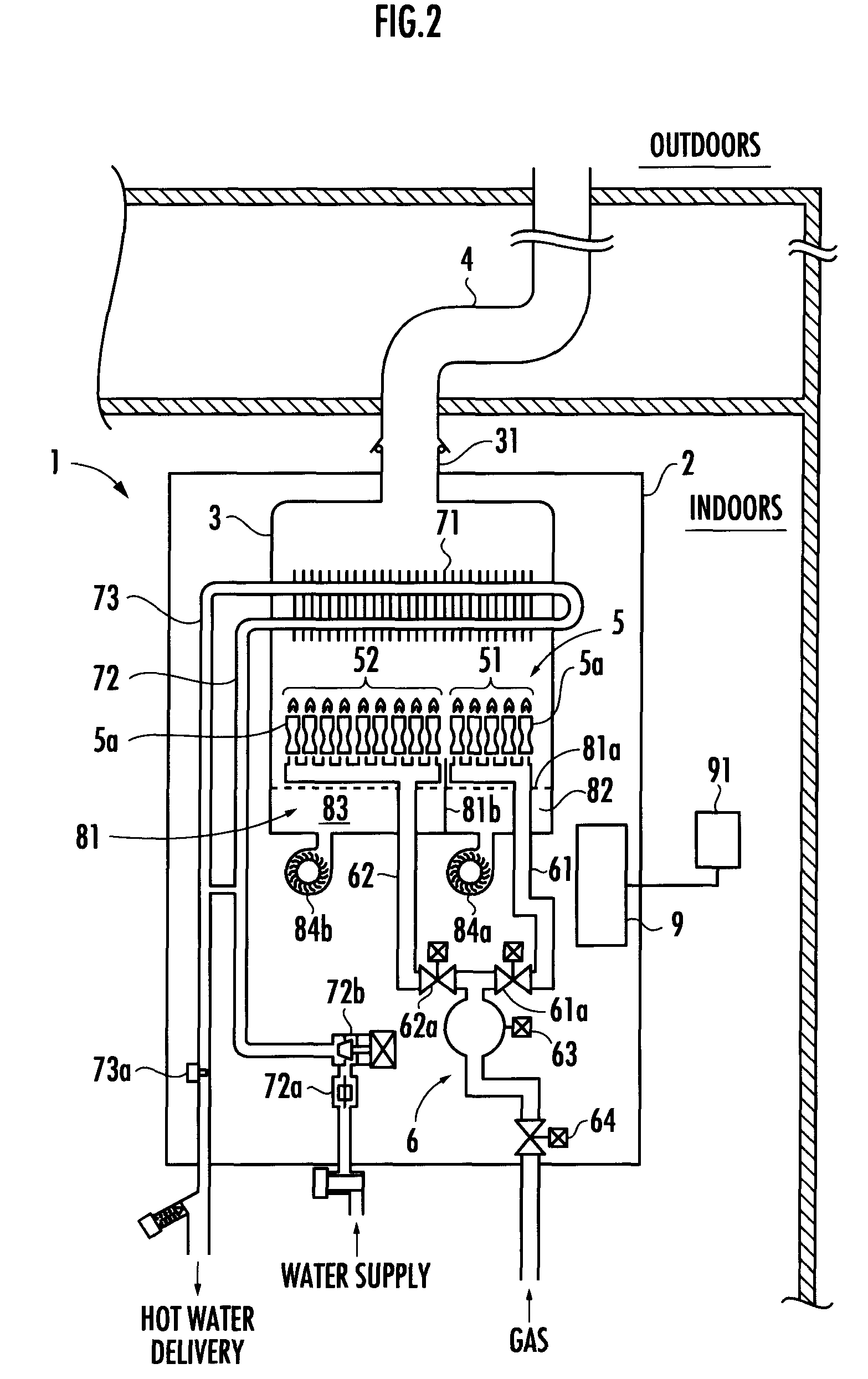

Water heater

ActiveUS8267051B2Improve heating efficiencyReduce the temperatureHeating fuelAir supply regulationCombustionCombustor

There is provided an indoor mounting water heater in which combustion exhaust gas is discharged to the outdoors via an exhaust duct, wherein a decrease in draft force caused when the number of burner groups to be burned is reduced by a capacity changeover mechanism to decrease the combustion capacity can be prevented, and the heat efficiency can be improved. An air supply chamber 81 is divided into a plurality of parts 82 and 83 corresponding to a plurality of burner groups 51 and 52. The air sent from an air supply fan 84 is supplied to only a part of the air supply chamber corresponding to a burning burner group.

