Patents

Literature

96results about How to "Degree of opening is decreased" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

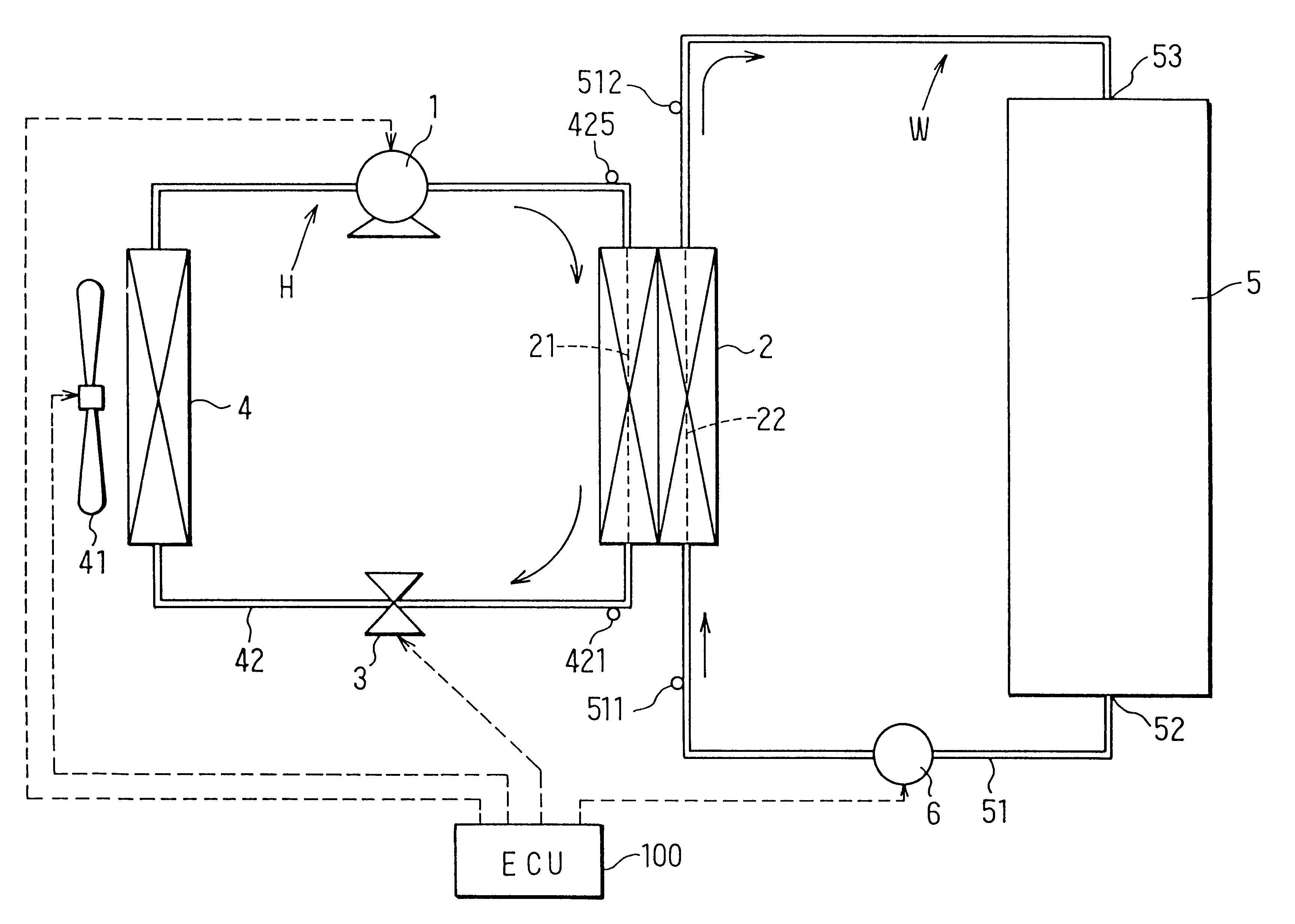

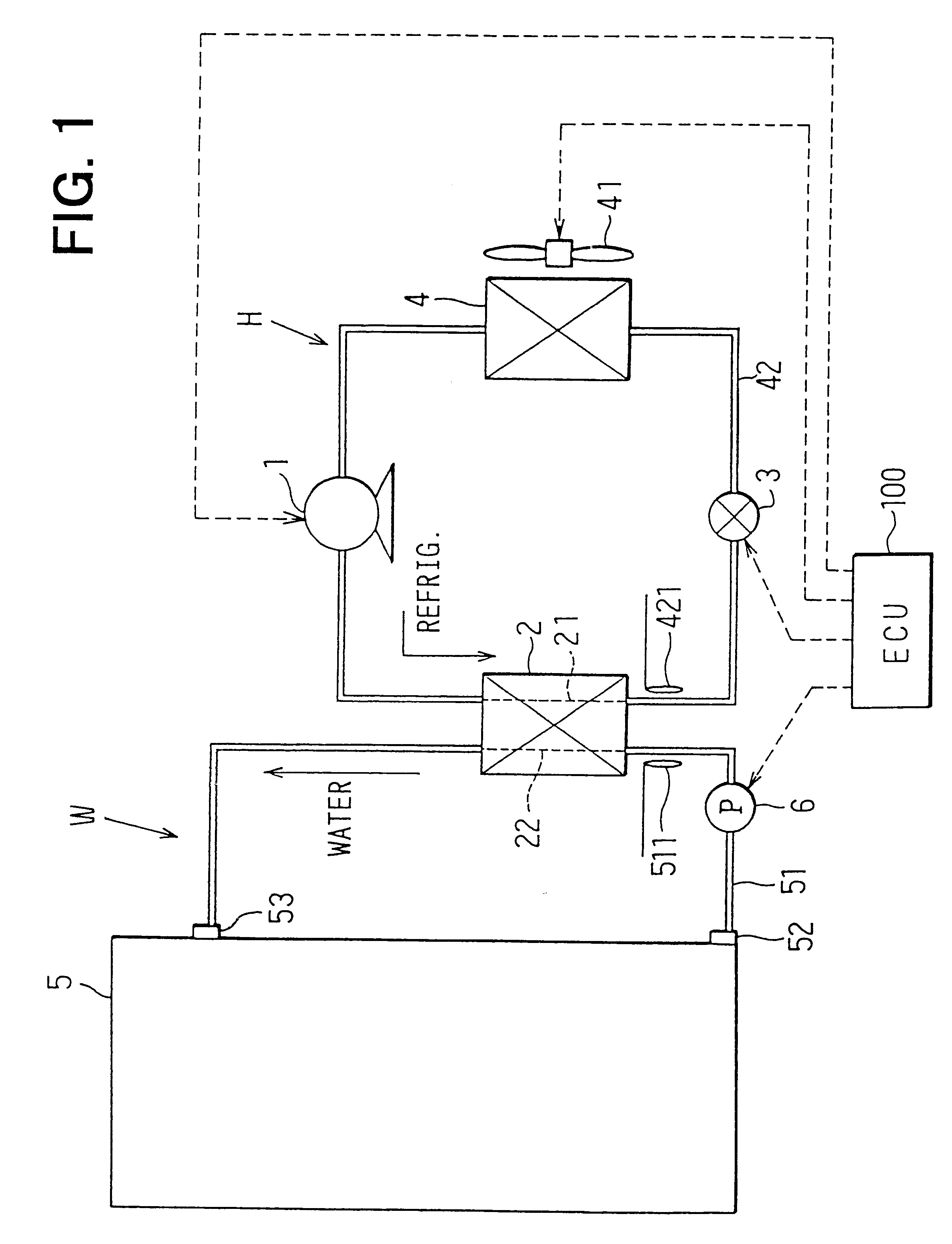

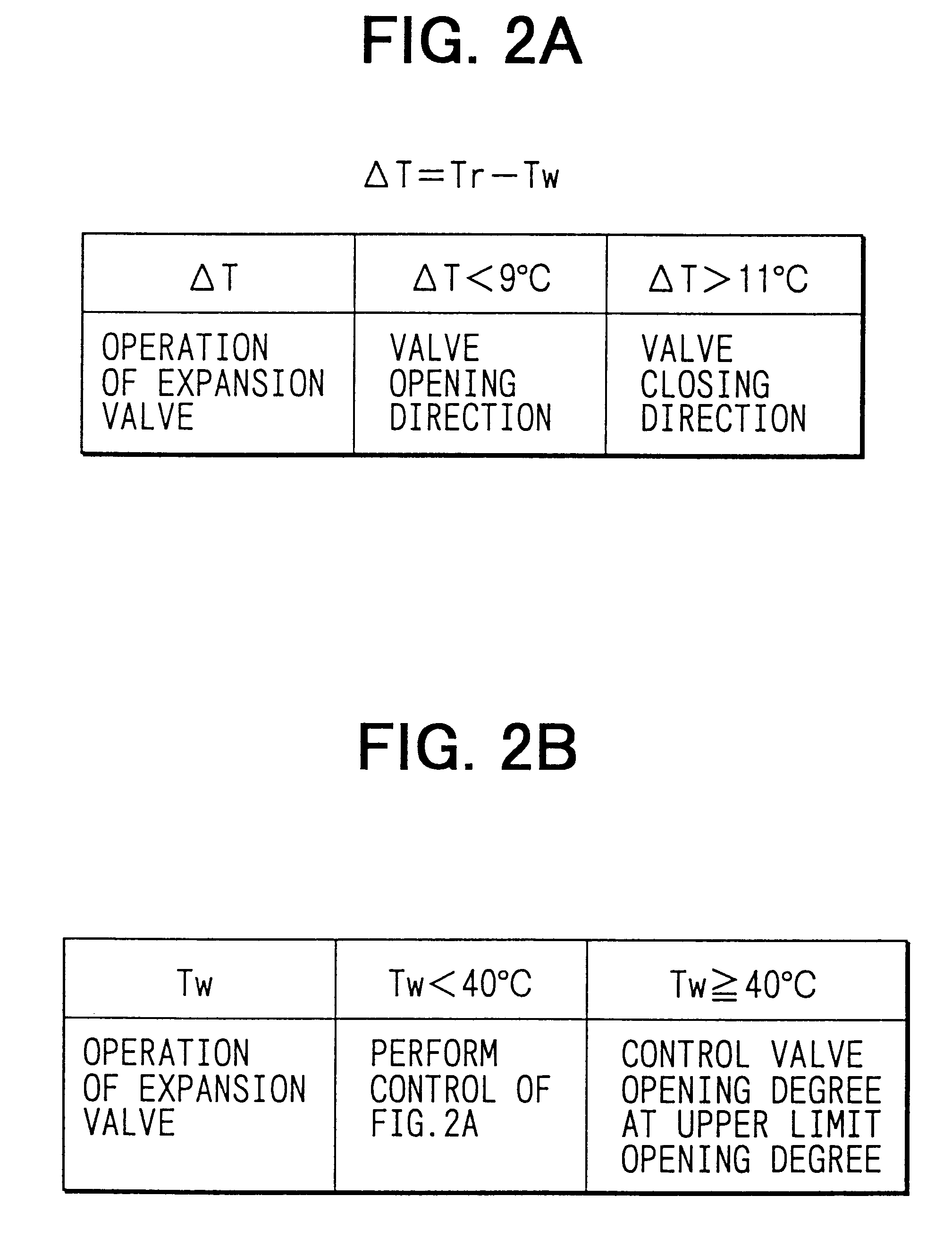

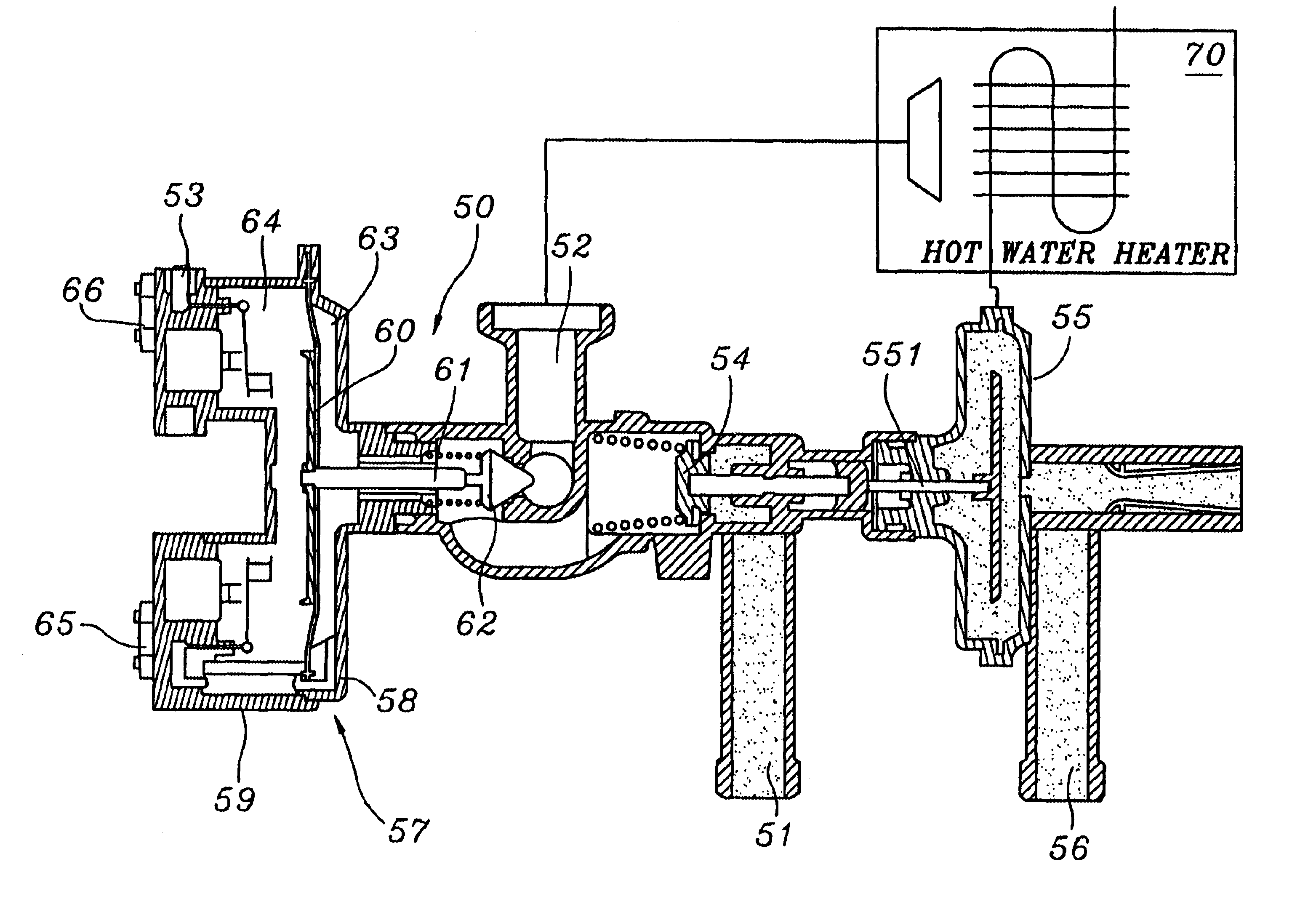

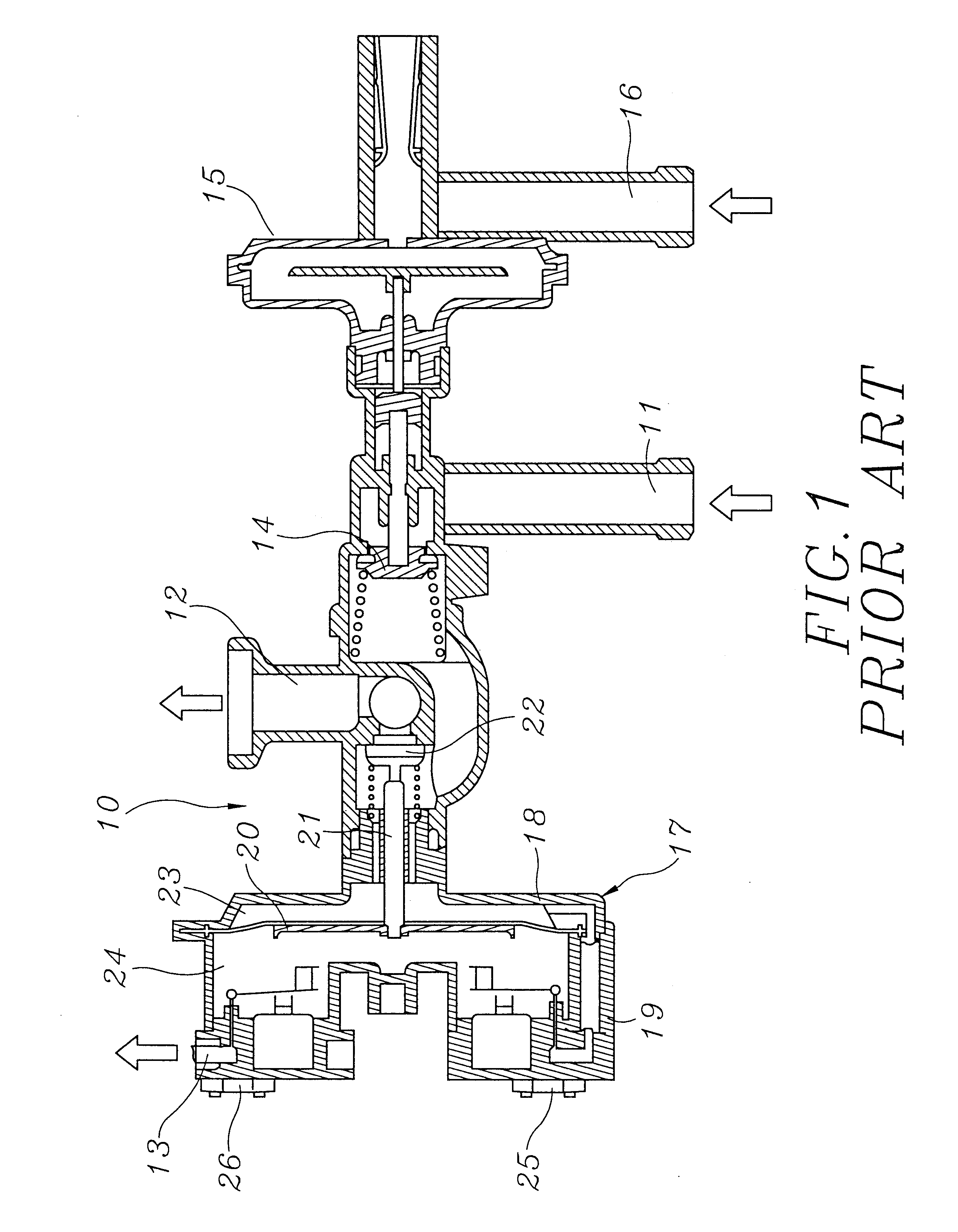

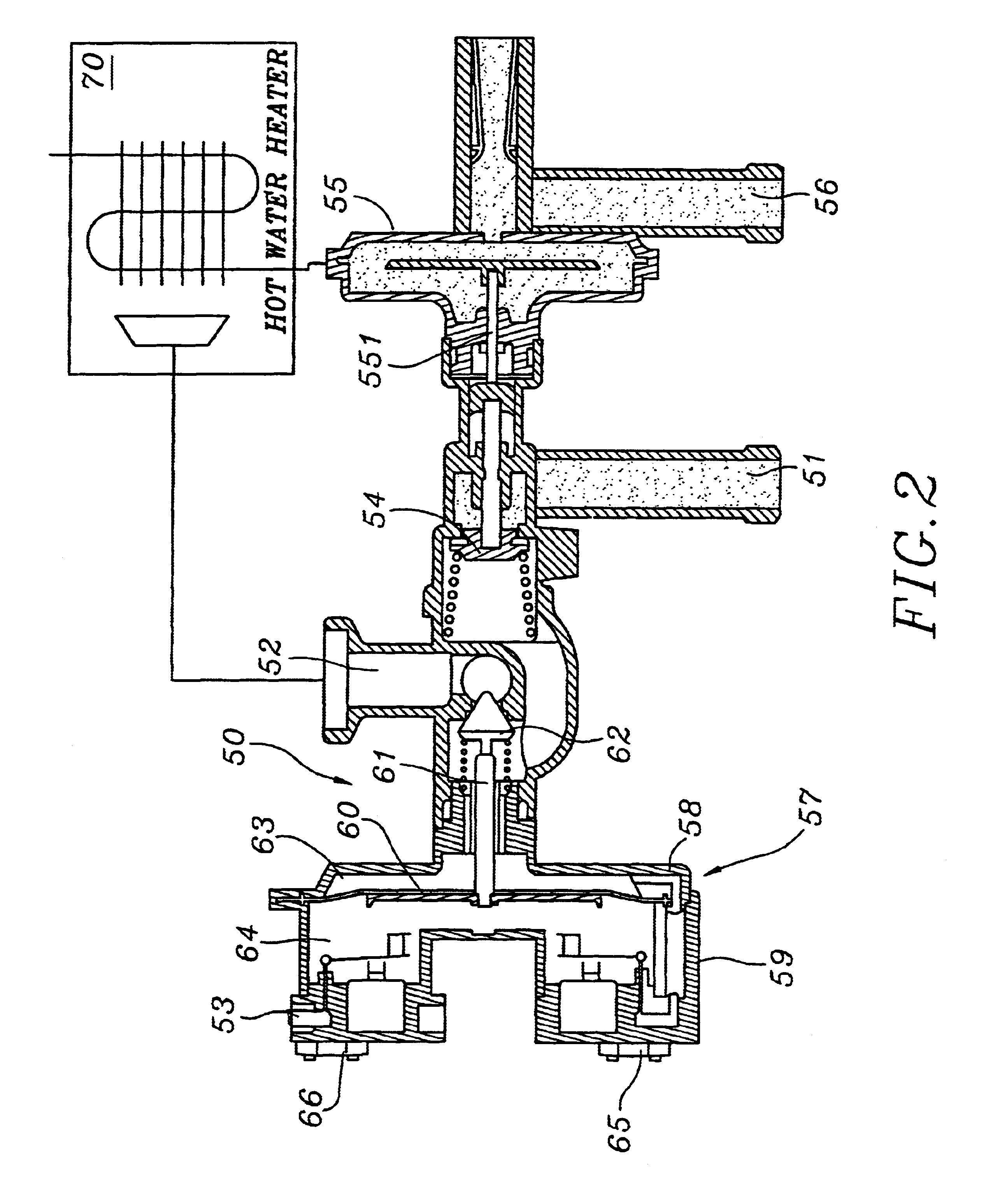

Hot-water supply system with heat pump cycle

InactiveUS6467289B2Improve stabilityImprove reliabilityMechanical apparatusHeat pumpsEngineeringTemperature difference

In a hot-water supply system with a heat pump cycle, a control unit controls operation of an expansion valve based on a temperature difference between a refrigerant temperature at an outlet side of a refrigerant passage in a water heat exchanger and a water temperature at an inlet side of a water passage in the water heat exchanger. When the expansion valve is controlled in a direction increasing a valve opening degree, the control unit sets an upper limit opening degree of the expansion valve, for obtaining a refrigerant pressure corresponding to a target hot-water temperature, and controls the expansion valve in an opening degree range smaller than the upper limit opening degree.