Owner:RINNAI CORP

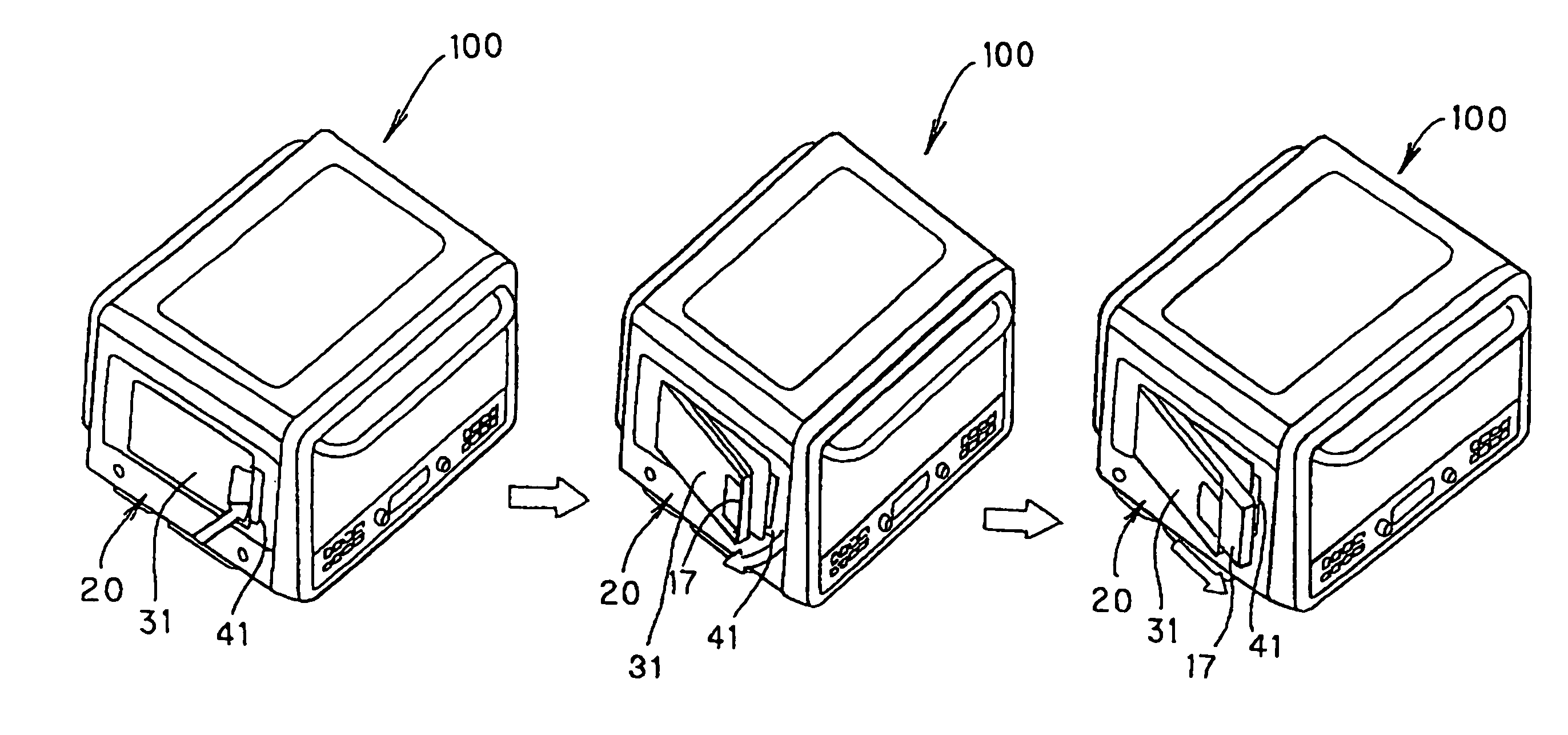

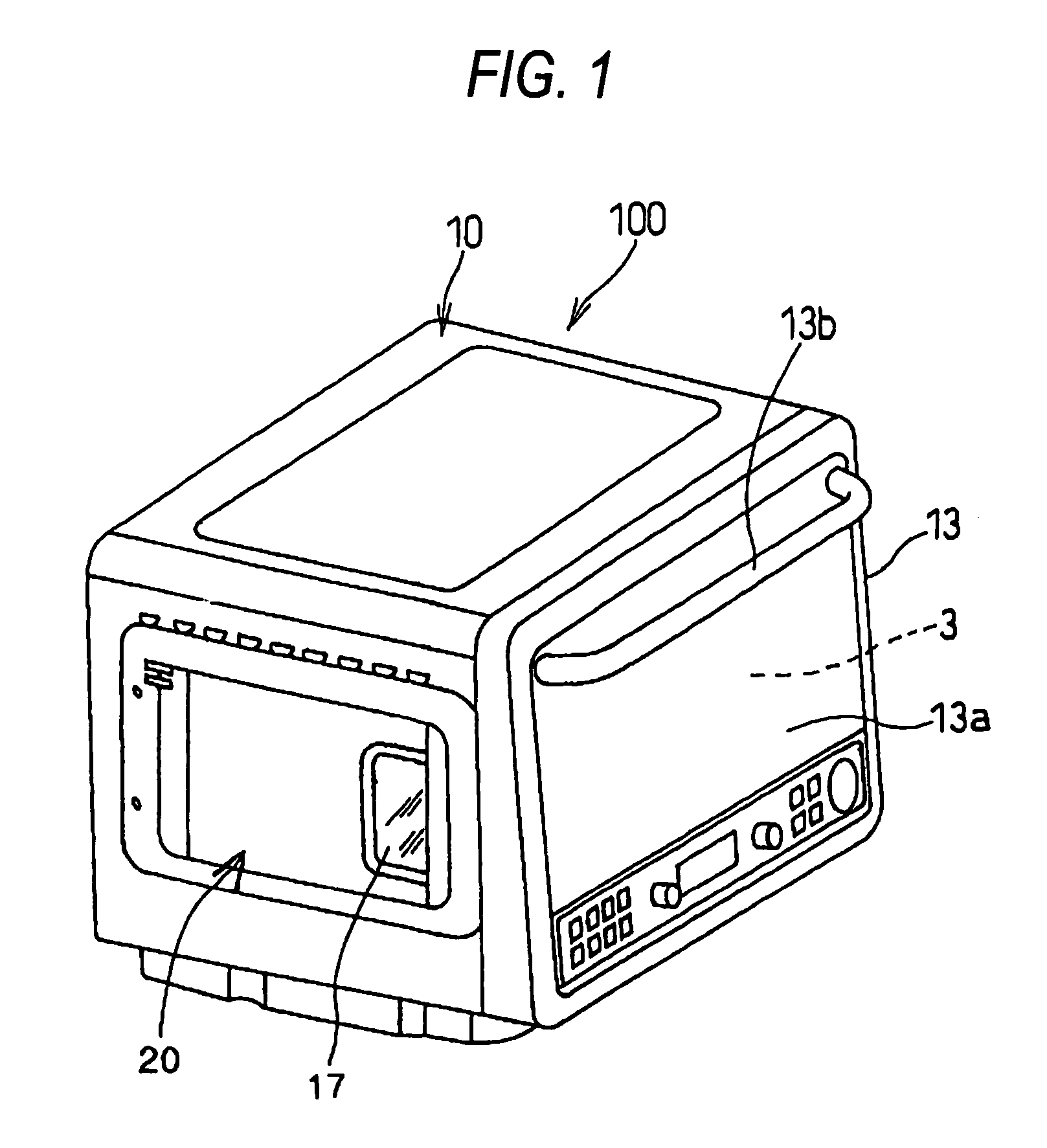

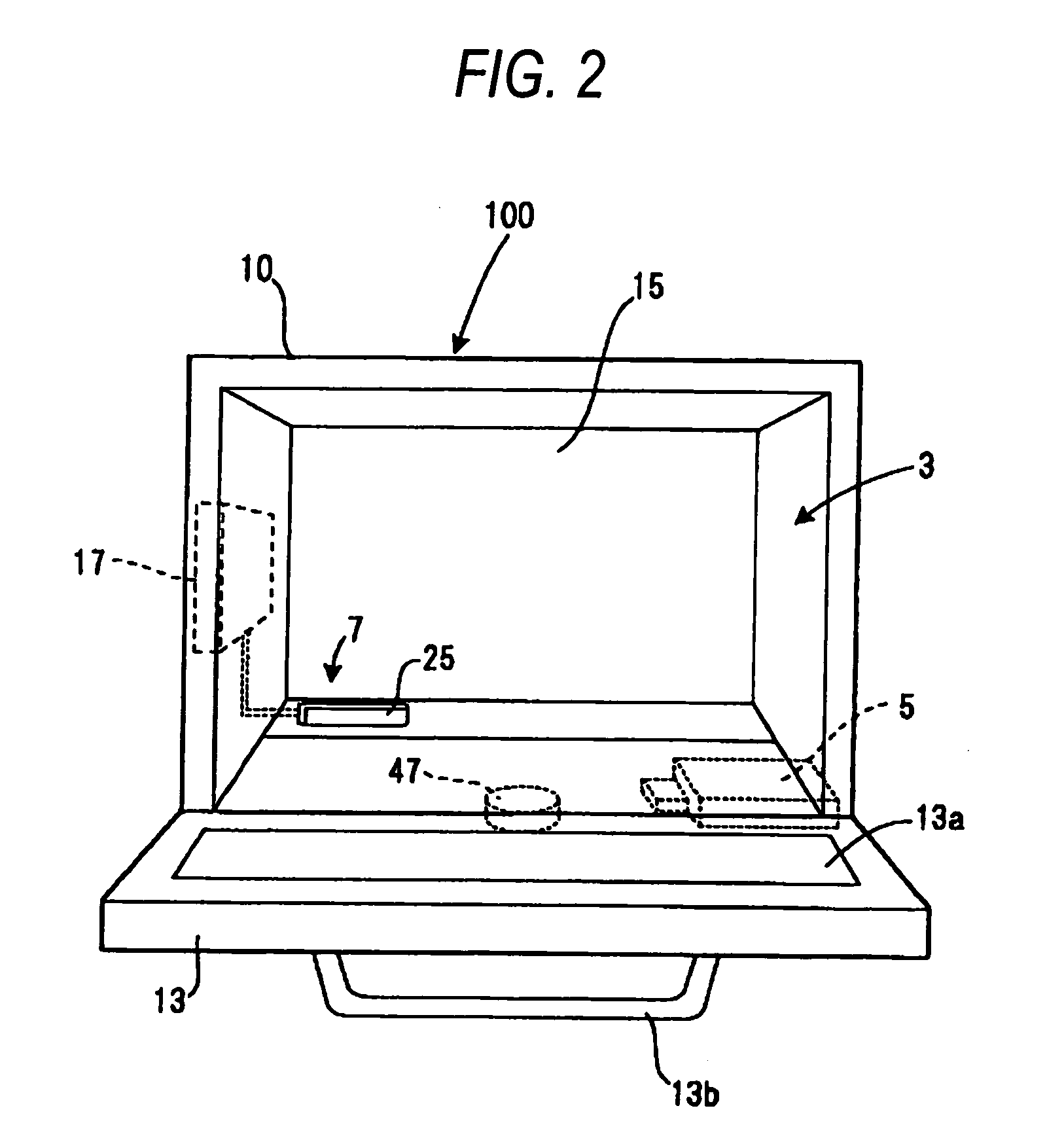

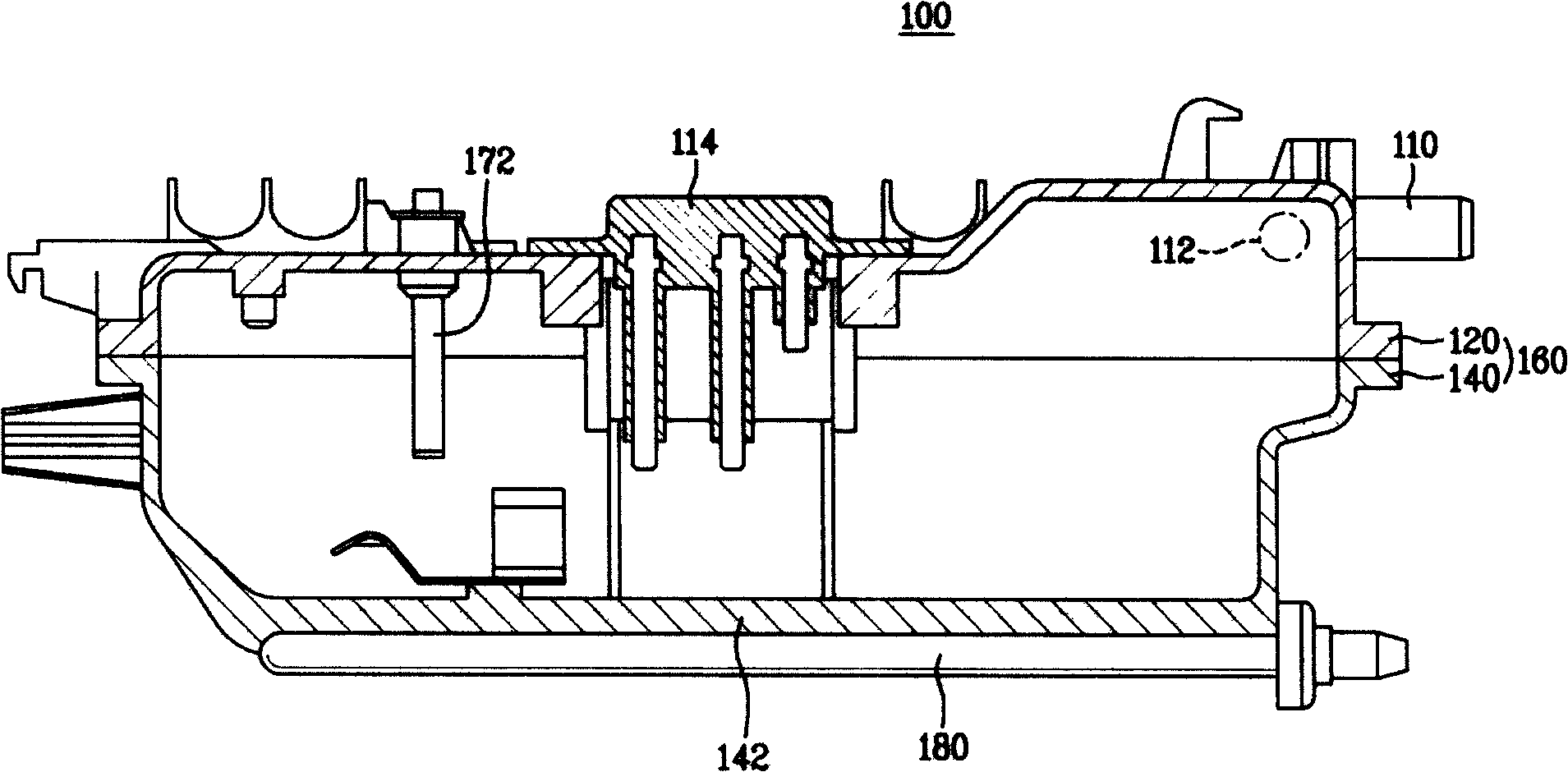

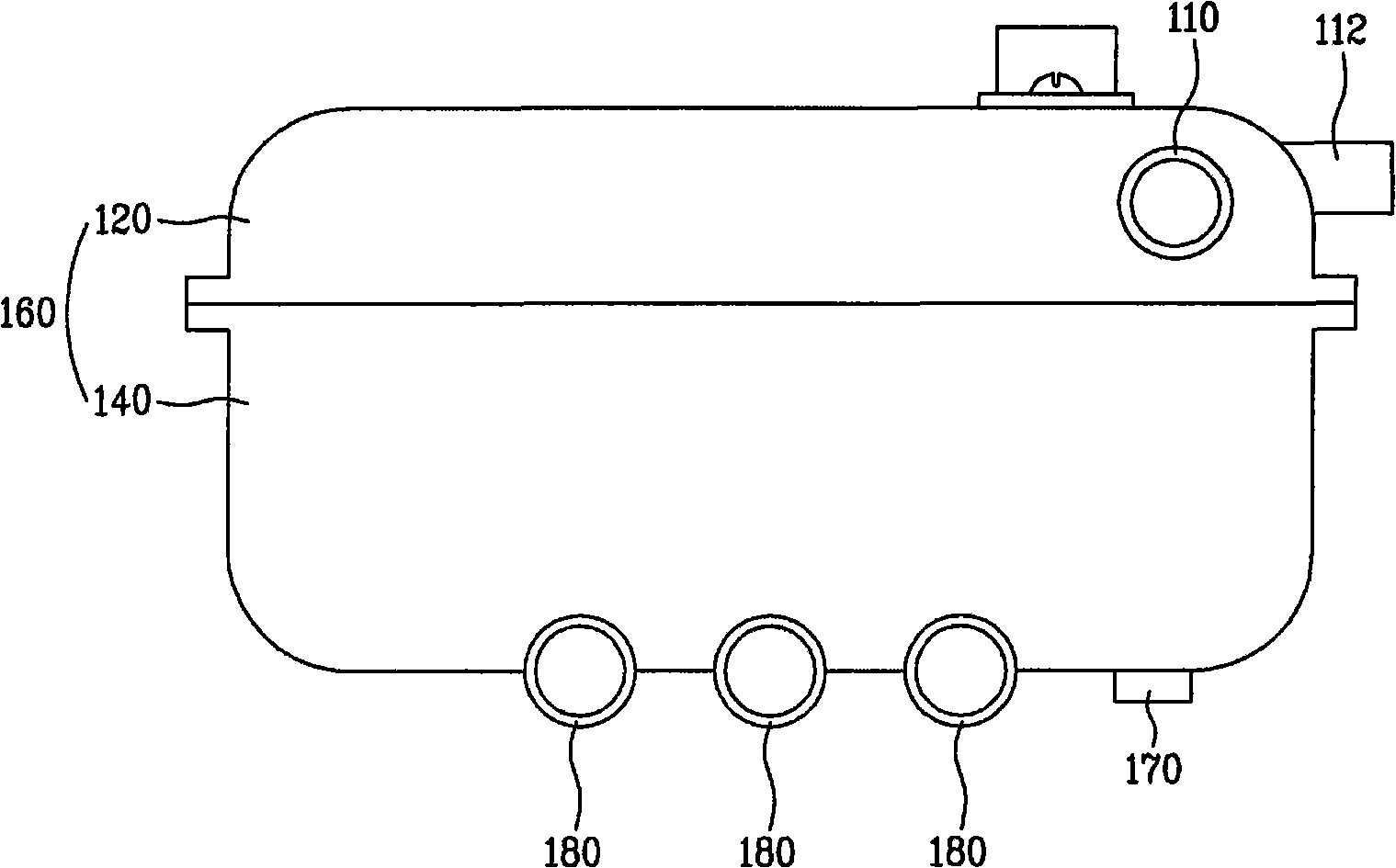

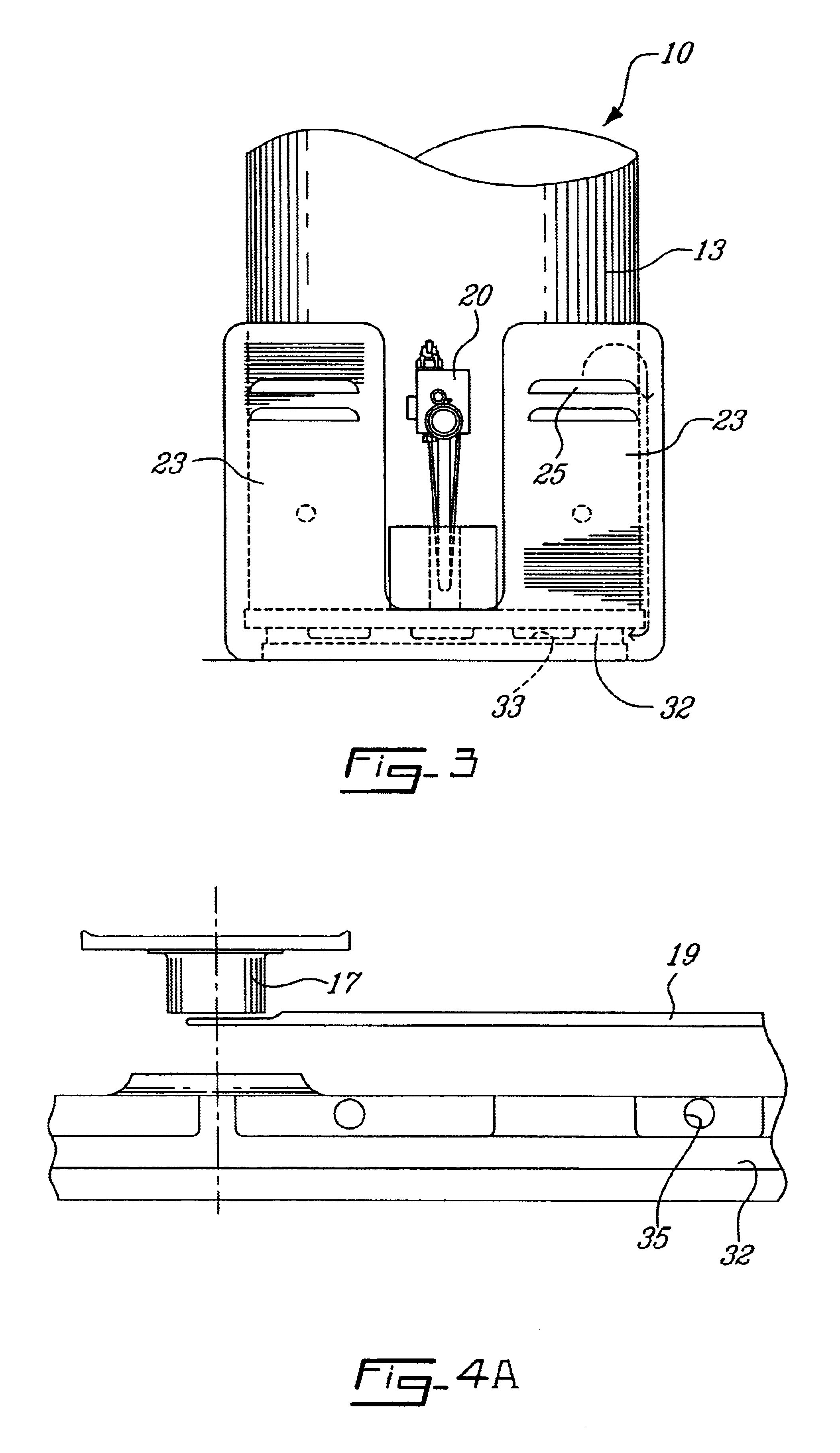

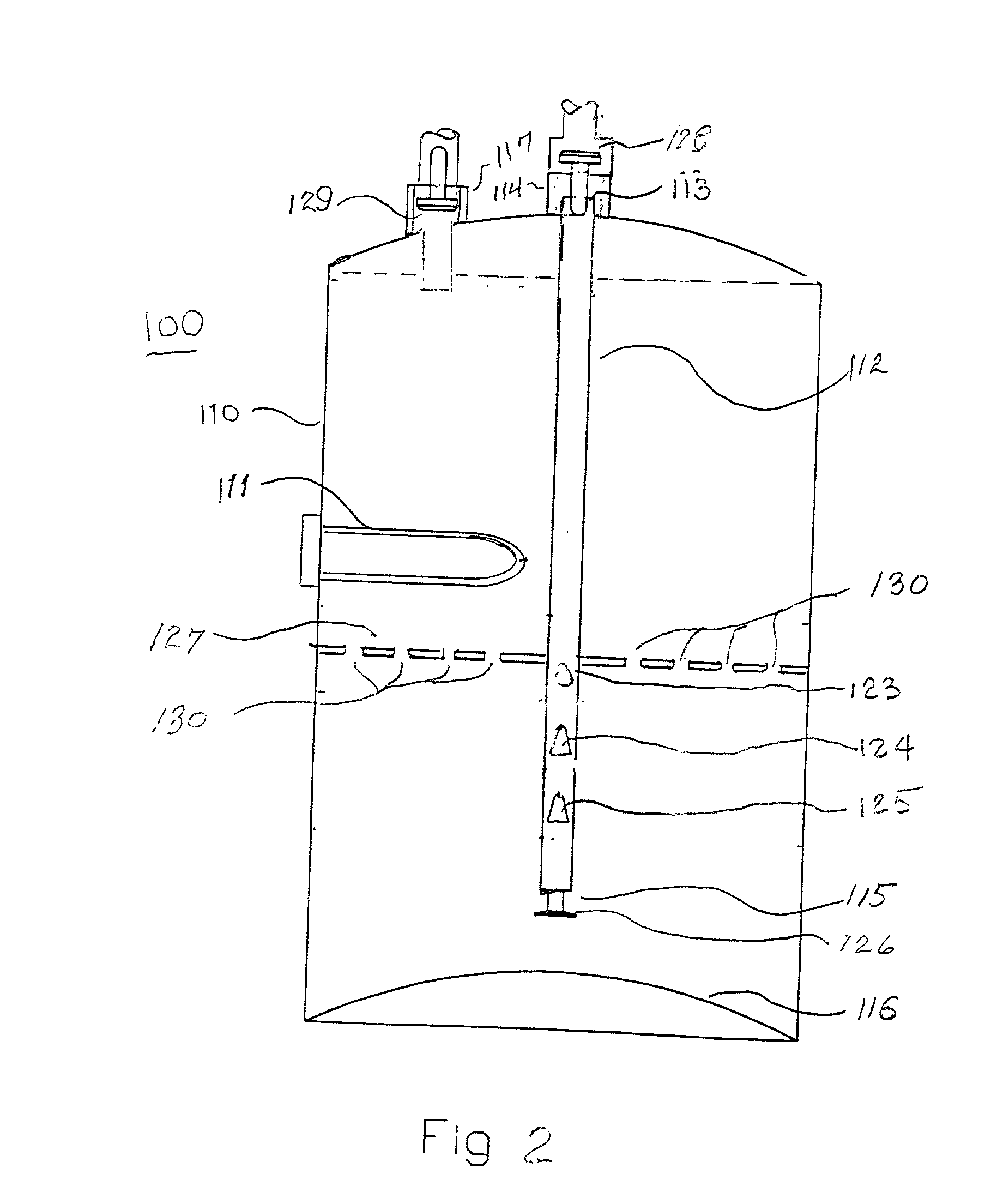

Water supply tank unit and heating apparatus having the same

ActiveUS7171923B2Not remainForming newlyDomestic stoves or rangesSteam generation heating methodsWaste managementHigh frequency

The present invention provides a water supply tank unit which can treat water that has leaked when a water supply tank is pulled out so that it does not remain. In the invention, a water supply tank unit which is attached to a high-frequency heating apparatus with a steam generating function and holds a water supply tank detachably, said tank unit comprises: a water supply tank 17 having a water supply port 55 on its side surface; a tank case door member 31 for supporting the water supply tank 17, which has a water inlet 59 connected to the water supply port 55 with an inserting operation of the water supply tank 17, and a scupper 60 formed around an elastic fitting piece by perforating a bottom part near the water inlet 59; and a sponge provided below the scupper 60.

Owner:PANASONIC CORP

Steam generator

PendingCN101290111AIncrease the heating areaImprove the heating effectBoiler drums/headersSteam generation heating methodsEngineeringHeating effect

Owner:NANJING LG PANDA APPLIANCES

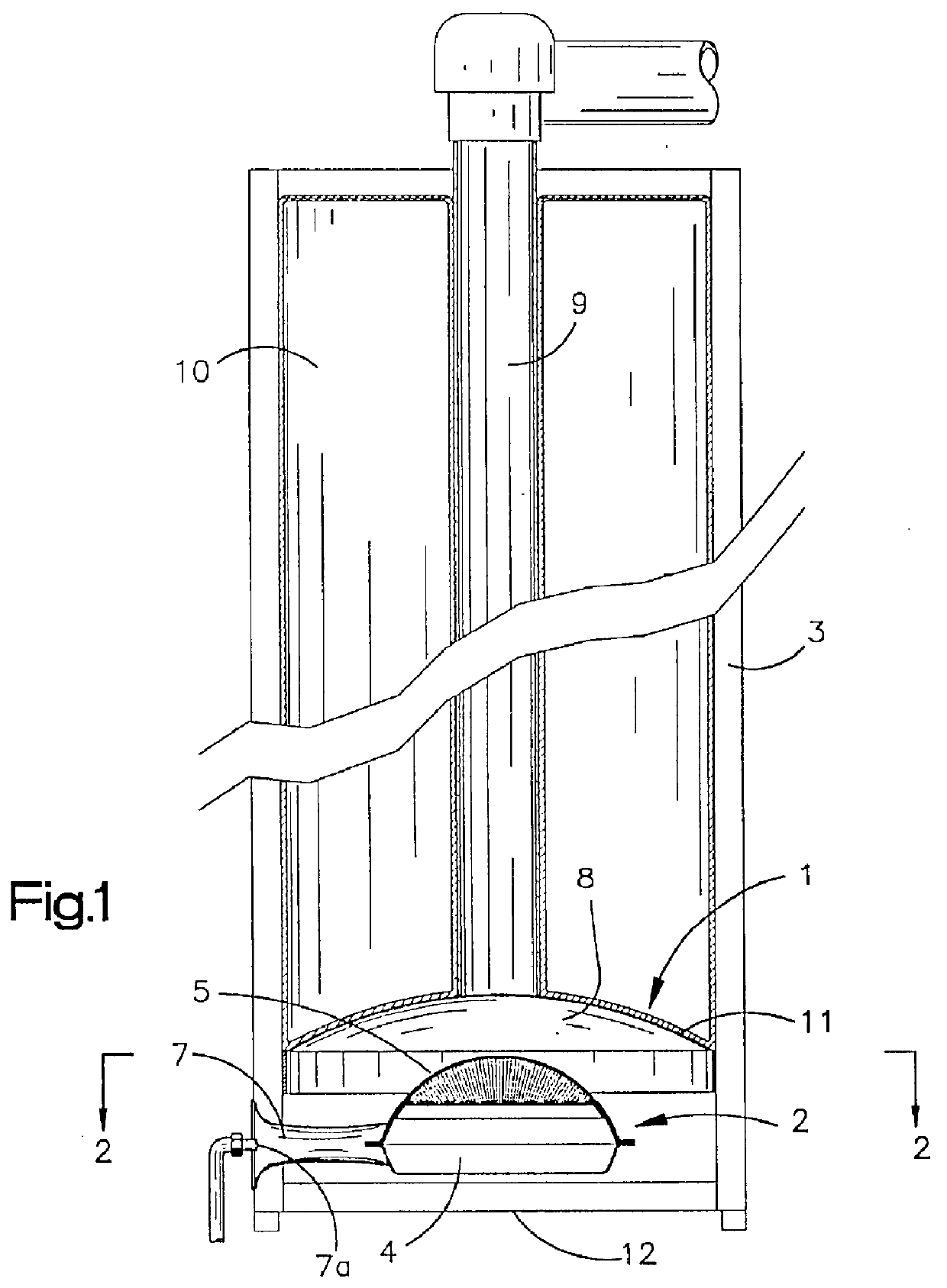

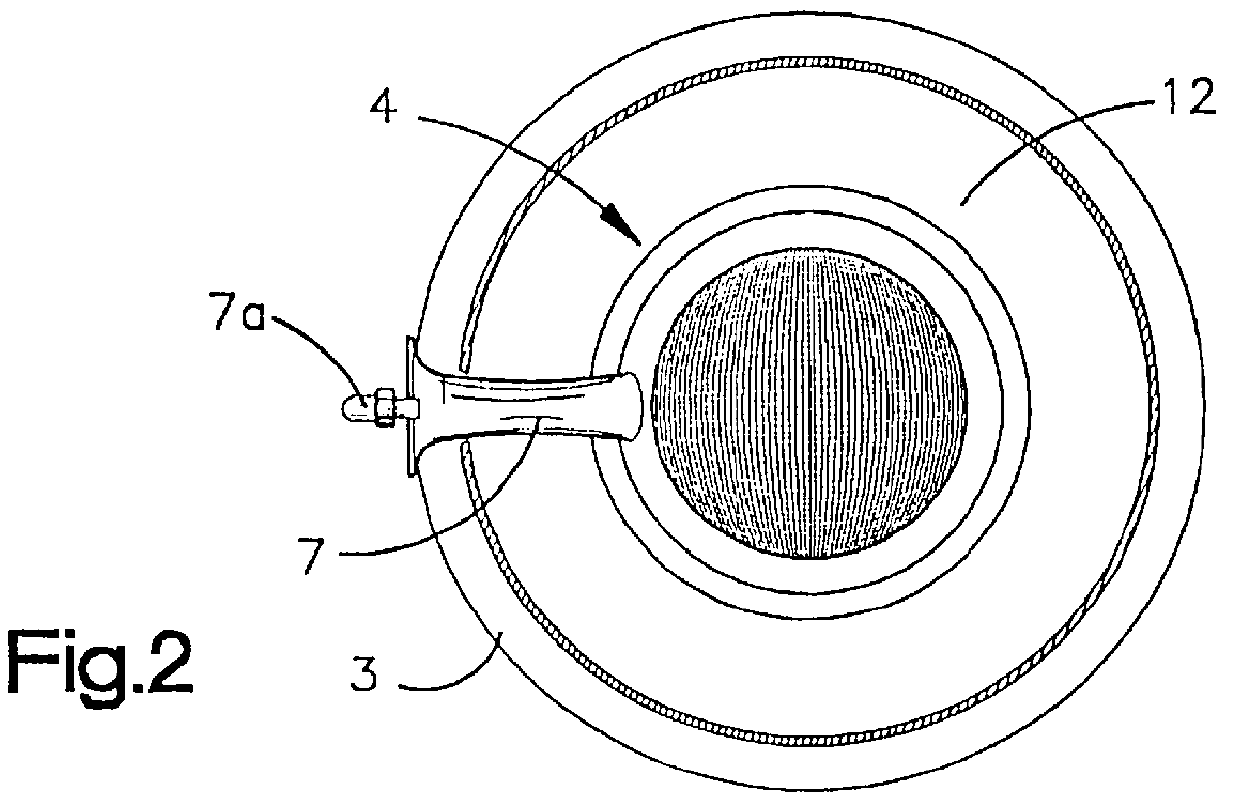

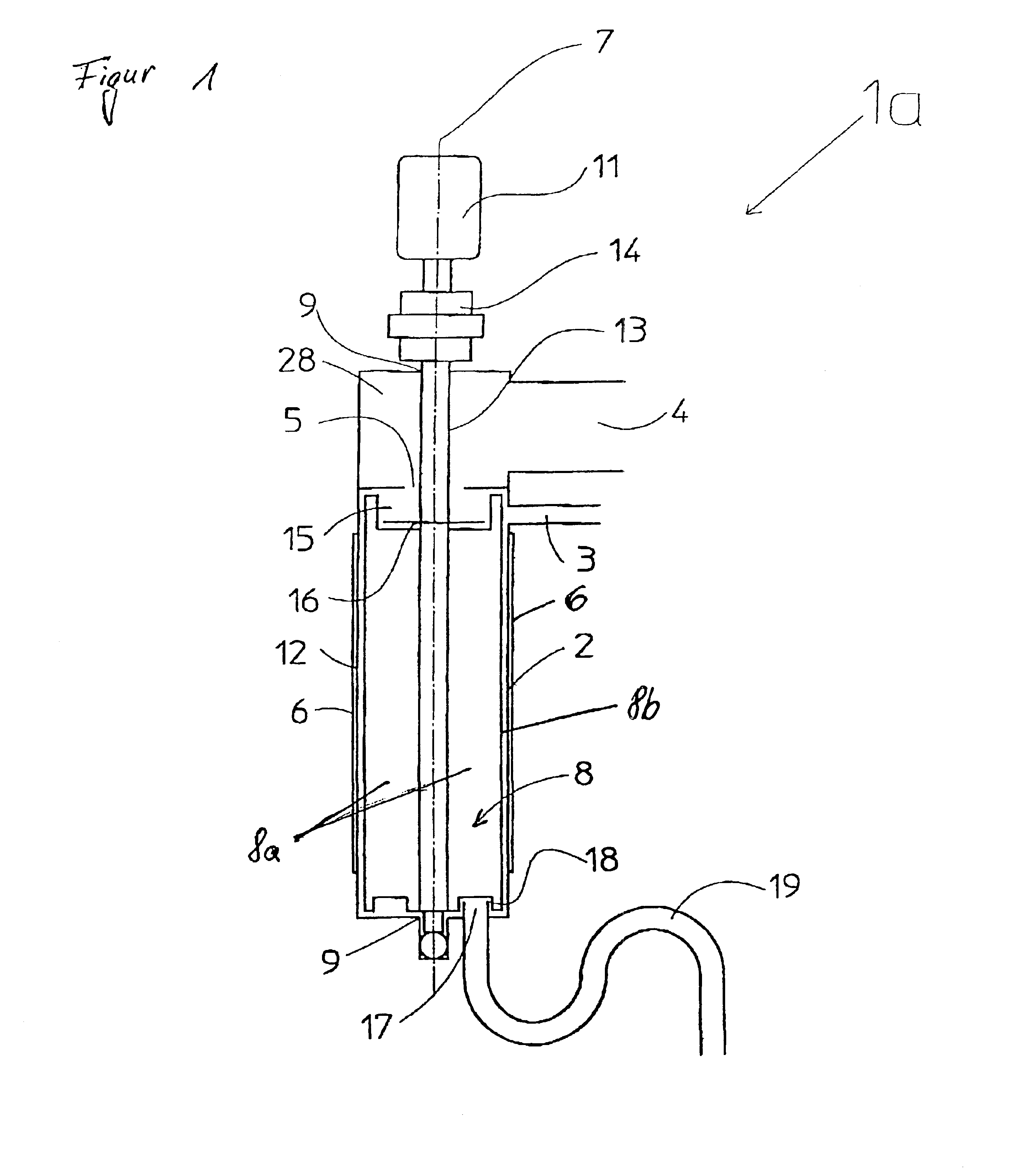

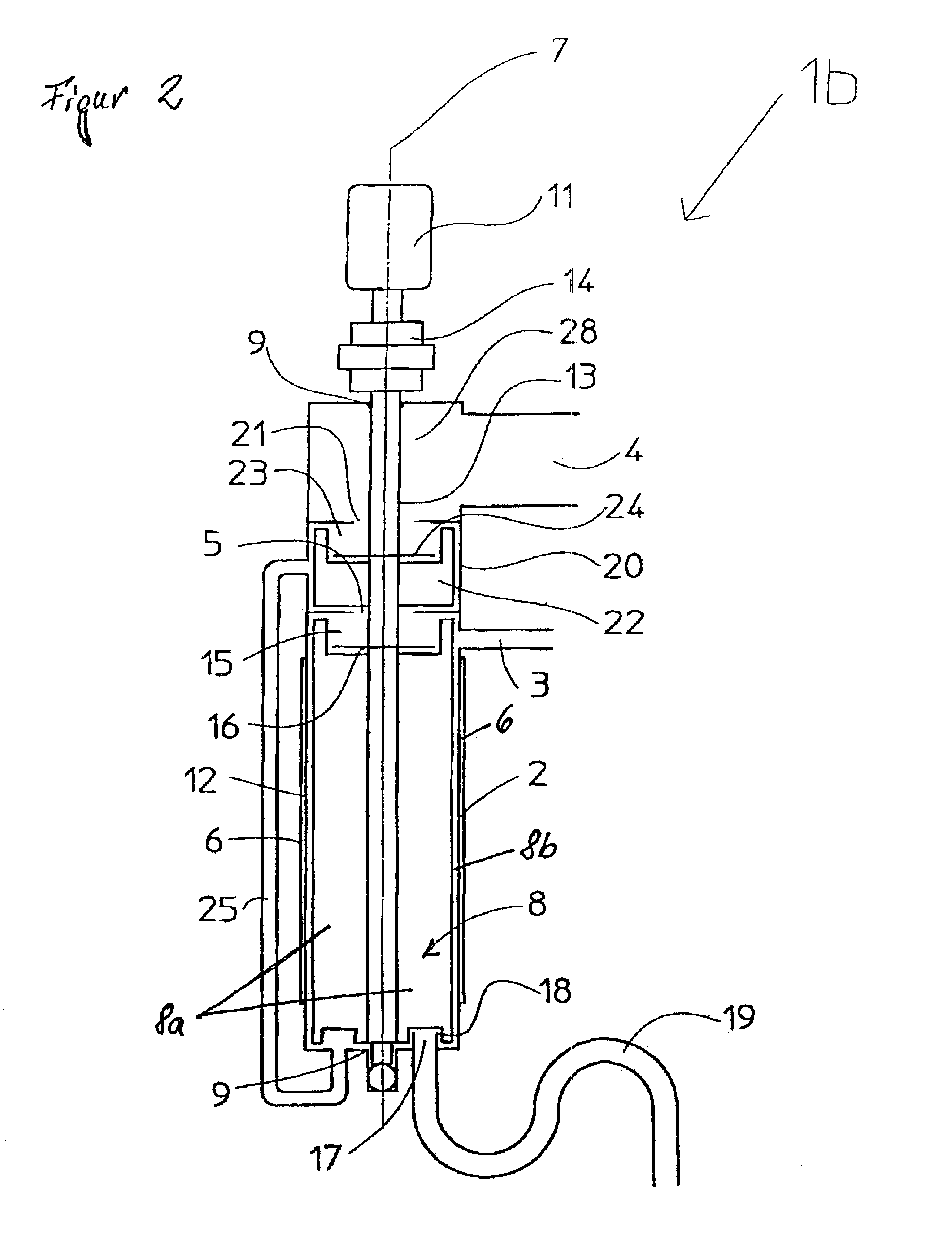

Explosion proof gas-fired water heater

InactiveUS6662757B2Enough timePropagation delayDrum steam boilersWater heatersCombustion chamberFresh air

An explosion proof gas-tired water heater is comprised of a housing having a water reservoir provided with a sealed combustion chamber thereunder. A flue pipe is disposed above the combustion chamber and extends through the reservoir. A gas burner and pilot are provided in the combustion chamber. At least one air supply channel is provided to supply fresh air to the combustion chamber. The air supply channel has an intake disposed a predetermined height above the floor to prevent combustible vapors from entering the combustion chamber. Vapor detectors and / or pressure sensors may be provided as added features to detect the presence of combustible vapors as well as the production of harmful carbon monoxide in the combustion chamber and to actuate the gas supply cut-off valve.

Owner:MICLAU S R I

Water heating and storage system

ActiveUS7726263B2Extended service lifeEasy to cleanSolar heating energySolar heat devicesElectricityWater storage tank

Owner:B I ENERGY

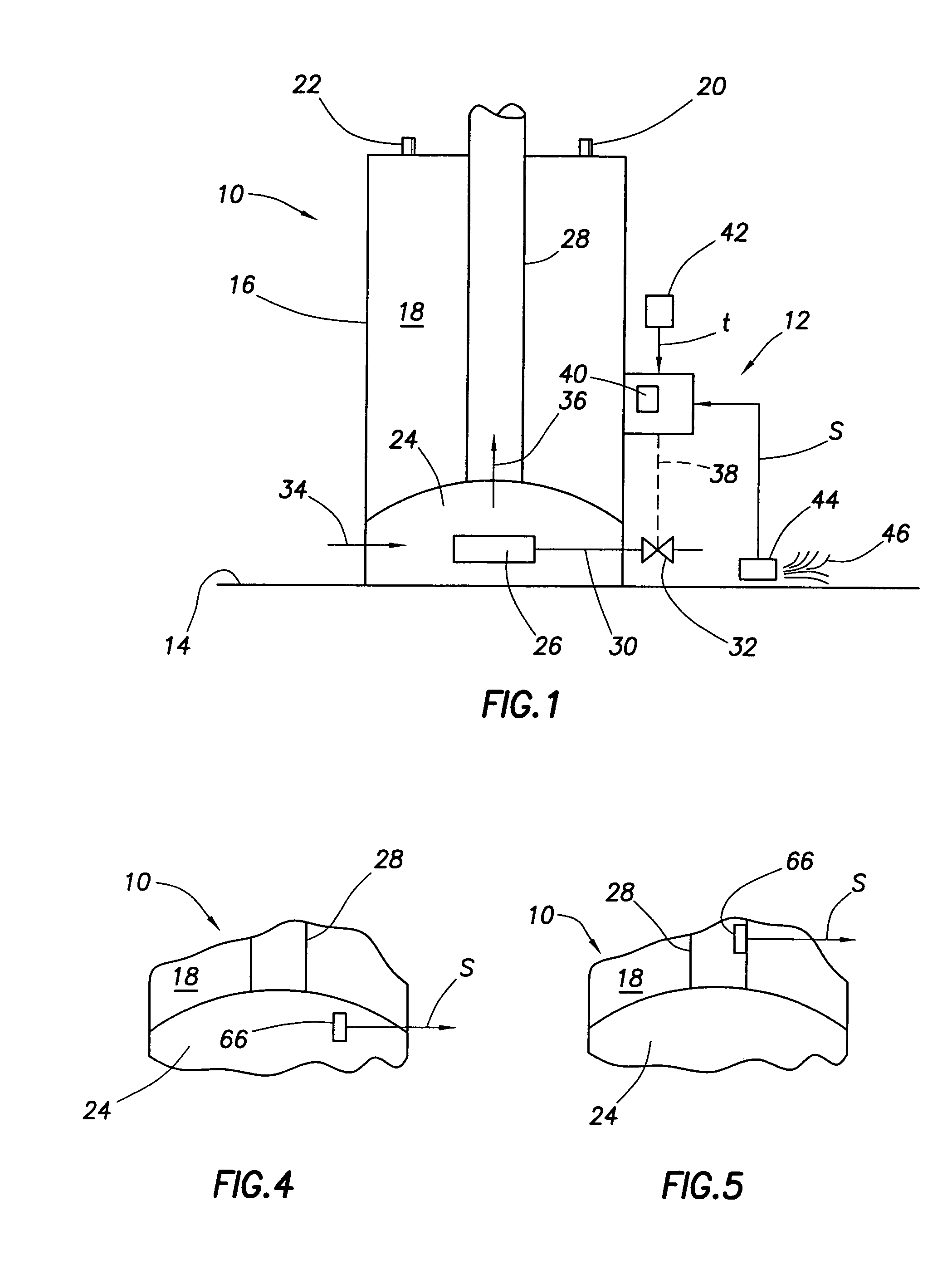

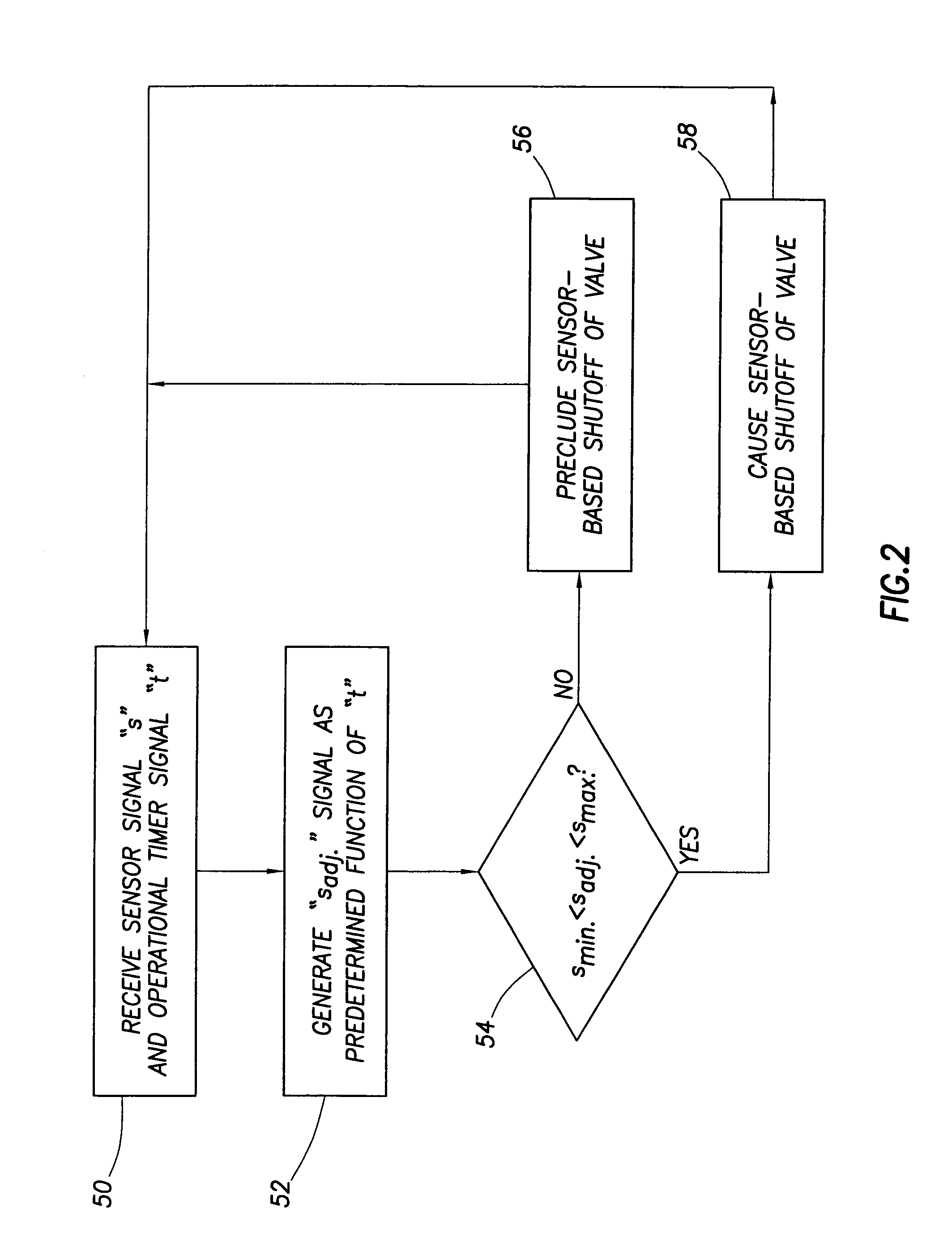

Control techniques for shut-off sensors in fuel-fired heating appliances

ActiveUS7242310B2Improve accuracyFluid heatersDrum steam boilersElectrical resistance and conductanceCombustion

In a flammable vapor sensor-based shut-off system of a fuel-fired water heater the sensor resistance output signal degradation caused by aging of the sensor is automatically compensated for using an operational timer having an output signal indicative of the total life of the sensor subsequent to its installation on the water heater. In one embodiment of the system, a resistance adjustment signal having a magnitude related in a predetermined manner to the timer output signal is created and added to the sensor resistance output signal. In another embodiment, the timer output signal is used to appropriately adjust the minimum-maximum received sensor signal magnitude range, based on the installed age of the sensor, which will preclude combustion in the appliance. Additionally, in each embodiment thereof the system is provided with an improved initial minimum-maximum sensor signal magnitude range. Other types of shut-off gas sensors may be alternatively utilized.

Owner:RHEEM MFG CO

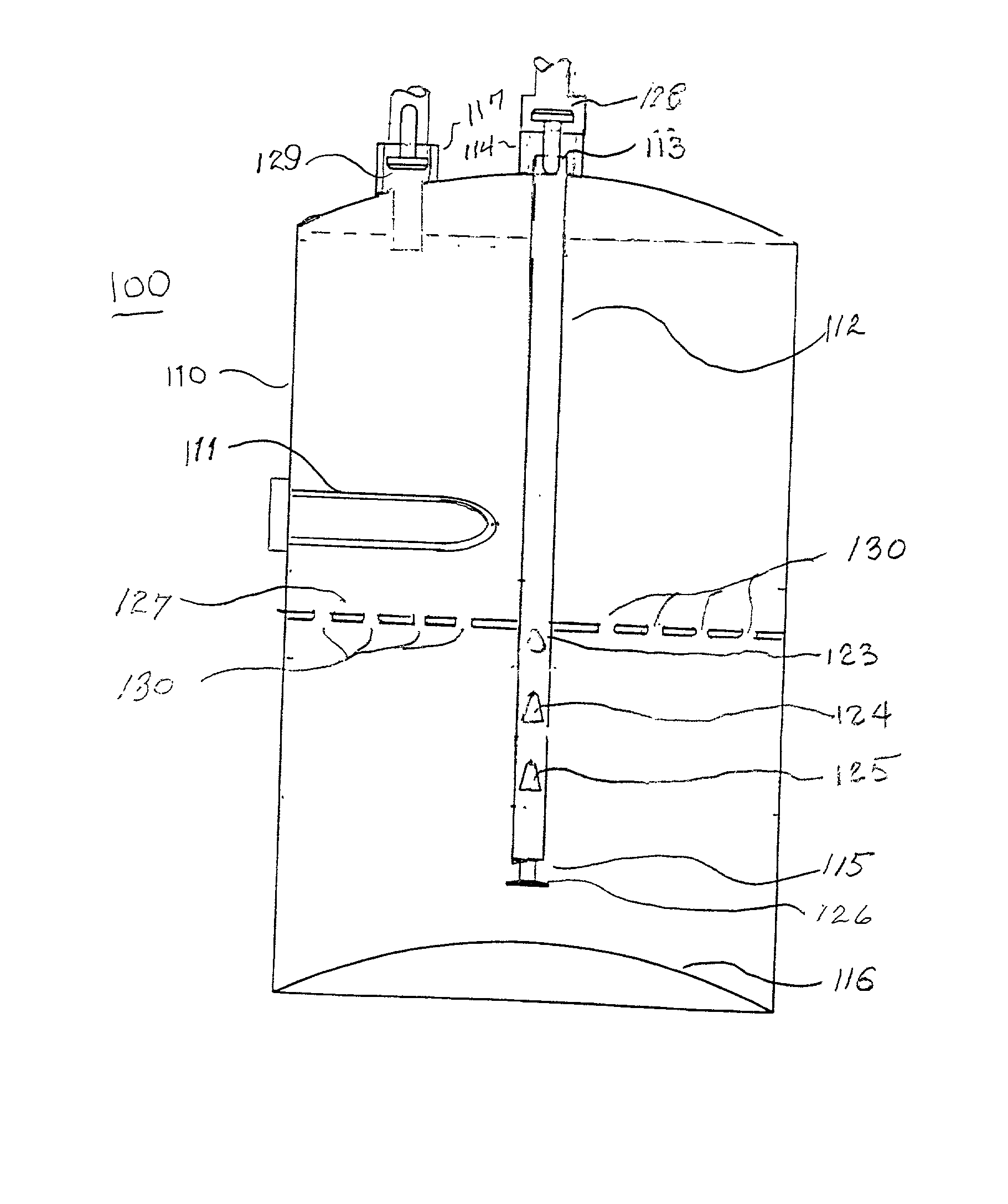

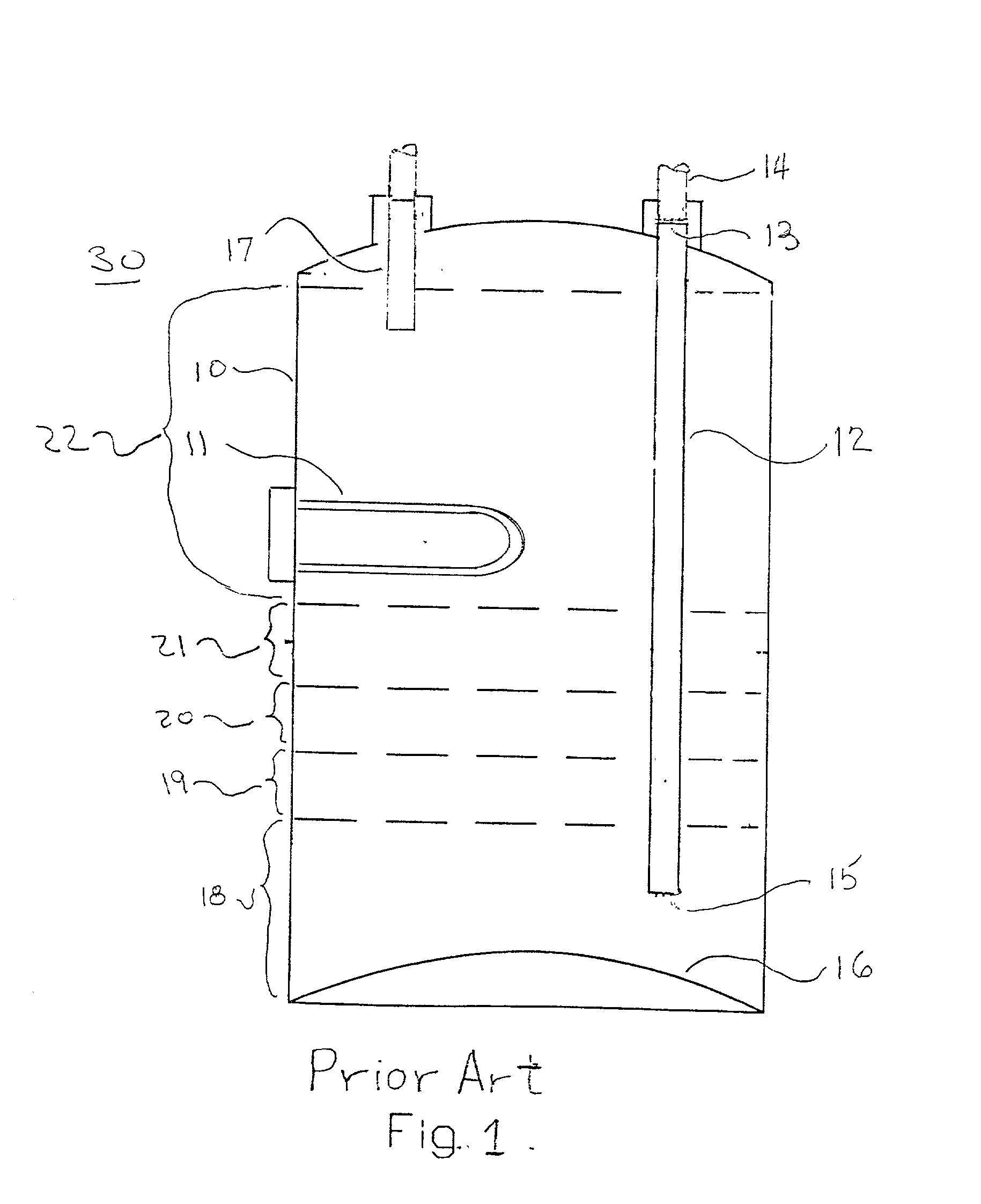

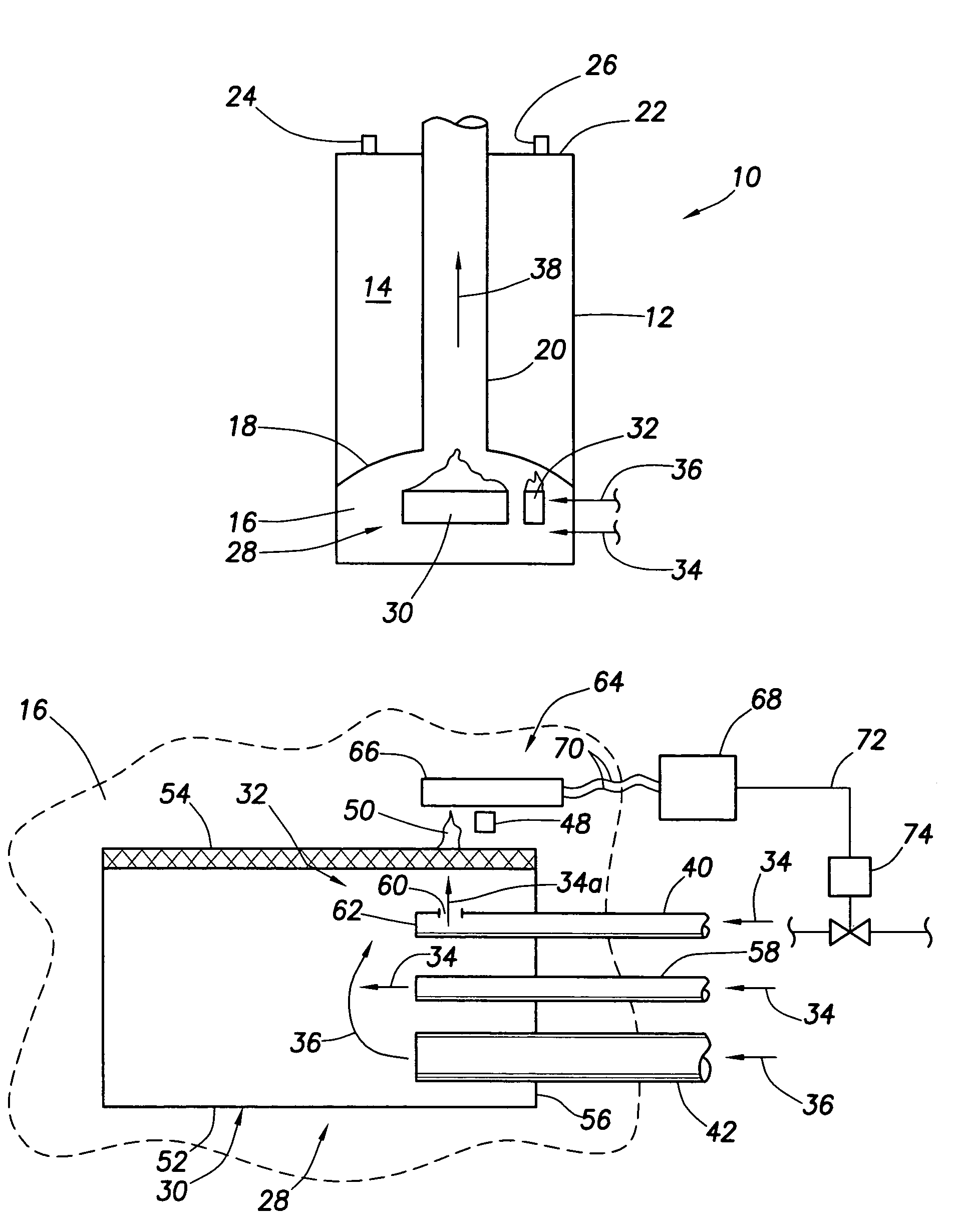

Water mixing system for water heaters

InactiveUS20020066419A1Temperature control without auxillary powerValve members for heating/coolingEngineeringStorage type

Disclosed herein are storage type water heaters having means for improved mixing of cold water supply with water stored in the water tank of a water heater, means for limiting surges of water into and out of a water tank, and means for disrupting formation and propagation of convection currents and water streamers in a water tank.