Owner:DENSO CORP +2

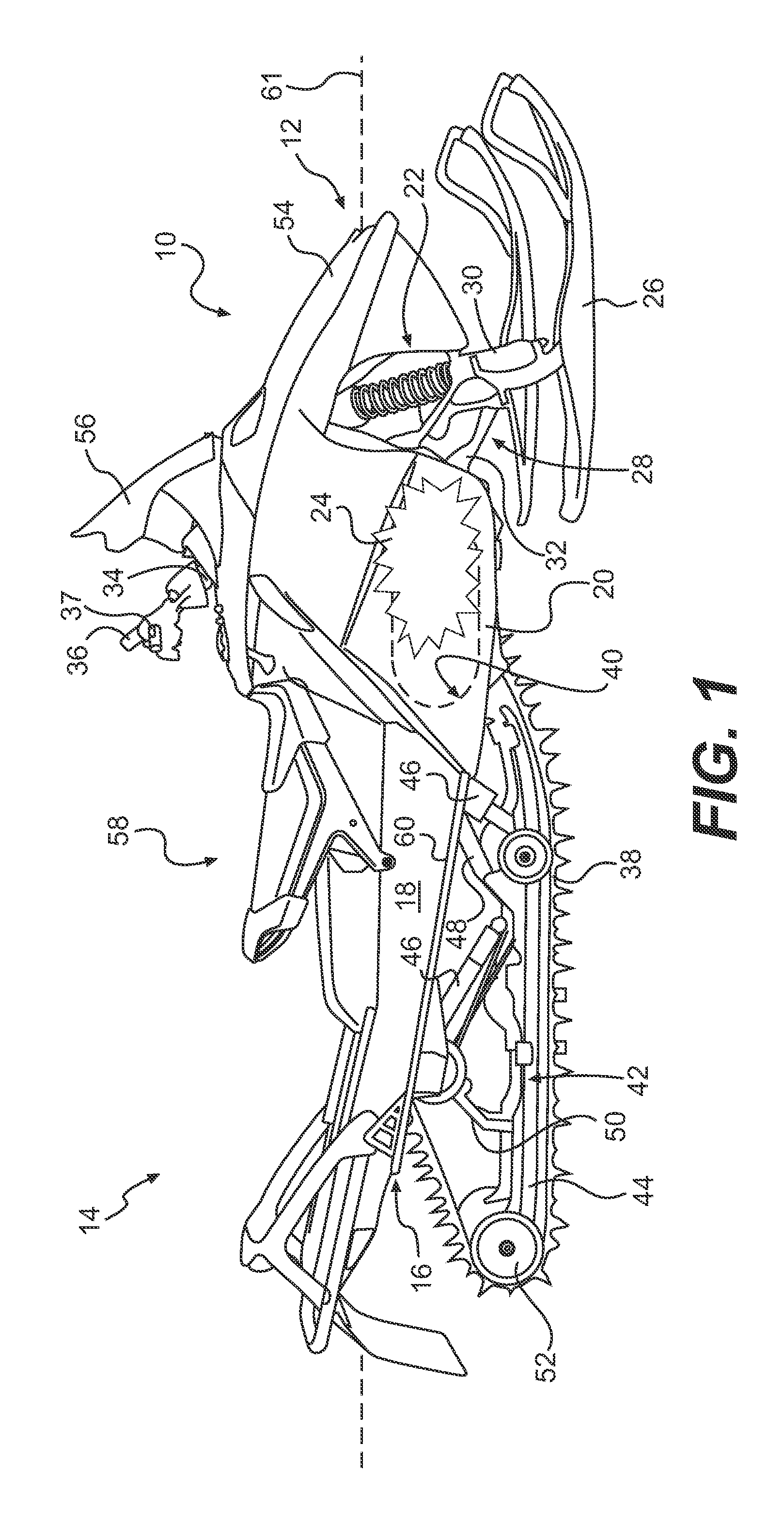

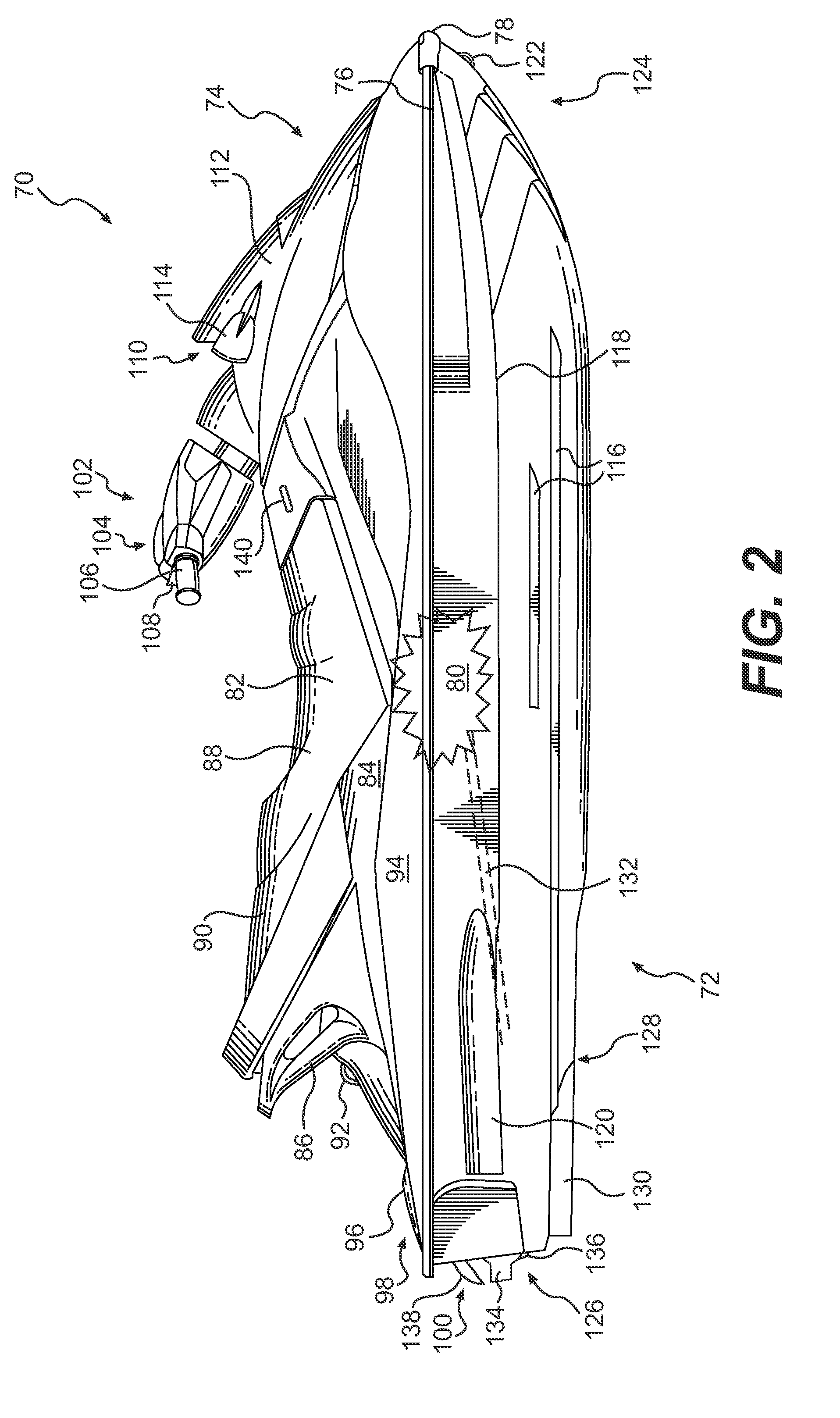

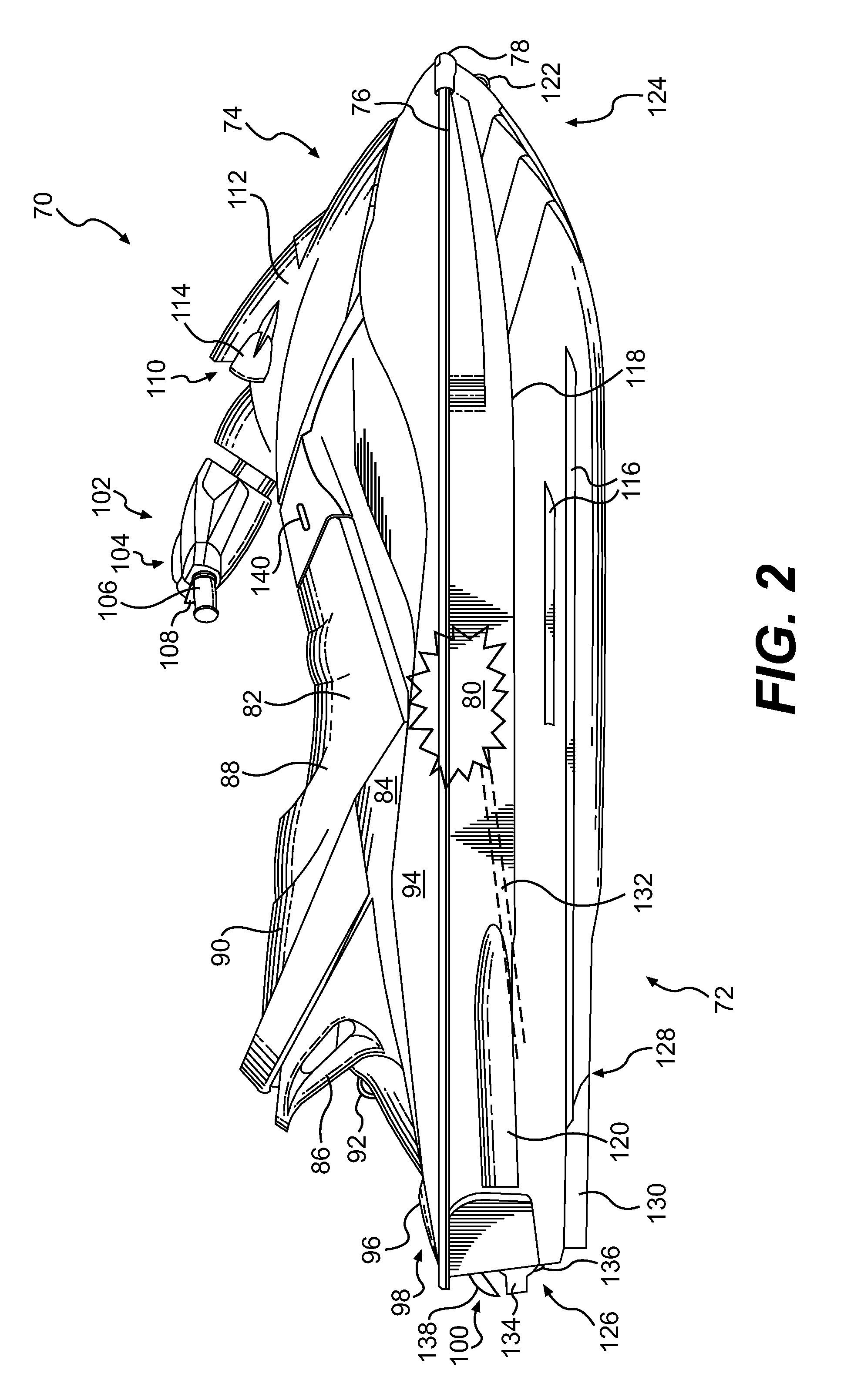

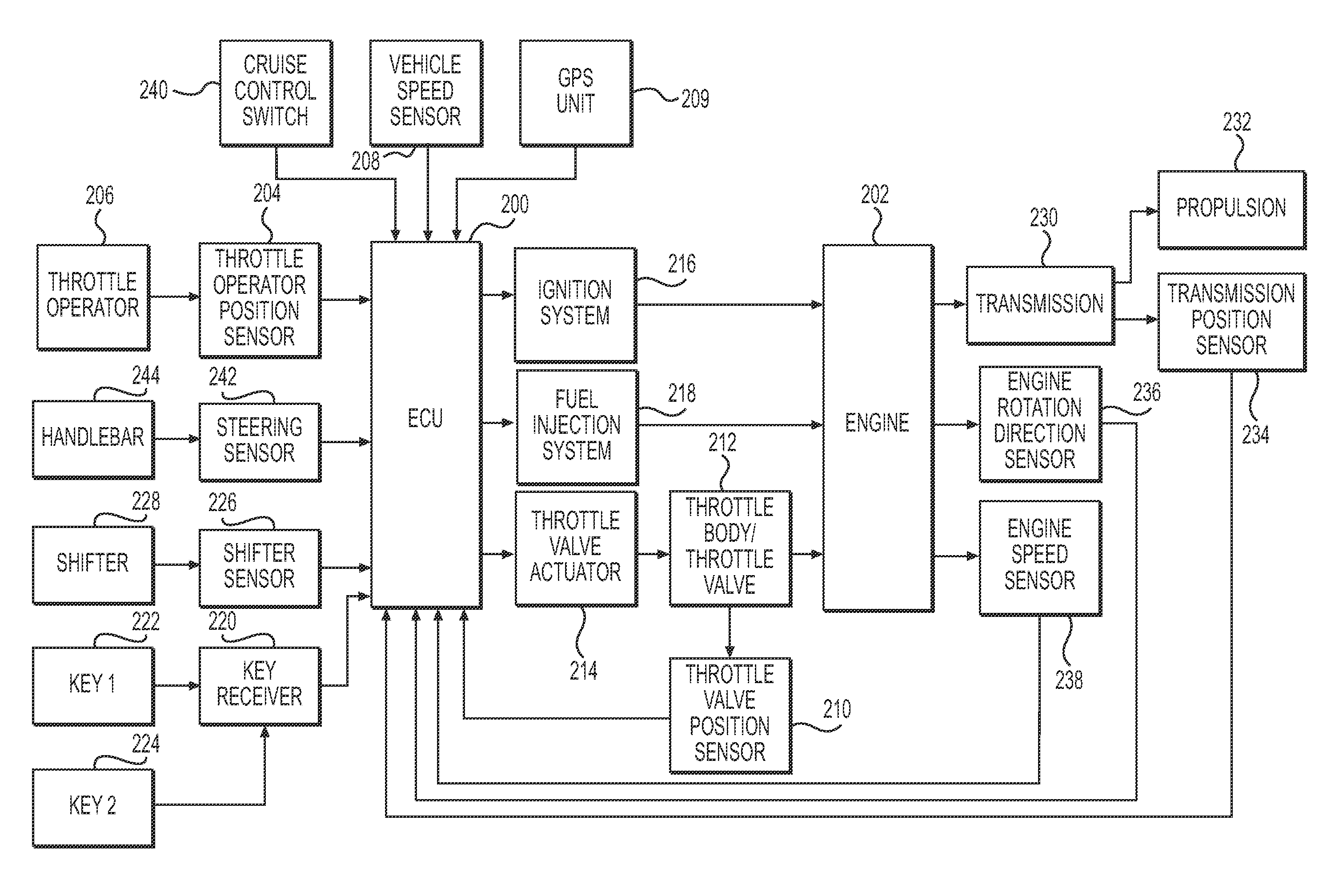

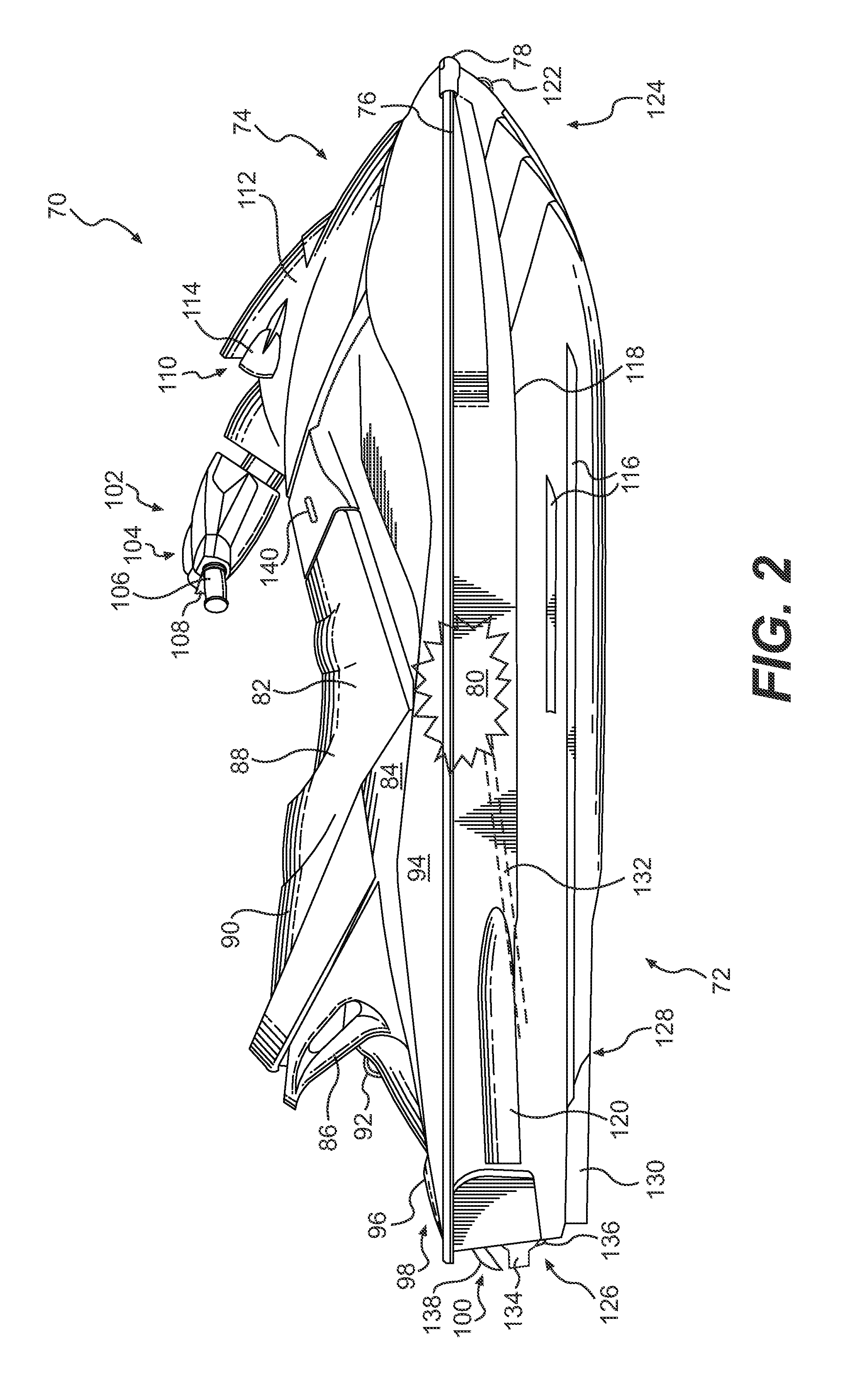

Vehicle speed limiter

ActiveUS7315779B1Reduce opening degreeIncrease speedAnalogue computers for vehiclesAcoustic signalElectronic control unitEngineering

A vehicle has a straddle seat, a handlebar, an engine, an electronic control unit (ECU), a throttle valve, a throttle valve actuator, and a throttle operator. A throttle operator position sensor senses a throttle operator position. A vehicle speed sensor senses a vehicle speed. The ECU sends a control signal to the throttle valve actuator based on the throttle operator position and the vehicle speed. The throttle valve actuator adjusts the opening of the throttle valve in response to the control signal. If the vehicle speed is lower than a predetermined maximum vehicle speed, the throttle valve actuator adjusts the opening of the throttle valve based on the throttle operator position signal. If the vehicle speed is higher than the predetermined maximum vehicle speed, the throttle valve actuator reduces the degree of opening of the throttle valve. A method of controlling an engine is also disclosed.

Owner:BOMBARDIER RECREATIONAL PROD INC

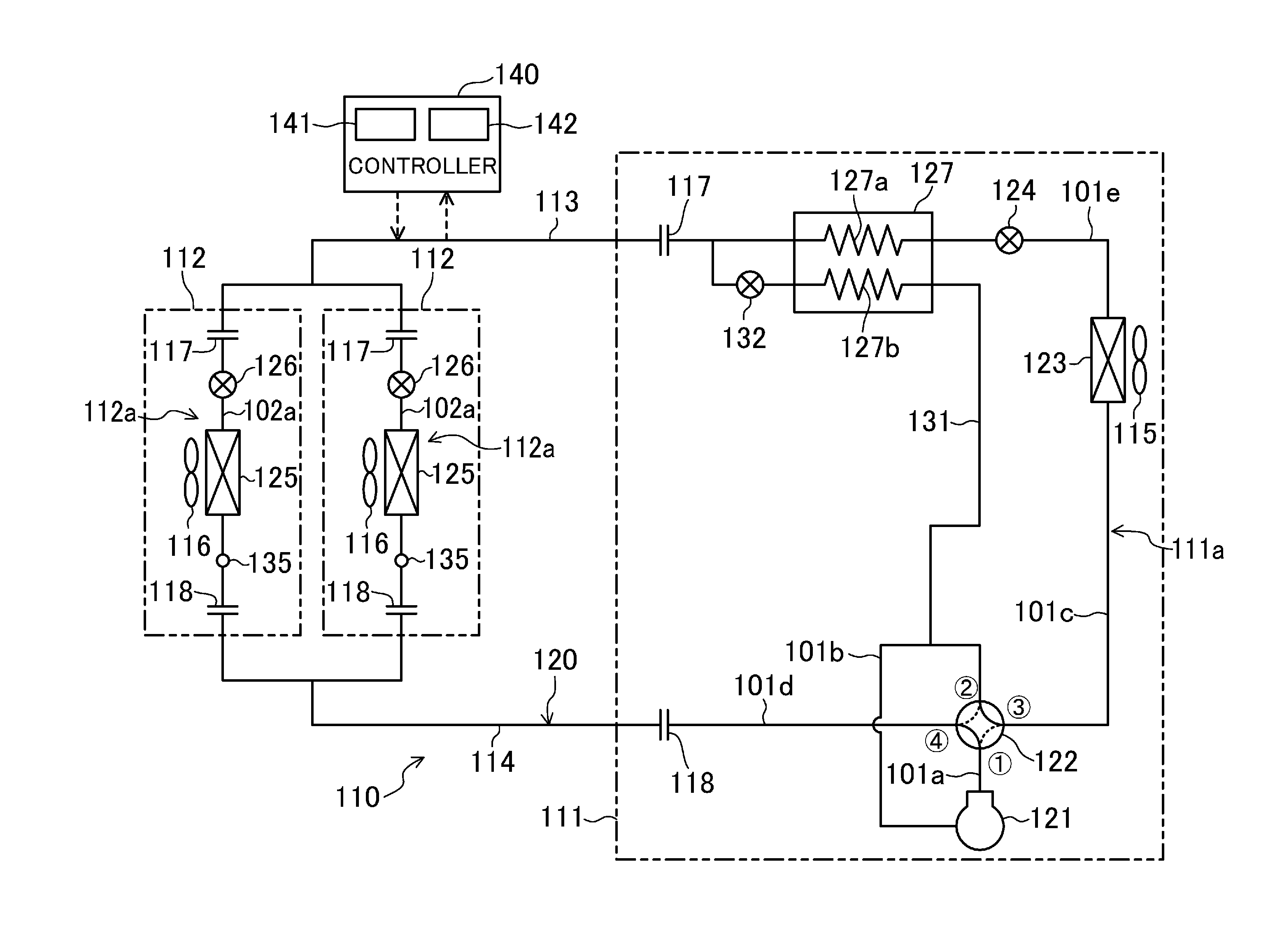

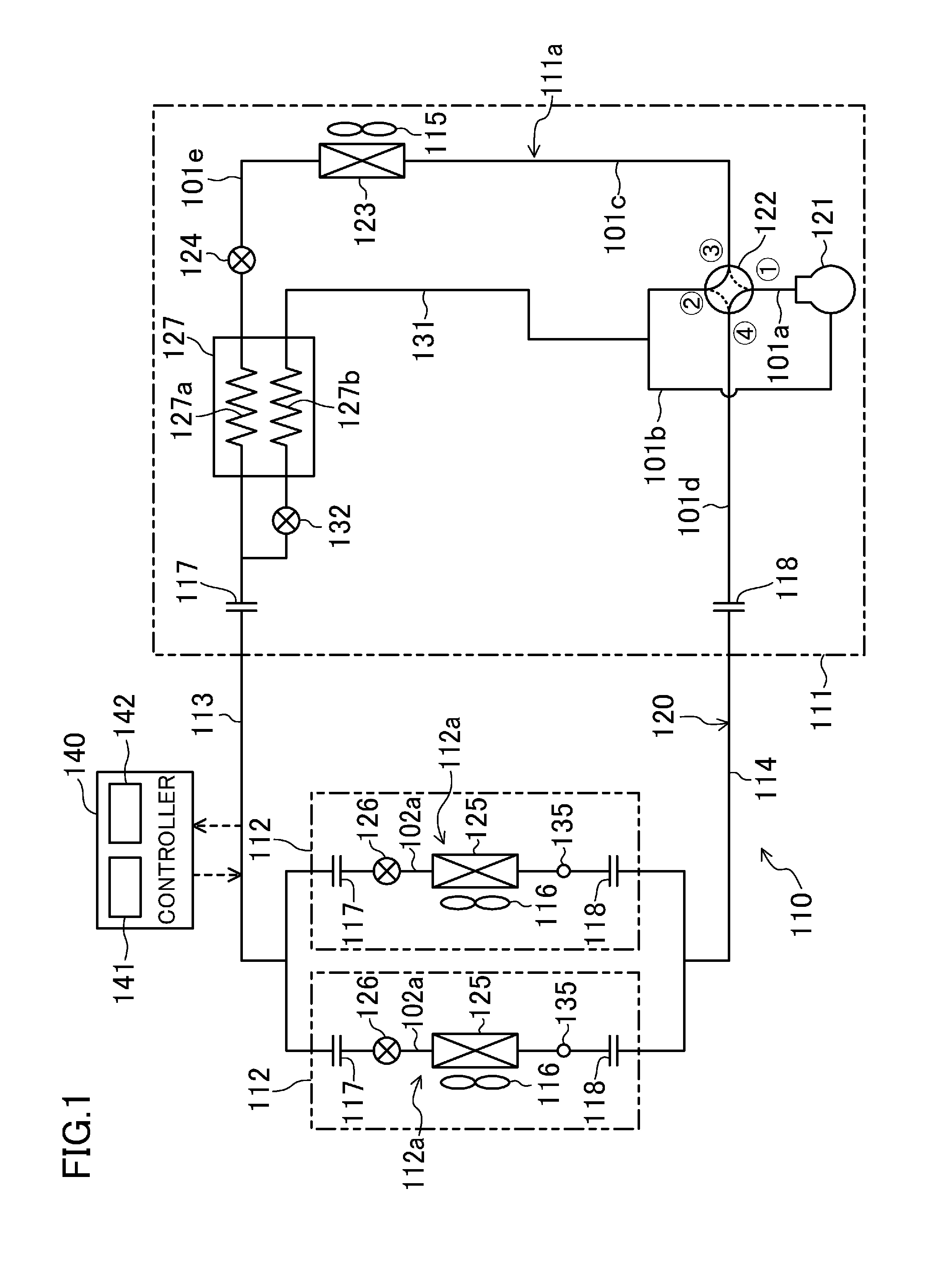

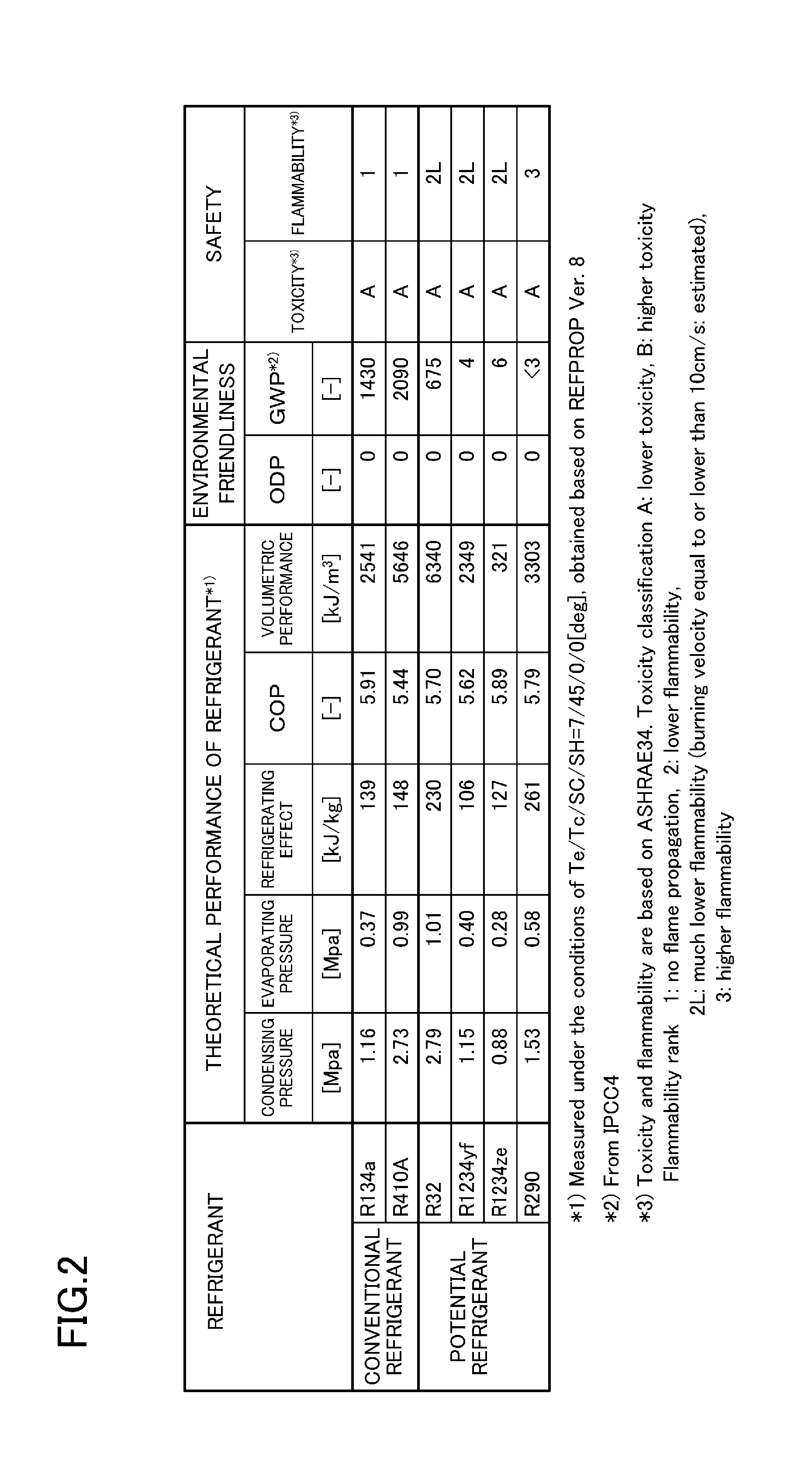

Refrigeration apparatus

ActiveUS20150233622A1Reduce the differenceReduce leak rateMechanical apparatusCompression machines with reversible cycleEngineeringRefrigerant

An air conditioner includes a refrigerant circuit which connects an outdoor circuit and a plurality of indoor circuits connected in parallel. The air conditioner includes a leak detection section which detects leak of a refrigerant from the indoor circuits, and a control section which circulates the refrigerant to perform a refrigeration cycle when the leak detection section detects leak of the refrigerant such that the refrigerant in the indoor circuits of the refrigerant circuit is at a low pressure. Providing the control section in the air conditioner can reduce the leak of the refrigerant from the indoor circuit at low cost.