Owner:BRADENBAUGH KENNETH A

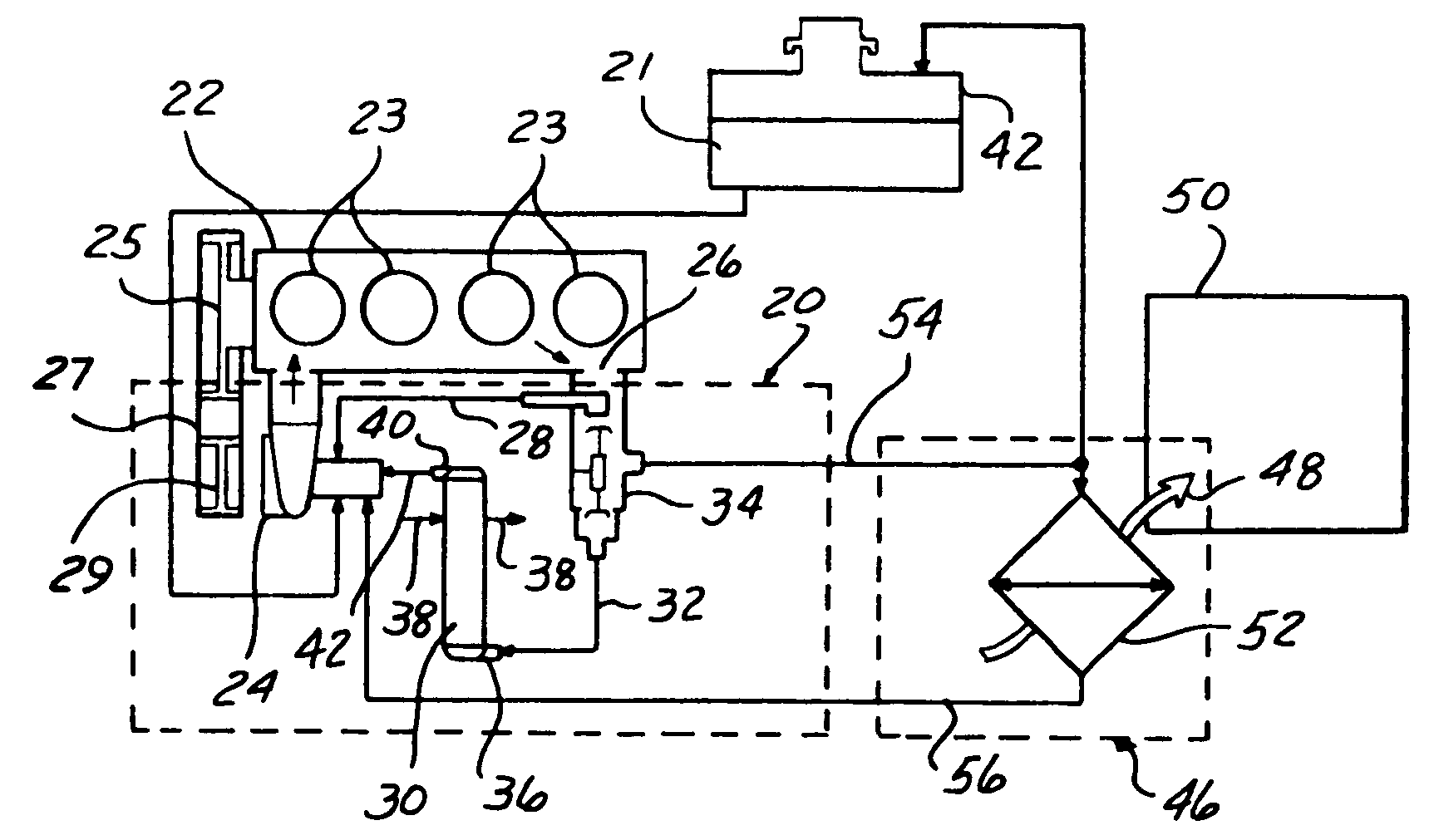

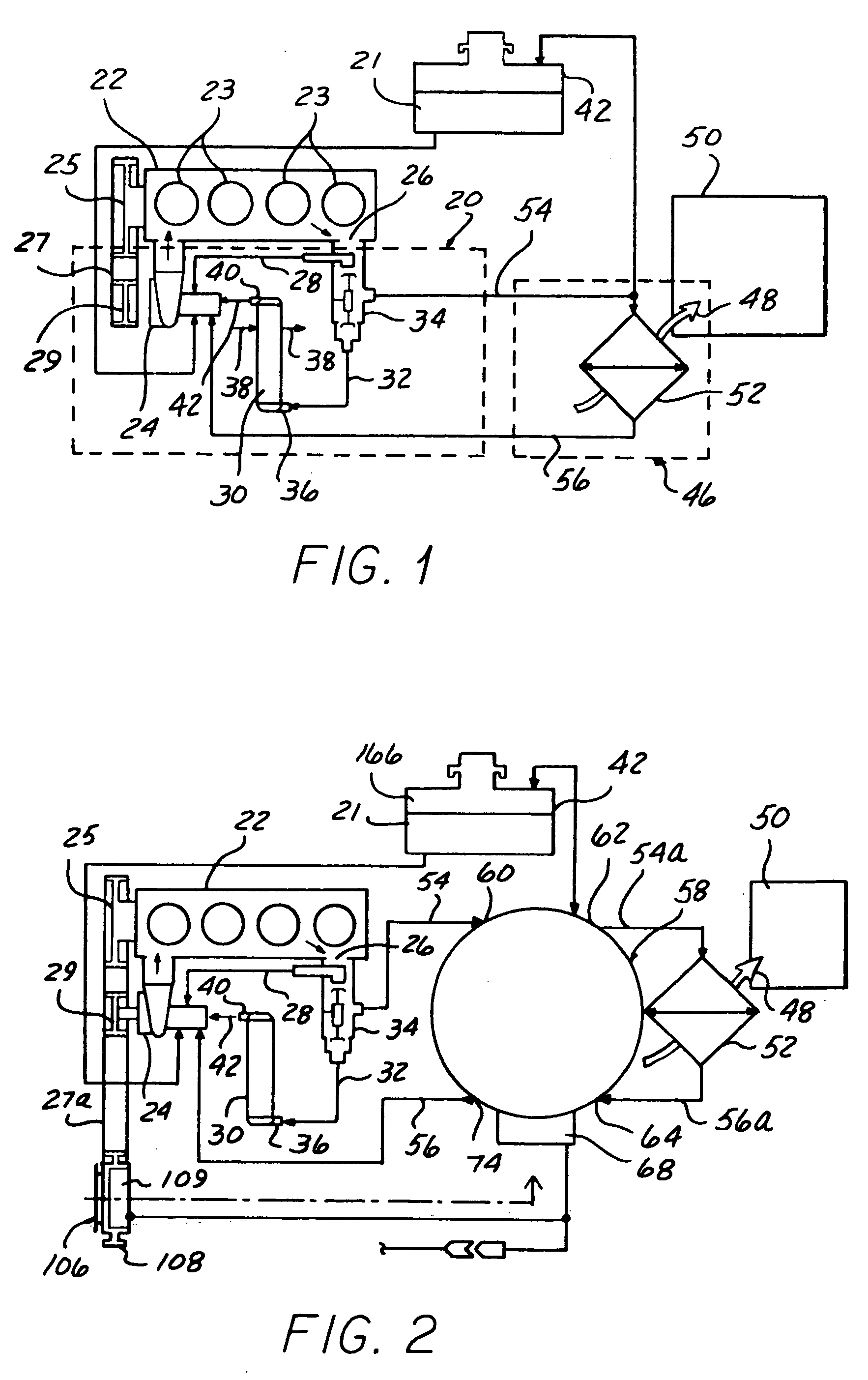

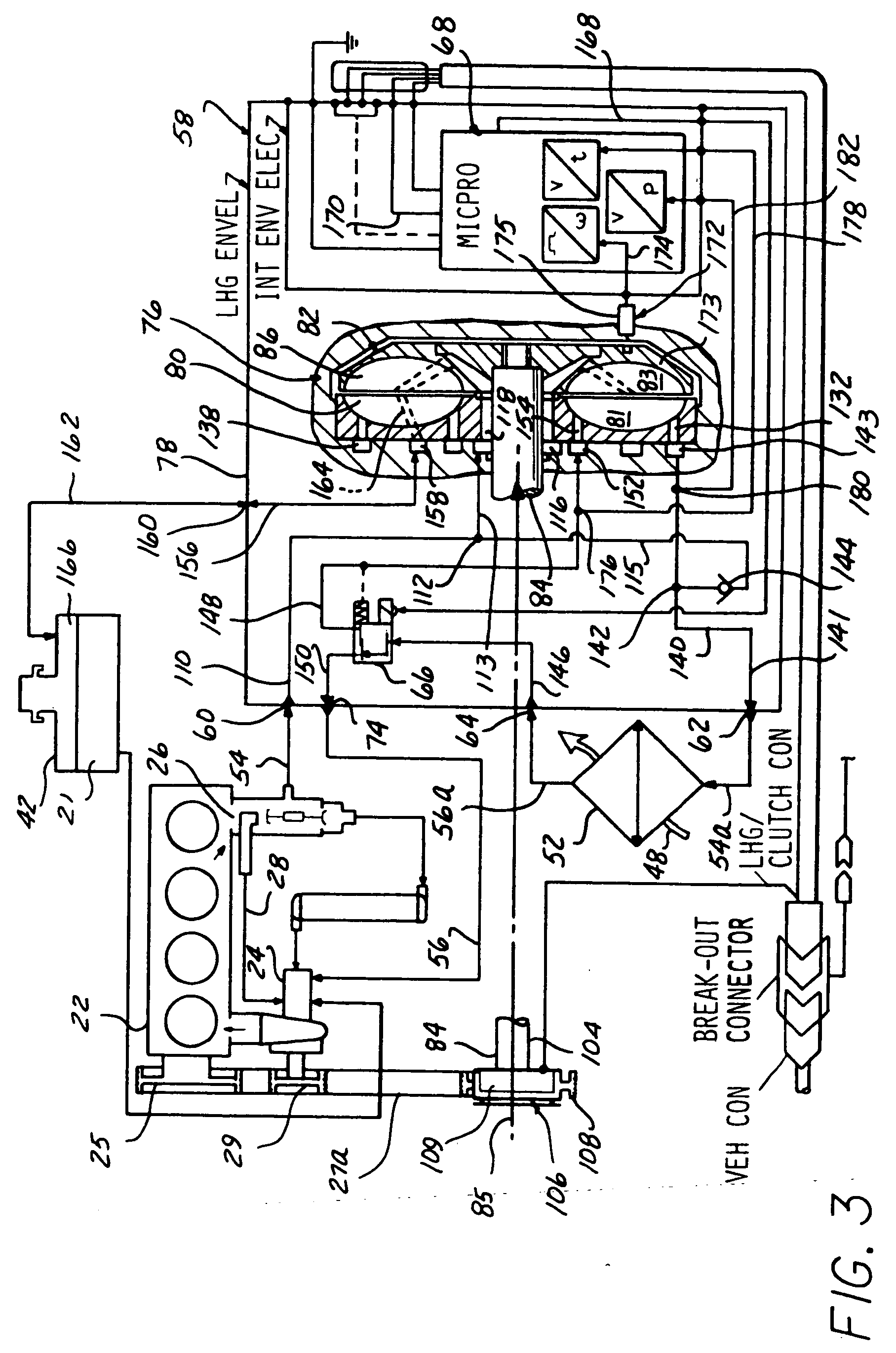

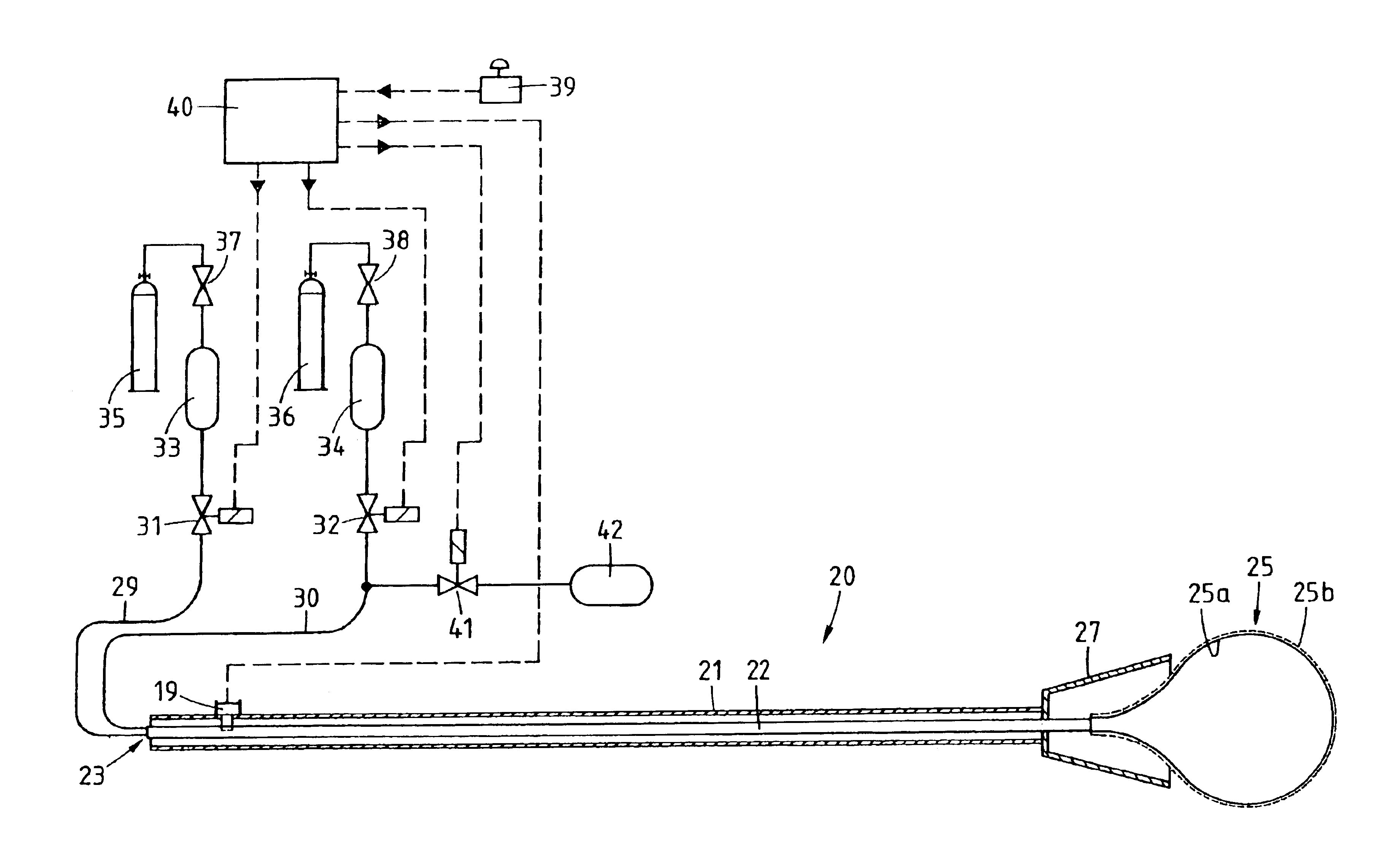

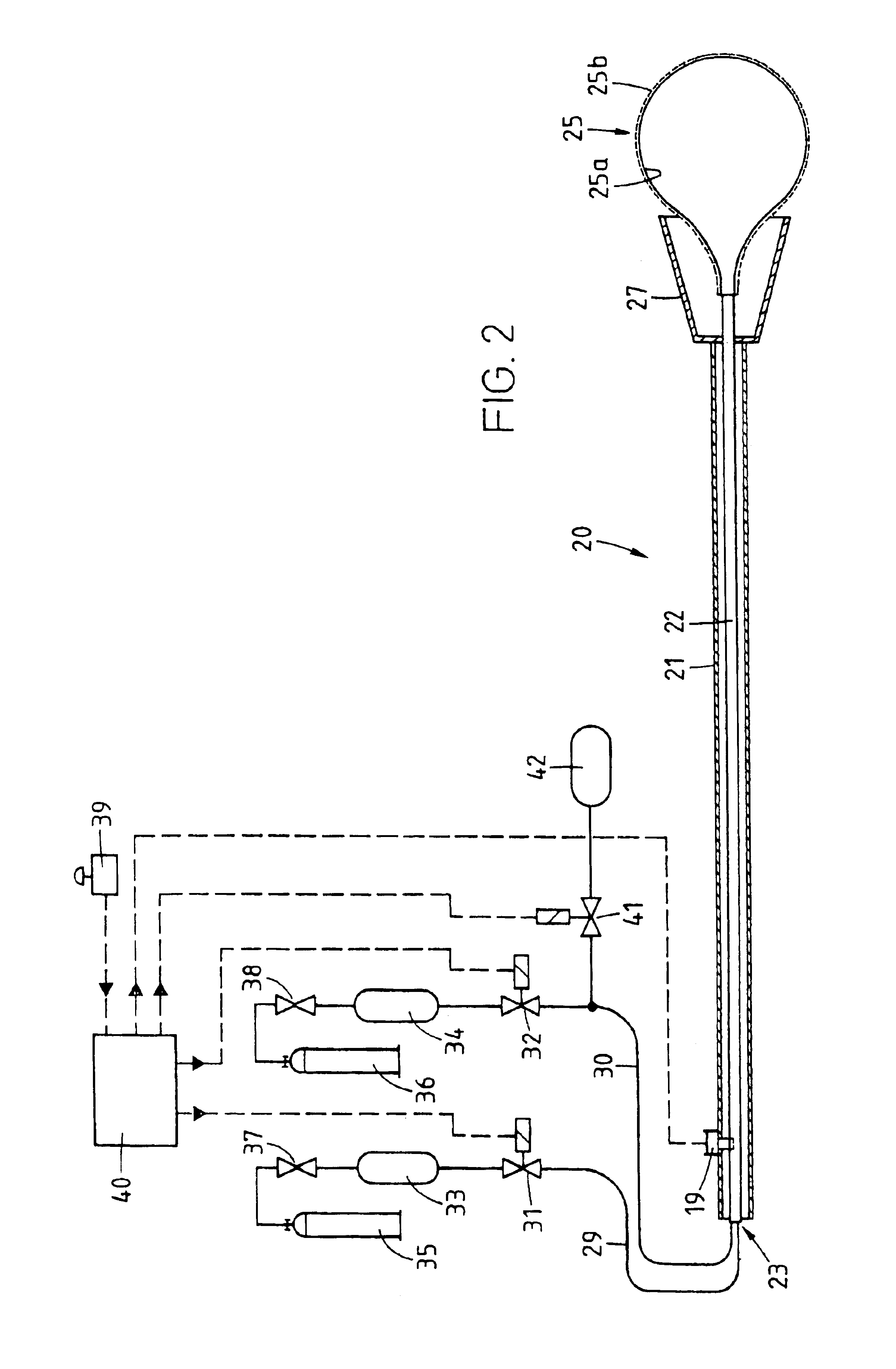

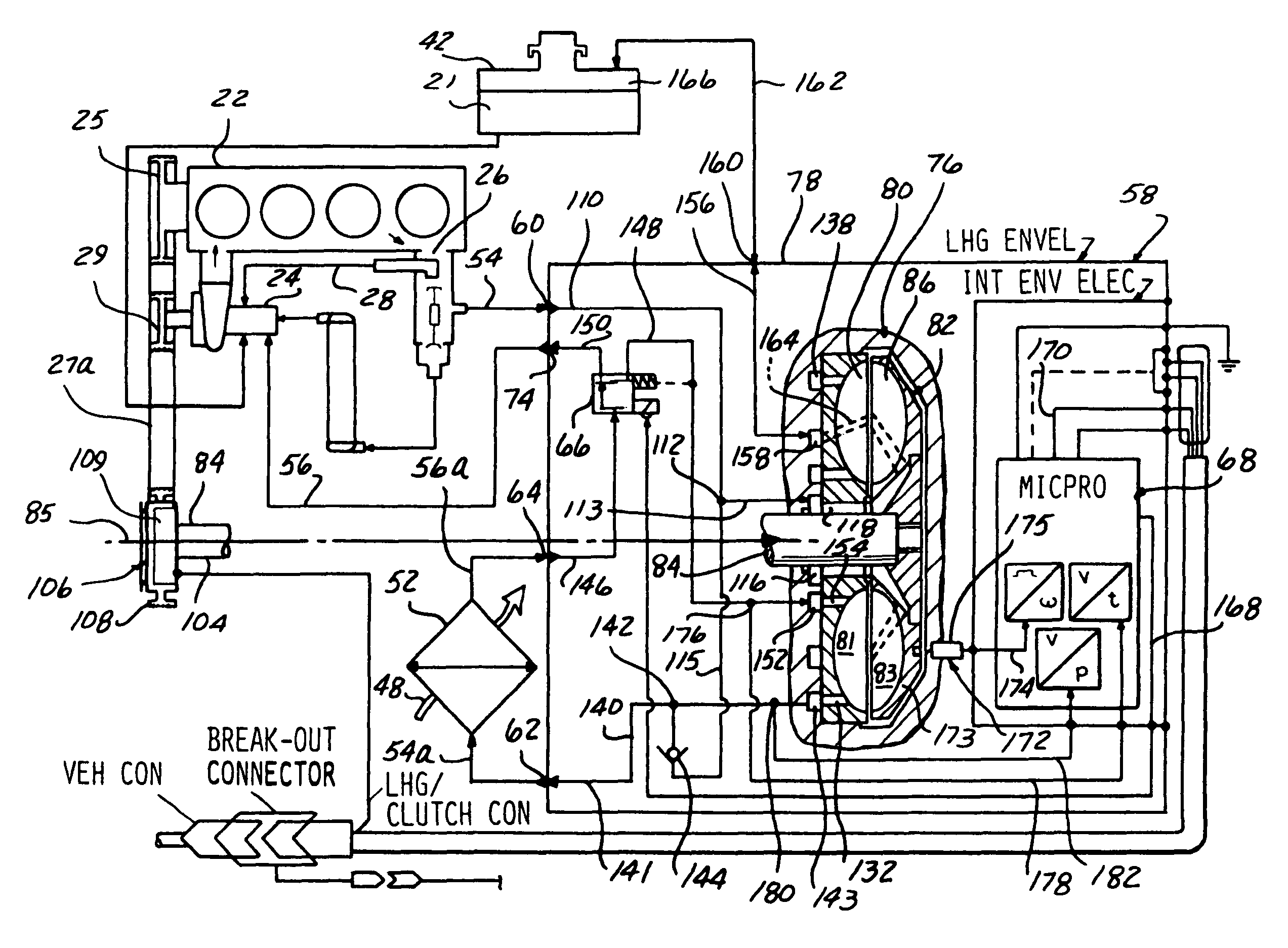

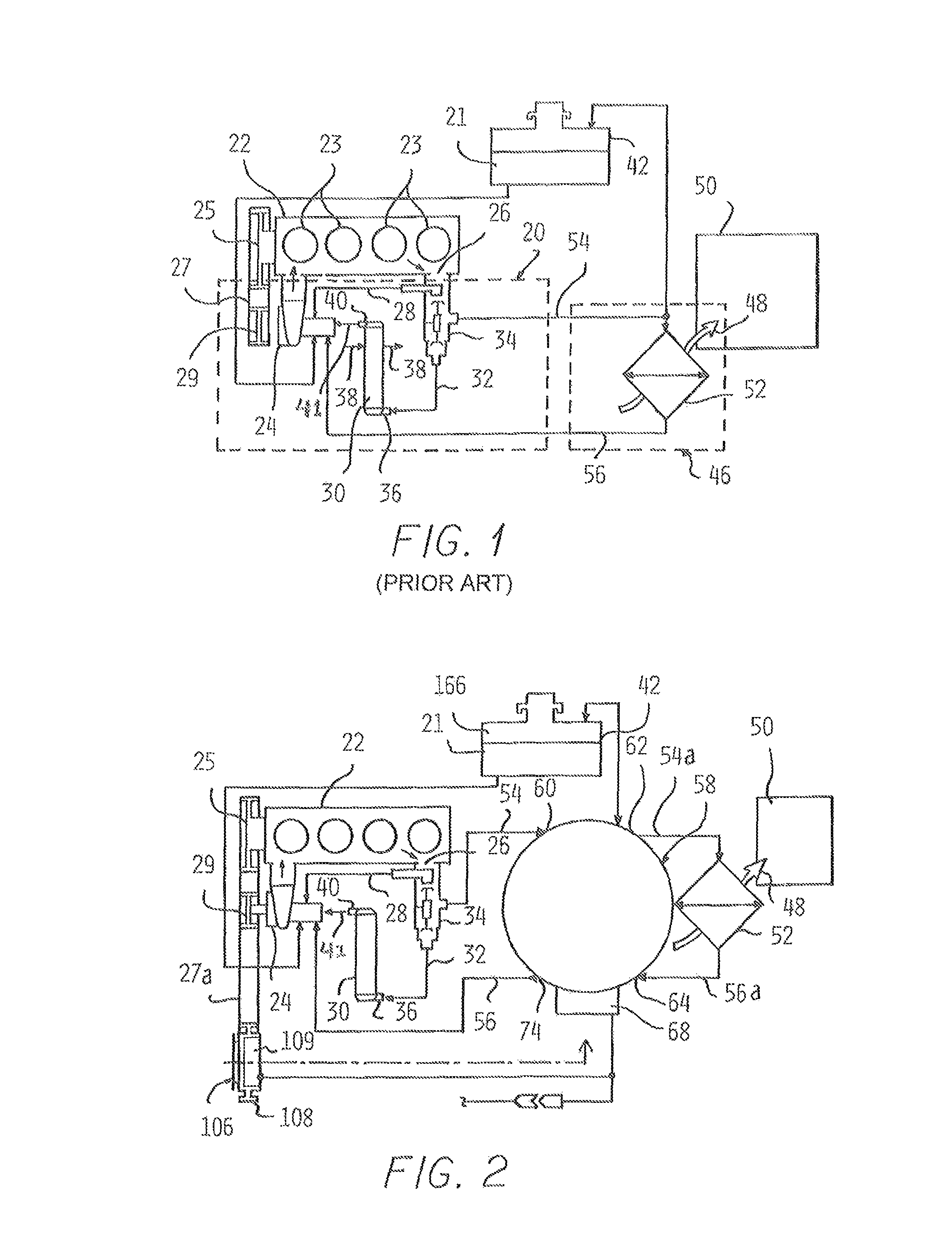

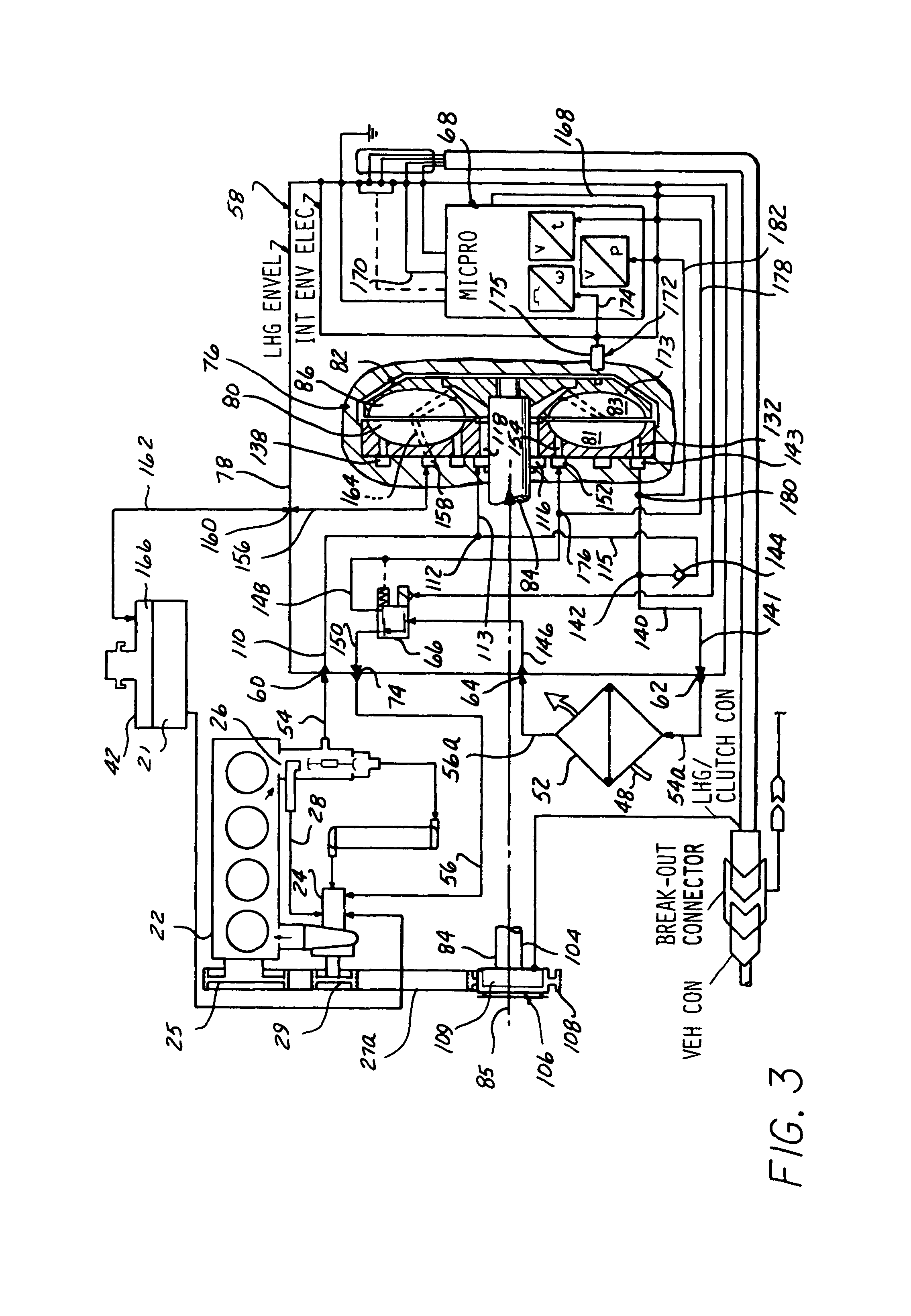

Vehicle supplemental heating system

A preferred embodiment supplemental heating system is fluidly connectable to a vehicle cooling system and includes a liquid heat generator operable for heating a cooling fluid delivered to the supplemental heating system from the vehicle's cooling system. The liquid heat generator includes a discharge passage connectable to a heater core of the vehicle and a inlet passage connectable to the vehicle's cooling system. The supplemental heating system further includes a control valve having an inlet connectable to an exit passage of a heater core of the vehicle, a discharge passage fluidly connected to the liquid heat generator, and a second discharge passage connectable to the vehicle's cooling system. The control valve is operable for controlling the proportion of cooling fluid exiting the heater core that is returned to the vehicle's cooling system and recirculated back to the liquid heat generator.