Owner:DAIKIN IND LTD

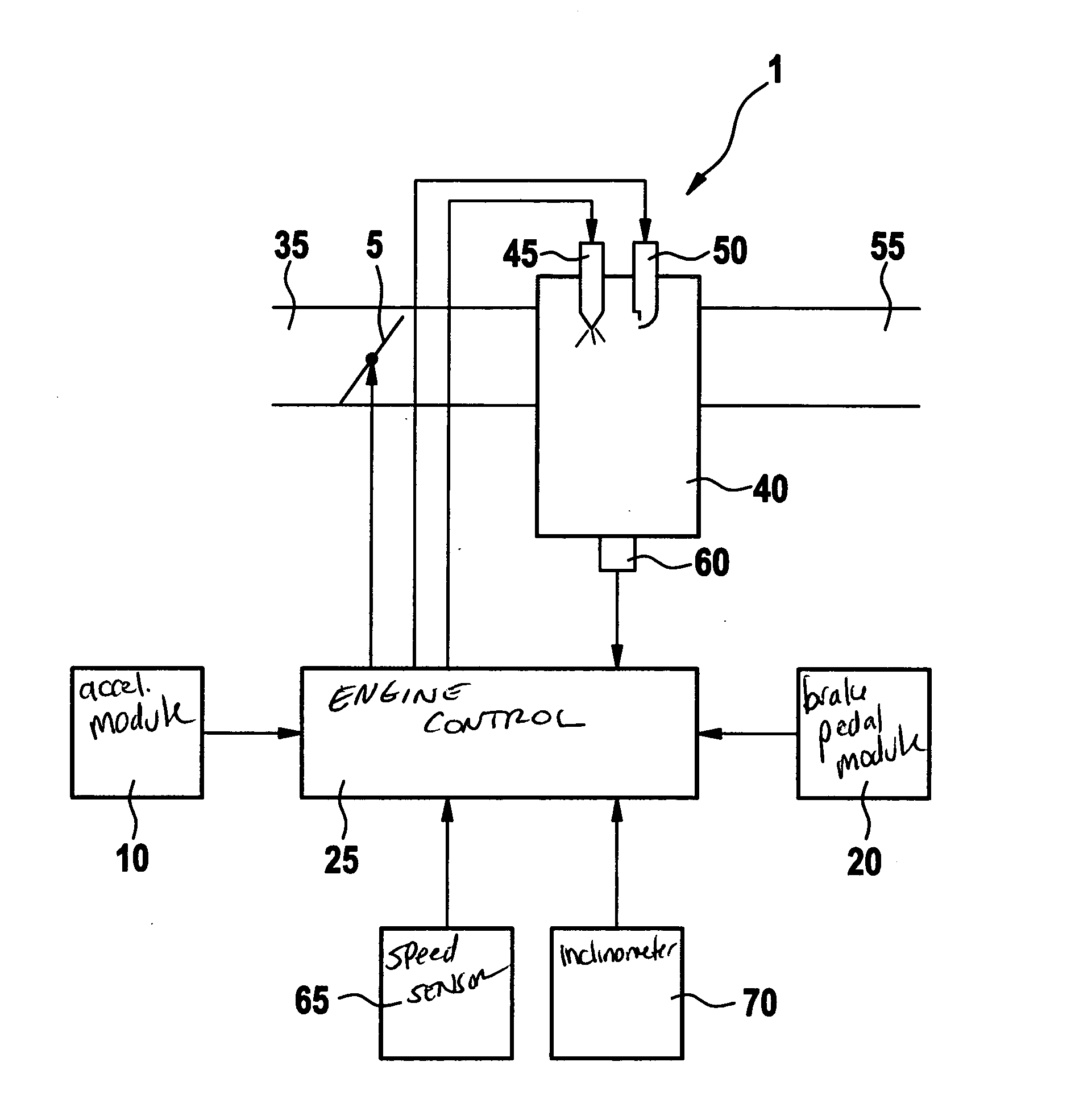

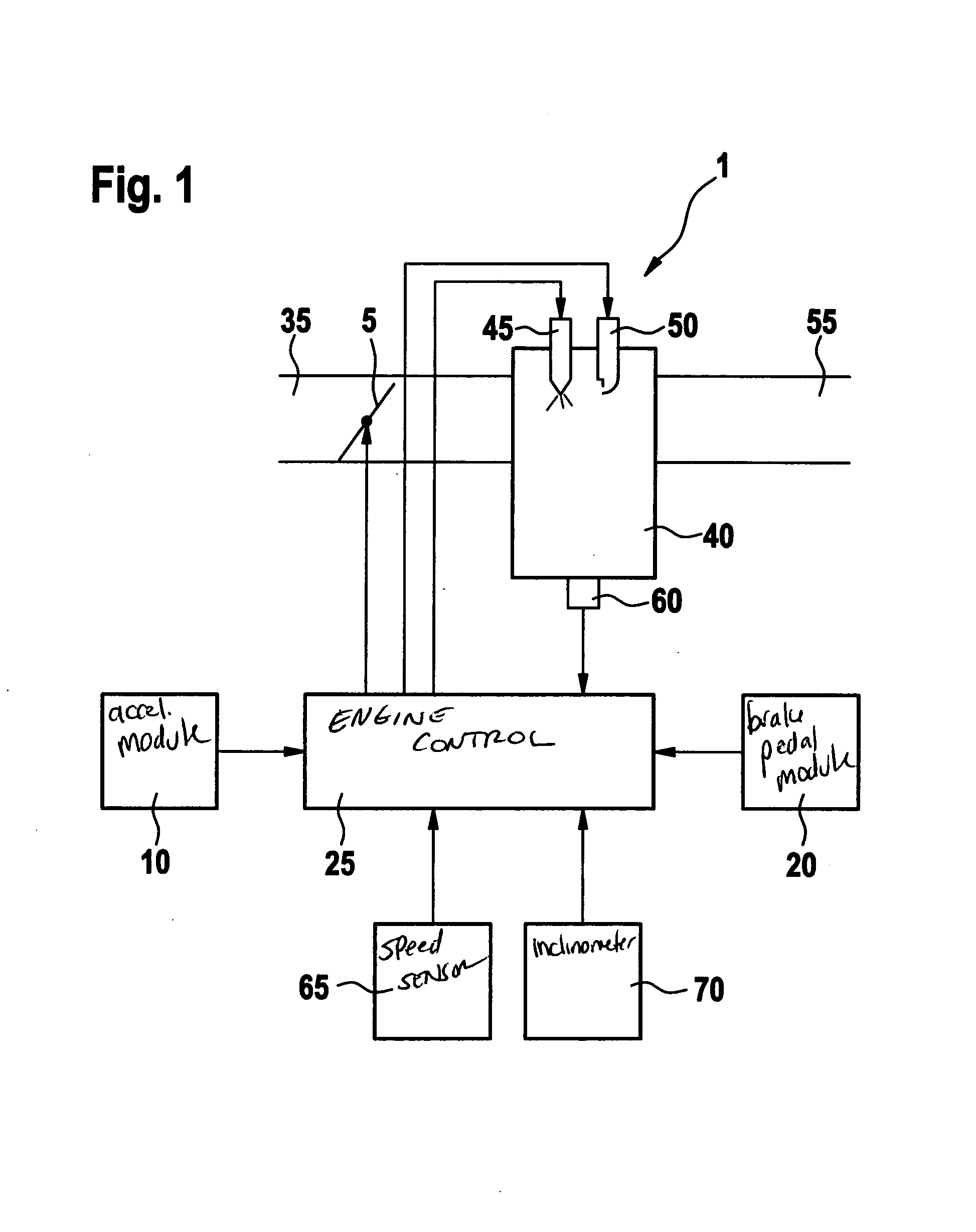

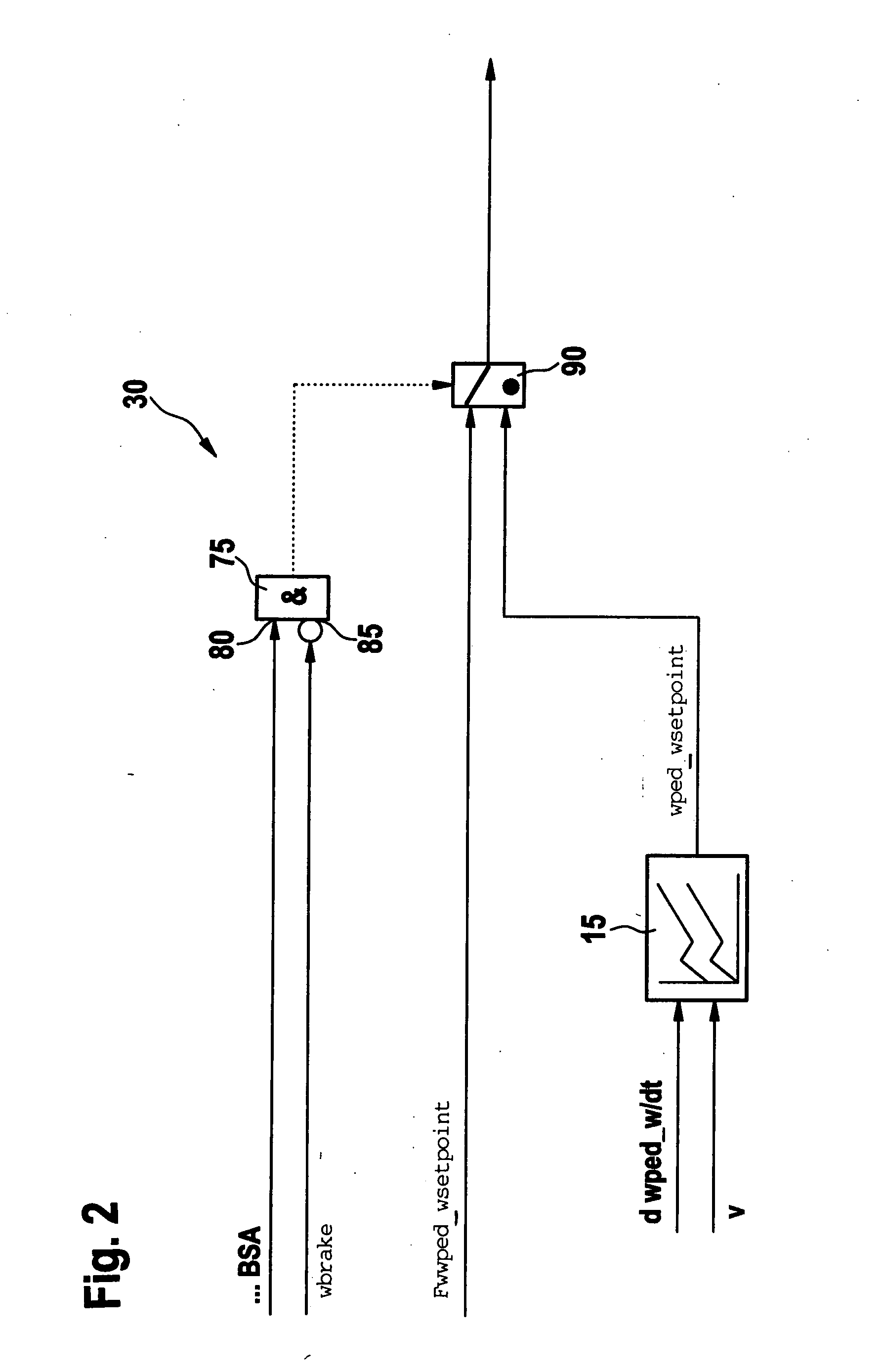

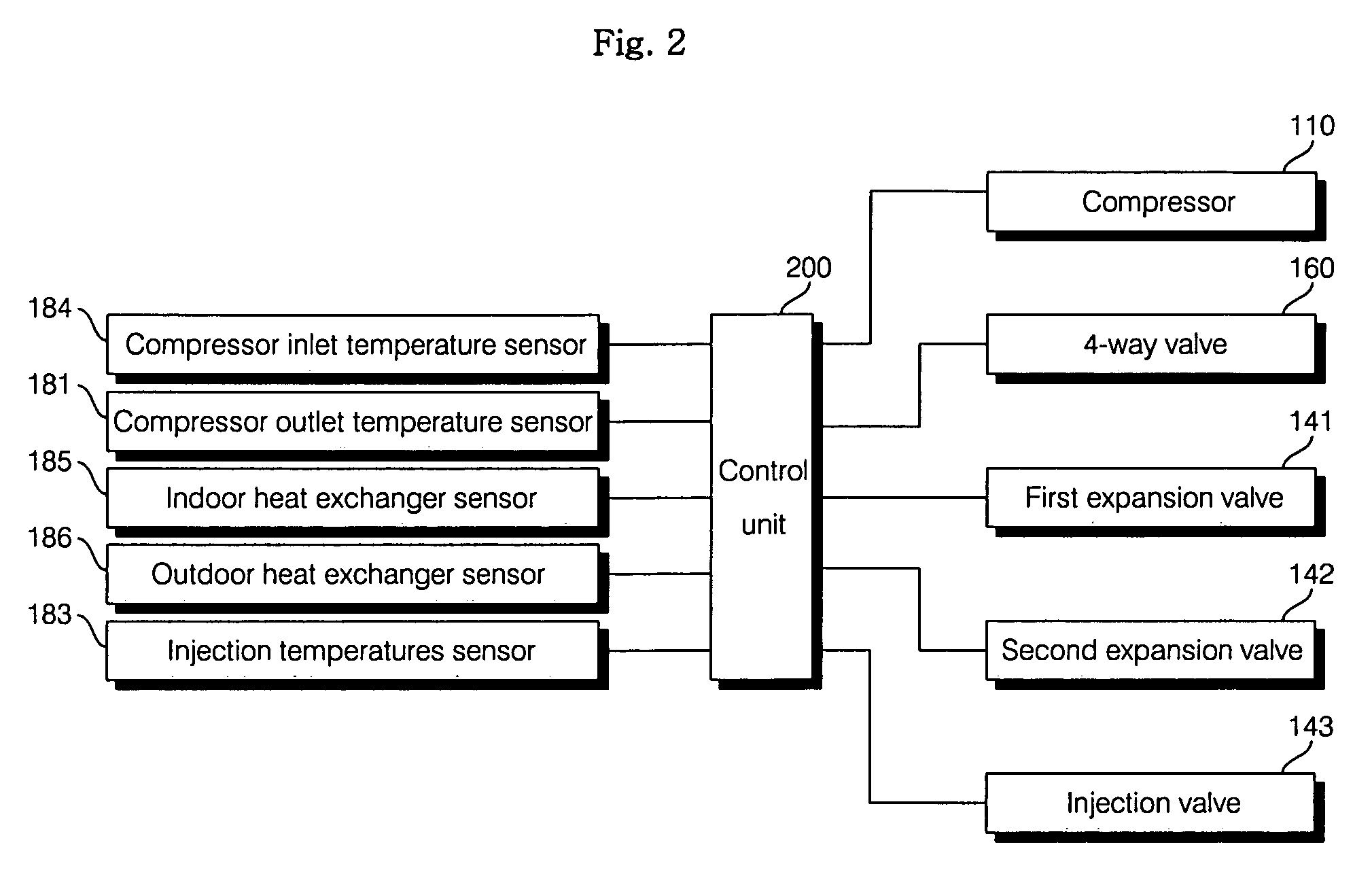

Method and device for operating a vehicle having an internal combustion engine

InactiveUS20050133006A1Reduce fuel consumptionConvenient travelElectrical controlFuel-injection pumpsInternal combustion engineCombustion

A method and a device are provided for operating a vehicle having a combustion engine, which result in reduced fuel consumption in overrun operation. In the process, the air supply to the combustion engine is adjusted via an actuator. In overrun operation of the combustion engine, an opening degree of the actuator is set as a function of a driving situation.

Owner:ROBERT BOSCH GMBH

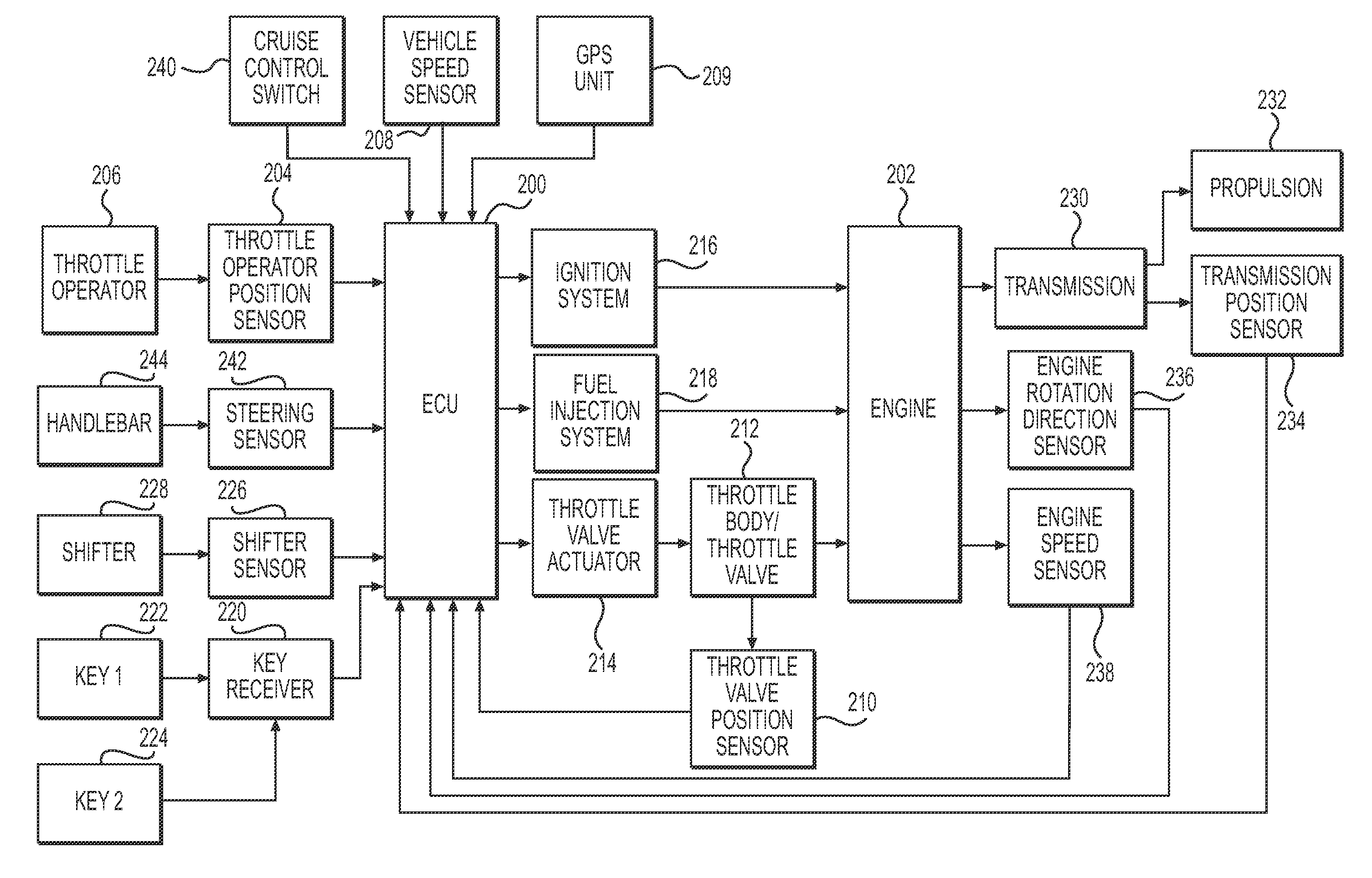

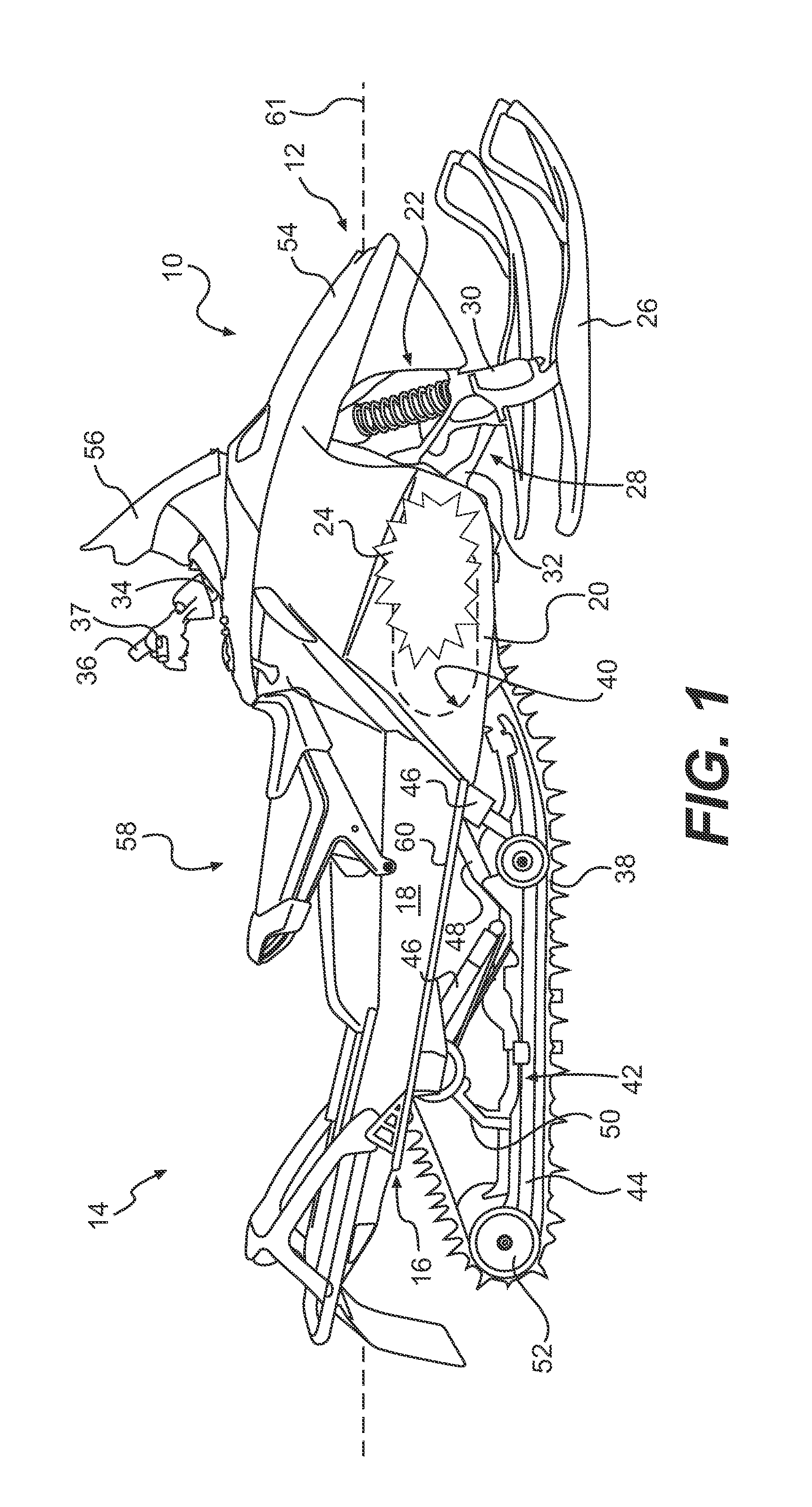

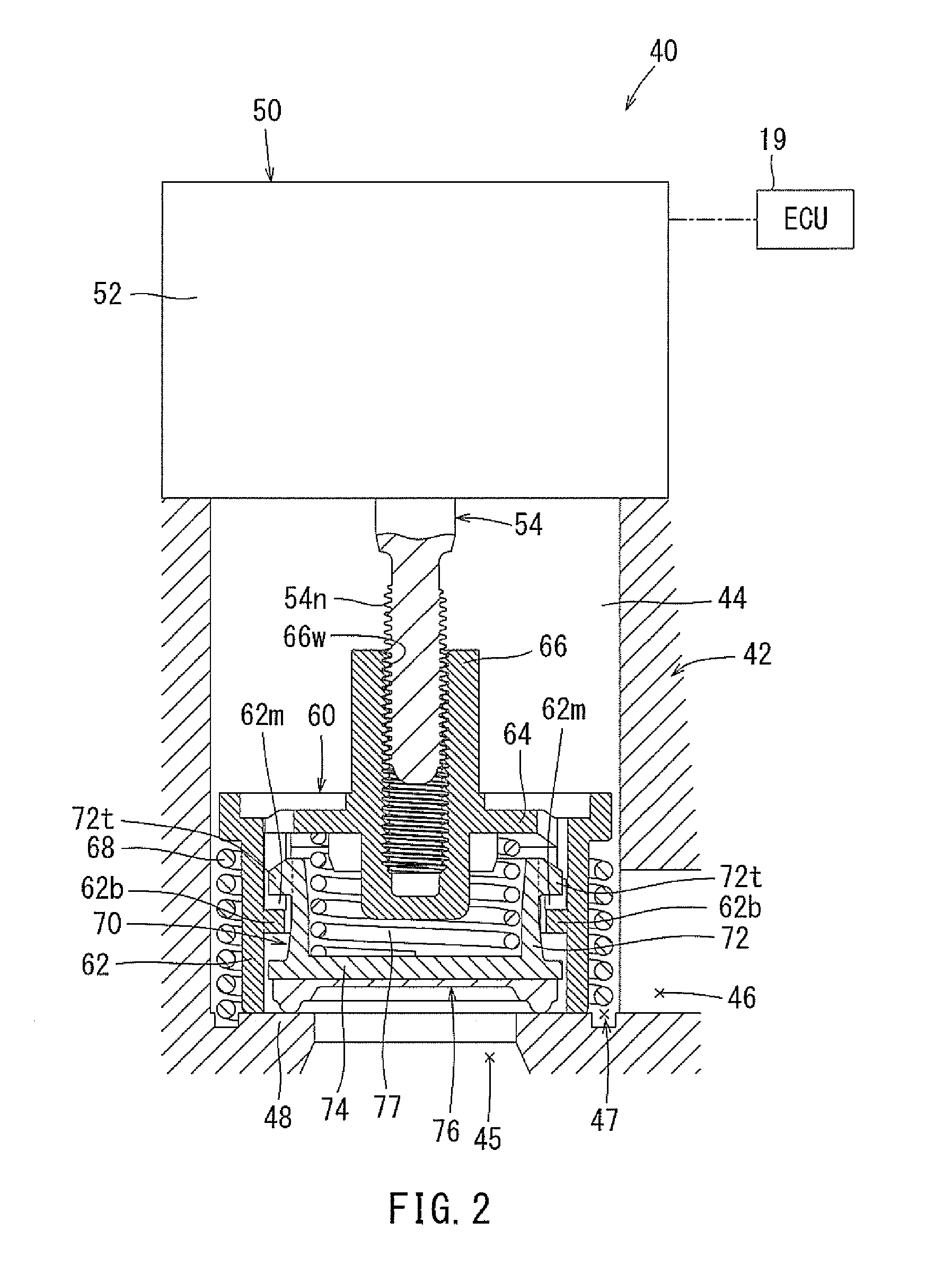

Vehicle cruise control

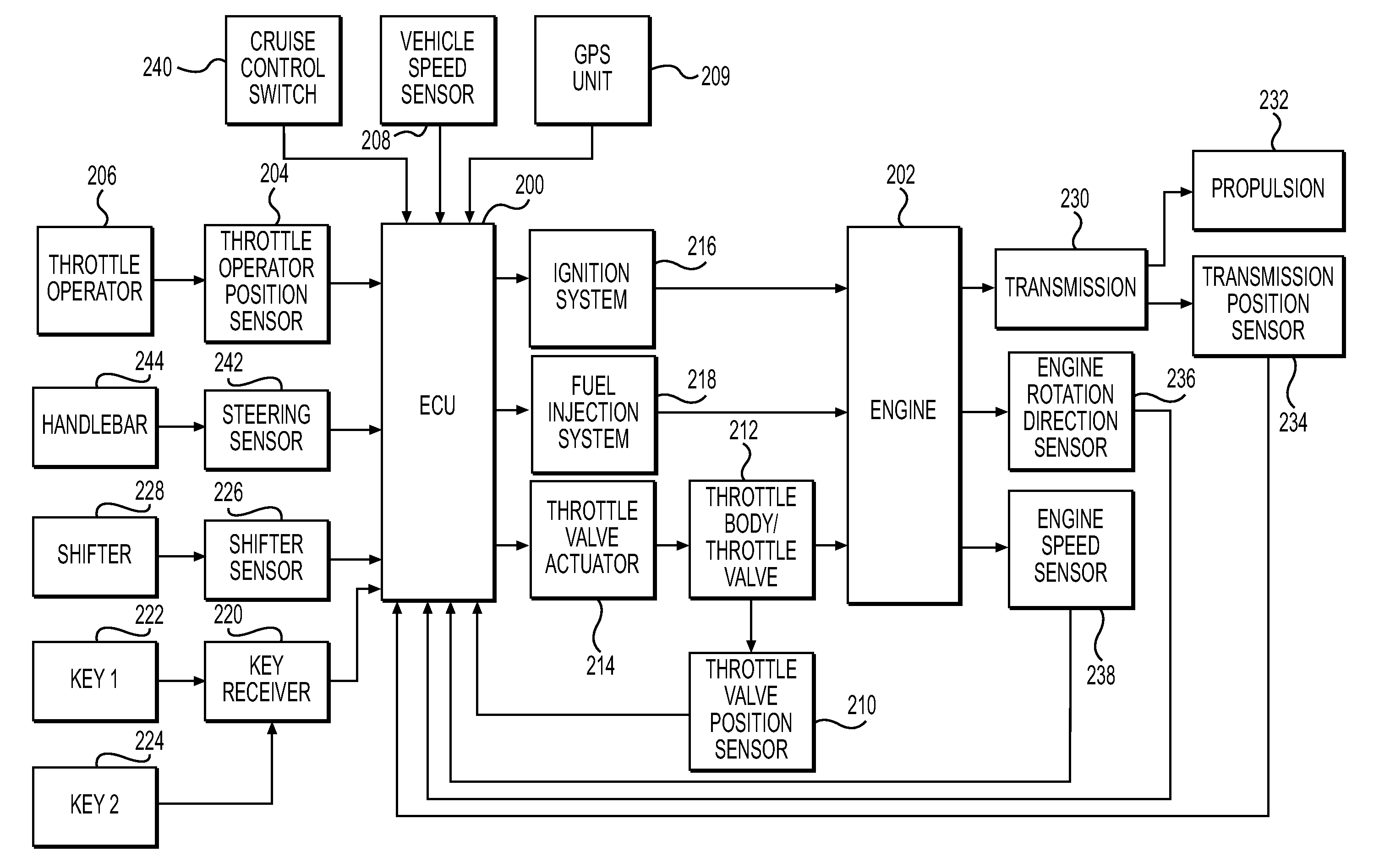

ActiveUS7530345B1Increase degree of openingDegree of opening is decreasedElectrical controlVehicle fittingsEngineeringThrottle

A vehicle having a vehicle body, a seat, an engine, a throttle body, a throttle valve, a throttle valve actuator, a throttle operator, a throttle operator position sensor, a cruise control switch, and a vehicle speed sensor. An ECU controls operation of the engine in one of a normal operation mode and a cruise control operation mode. When in the normal operation mode, the ECU sends a first control signal to the throttle valve actuator based on the throttle operator position signal. When the cruise control switch engages the cruise control operation mode, the ECU sends a second control signal to the throttle valve actuator based on the vehicle speed signal such that the vehicle speed is maintained at a vehicle cruising speed. The ECU returns to the normal operation mode when the throttle operator position becomes less than or equal to a reference throttle operator position.

Owner:BOMBARDIER RECREATIONAL PROD INC

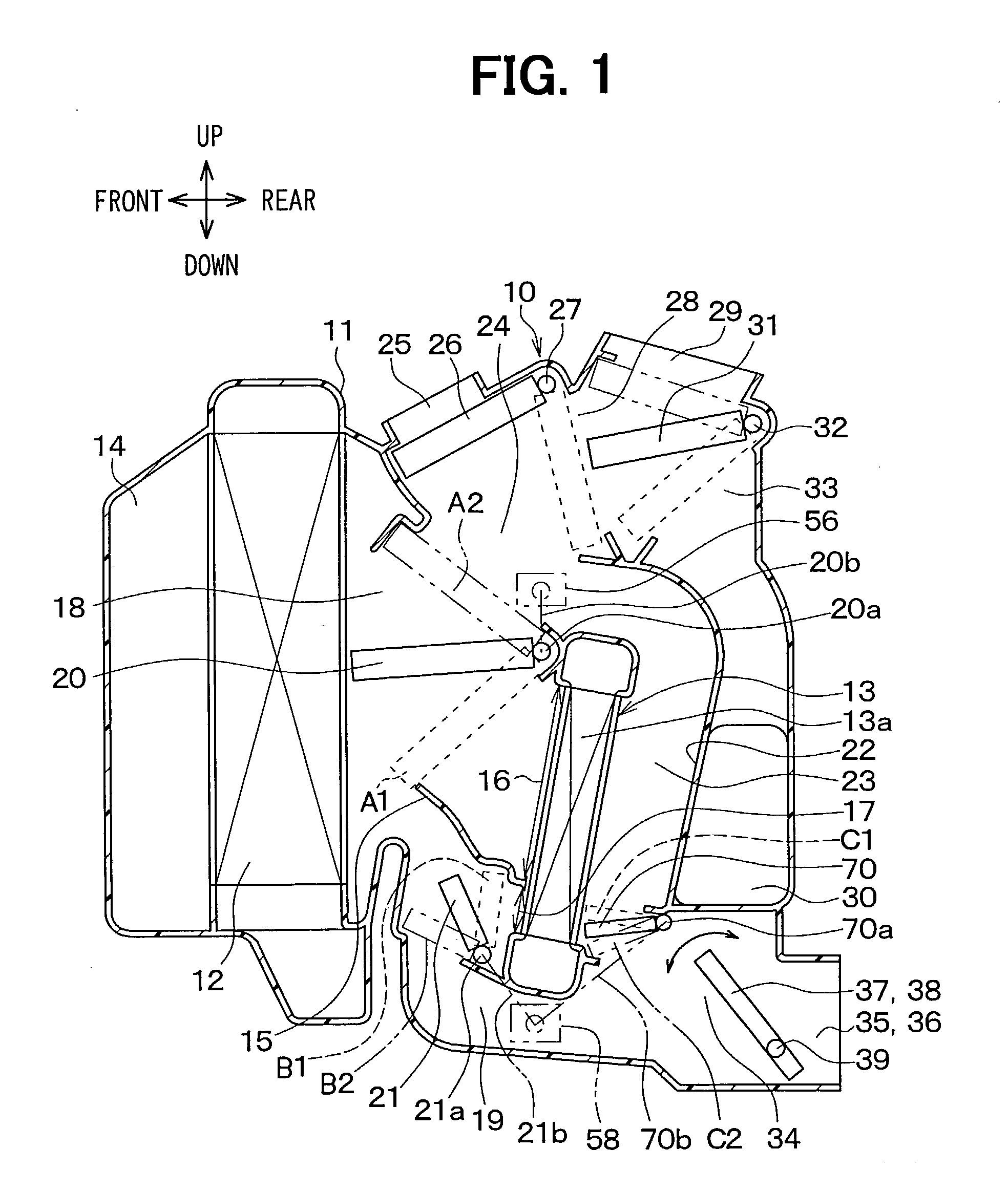

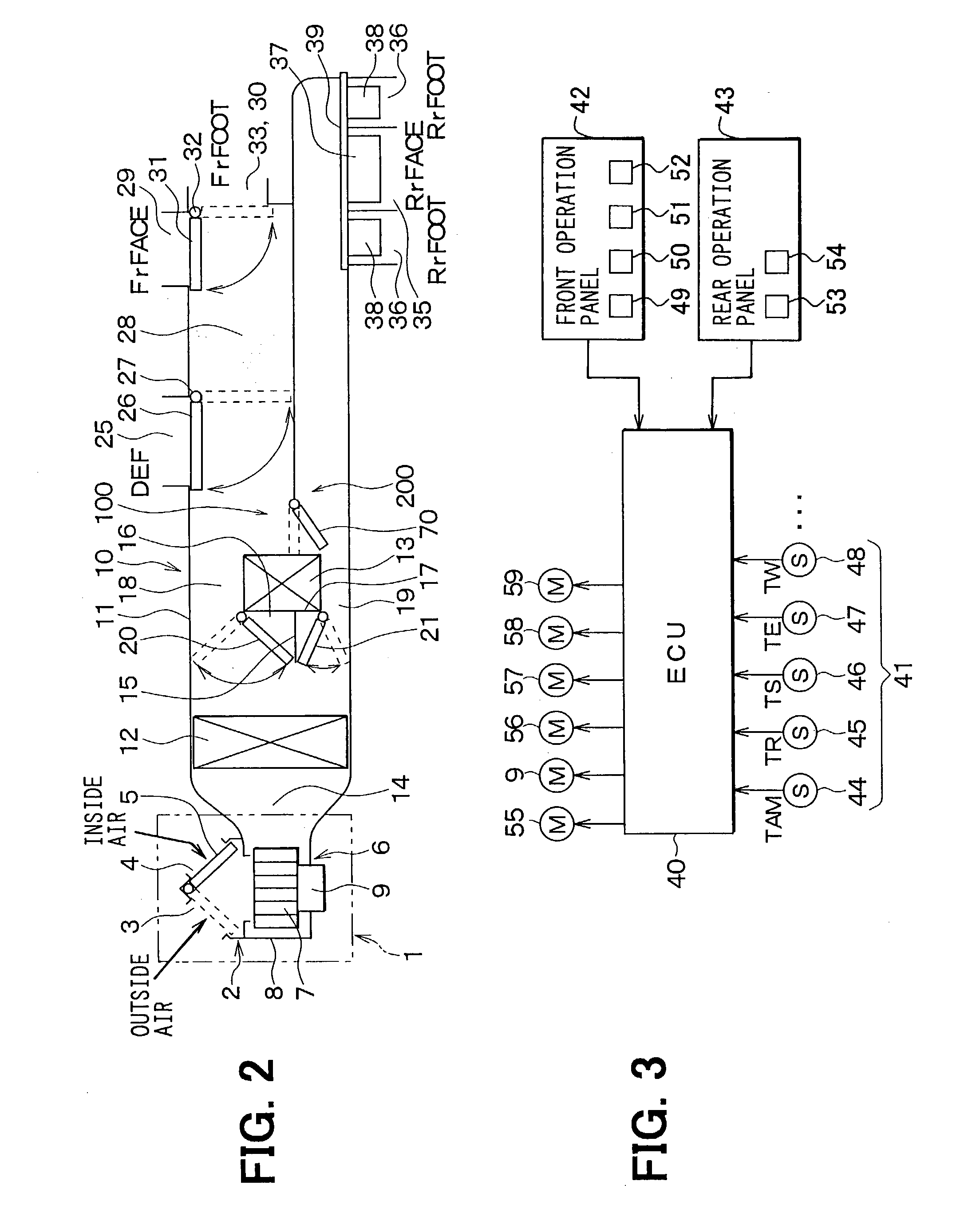

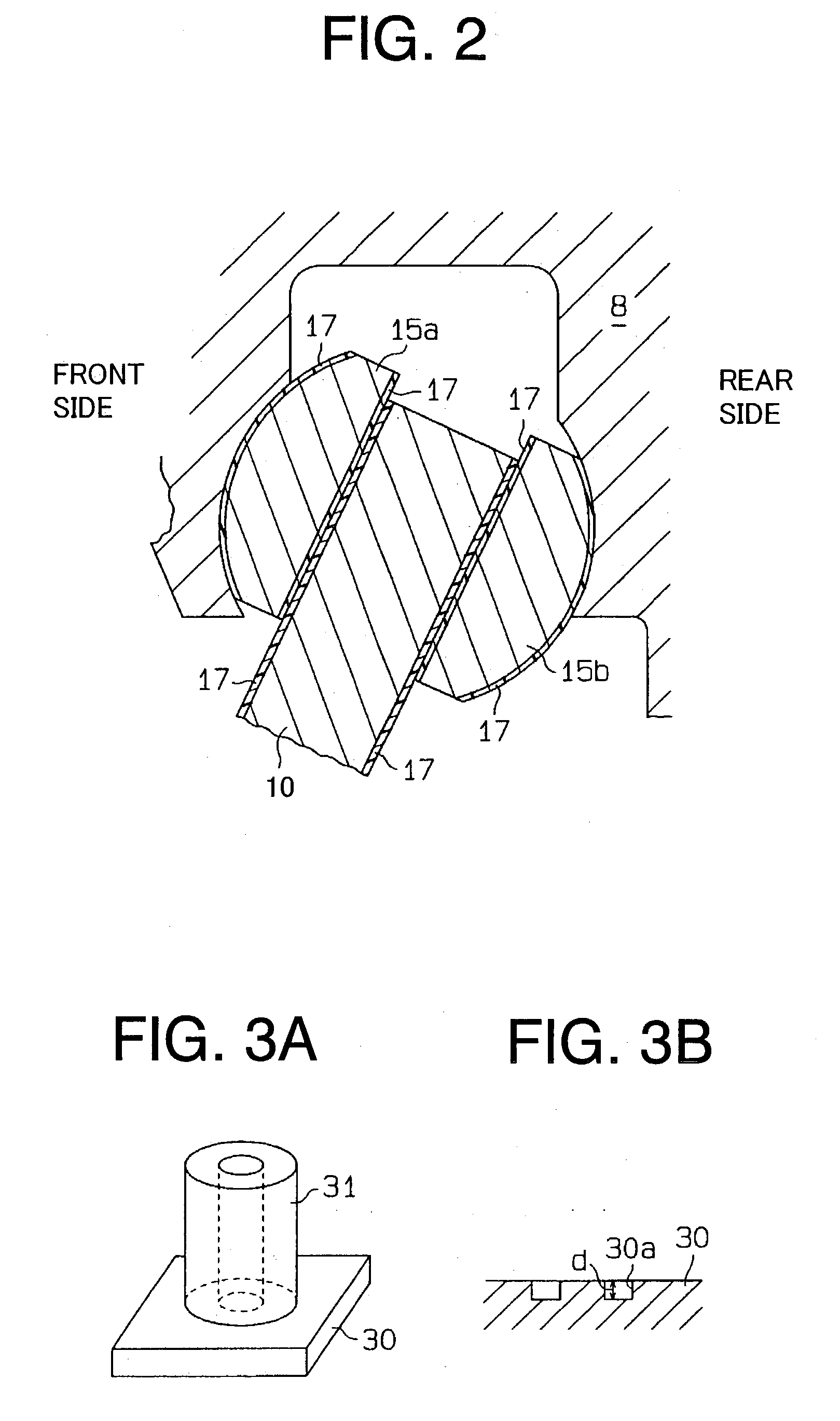

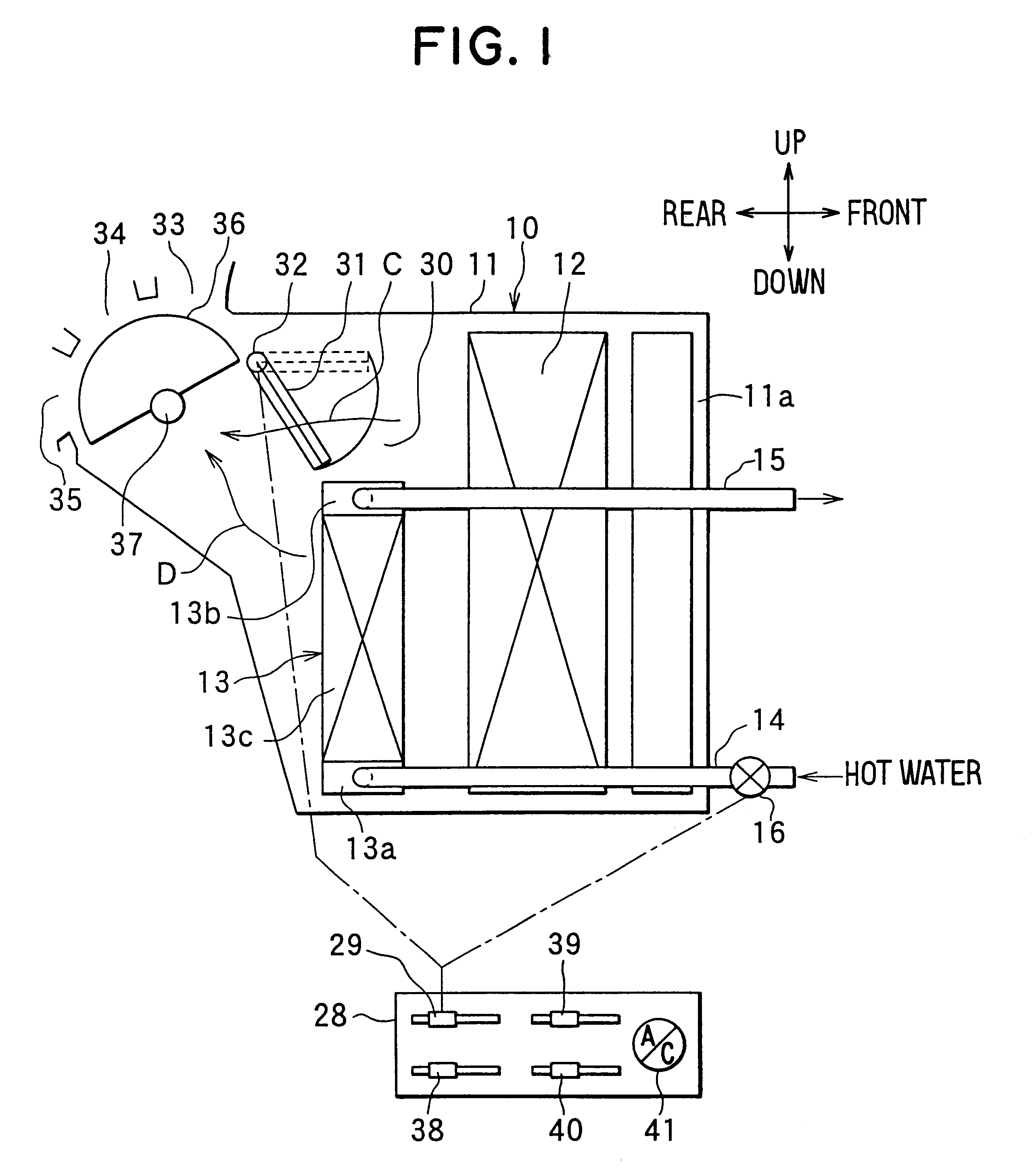

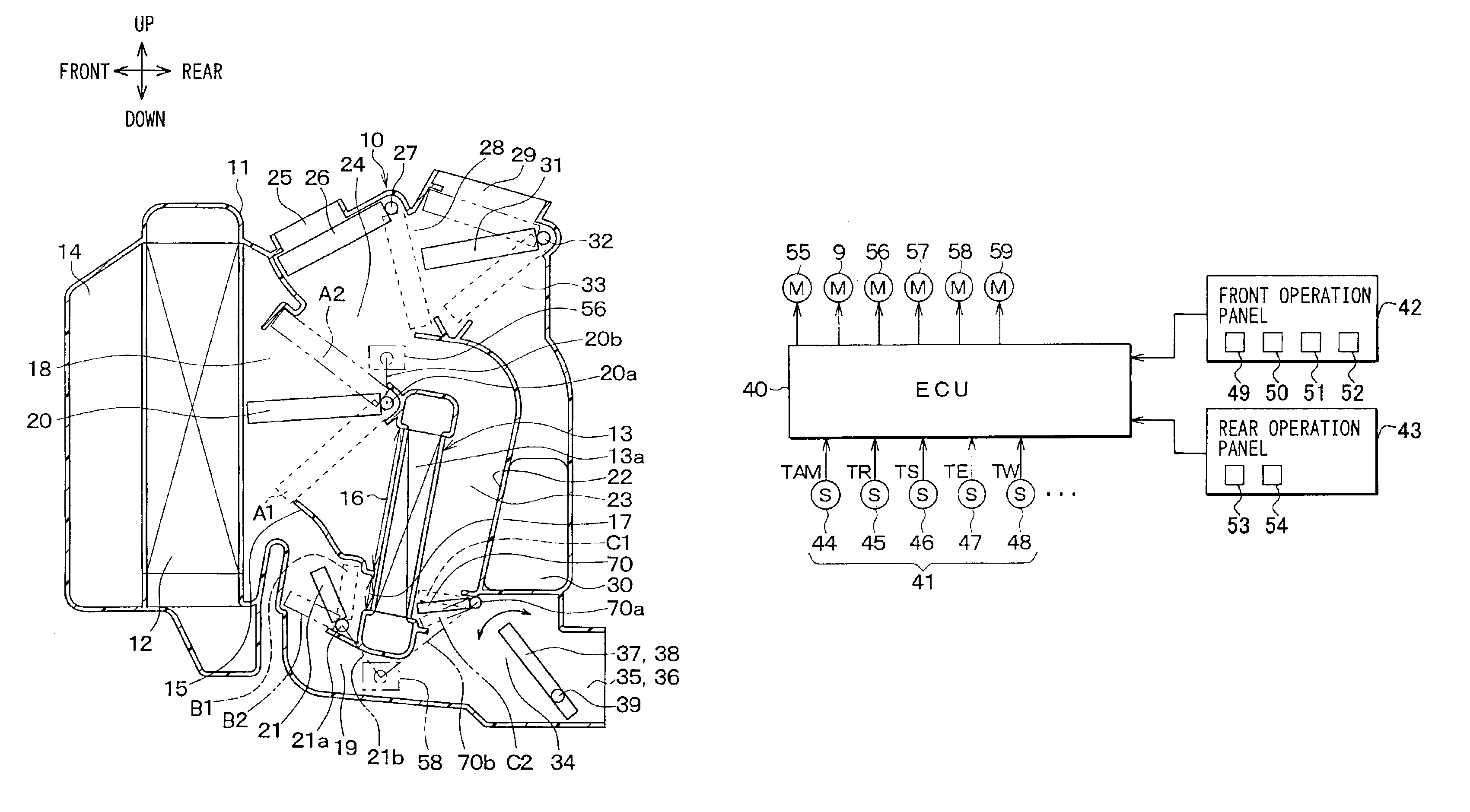

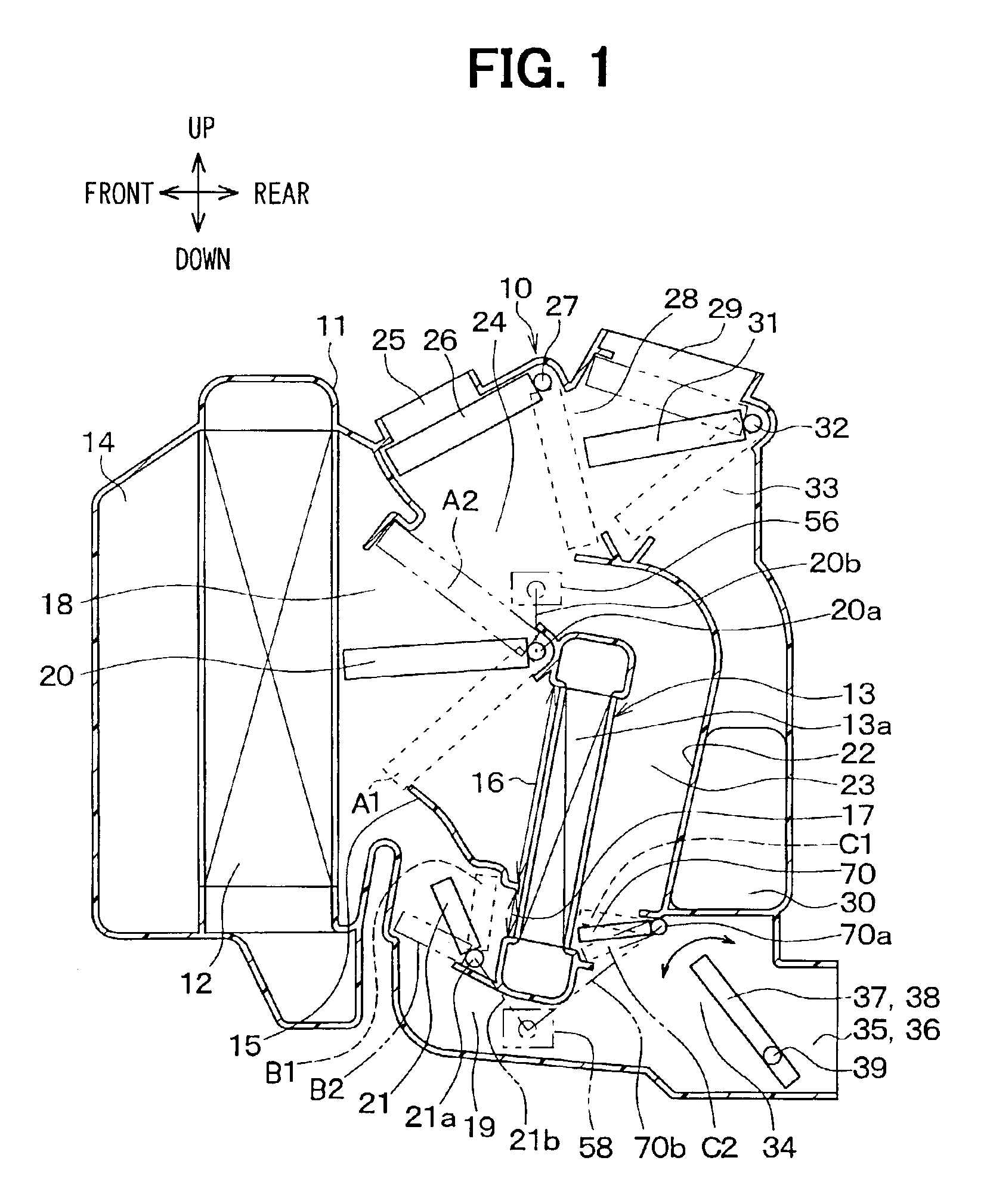

Air conditioner for vehicle

InactiveUS20030094262A1Good temperature control effectSimple structureAir-treating devicesRailway heating/coolingCold airAir conditioning

In a vehicle air conditioner, a heater core is disposed in an air conditioning case to form front and rear cool air bypass passage through which cool air bypasses the heater core, and front and rear air mixing doors are disposed to independently adjust temperature of air blown toward a front seat side and temperature of air blown toward a rear seat side in a passenger compartment. A switching door is disposed to partition front and rear passage portions of the heater core from each other at a partition position, and to shut the rear passage portion at a rear shutting position. The switching door and the rear air mixing door are connected to a common operation mechanism to be operatively linked with each other.