Owner:WEBASTO AG

Control System For Modulating Water Heater

ActiveUS20090064944A1Reduce temperature fluctuationsReact much more quicklyHeating fuelFuel supply regulationImpact systemFlue gas

A control system is provided for a modulated heating system including at least one modulating water heater and a controller. A deadband control scheme provides for reduced cycling of the modulating heater when total system heat demand falls between the maximum output of one heater and the sum of the maximum output of that one point and the minimum firing point of the next subsequent heater. Condensation of flue gas products is prevented by monitoring flue exhaust temperature for each heater and controlling the modulation of each heater to maintain a minimum heater output sufficiently high to prevent condensation of flue gas products from that heater. Rapid reaction to changes in system heat demand is provided by sensing changes in flow rate in a primary loop of the system and anticipating resulting changes in temperature thus allowing for change in heater output prior to the time the change in flow rate has fully impacted system temperature.

Owner:LOCHINVAR

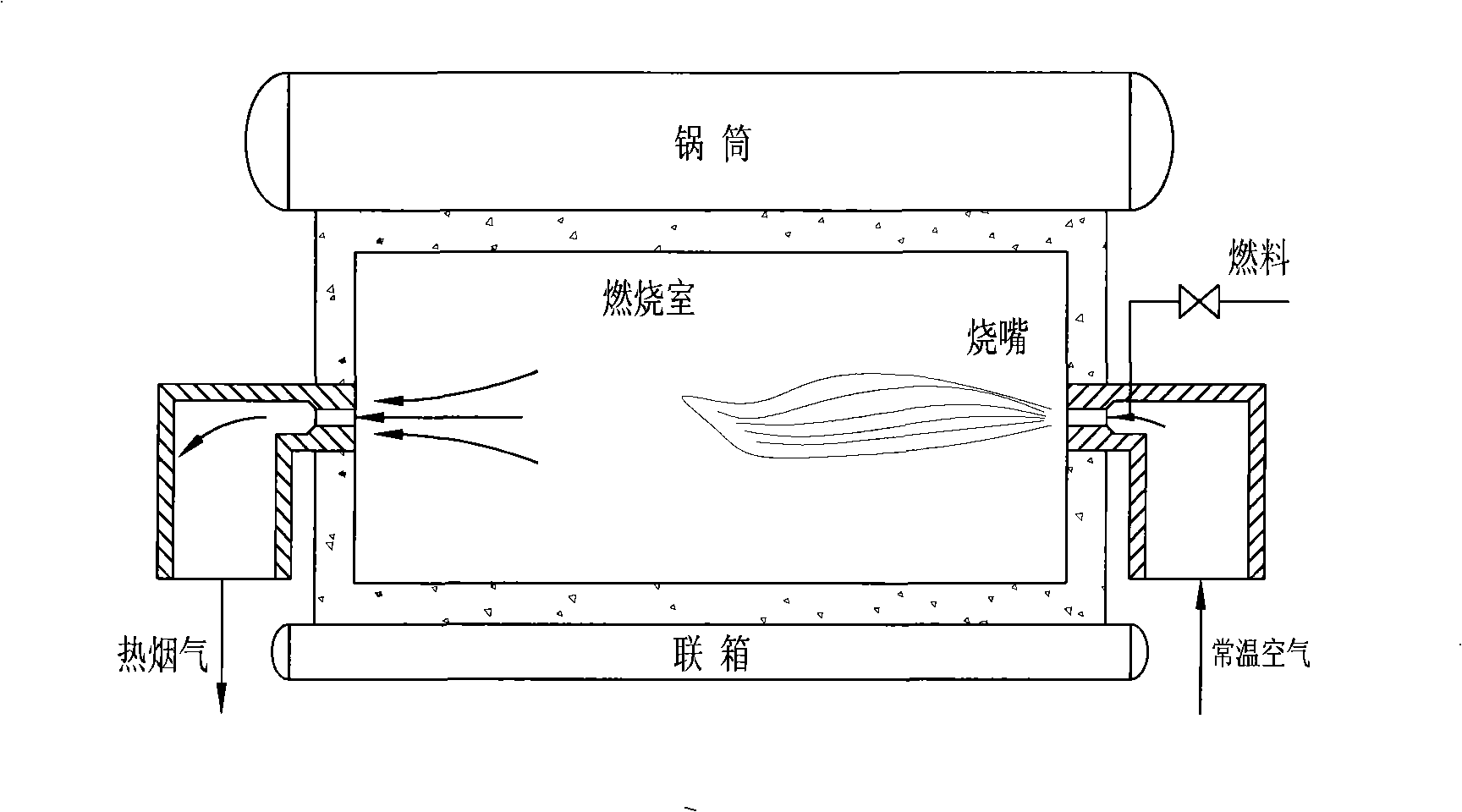

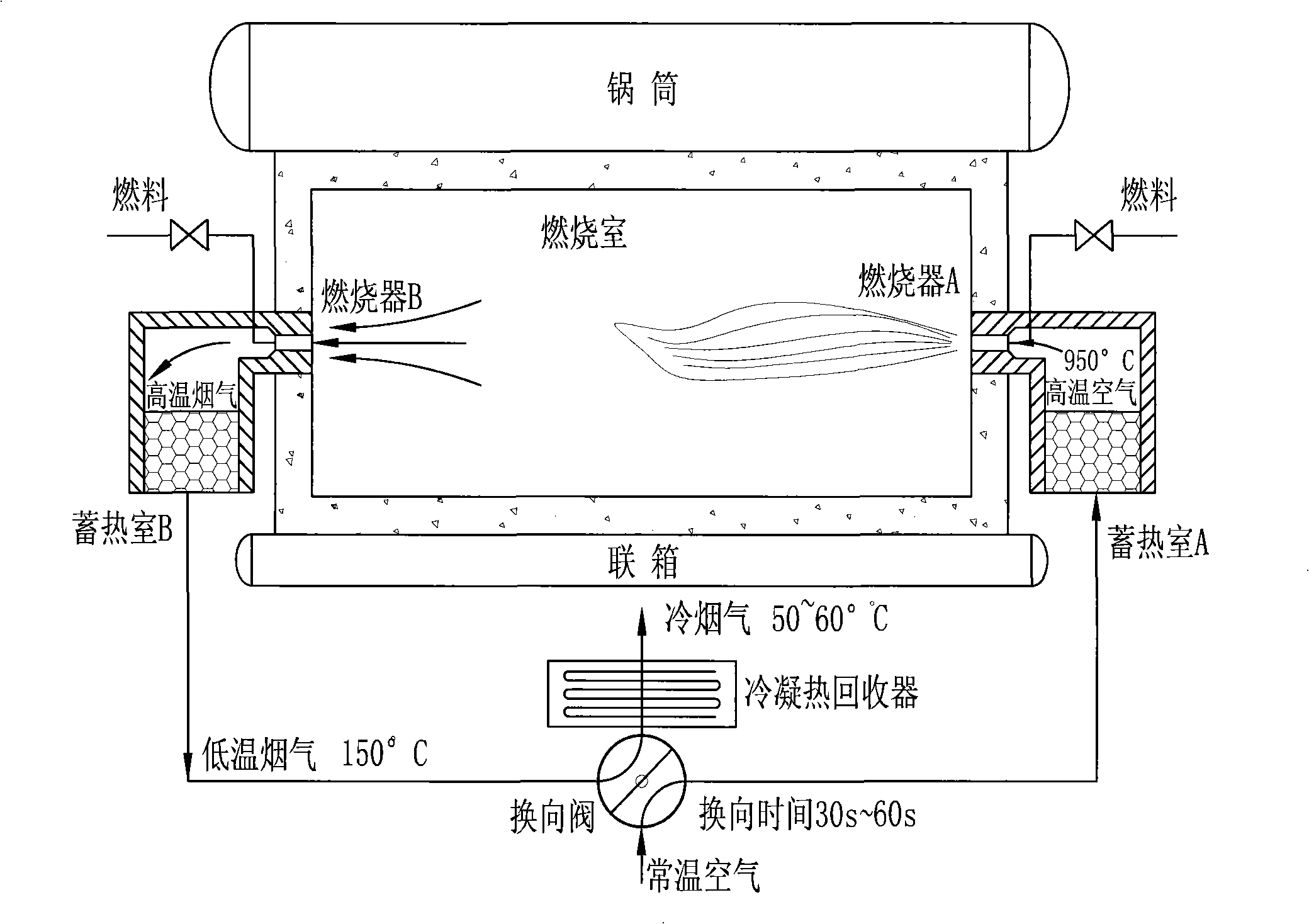

High performance fuel heat accumulation type condensation energy-saving boiler

InactiveCN101319788AReduce lossesEliminate local hot spotsCombustion processDrum steam boilersCombustorHigh energy

The invention discloses a heat accumulating type condensing and energy saving boiler for high energy fuel, which comprises a boiler body. Two or more combustors are arranged in the boiler body, a high-temperature combustion-supporting air inlet opening and a fuel spraying opening are arranged on the combustor, a checker chamber is connected with the high-temperature combustion-supporting air inlet opening, a normal temperature combustion-supporting air inlet and a low-temperature flue gas outlet are connected with the checker chamber, a direction change device is arranged between the normal temperature combustion-supporting air inlet and the low-temperature flue gas outlet, and a condensing heat recoverer is connected with the low-temperature flue gas outlet. On one hand, when the fuel gas is discharged, the waste heat of the fuel gas is recovered through the checker chamber and the condensing heat recoverer, thereby the heat energy loss is reduced, and the combustion efficiency is enhanced; on the other hand, after passing through the checker chamber, the normal temperature combustion-supporting air assists in combustion supporting, and thereby the combustion temperature can be increased; thirdly, a plurality of combustors adopts periodic reversing combustion, thereby the partial high temperature zones in the combustors are avoided, and the internal temperature distribution of the combustors is more uniform. The boiler is applied to various gas fired boilers.