Owner:DENSO CORP

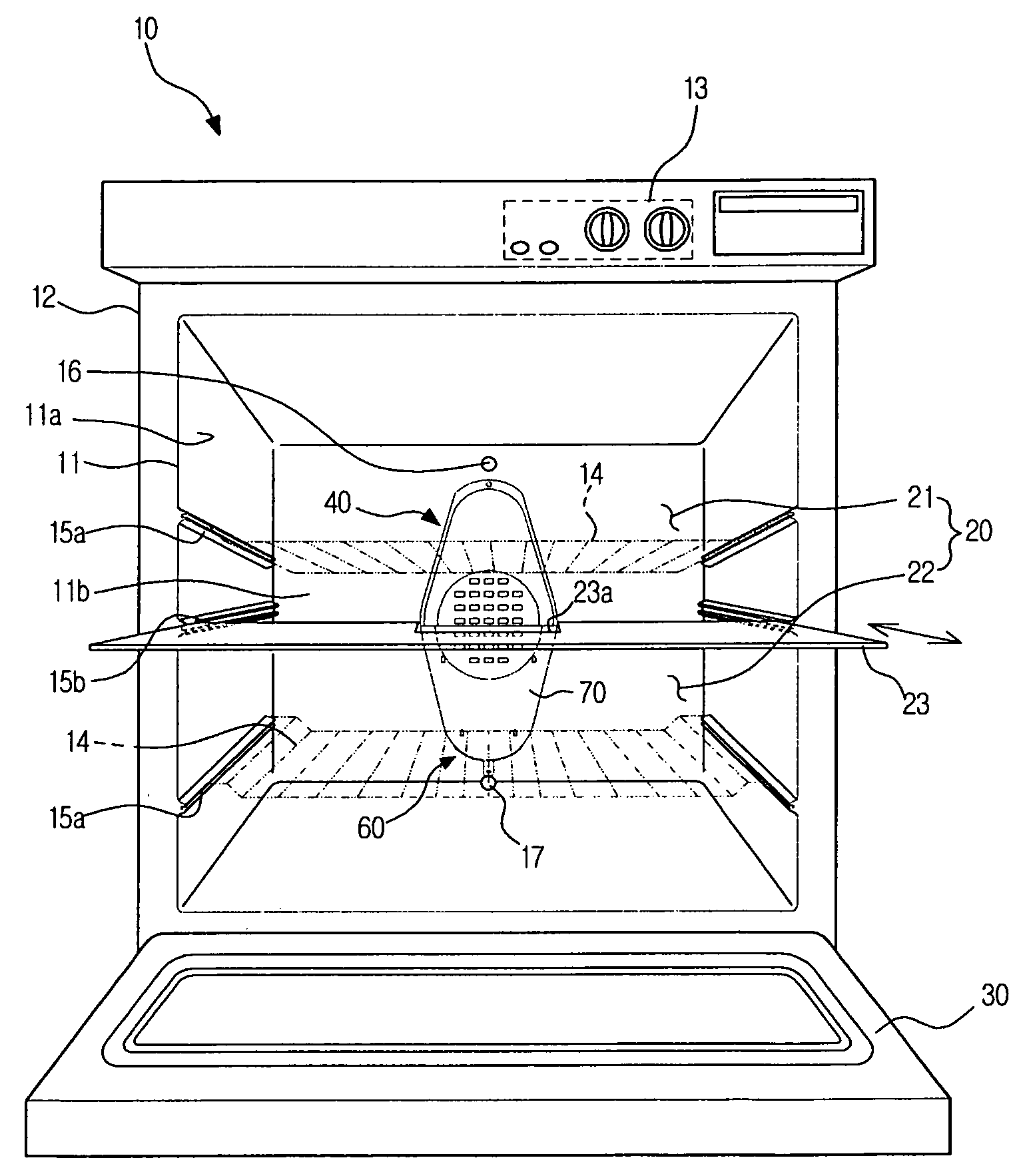

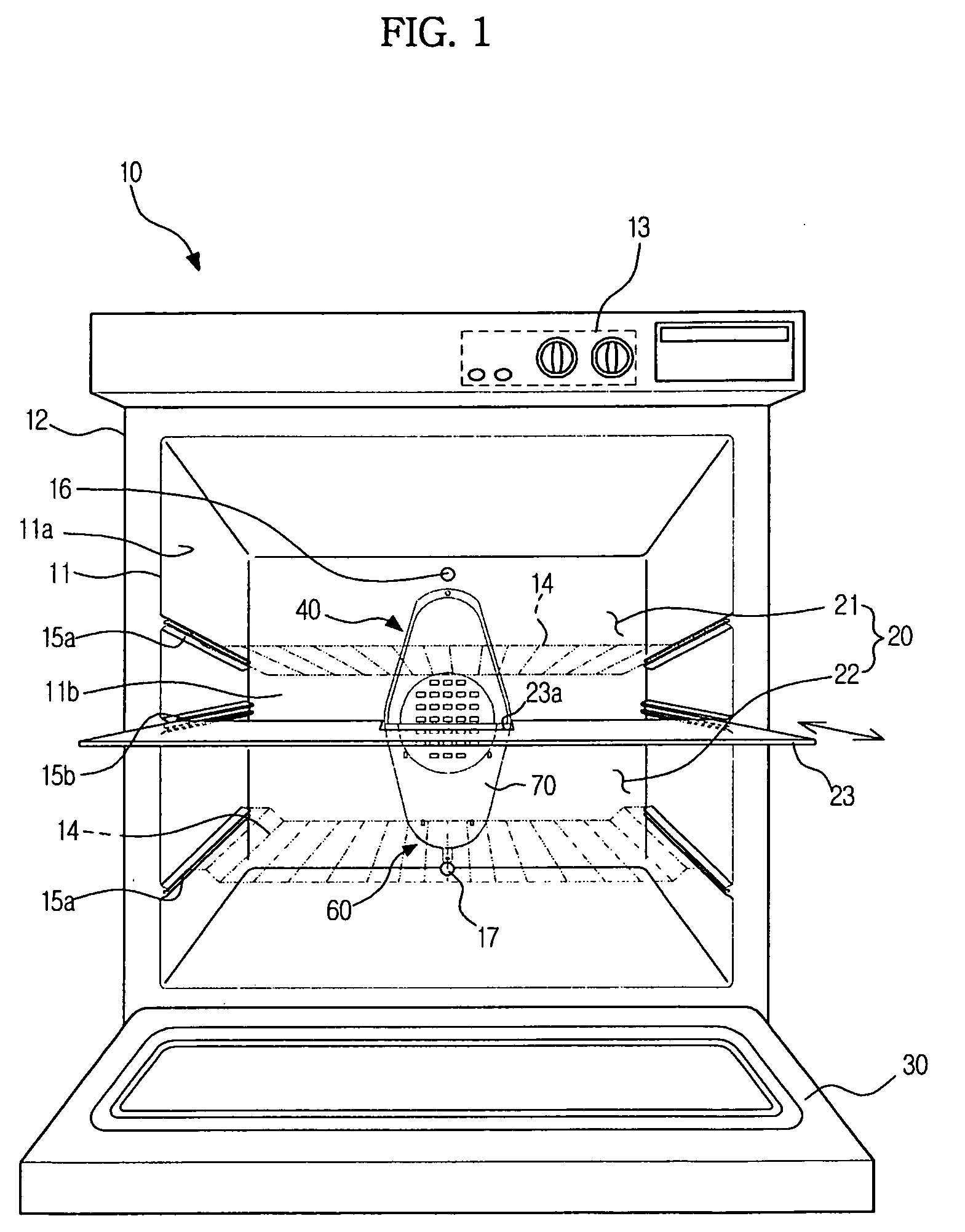

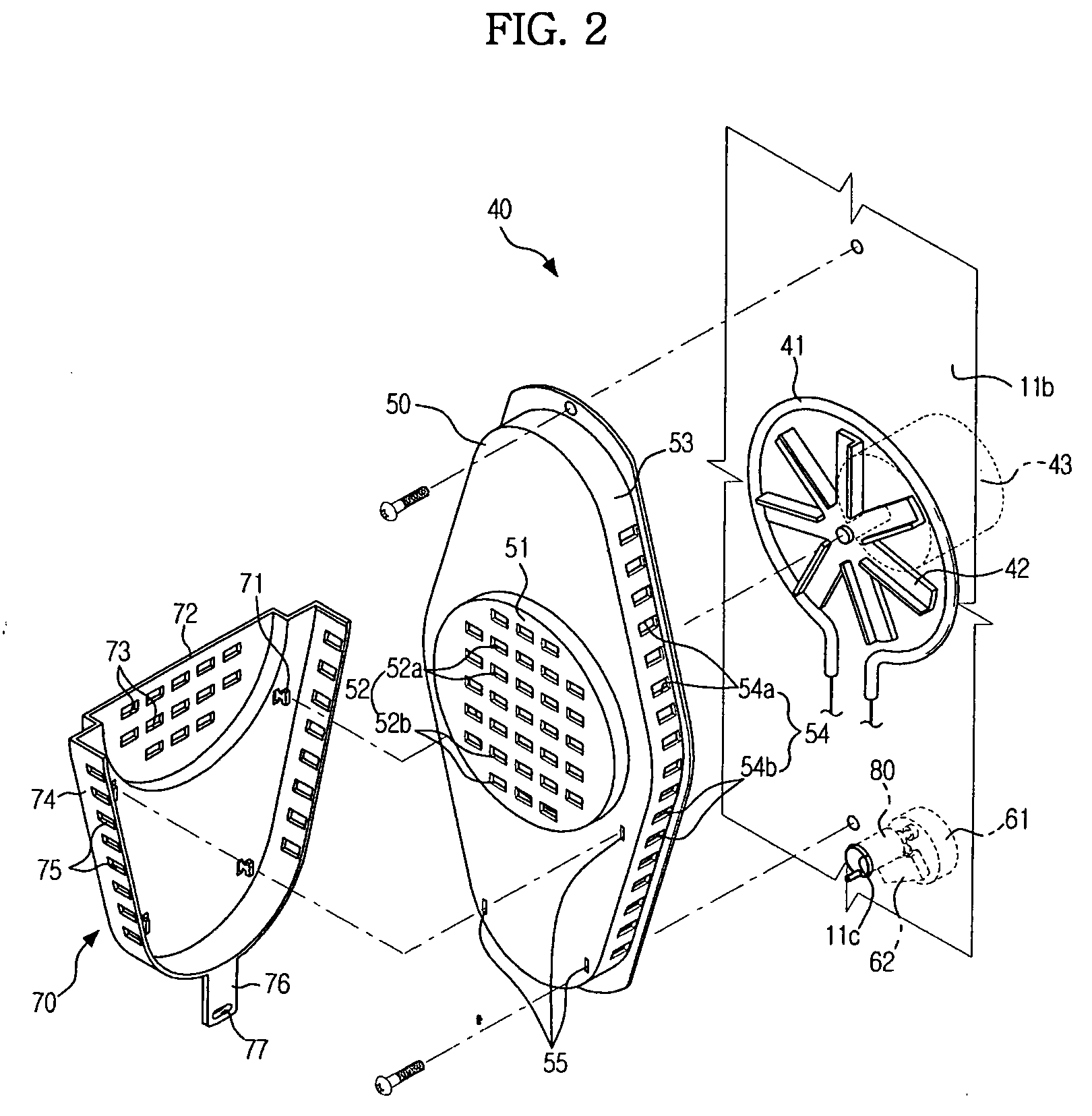

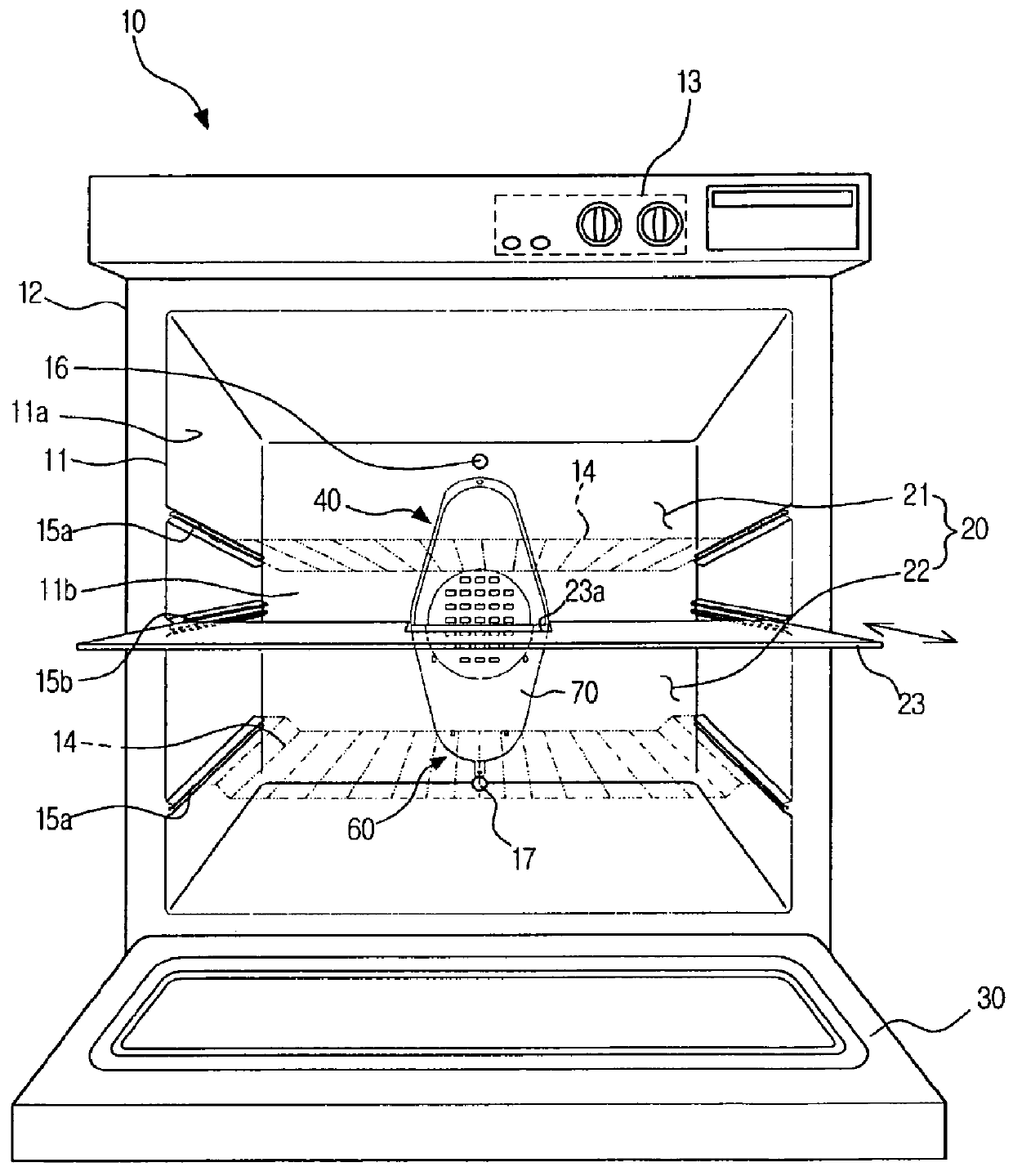

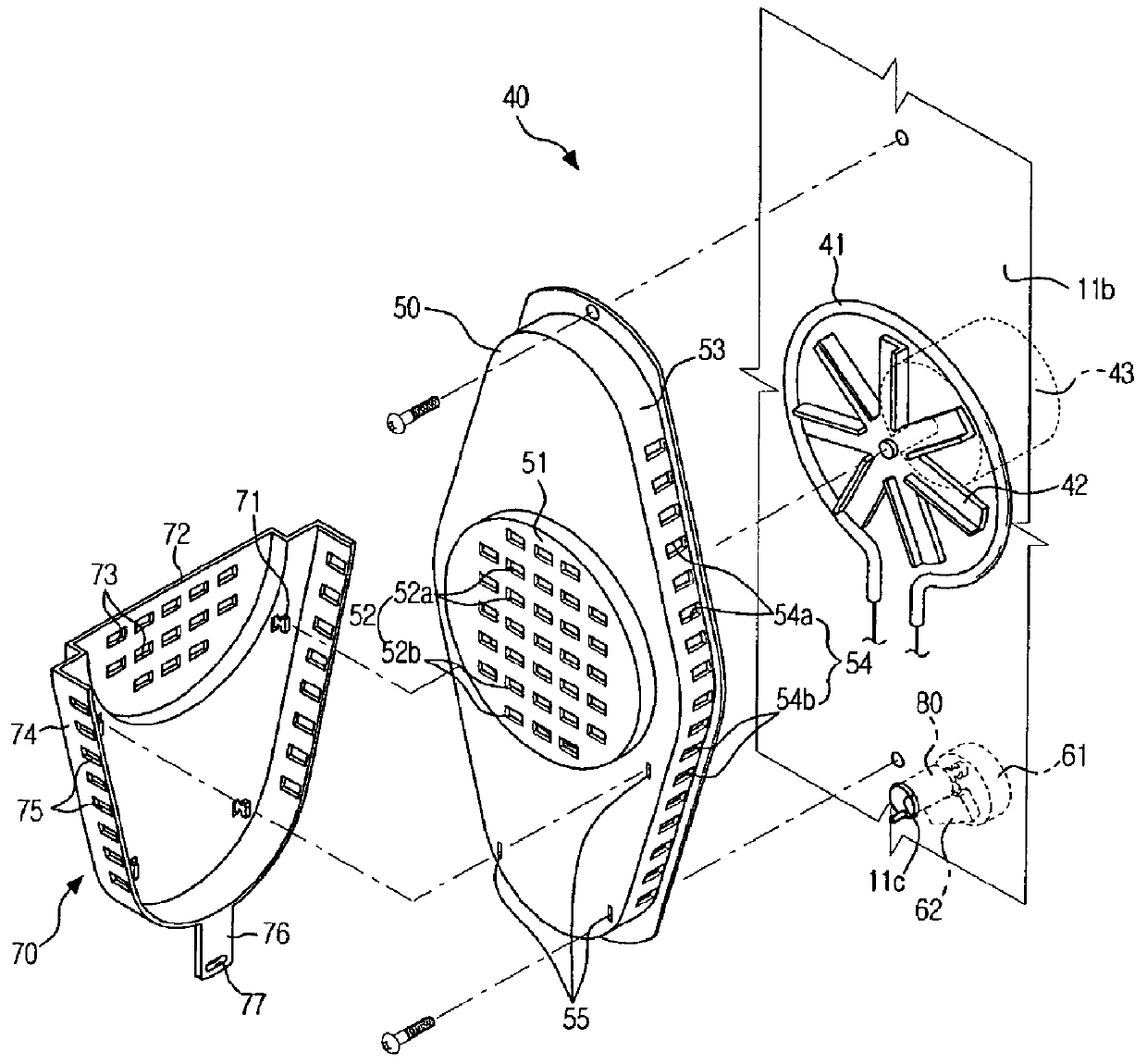

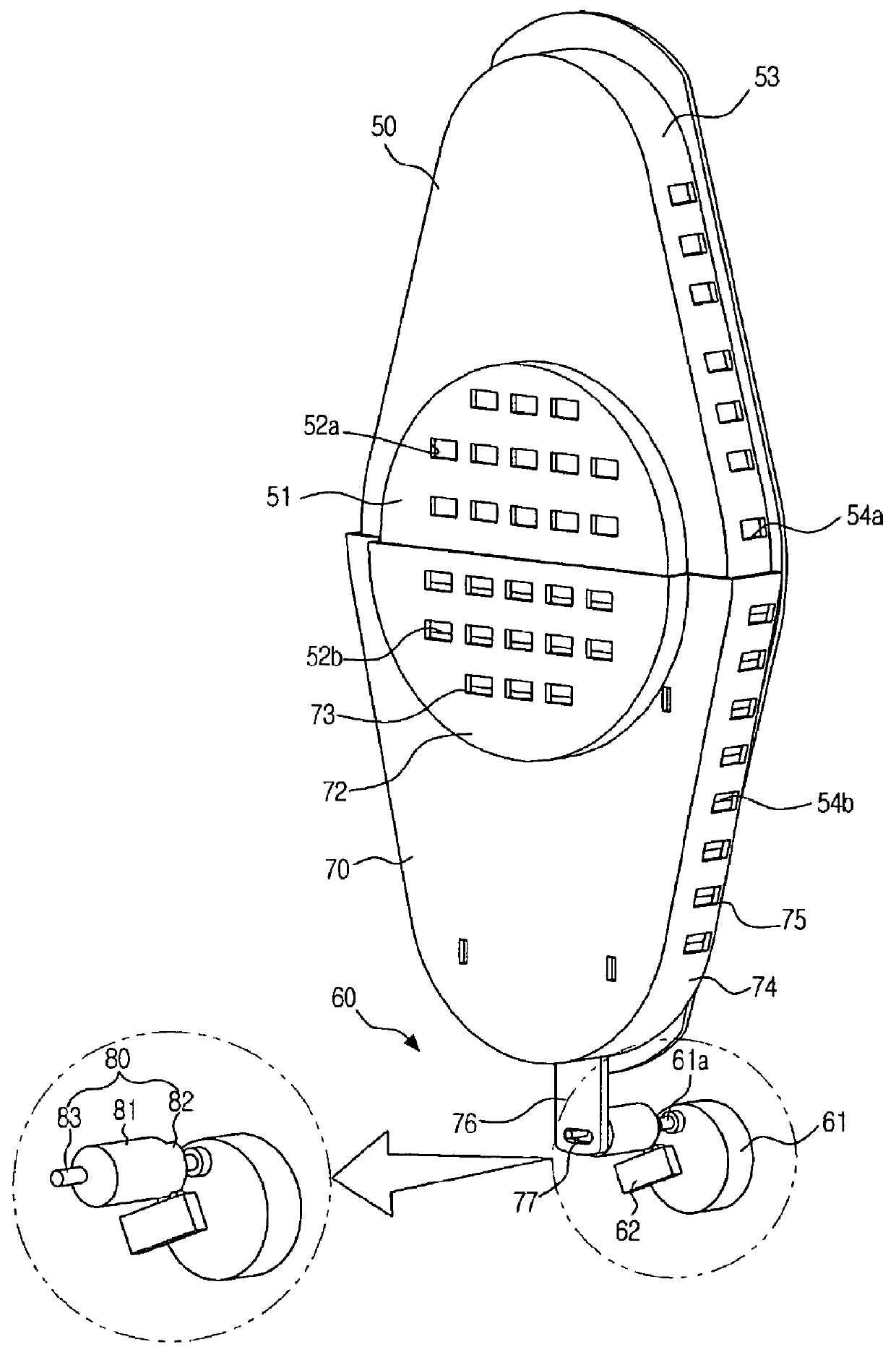

Cooking apparatus and method of controlling the same

ActiveUS20090032521A1Reduce temperature changesDegree of opening is decreasedDomestic stoves or rangesElectrical heating fuelProcess engineeringInternal temperature

A cooking apparatus and a method selectably cook food using one or more of a plurality of cooking spaces formed by a divider while using a same heat source and control different temperatures of the cooking spaces formed by the divider. An embodiment of the cooking apparatus includes a cooking chamber, a divider to divide the cooking chamber into cooking spaces, a heated air supply unit including a fan cover having upper and lower ventilation holes, a detection unit including temperature sensors to detect the interior temperatures of the cooking spaces, an airflow adjusting unit to adjust an amount of heated air supplied, and a control unit to control the amount of heated air, based on an interior temperature of the cooking space, to adjust a temperature to a target temperature set by a user.

Owner:SAMSUNG ELECTRONICS CO LTD

Sliding component

InactiveUS20040052649A1Small displacement volumeReducing pressure of chamberBearing componentsEngine componentsEpoxySilanes

A sliding component has a metal base member and a coating layer. The metal base member has a sliding surface. The layer is made of silane-modified resin. The silane-modified resin is made from resin that is soluble in solvent and is equal to or higher in heat-resistant than epoxy resin. The coating layer is formed on the sliding surface.

Owner:ARAKAWA CHEM IND LTD

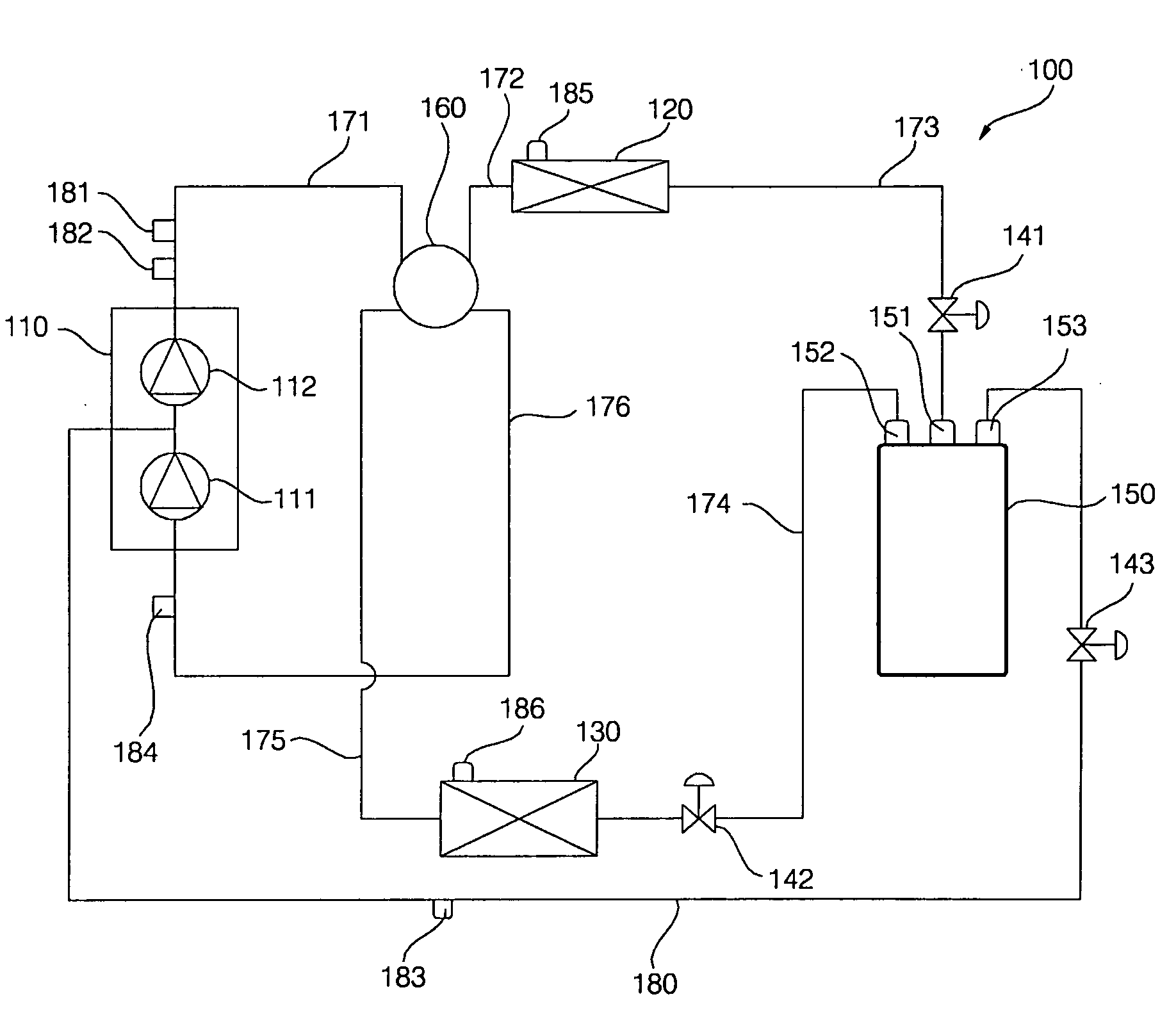

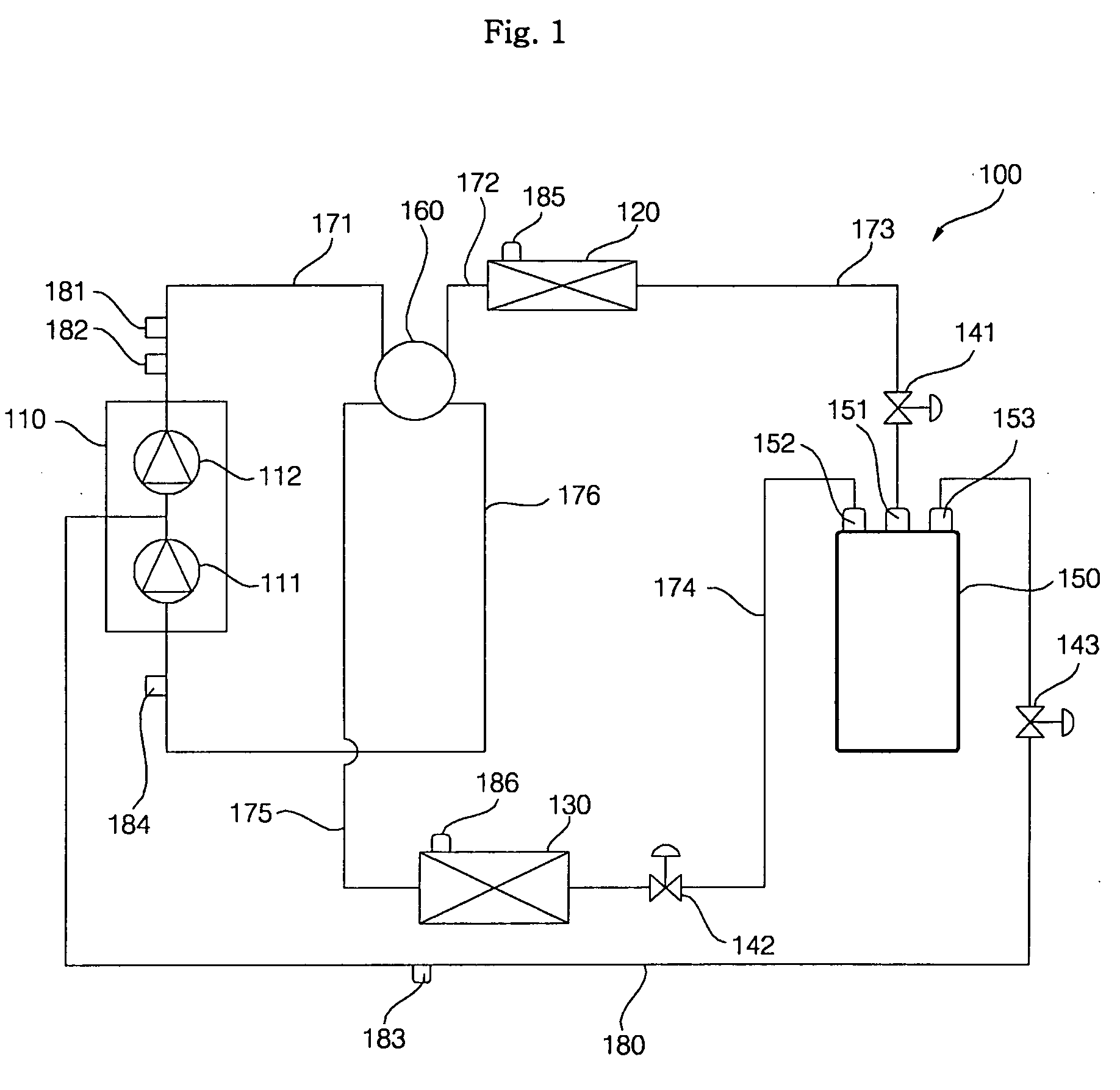

Air conditioning system

InactiveUS20090158764A1Reduce the amount requiredAdjustable pressureMechanical apparatusCompression machines with non-reversible cycleRefrigerantEngineering

Owner:LG ELECTRONICS INC

Device for purifying exhaust gas of a diesel engine

InactiveUS20090250041A1Promote combustionSuppressing formation of NOxGas treatmentElectrical controlHomogeneous charge compression ignitionExhaust fumes

A device for purifying exhaust gas of a diesel engine is equipped with a continuously regenerating diesel particulate filter (DPF) that uses a catalyst. A second continuously regenerating DPF of a small capacity is disposed in a by-path that by-passes the exhaust gas passage of the diesel engine equipped with the continuously regenerating DPF. The particulate matter (PM) is trapped by the second continuously regenerating DPF in the region of low exhaust gas temperatures. A homogeneous charge compression ignition is executed by advancing the timing for injecting the fuel into the cylinders to reduce the formation of PM. Therefore, the PM can be trapped to a sufficient degree despite the second continuously regenerating DPF has a small capacity. To suppress the formation of NOx, further, the cooled exhaust gas is recirculated into the cylinders and, besides, a urea-added SCR catalyst is disposed in the exhaust gas passage to reduce and decompose NOx in the exhaust gas to further reduce NOx.

Owner:ISUZU MOTORS LTD

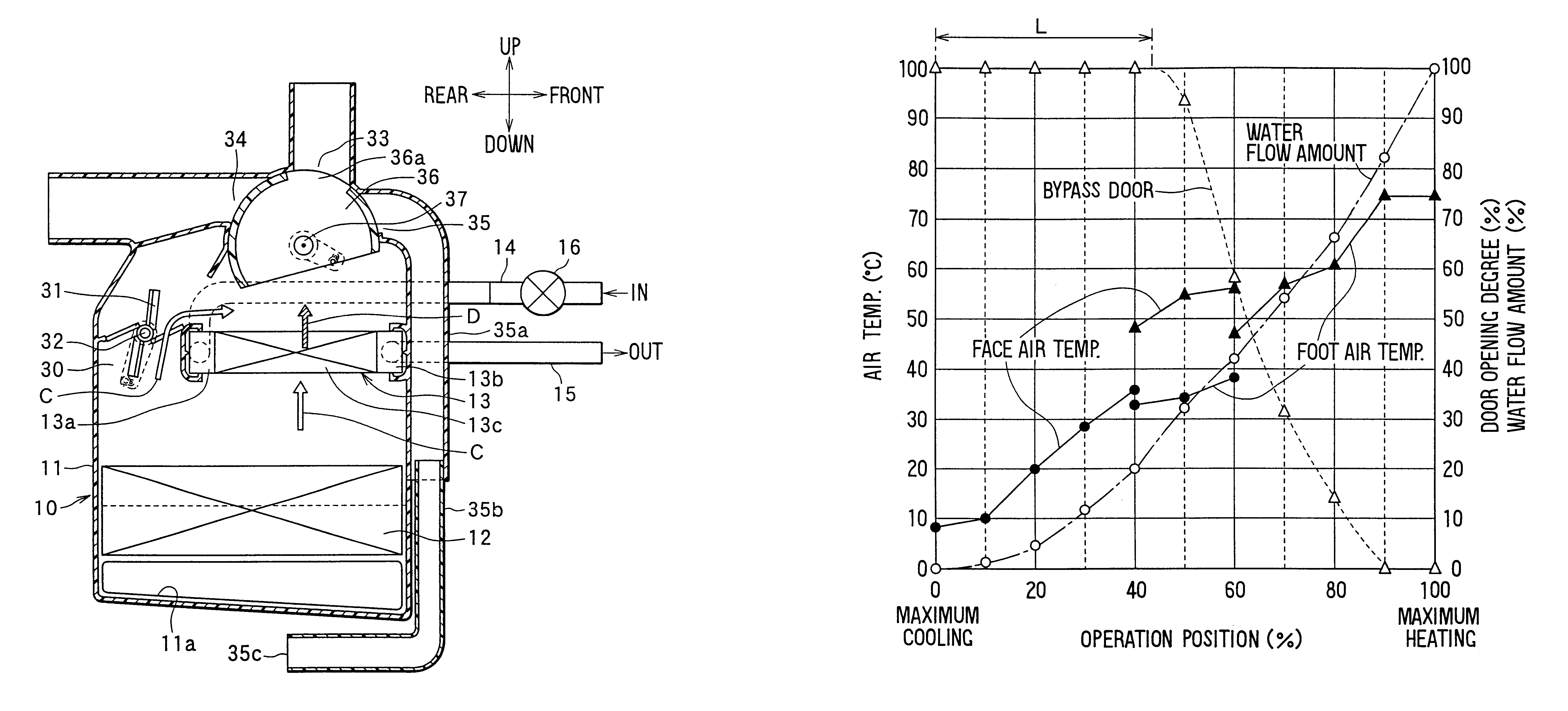

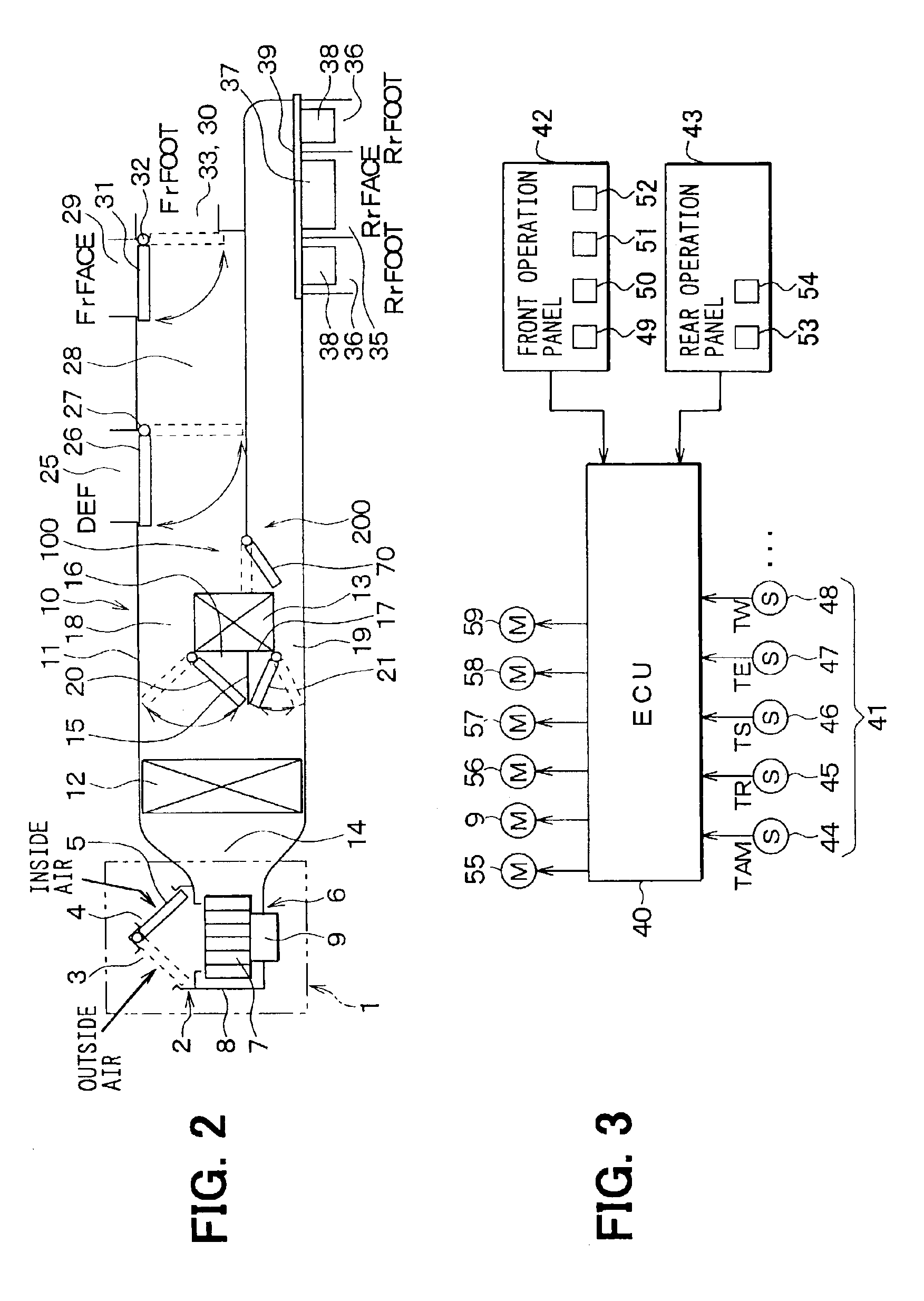

Air conditioning apparatus with air-temperature adjustment

InactiveUS6352208B1Easy to adjustReduce flow noiseAir-treating devicesRailway heating/coolingWater flowEngineering

A vehicle air conditioning apparatus includes a hot water valve for adjusting a flow amount of hot water flowing into a heating heat exchanger, a bypass passage through which air bypasses the heating heat exchanger, and a bypass door for opening and closing the bypass passage. In a high-temperature side area where temperature of air blown into the passenger compartment becomes higher, the temperature of air to be blown into the passenger compartment is adjusted by a hot-water flow adjustment of the hot water valve while the bypass door is operated at a fully closed position. On the other hand, in a low-temperature side area where temperature of air blown into the passenger compartment becomes lower, the temperature of air to be blown into the passenger compartment is adjusted by combining the hot-water flow adjustment of the hot water valve and the air flow adjustment of the bypass door. Thus, even in a minute flow area of hot water flowing into the heating heat exchanger, the temperature of air blown into the passenger compartment is accurately adjusted.

Owner:DENSO CORP

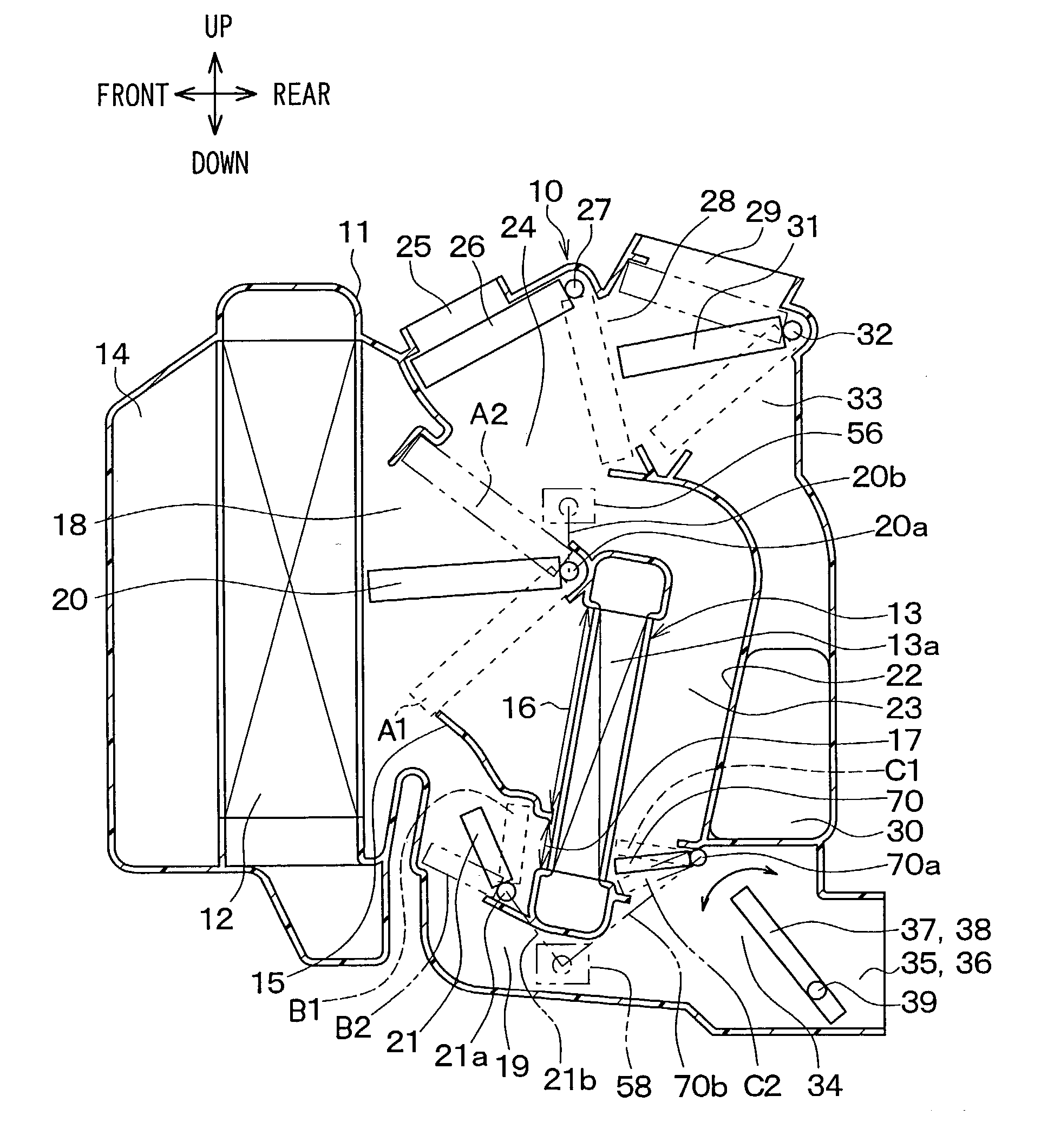

Air conditioner for vehicle

InactiveUS7013967B2Small sizeSimple structureAir-treating devicesVehicle heating/cooling devicesCold airAir conditioning

In a vehicle air conditioner, a heater core is disposed in an air conditioning case to form front and rear cool air bypass passage through which cool air bypasses the heater core, and front and rear air mixing doors are disposed to independently adjust temperature of air blown toward a front seat side and temperature of air blown toward a rear seat side in a passenger compartment. A switching door is disposed to partition front and rear passage portions of the heater core from each other at a partition position, and to shut the rear passage portion at a rear shutting position. The switching door and the rear air mixing door are connected to a common operation mechanism to be operatively linked with each other.

Owner:DENSO CORP

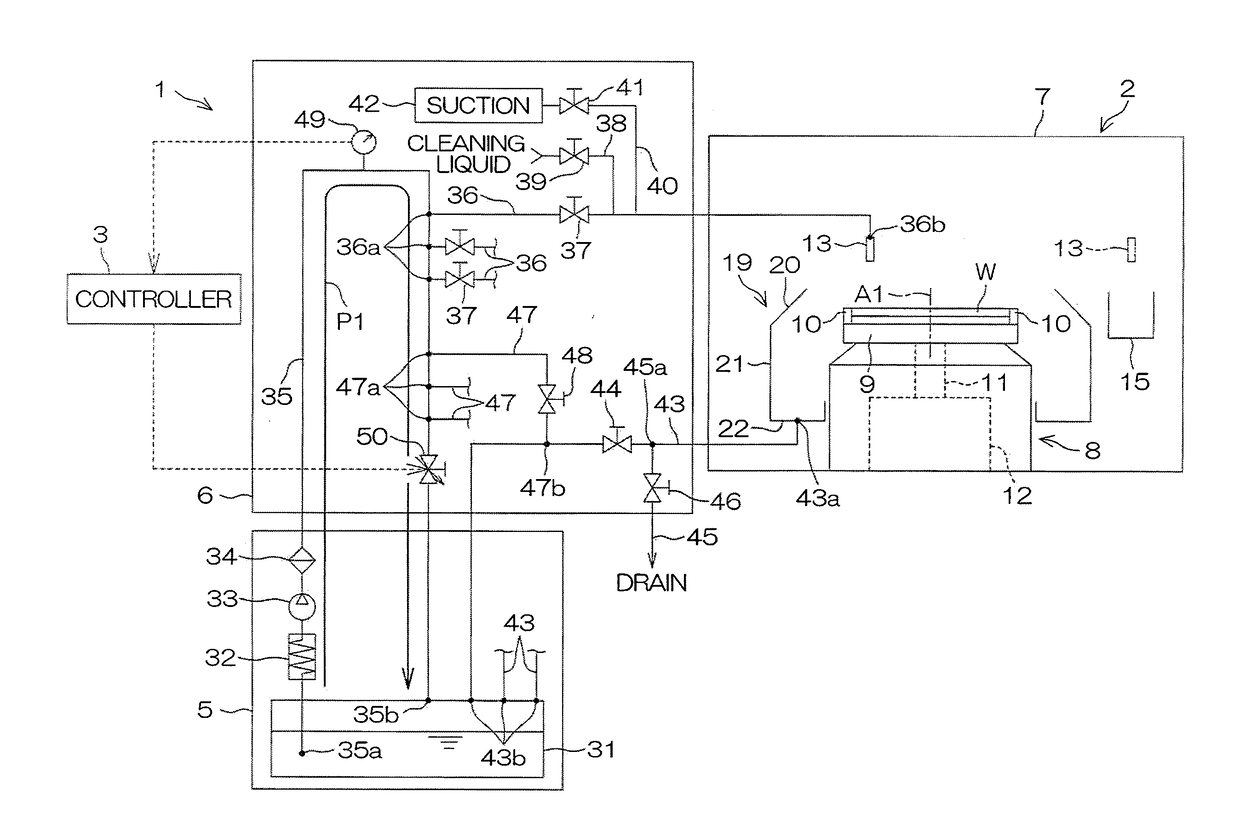

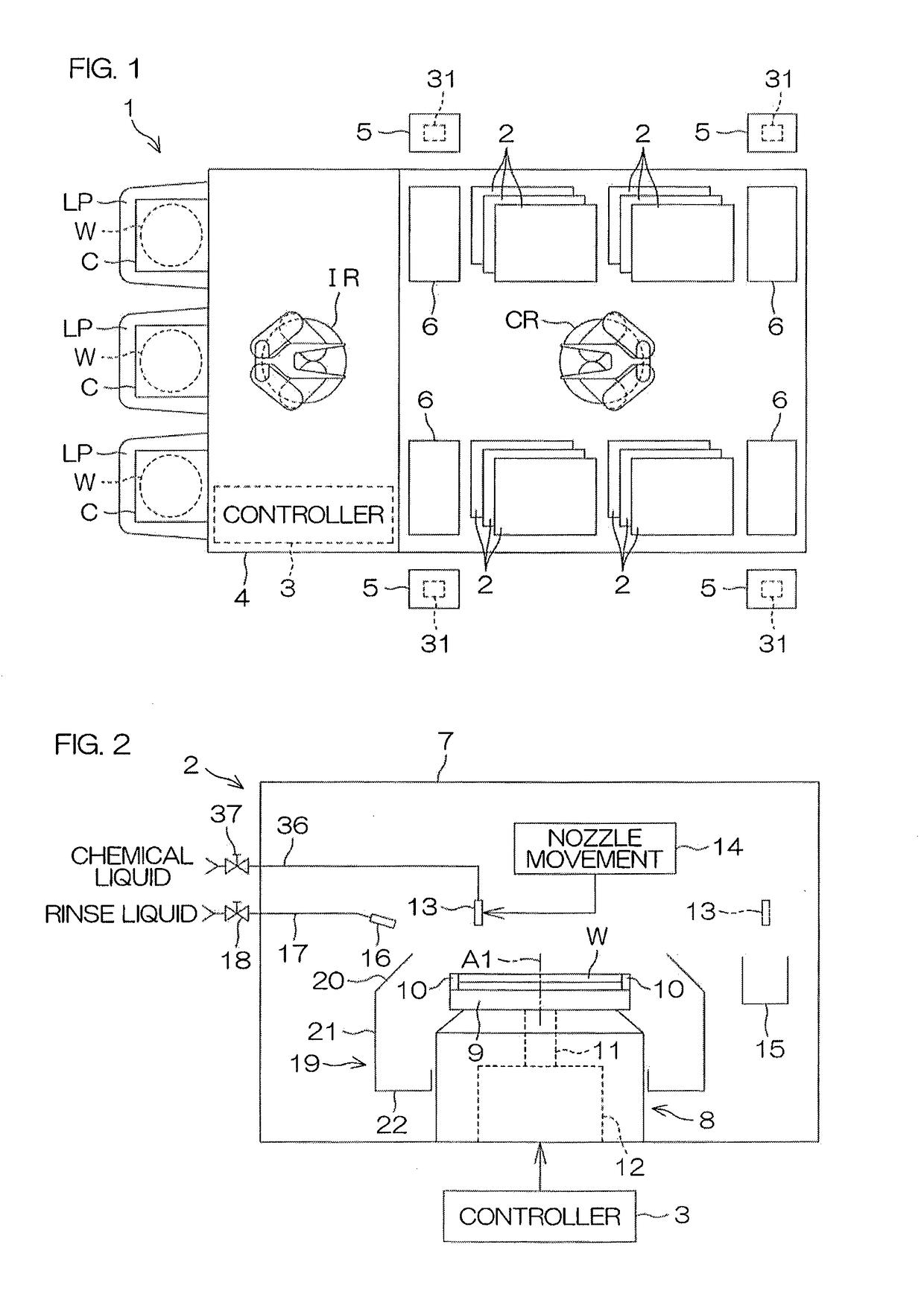

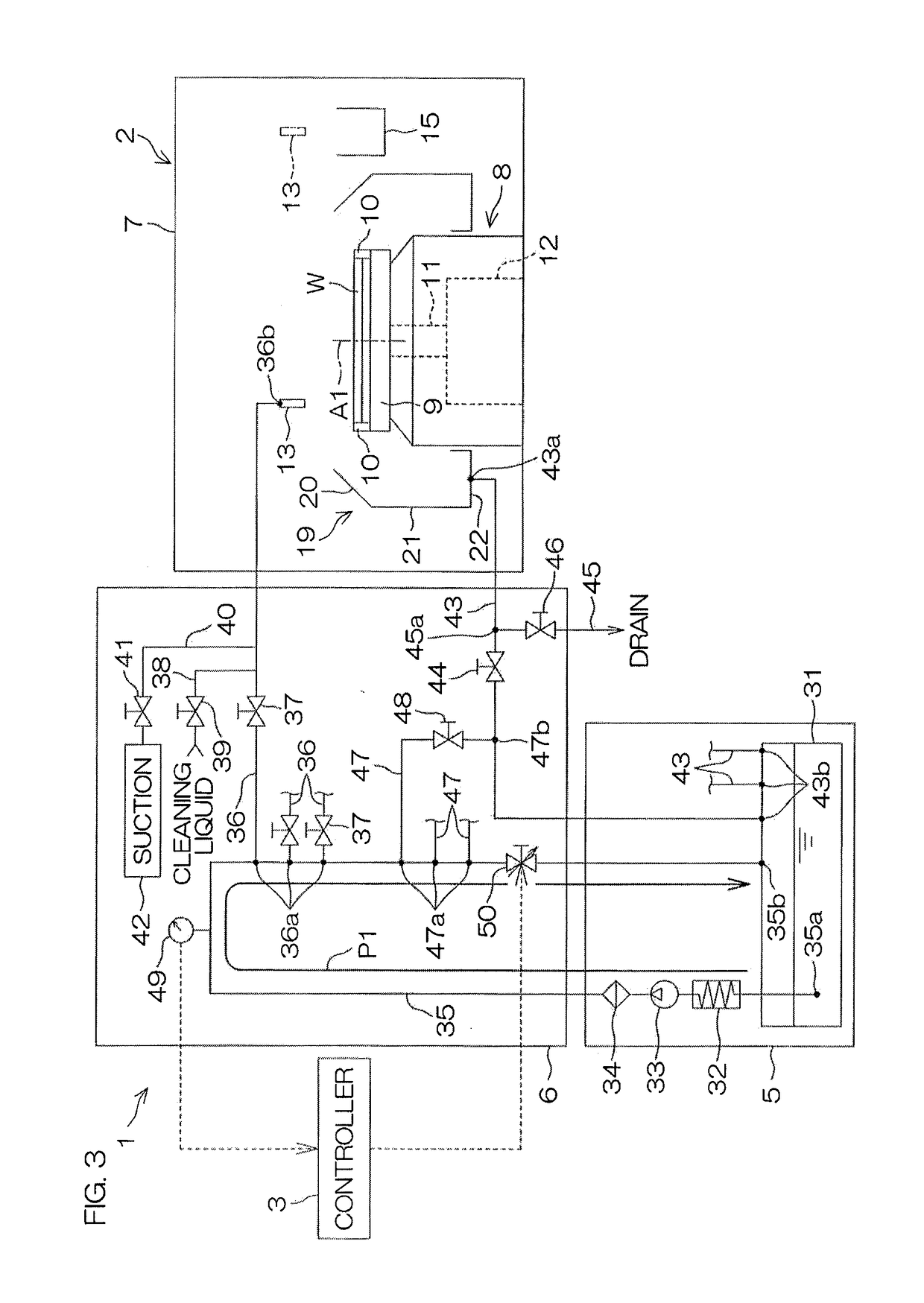

Substrate processing device

ActiveUS20170256426A1Easy to changeDifficult to dissociateLiquid surface applicatorsSpraying apparatusSpray nozzleEngineering

A substrate processing apparatus includes: a circulation pipe which defines a circulation passage through which a chemical liquid within a chemical-liquid tank is circulated; a supply pipe which guides the chemical liquid from the circulation pipe to a chemical-liquid nozzle; a supply valve which is switched between an open state in which the chemical liquid flowing through the supply pipe toward the chemical-liquid nozzle is passed and a closed state in which the supply of the chemical liquid from the supply pipe to the chemical-liquid nozzle is stopped; a recovery pipe which guides the chemical liquid from a cup to the chemical-liquid tank; and a branch pipe which guides the chemical liquid within the circulation pipe to the recovery pipe.