Owner:SHENWU TECH GRP CO LTD

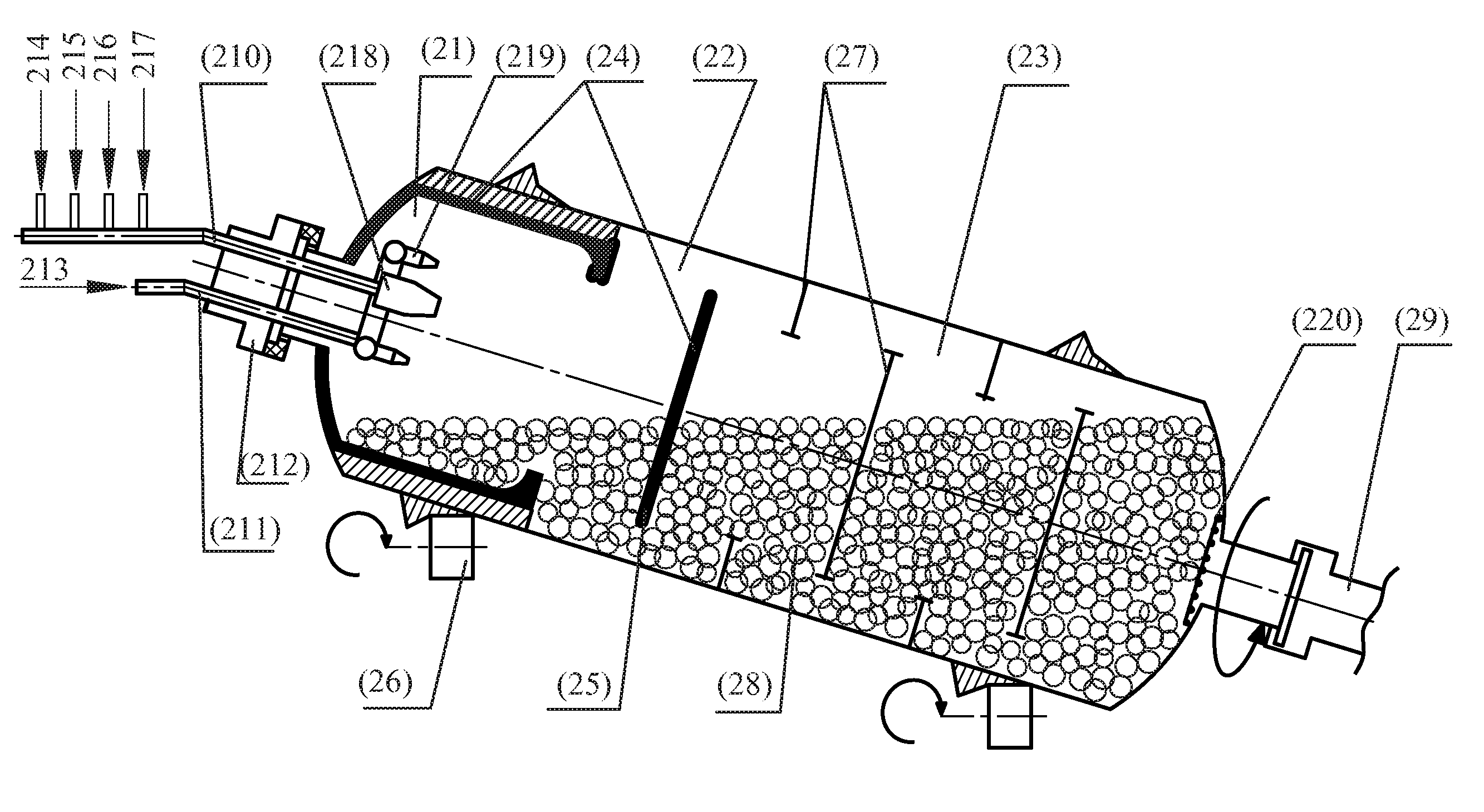

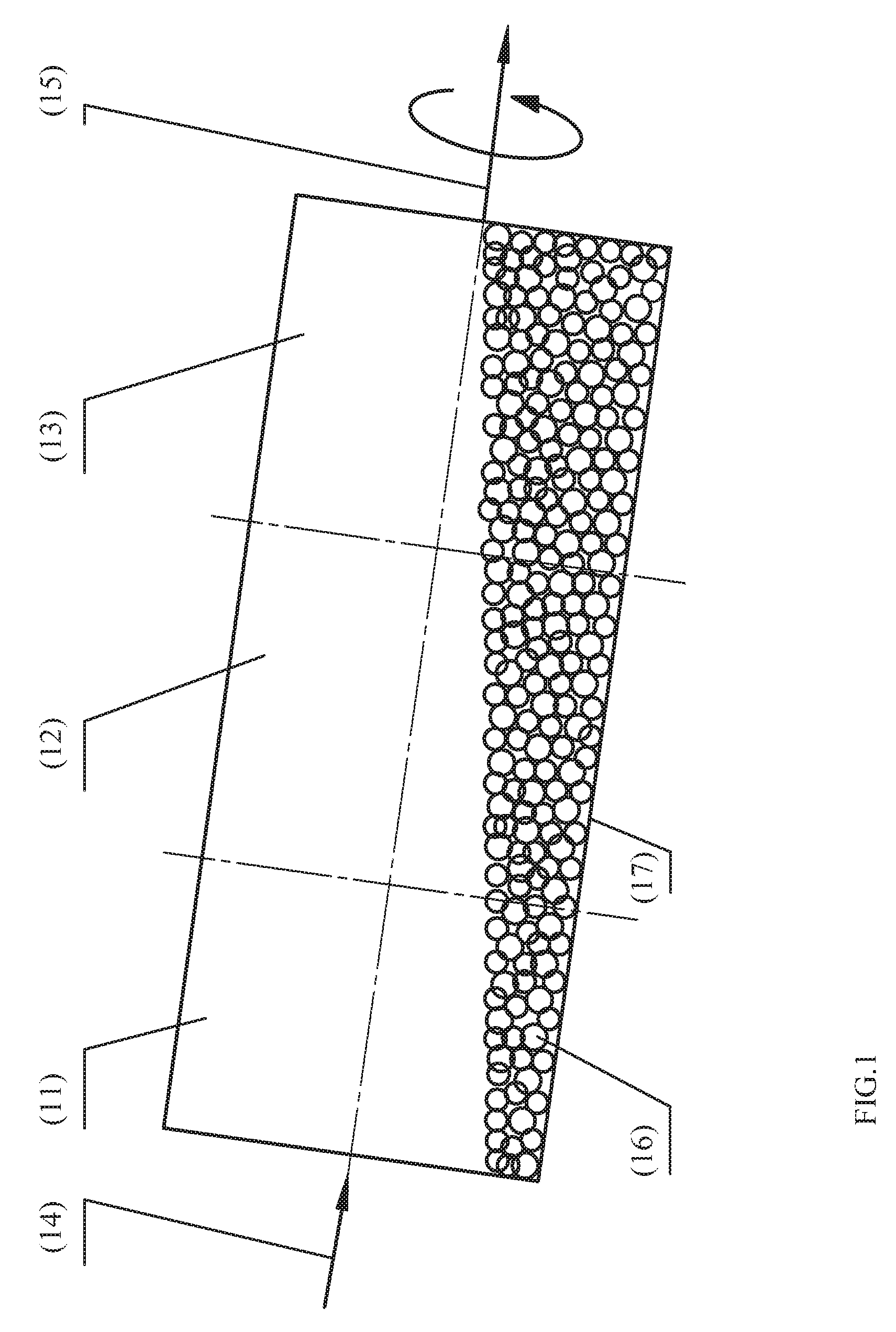

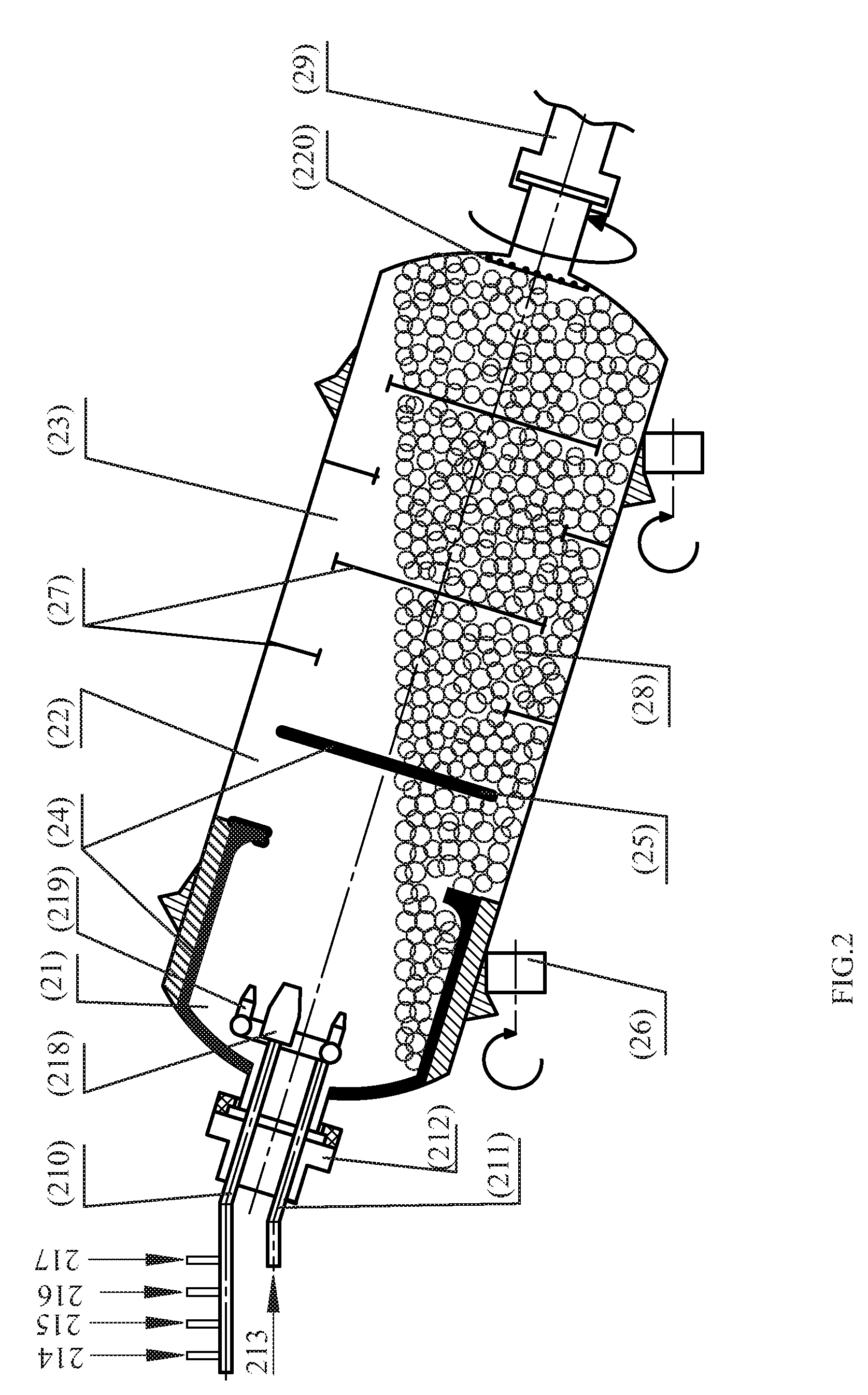

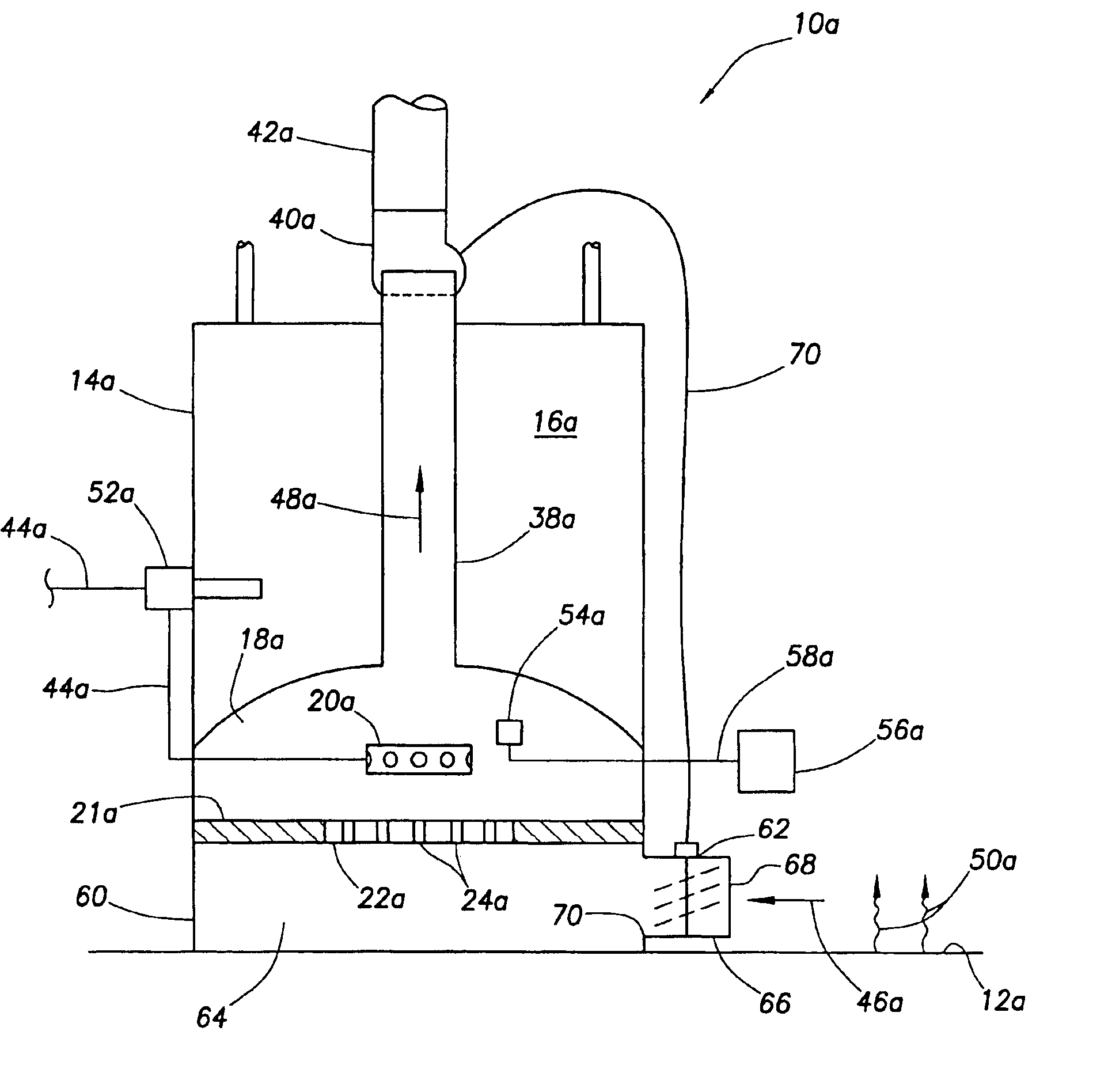

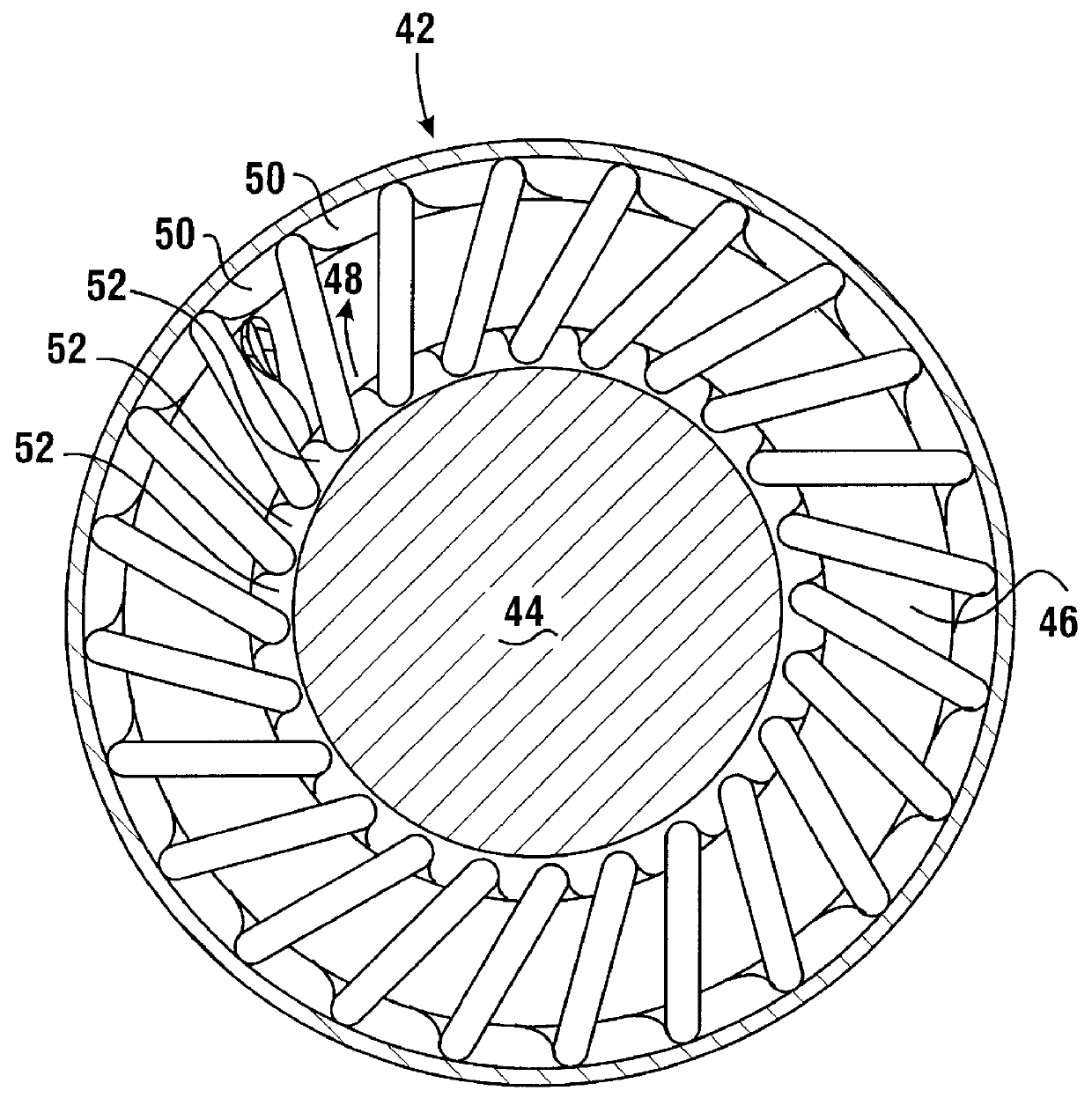

Reaction chamber for a direct contact rotating steam generator

InactiveUS7814867B2Lower the volumeEliminate needBoiler water tubesRotary drum furnacesCombustionProduct gas

Owner:EX TAR TECH

Combustion chamber shield for hot water heaters

InactiveUS6698385B1Overcome disadvantagesReduce heat lossCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberCombustor

A shield for a combustion chamber of a hot water heater is described. The combustion chamber is a sealed or not combustion chamber and the metal heat shield encircles and is spaced about the burner and pilot which is located in the combustion chamber. The shield is also spaced from the skirt and a bottom wall of the combustion chamber. The shield is further provided with apertures to permit passage of air supplied by an air supply duct. The shield provides for heat concentration on a lower heat transfer wall of the inner casing containing the water to be heated. The shield also reduces heat loss through the skirt and the bottom end wall of the combustion housing.

Owner:MICLAU S R I

Water heater with normally closed air inlet damper

A fuel-fired, power vented water heater has a combustion chamber with an outer wall portion defined by an arrestor plate in which flame quenching air inlet openings are formed. All combustion air entering the combustion chamber must first pass through an air inlet plenum extending outwardly from the arrestor plate and then pass inwardly through the flame quenching openings into the combustion chamber. The air inlet plenum is provided with a normally closed inlet damper which automatically closes during non-firing periods of the water heater to prevent passage of combustion air (and extraneous flammable vapors, if present, adjacent the water heater) into the combustion chamber, and opens during firing periods of the water heater to permit operative combustion air delivery to the combustion chamber.

Owner:RHEEM MFG CO

Control method of thermostatic system

InactiveUS6648235B2Easy to controlDegree of opening is decreasedFluid heatersFuel supply regulationThermal waterElectromagnetic valve

Owner:GUARD SOUND IND CO LTD

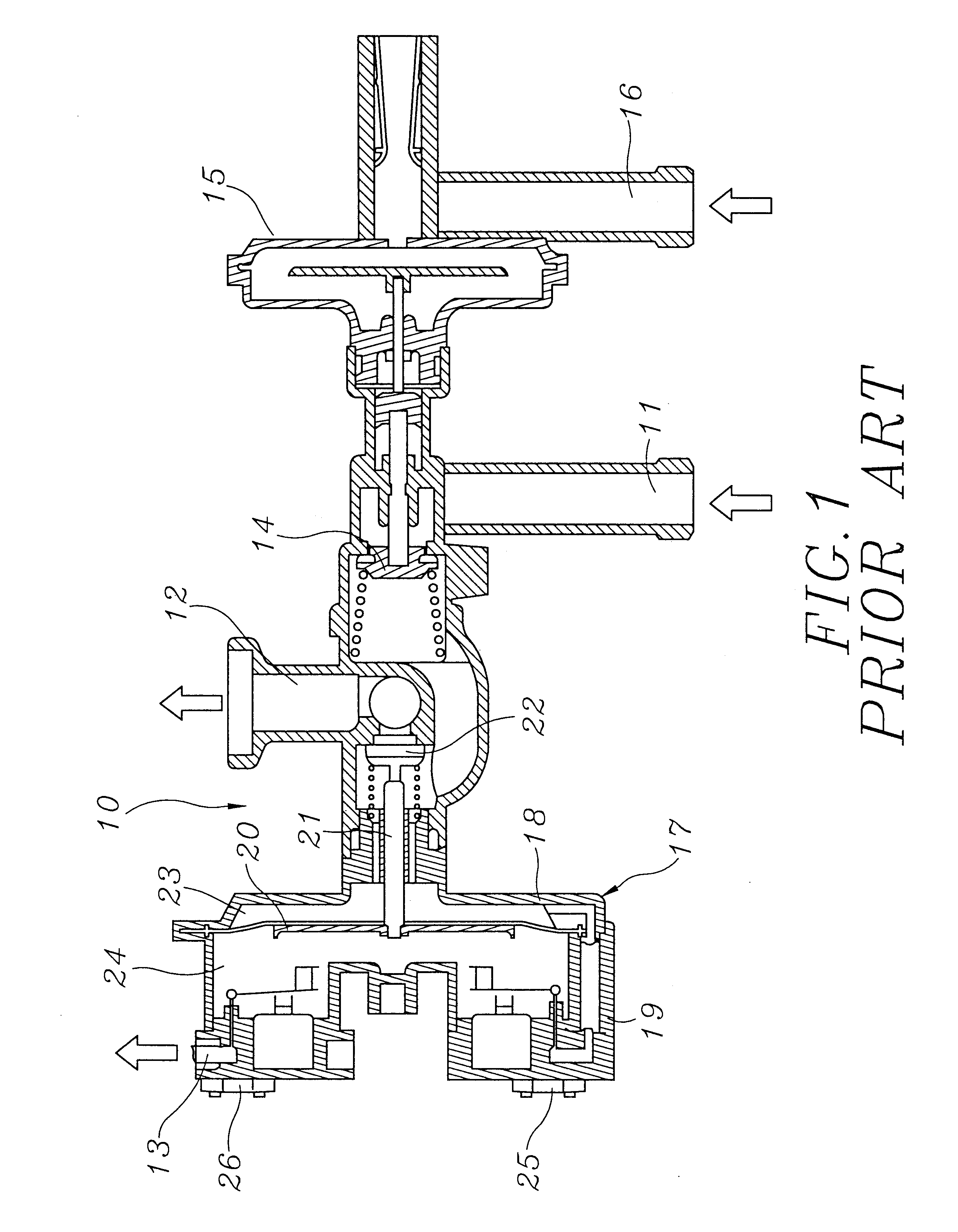

Water heater having raw fuel jet pilot and associated burner clogging detection apparatus

ActiveUS7028642B2High sensitivityBurner safety arrangementsDrum steam boilersParticulatesCombustion chamber

A radiant gas burner within the combustion chamber of a water heater has a pilot flame created using a raw fuel jet that impinges on an interior surface portion of a flame holding outer burner wall portion, representatively of a metal wire mesh material, and is mixed within the burner with combustion air delivered thereto from outside the combustion chamber. The resulting fuel / air mixture passes outwardly through the impinged upon mesh wall portion, which functions as a pilot flame stabilizing structure, and is ignited to form a pilot flame on the exterior of the burner body. A thermocouple portion of a clogging detection system senses a change in the pilot flame shape caused by particulate clogging of the metal mesh material and responsively terminates further gas supply to the water heater.

Owner:RHEEM MFG CO

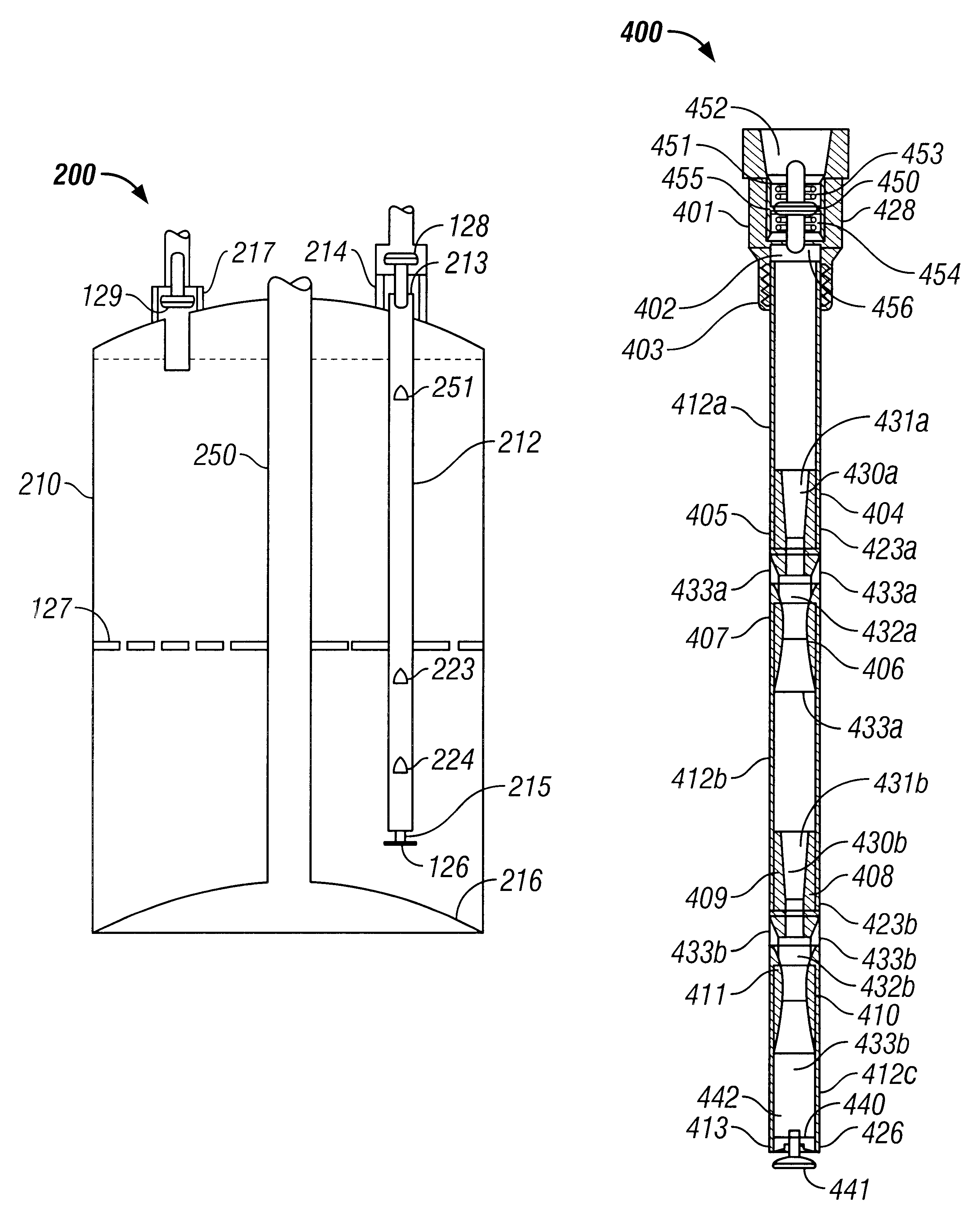

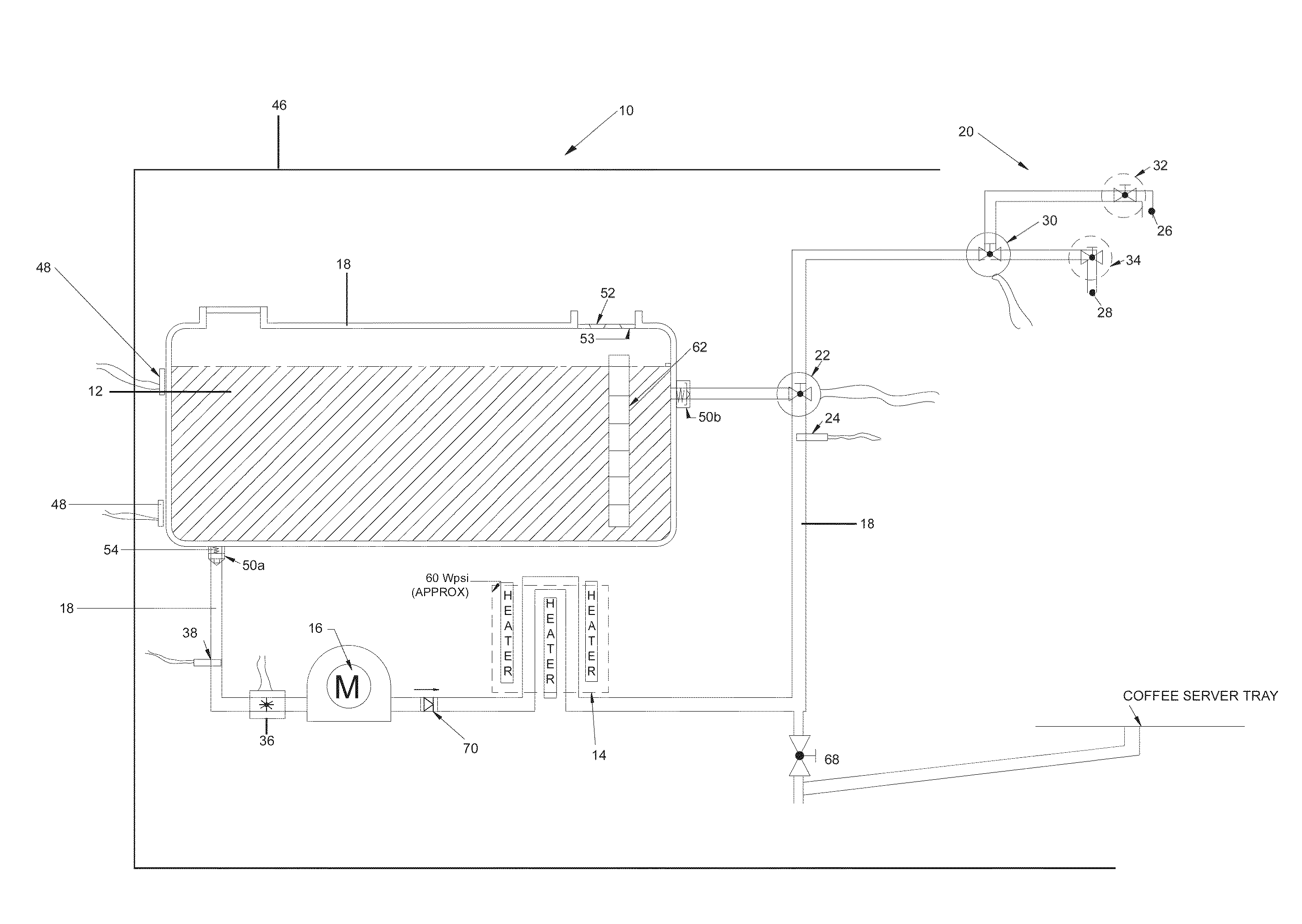

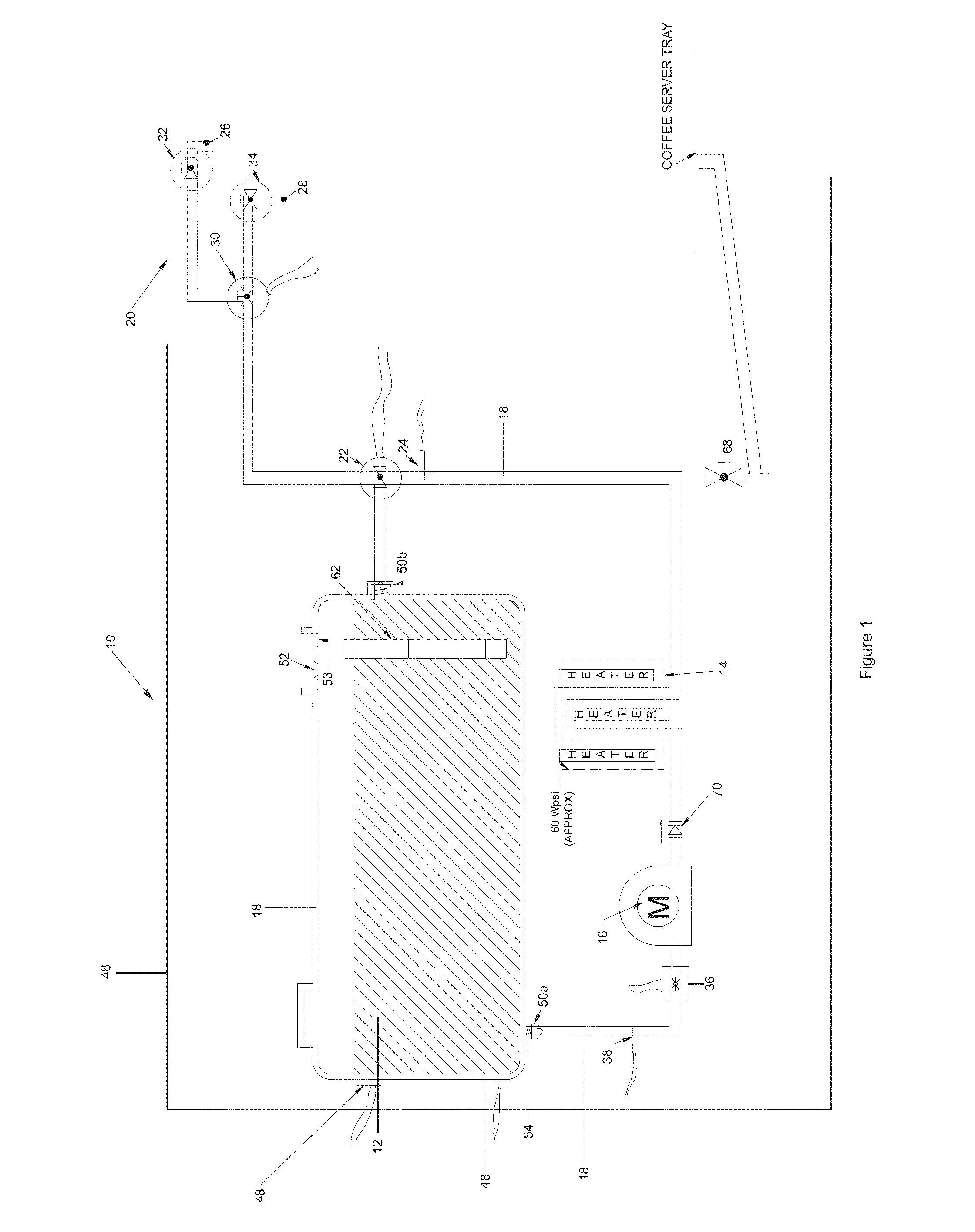

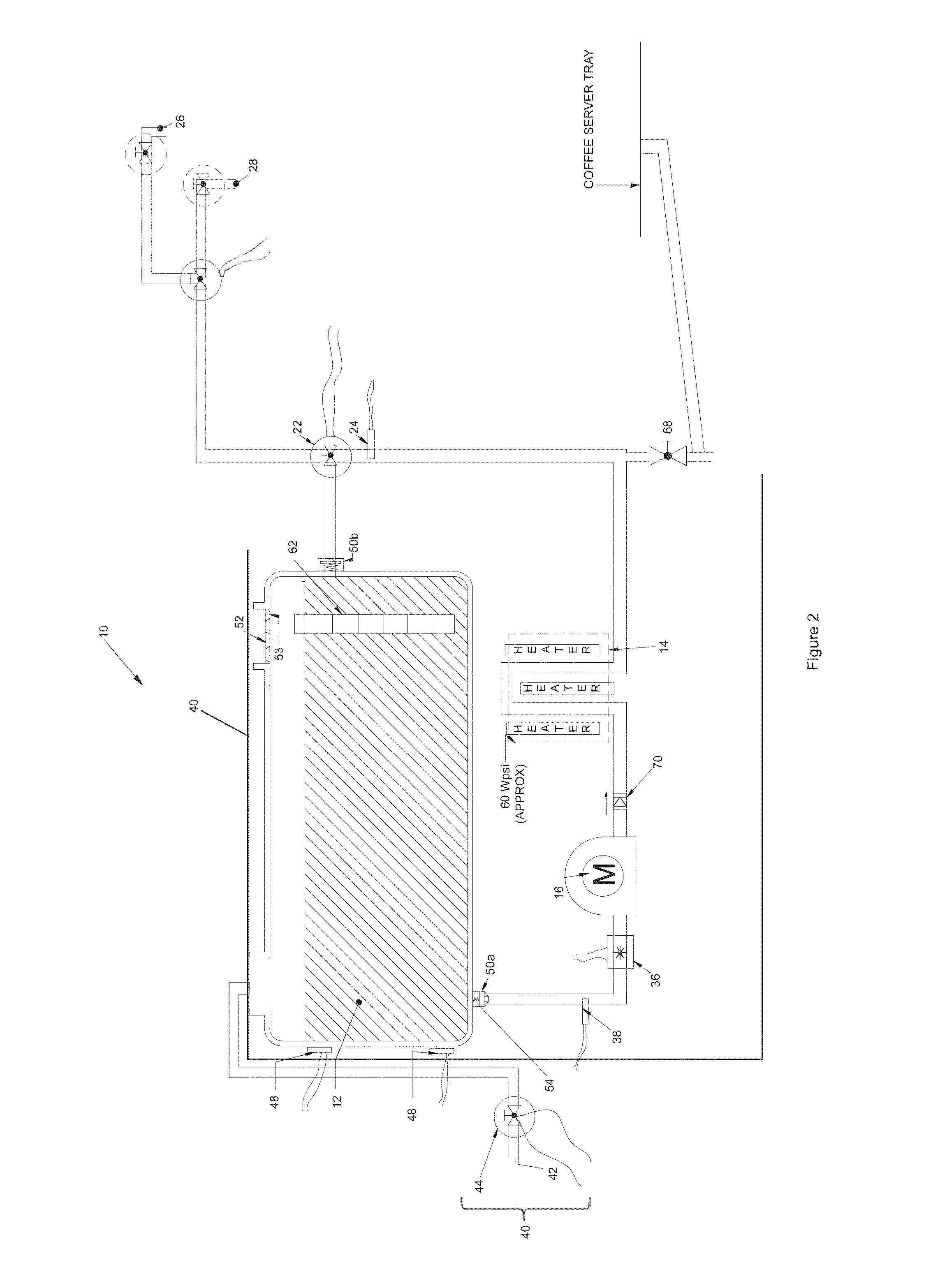

Coffee maker water heater

InactiveUS20140069353A1Heating fastReduce power consumptionDrum steam boilersBeverage vesselsProcess engineeringThermal water

Embodiments of the present invention provide improved heating methods for use in coffee makers and other beverage makers that use hot water for various beverages and other purposes. These improvements find particular use on-board aircraft or other passenger transport vehicles, where quick heating and reduced power consumption are particularly desirable and beneficial. Further embodiments also relate to improved water level sensing, improved water reservoirs, and improved carafe features.