Owner:DAINIPPON SCREEN MTG CO LTD

Cooking apparatus and method of controlling the same

ActiveUS8212188B2Reduce temperature changesDegree of opening is decreasedDomestic stoves or rangesElectrical heating fuelProcess engineeringIngested food

A cooking apparatus and a method selectably cook food using one or more of a plurality of cooking spaces formed by a divider while using a same heat source and control different temperatures of the cooking spaces formed by the divider. An embodiment of the cooking apparatus includes a cooking chamber, a divider to divide the cooking chamber into cooking spaces, a heated air supply unit including a fan cover having upper and lower ventilation holes, a detection unit including temperature sensors to detect the interior temperatures of the cooking spaces, an airflow adjusting unit to adjust an amount of heated air supplied, and a control unit to control the amount of heated air, based on an interior temperature of the cooking space, to adjust a temperature to a target temperature set by a user.

Owner:SAMSUNG ELECTRONICS CO LTD

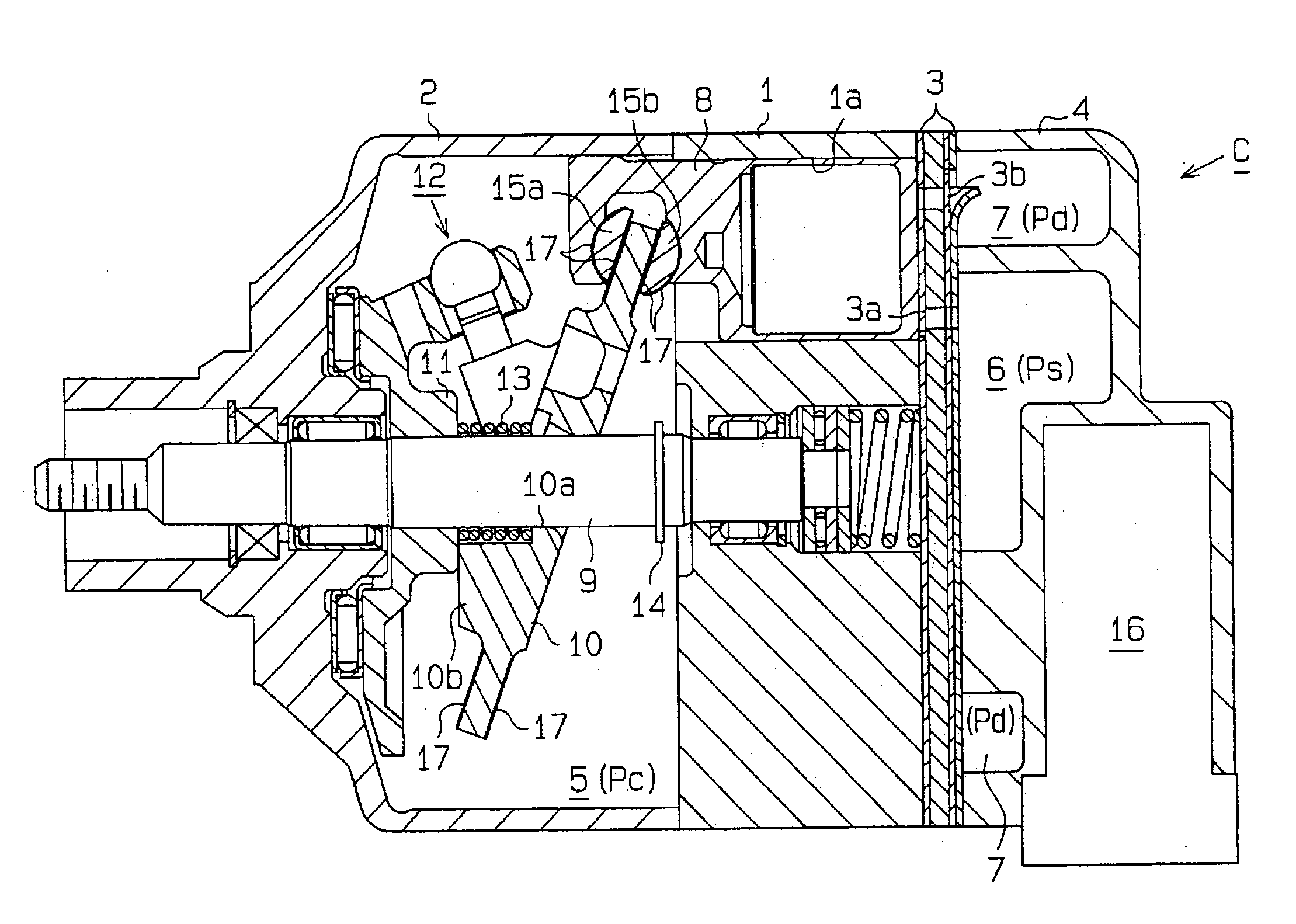

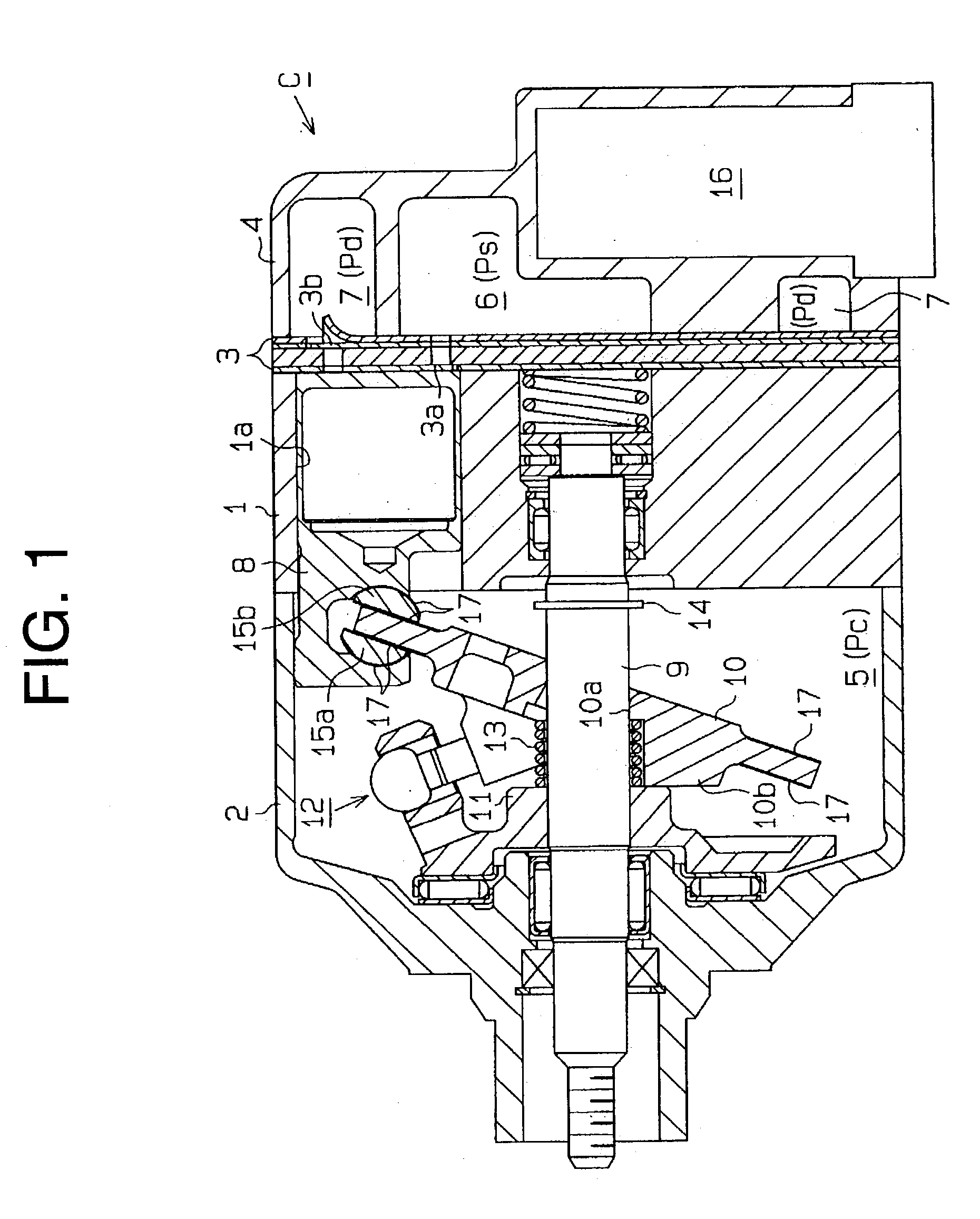

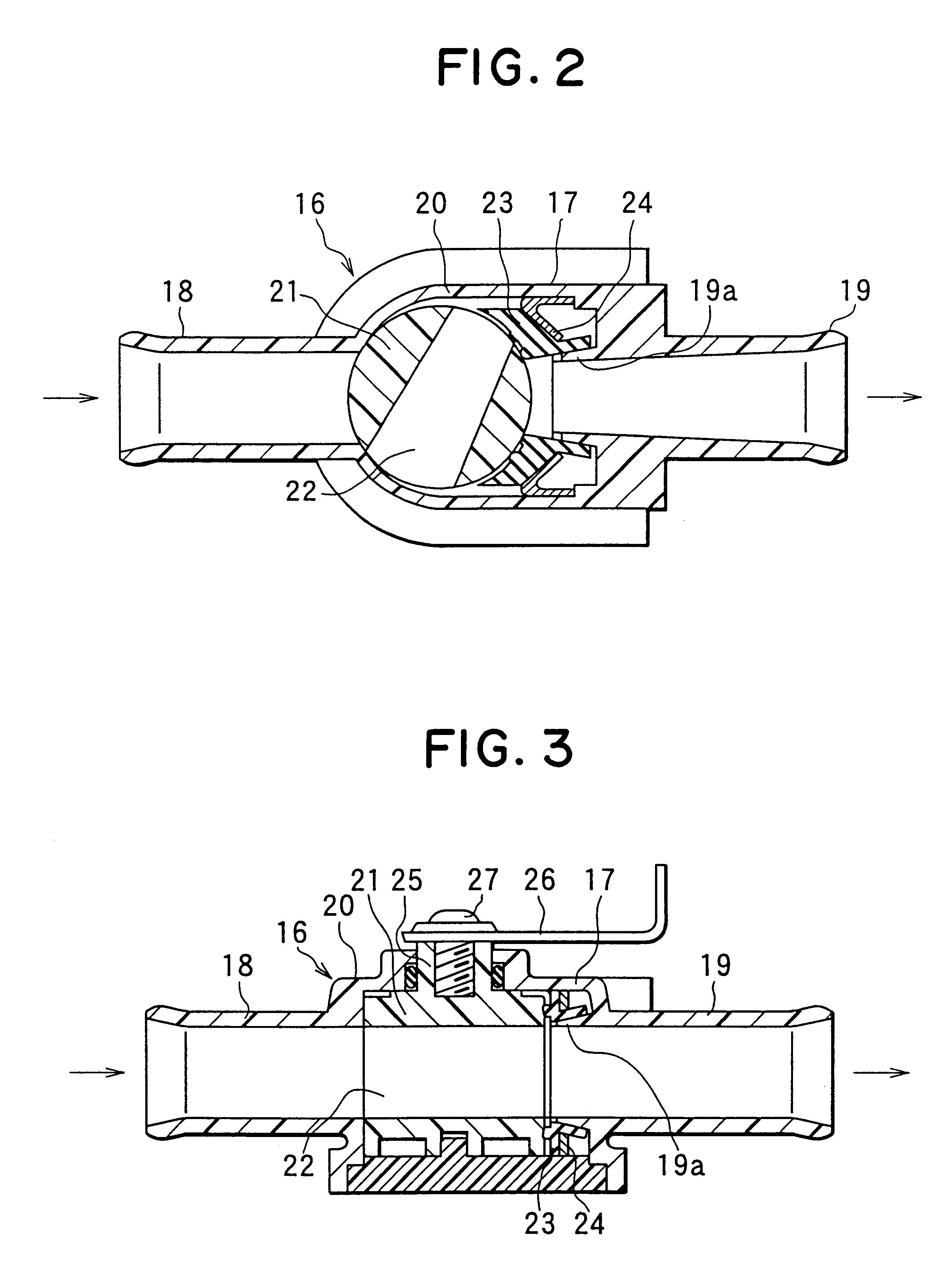

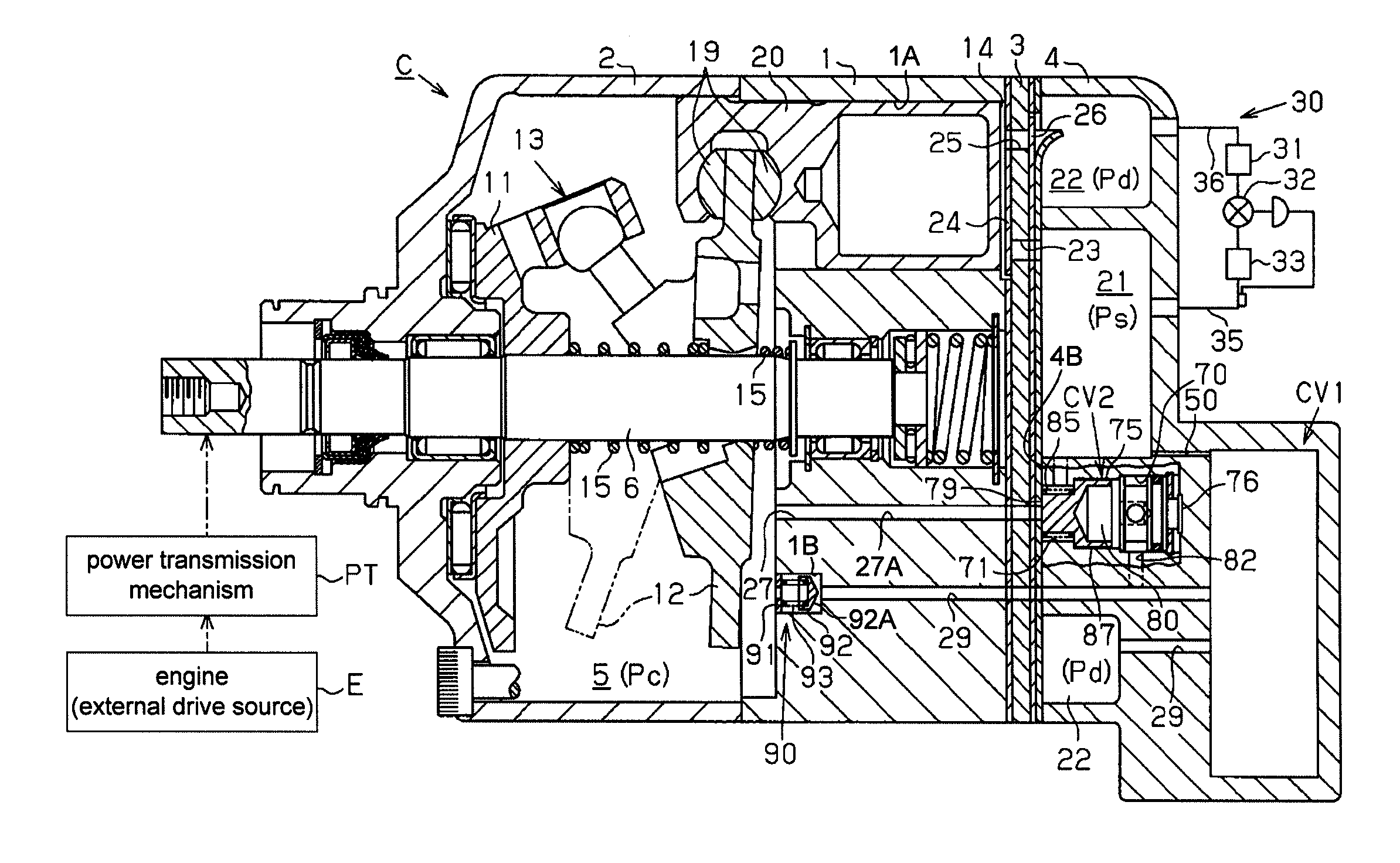

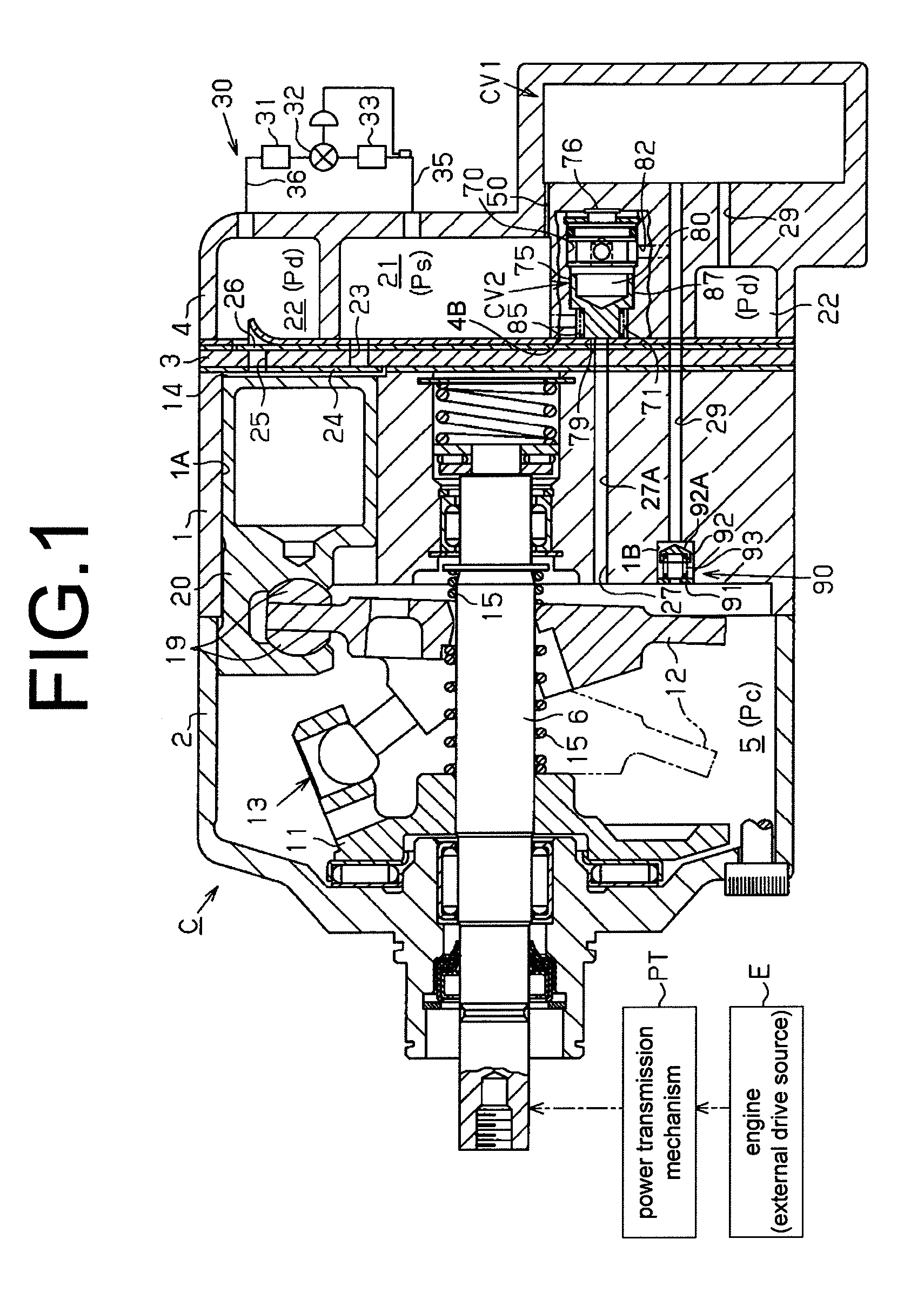

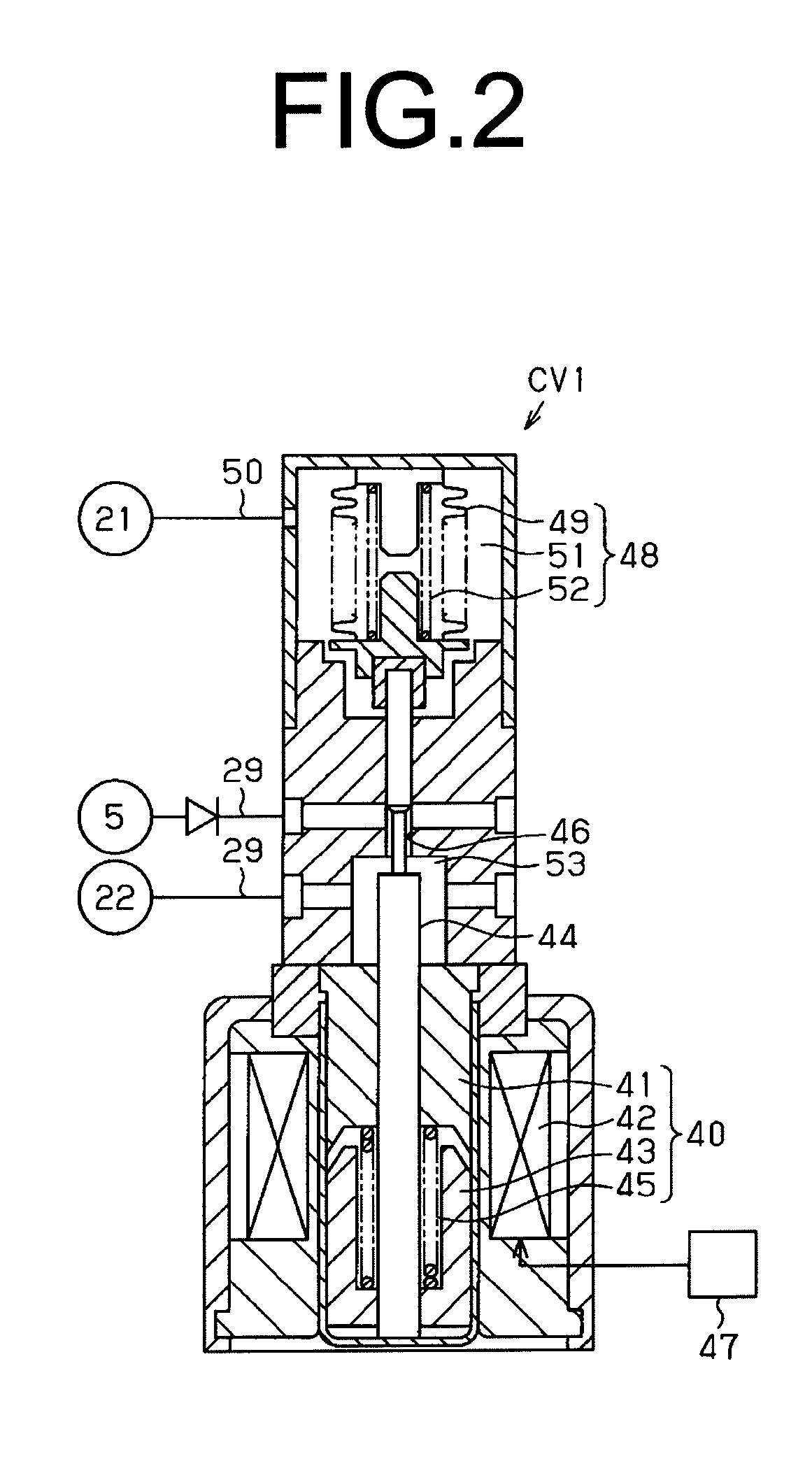

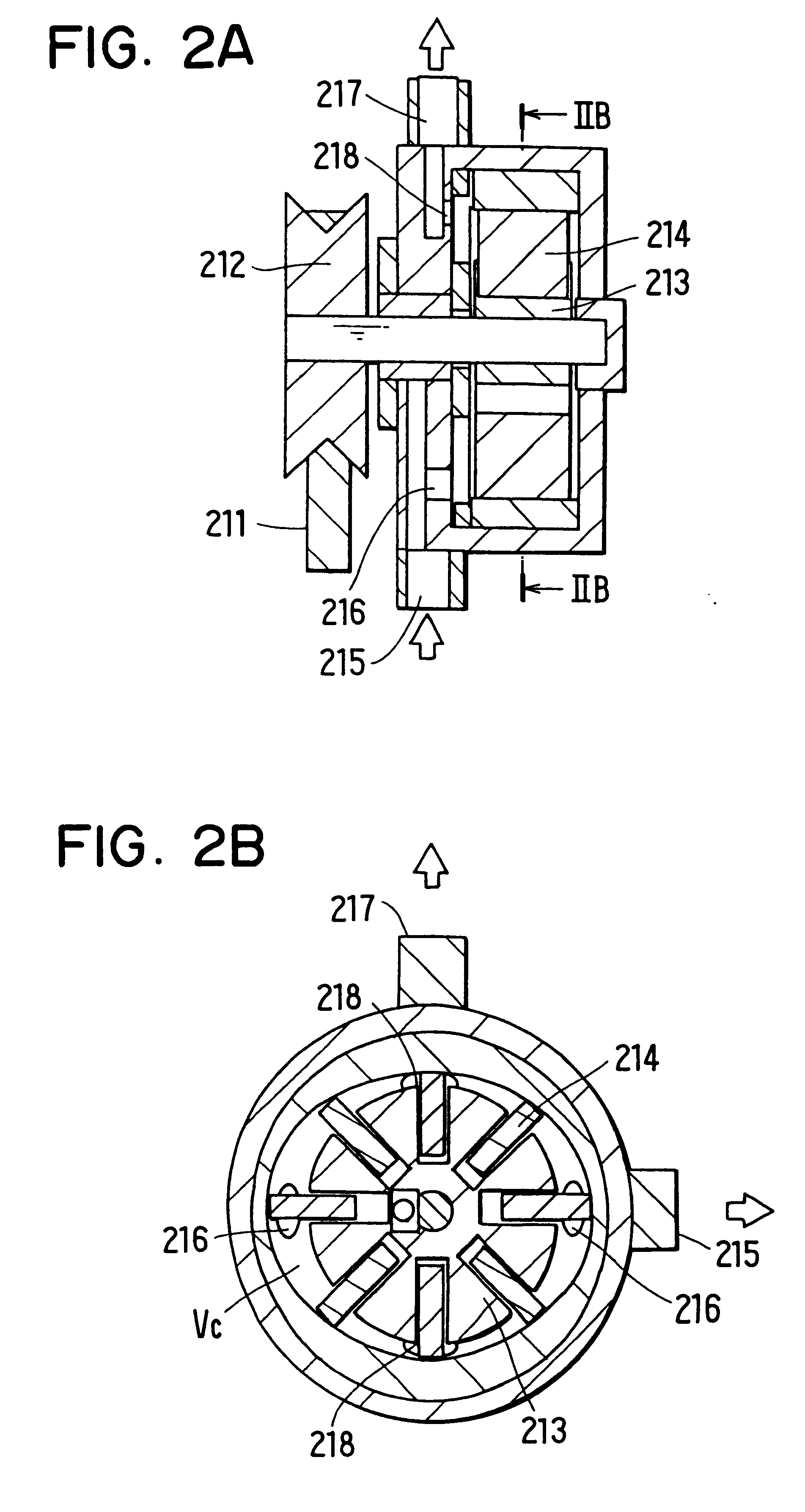

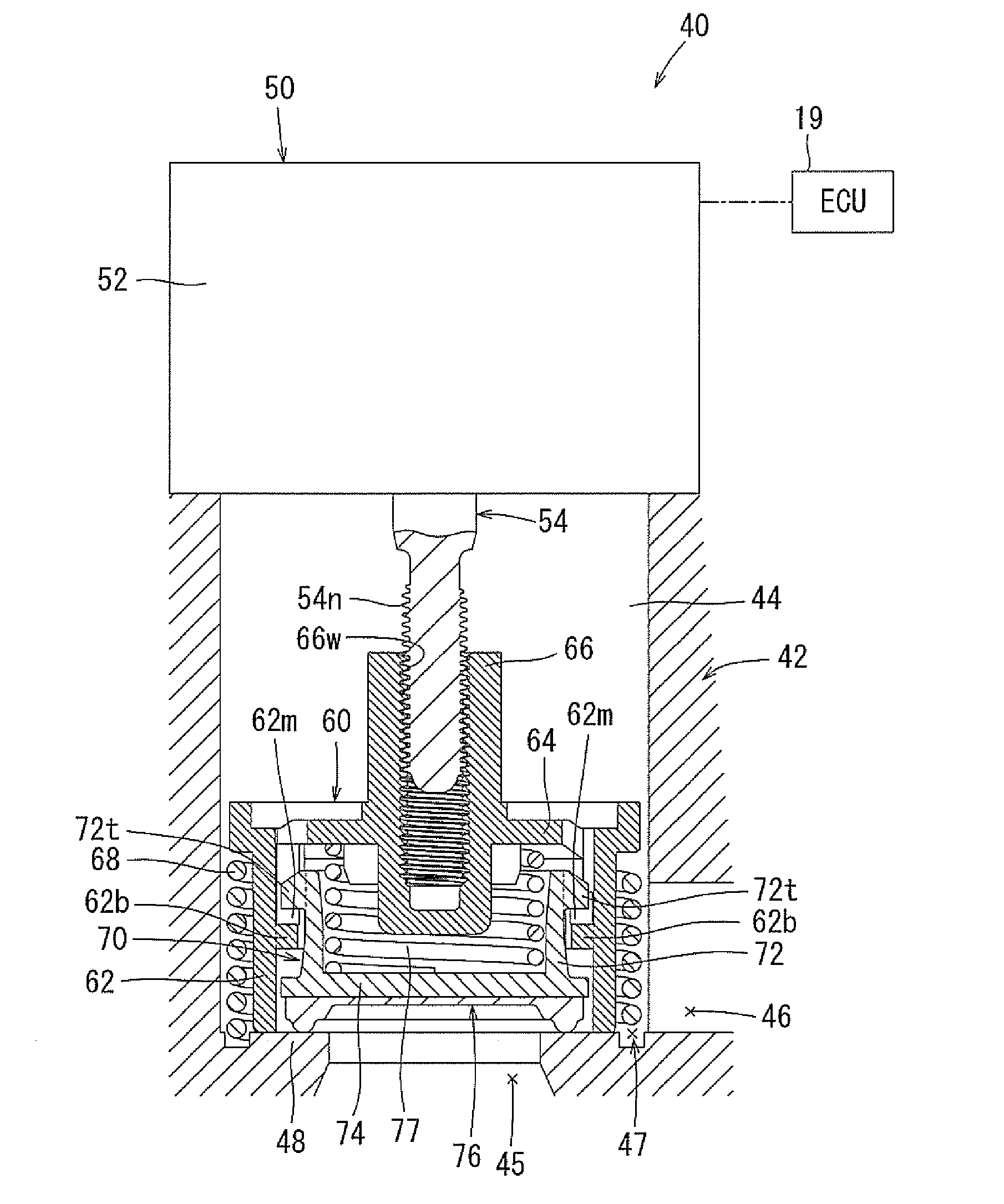

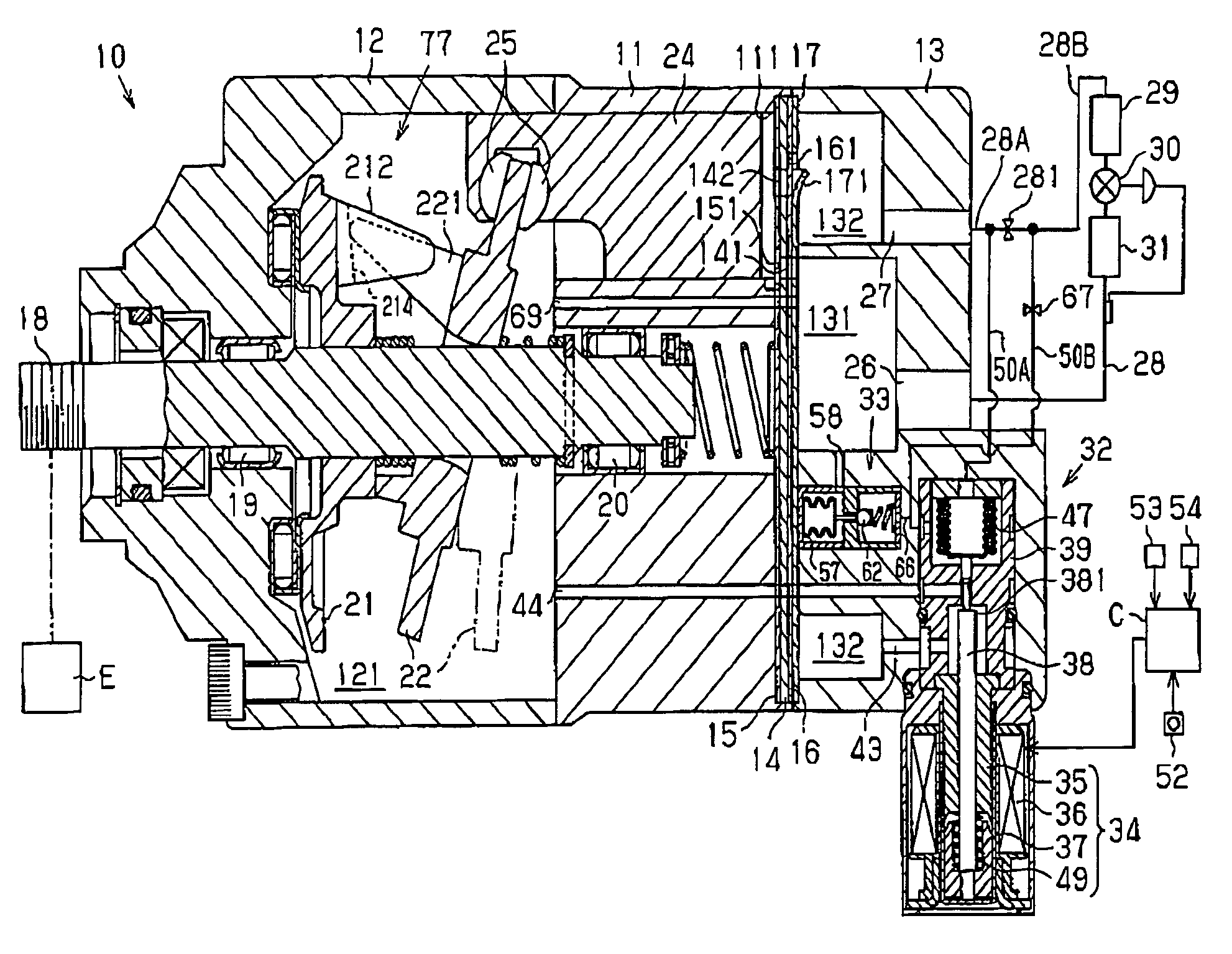

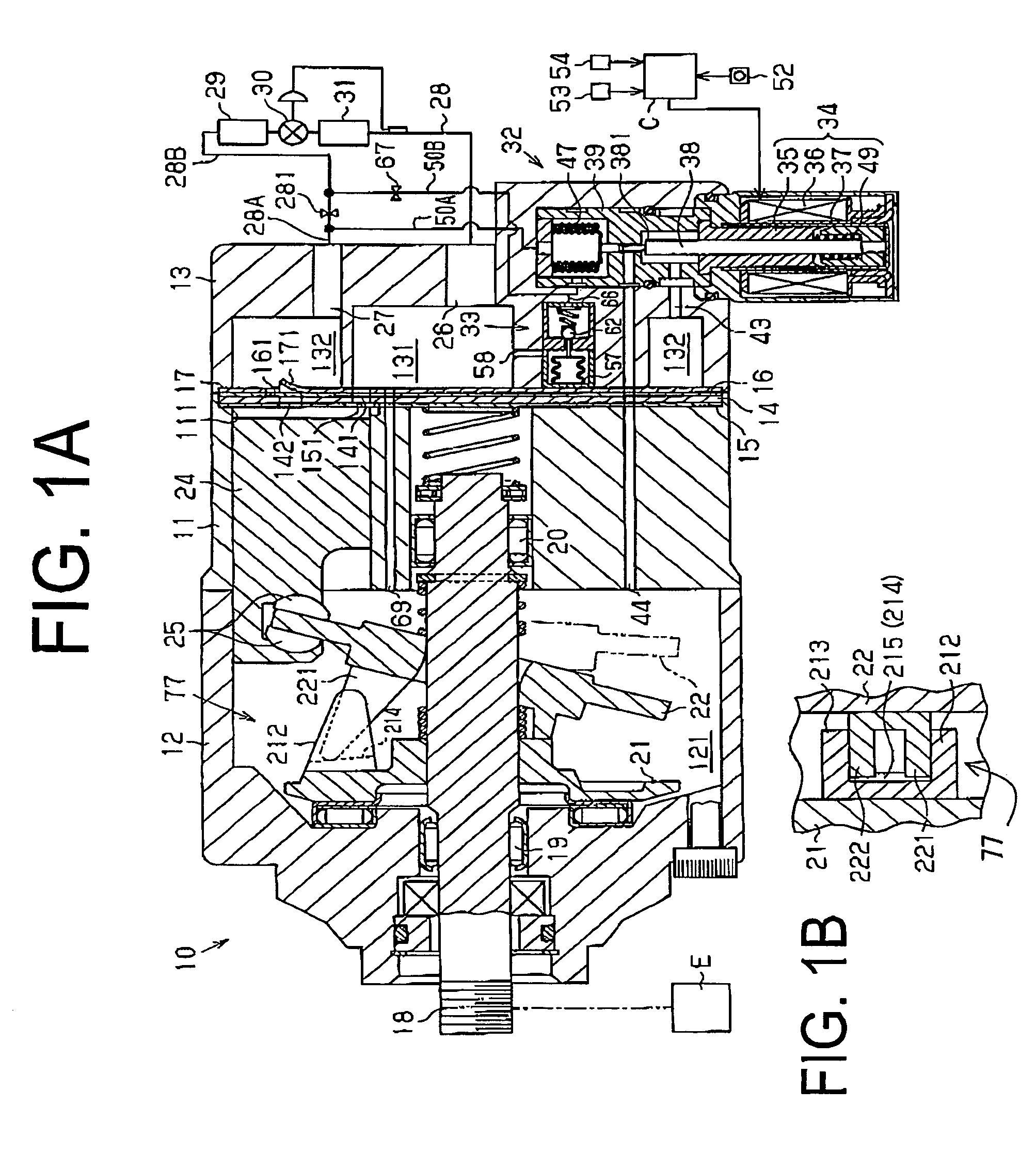