Owner:THE RICHARDS CORP

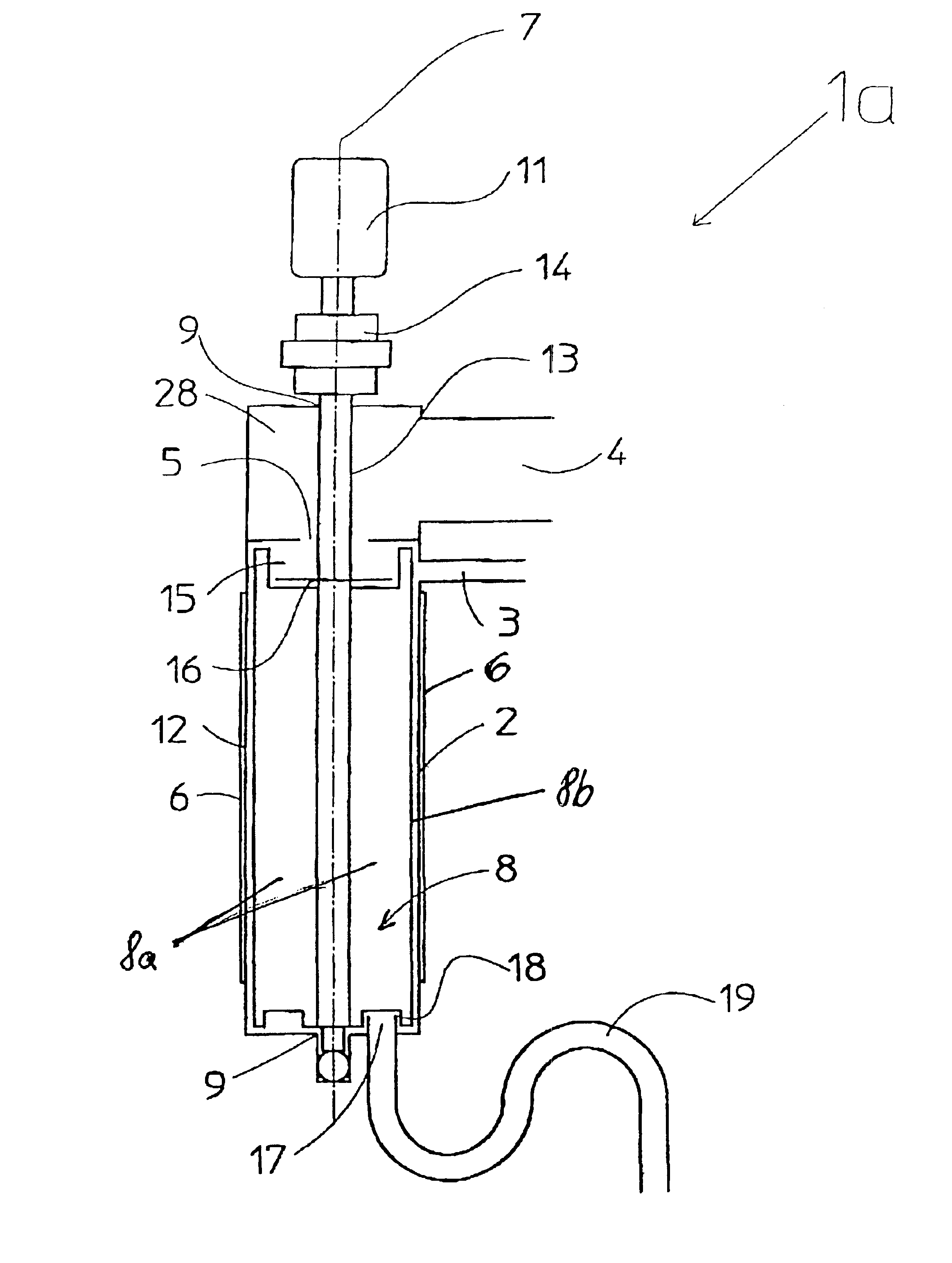

Method and apparatus for generating steam for a cooking device

InactiveUS6959668B2Easy to installSimple contactSteam generation using mechanical energyDomestic stoves or rangesVaporizationEngineering

Owner:RATIONAL AG

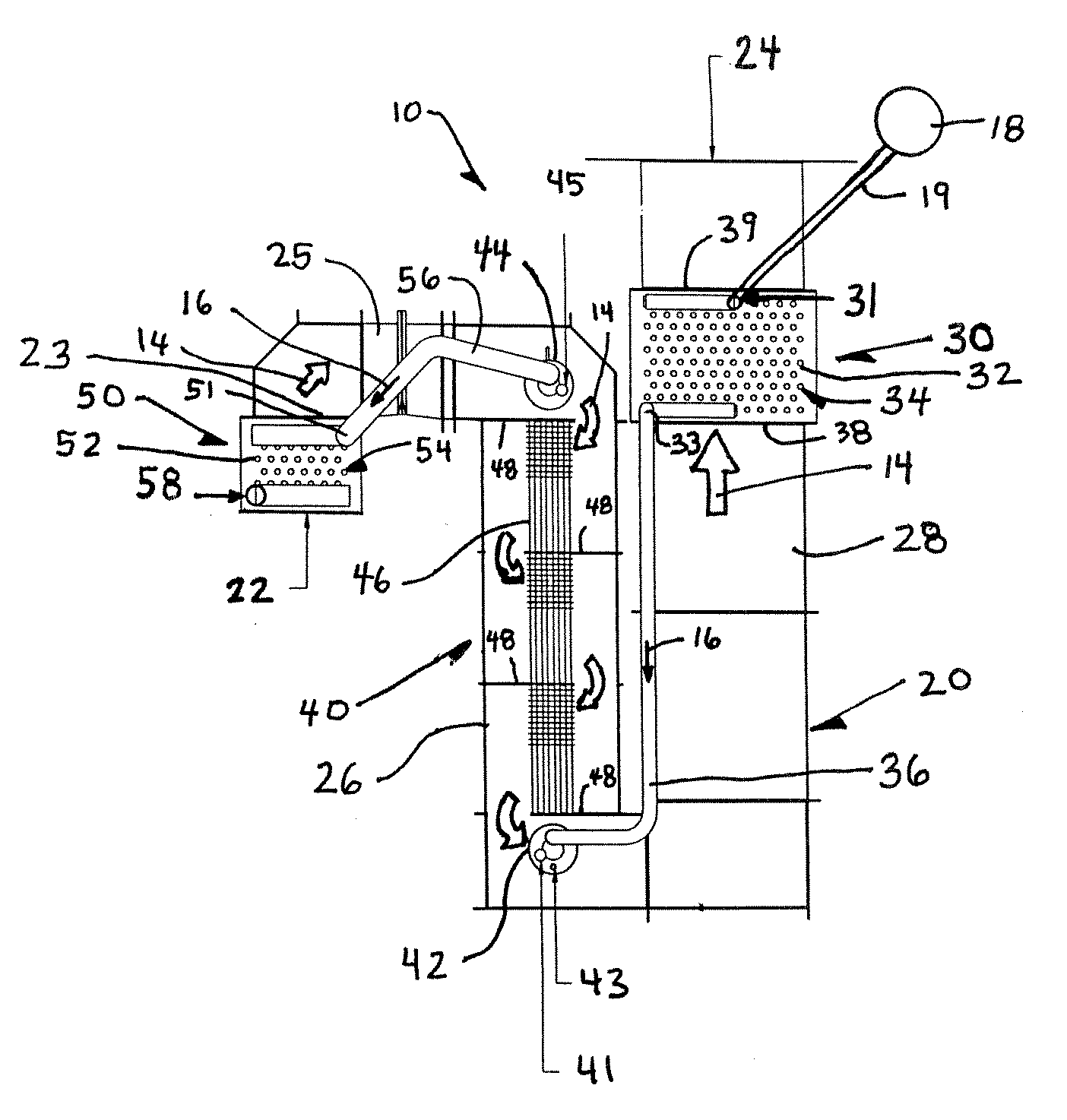

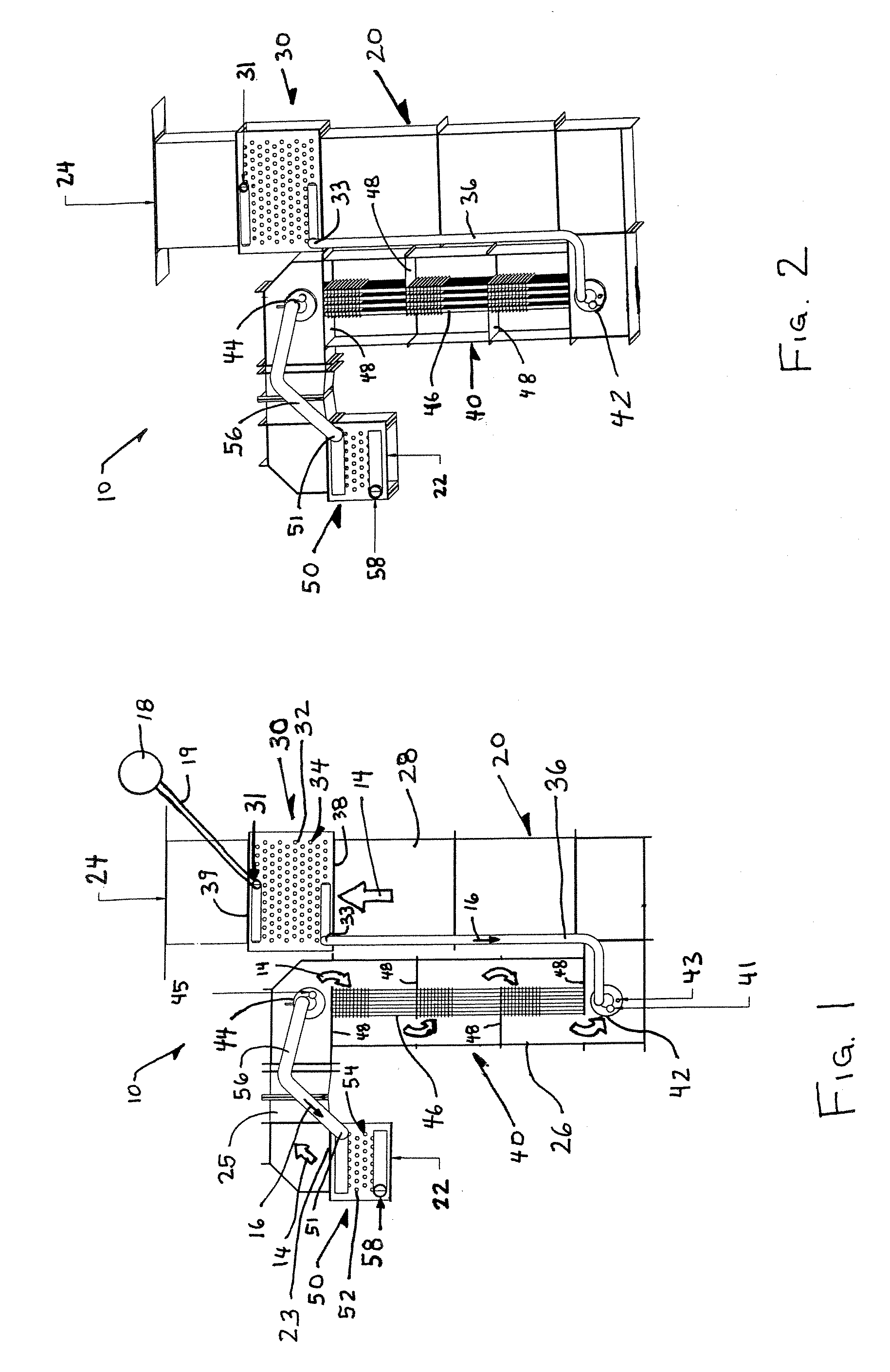

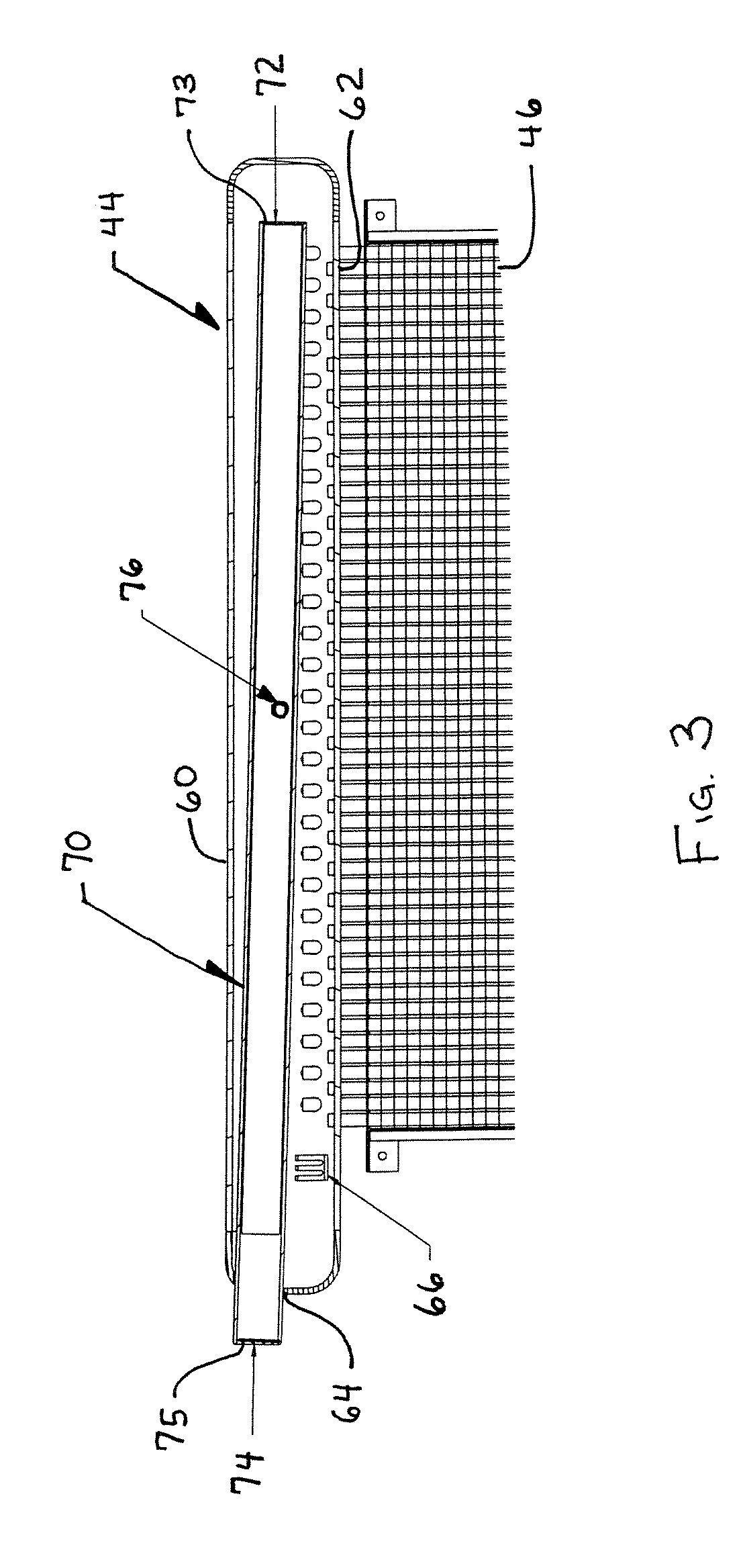

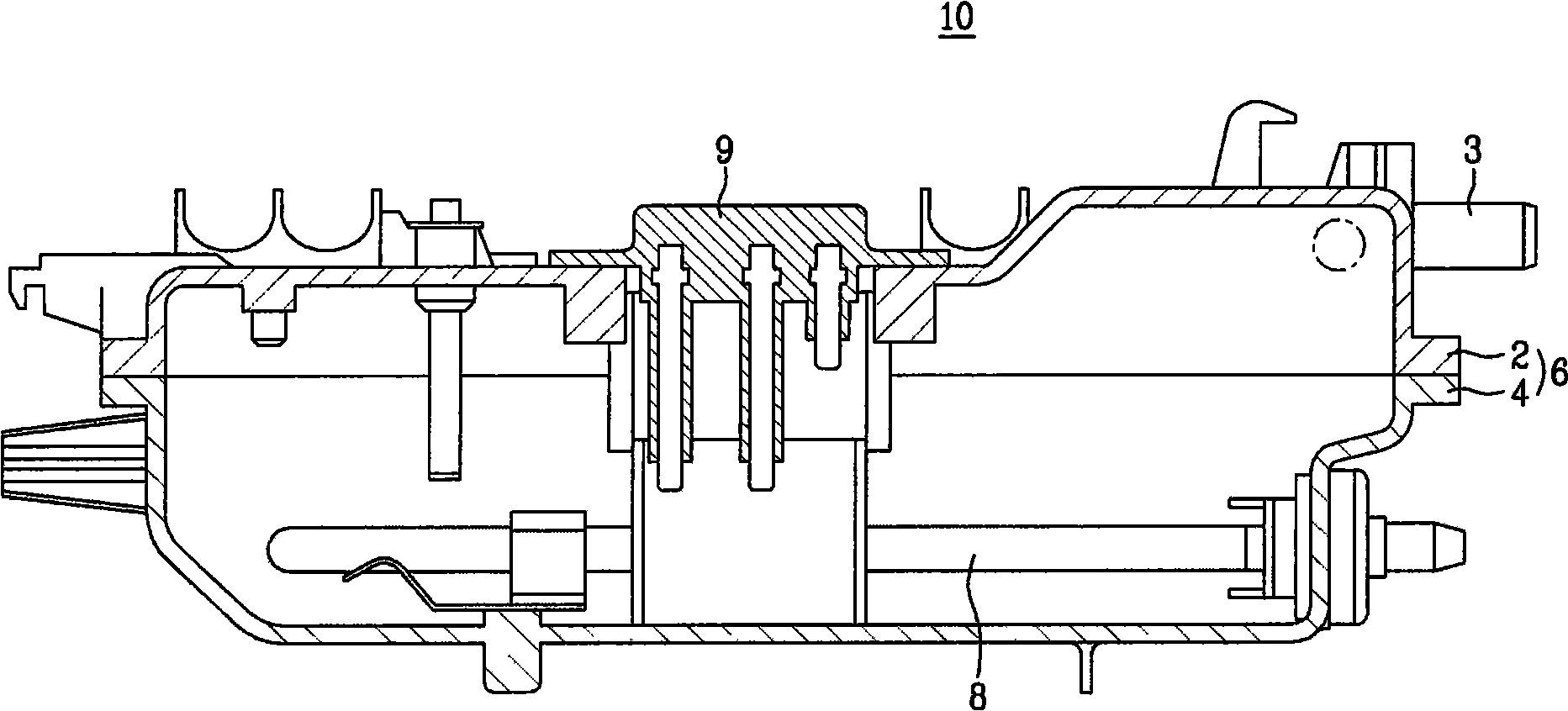

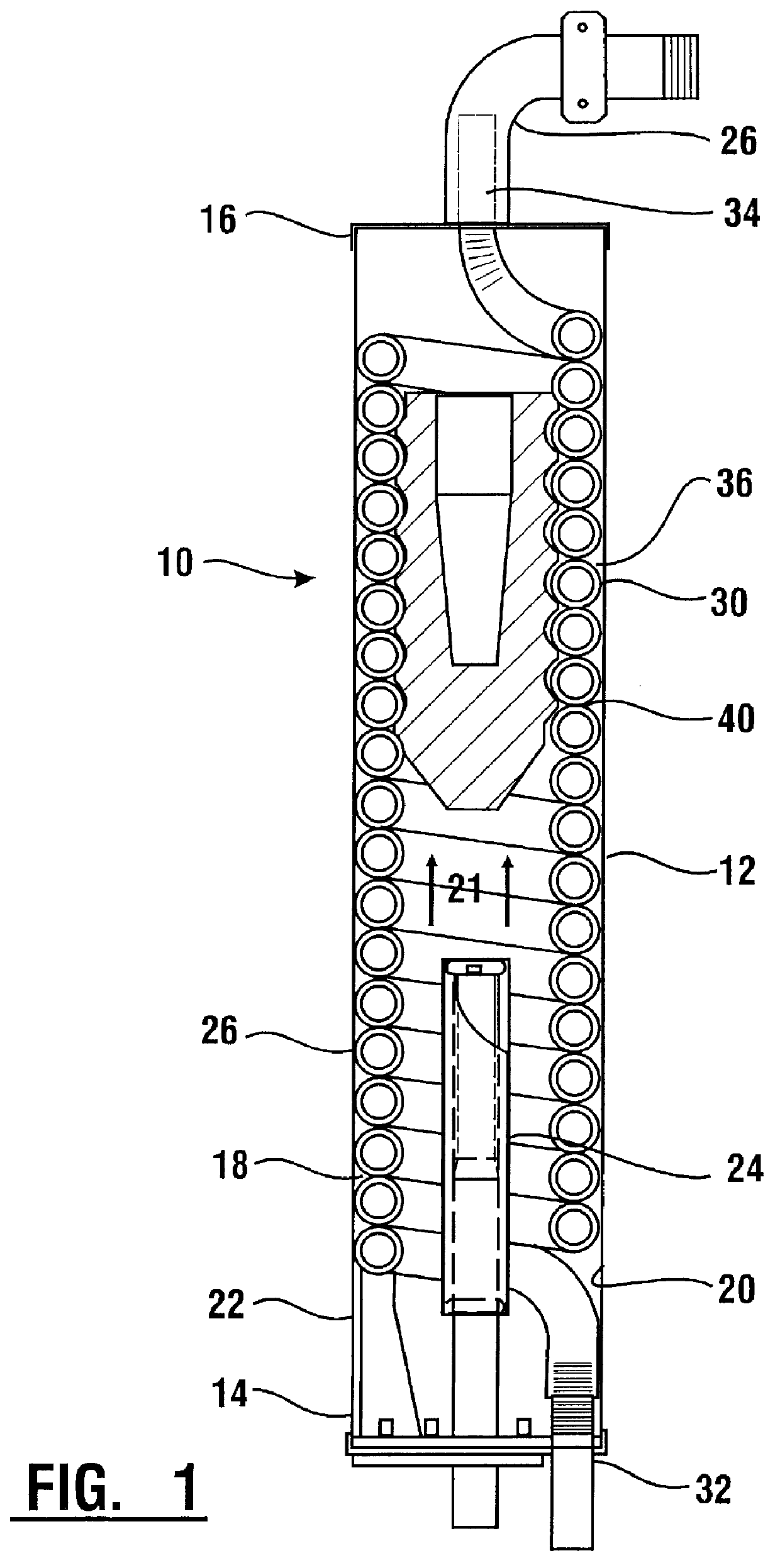

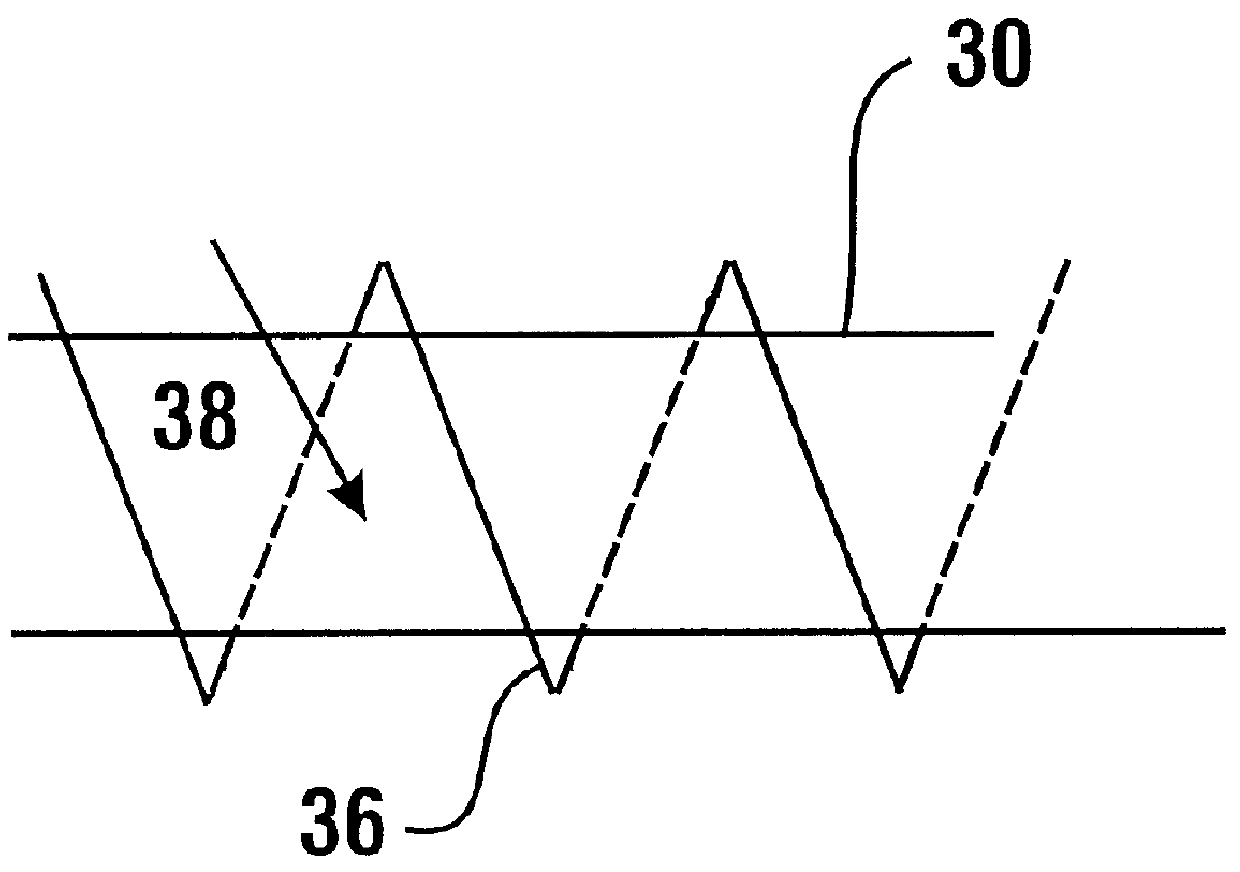

Plug core heat exchanger

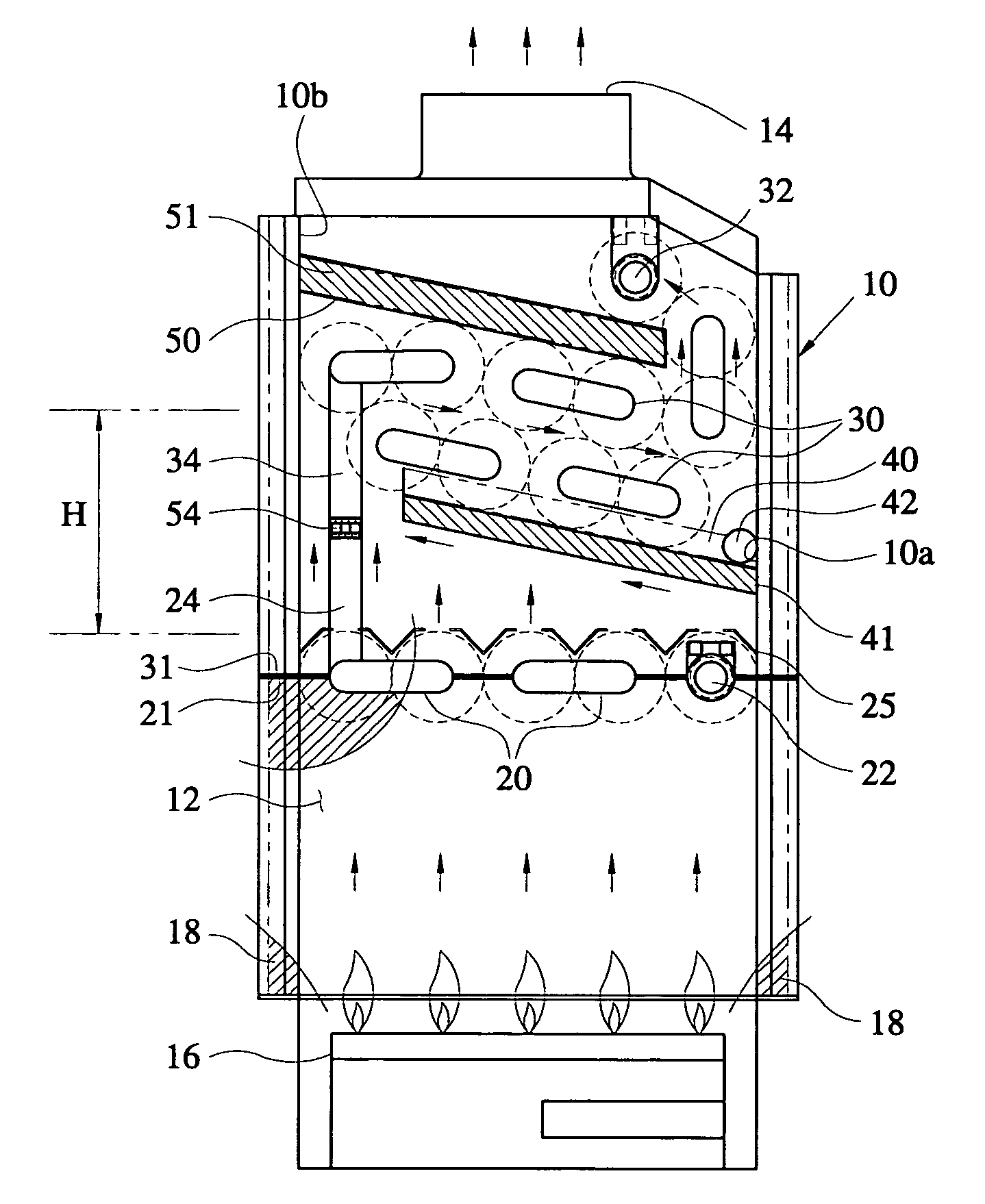

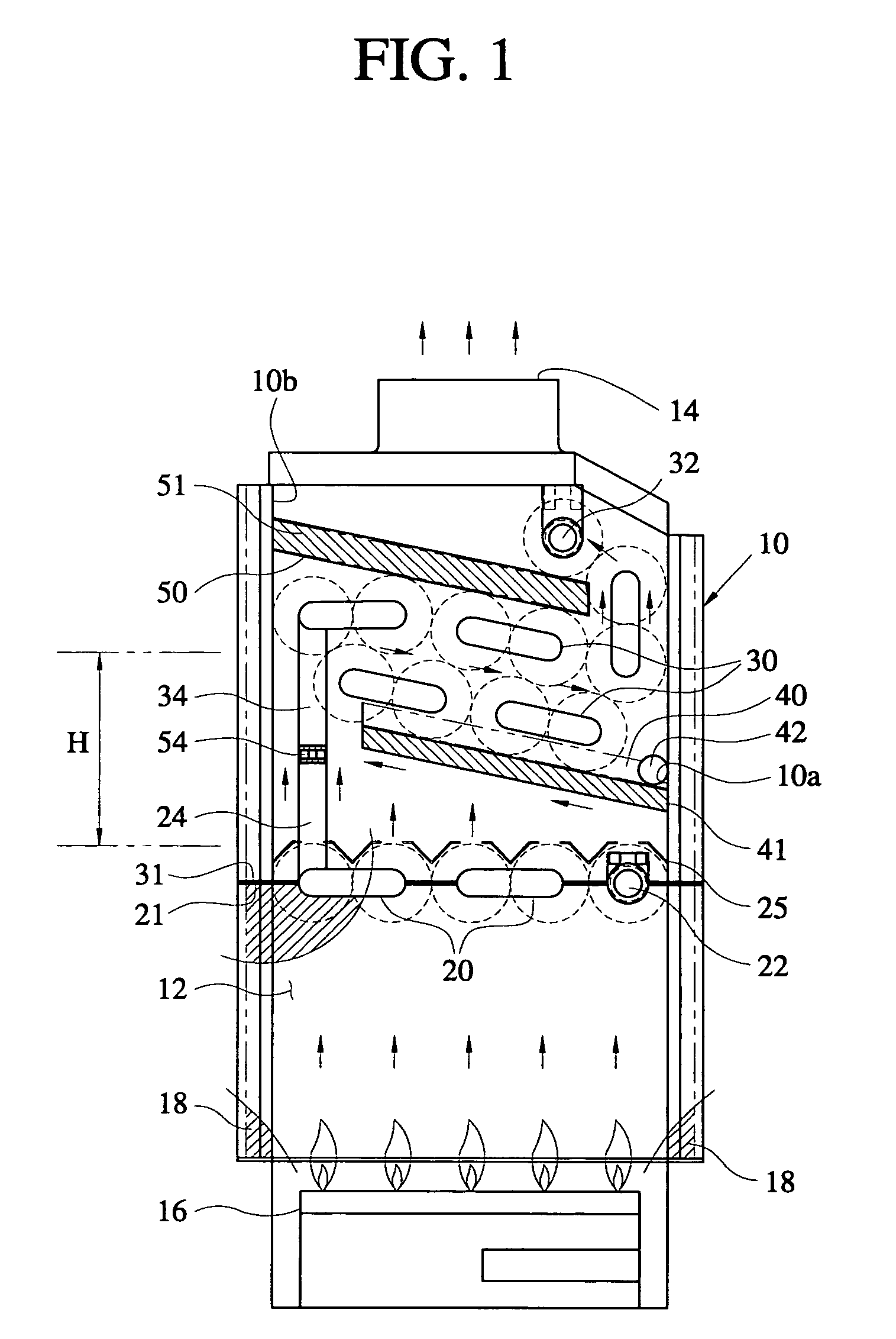

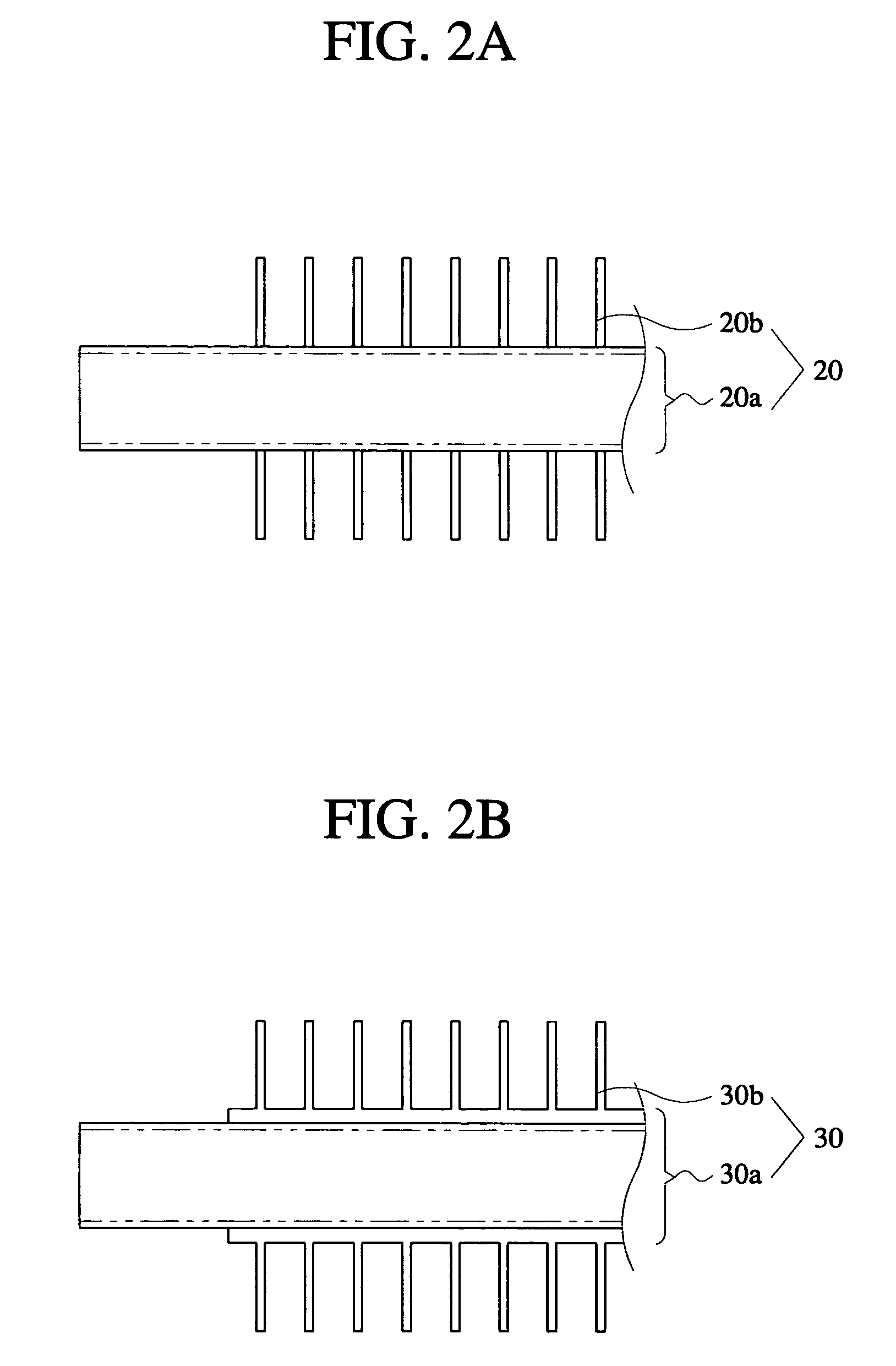

InactiveUS6026801AMaximizes flow lengthMaximizes residence timeWater circulationDrum steam boilersCombustorNuclear engineering

An apparatus (10) for transferring heat to a fluid from combustion gases including a housing (12) extending between a first end (14) and a second end (16). The apparatus further includes a burner (24) in which a combustible gas and oxygen react to form hot combustion gases which flow from the burner to a gas outlet (28) in the second end. The fluid flows in a length of helically coiled tubing (30) extending the length of the housing. The tubing includes a fin portion (36) which is spirally wound about the length of tubing. The apparatus further includes a core member (40) which extends within the coils of the tubing, and which engages the tubing. The core member includes a spirally-wound threaded area (62) about which the tubing is wrapped. The core member further includes a recessed portion (66) which creates stagnant air pocket adjacent the end of the core member. In operation the combustion gases leaving the burner are prevented from being short circuited and are directed into the tubing by the core member. The combustion gases are routed by the fin portion along a helical flow path throughout the length of the core member. The combustion gases are transferred into contact with the core member every revolution around the tubing. The recessed portion reduces the heat transfer between the core member and the exiting combustive gases.

Owner:BARKAN KENNETH C

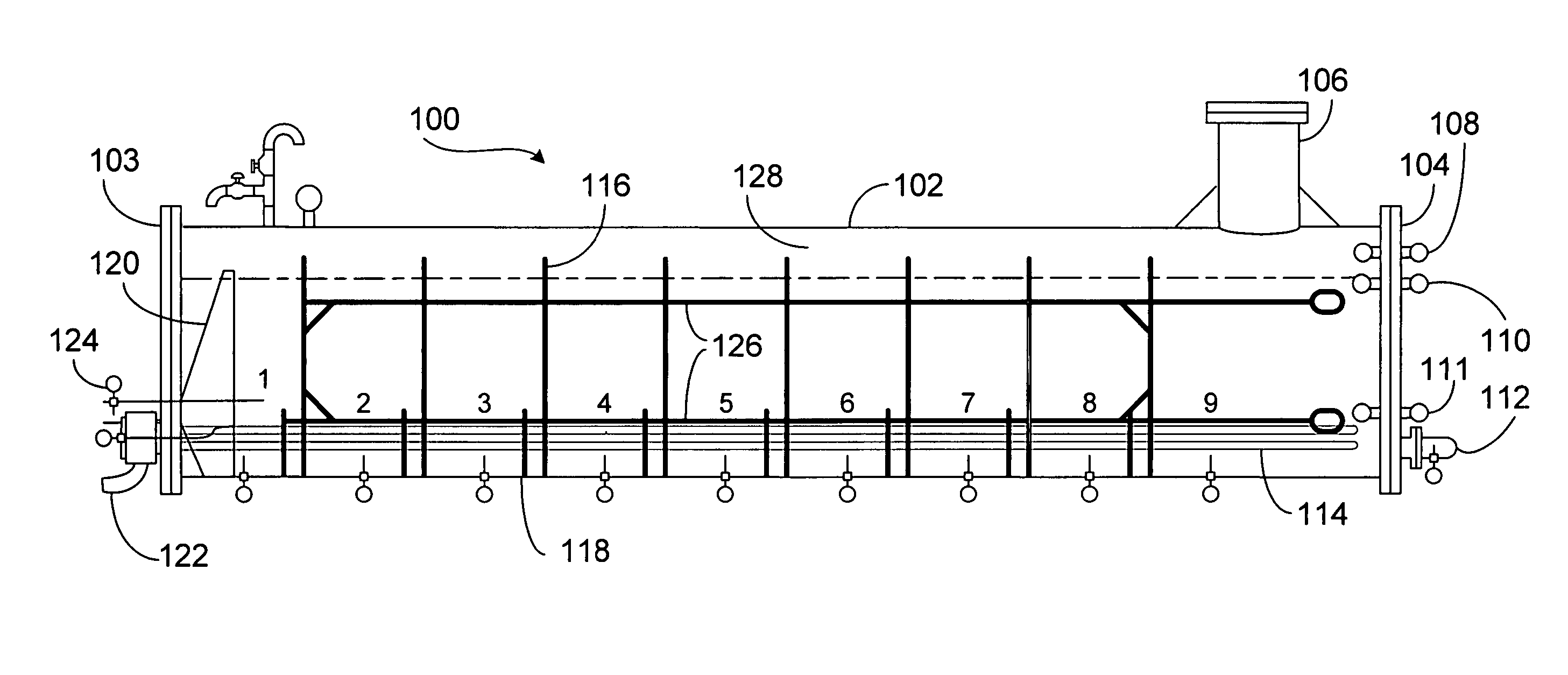

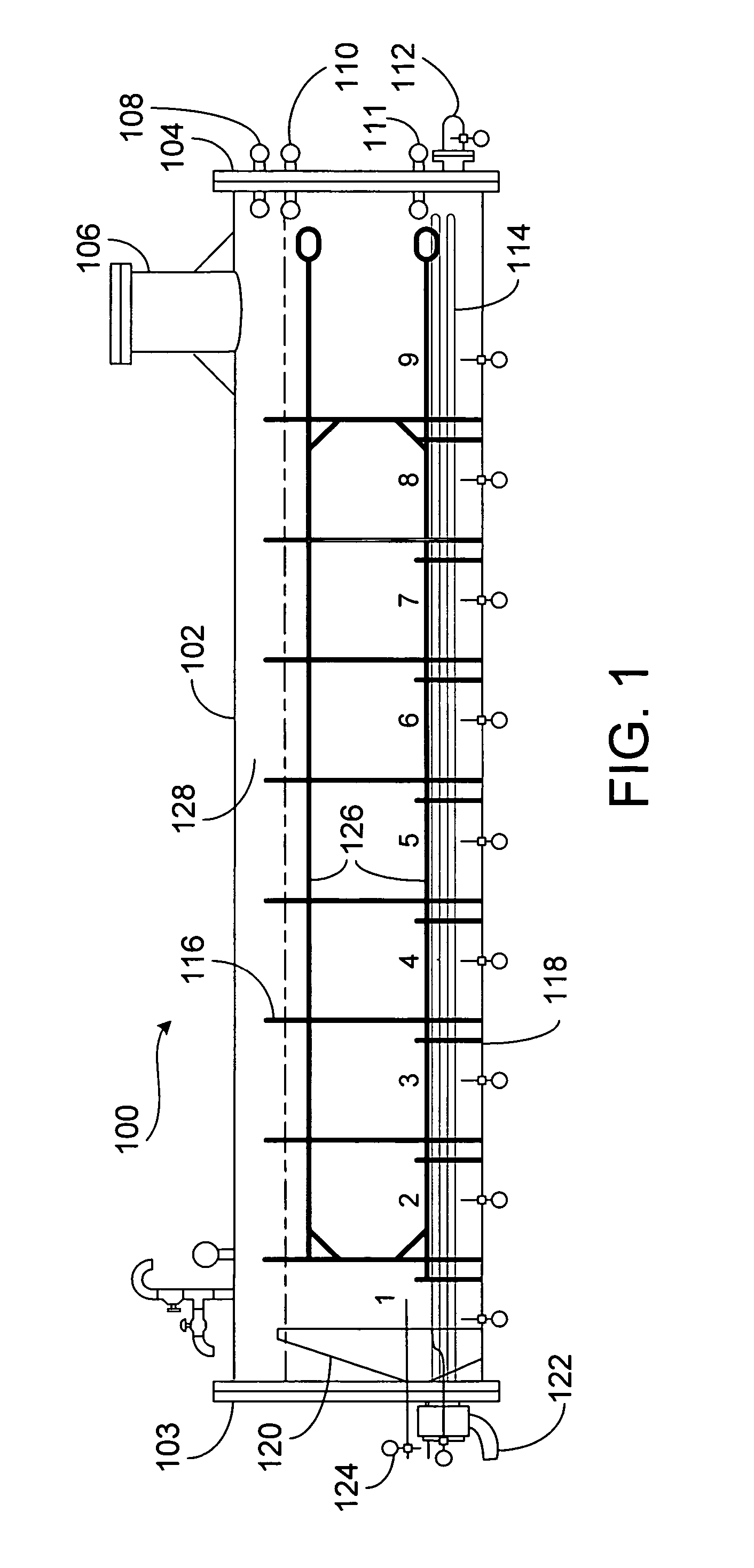

Ethanol continuous flow boiler

An improved boiler that allows distillation of ethanol from a continuous flow of a hydrous feedstock compound, which may be beer or other semi-solid substance. The internal compartment of the boiler is separated into different zones by a plurality of primary baffle plates and secondary baffle plates. The hydrous feedstock compound is heated as it passes from one zone to another zone and ethanol inside the hydrous feedstock compound vaporizes. The ethanol rich vapor is channeled through a collector column and then collected for further processing. The temperature of the hydrous feedstock compound is slightly different from one zone to another zone because of ethanol concentration changes as the hydrous feedstock compound moves from one zone to another. At the last zone, where most of ethanol is removed, the remaining hydrous feedstock compound is removed from the boiler.

Owner:LING MICHAEL R

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com