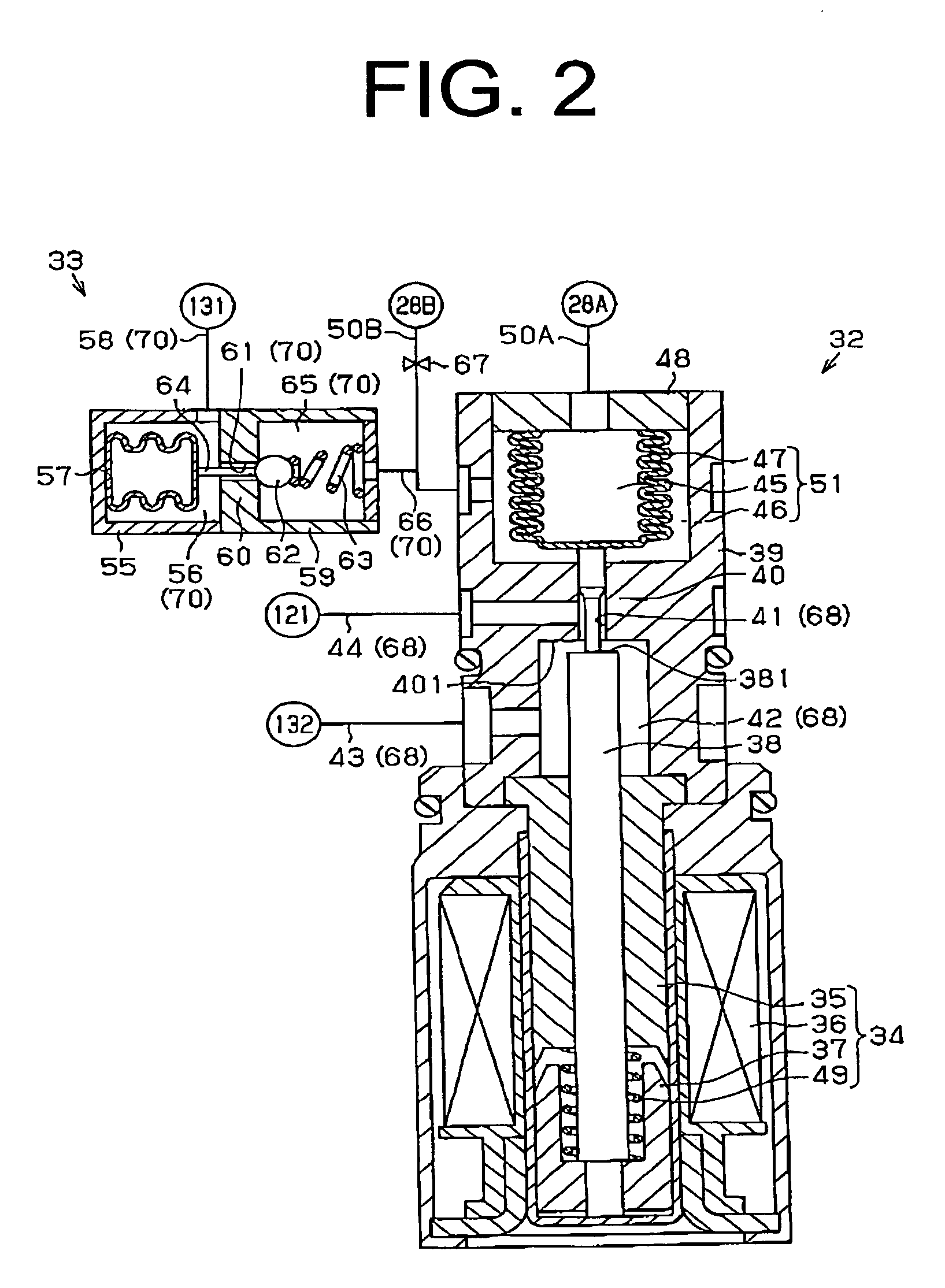

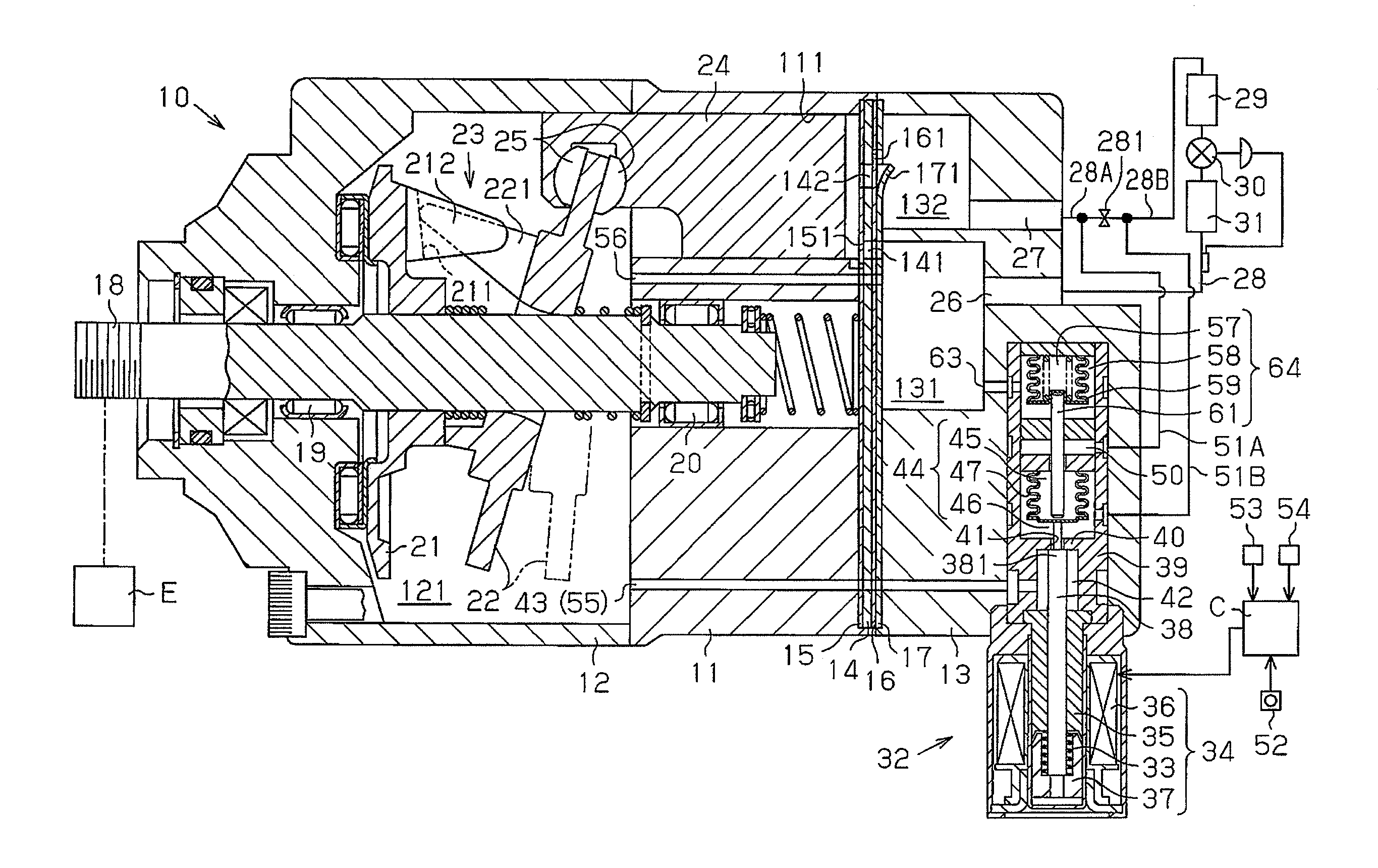

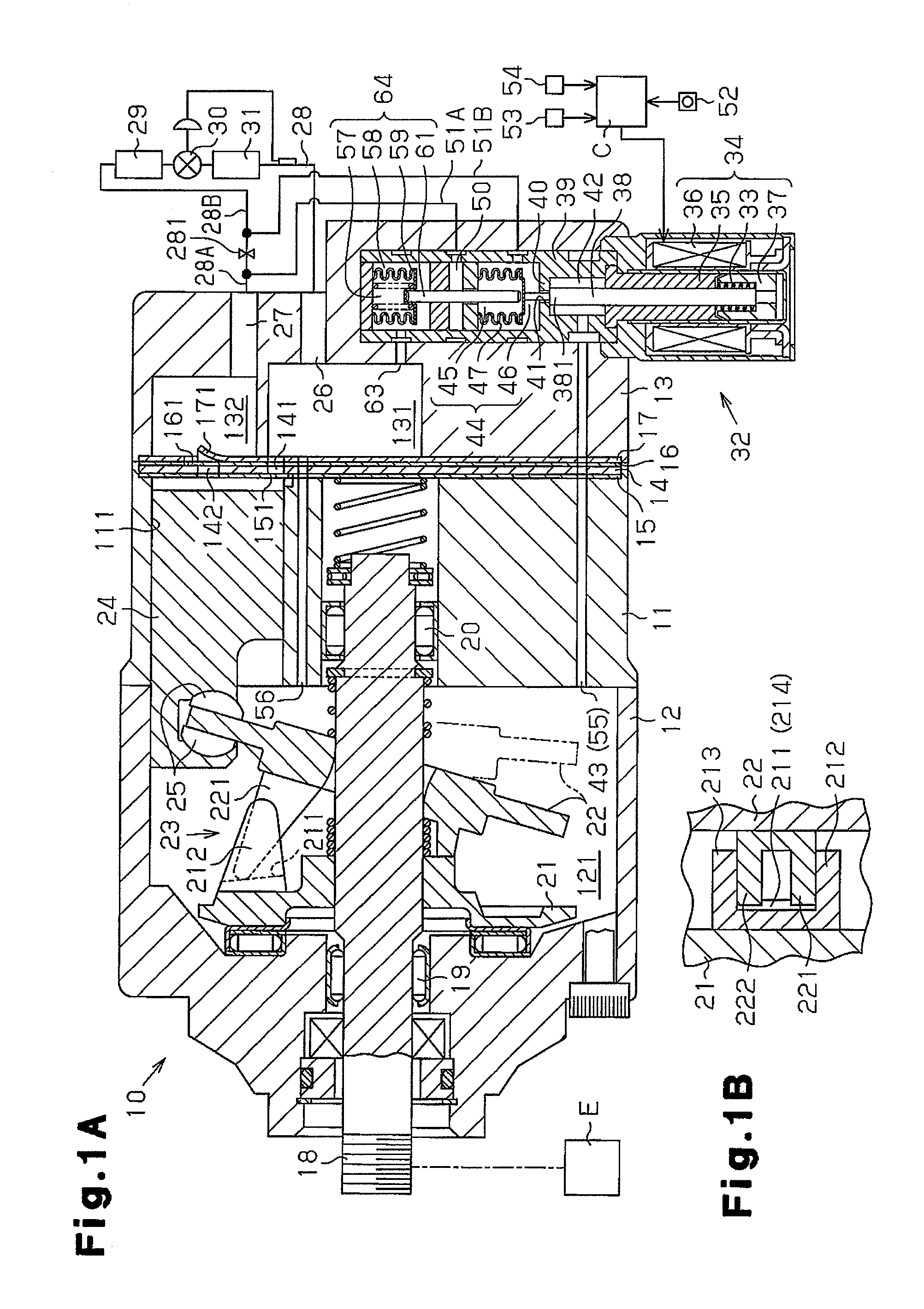

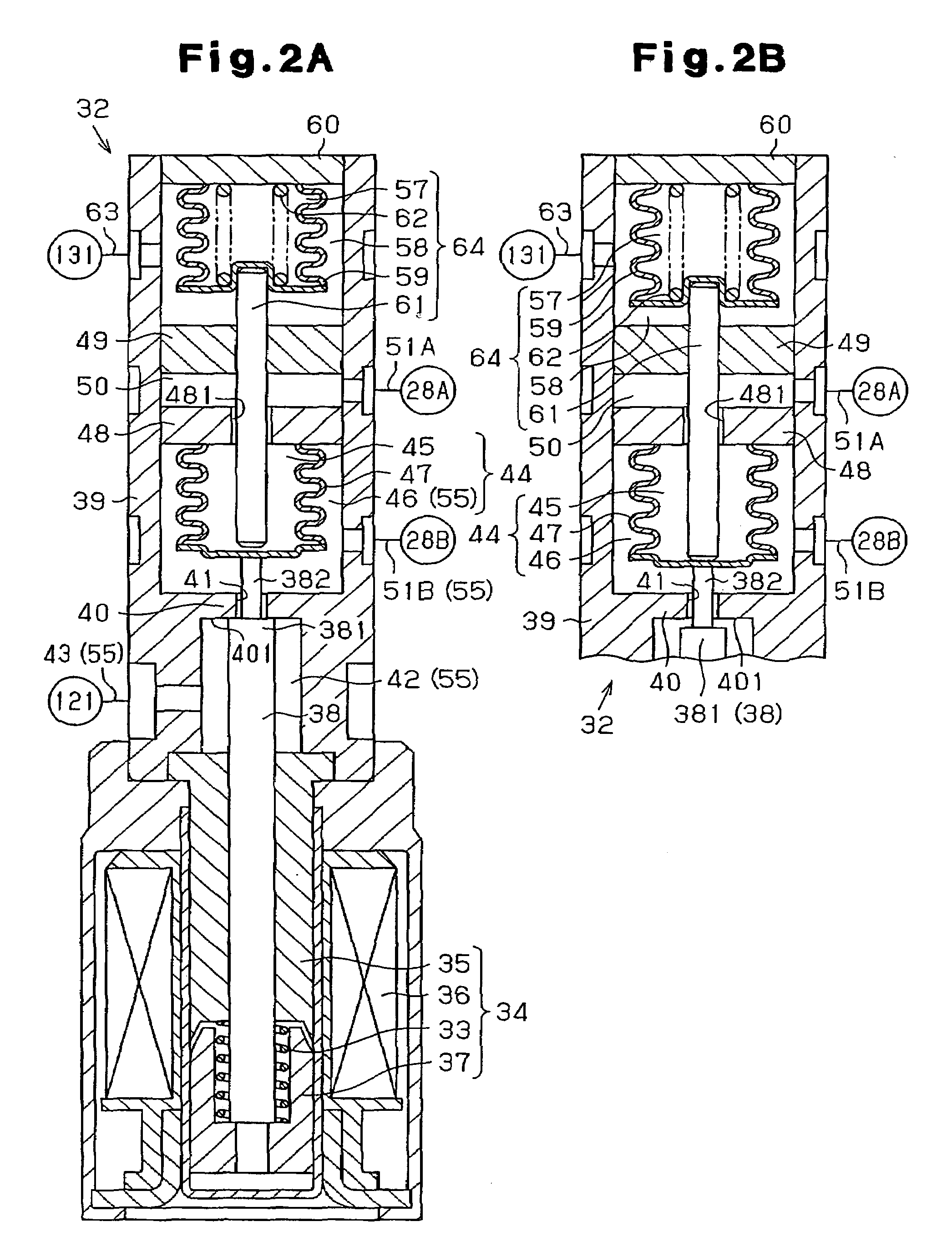

Variable displacement type compressor with displacement control mechanism

ActiveUS20100104454A1Reduce the degree of openingAvoid flowMulti-stage pumpsPositive-displacement liquid enginesControl roomEngineering

A variable displacement type compressor has a supply passage for supplying refrigerant gas to a pressure control chamber, a release passage for releasing the refrigerant gas from the pressure control chamber, a first control valve for controlling the amount of the refrigerant gas flowing through the supply passage, a check valve provided between the first control valve and the pressure control chamber and preventing the refrigerant gas from flowing from the pressure control chamber to the first control valve by closing the supply passage and a second control valve for adjusting a cross-sectional area of the release passage from minimum to maximum. The second control valve has a back pressure chamber communicating with the supply passage, a valve chamber forming a part of the release passage and communicating with a suction-pressure region, a valve hole forming a part of the release passage and communicating with the valve chamber and a spool having a valve portion located in the valve chamber. When a pressure in the back pressure chamber increases, the valve portion decreases the degree of opening of the valve hole.

Owner:TOYOTA IND CORP

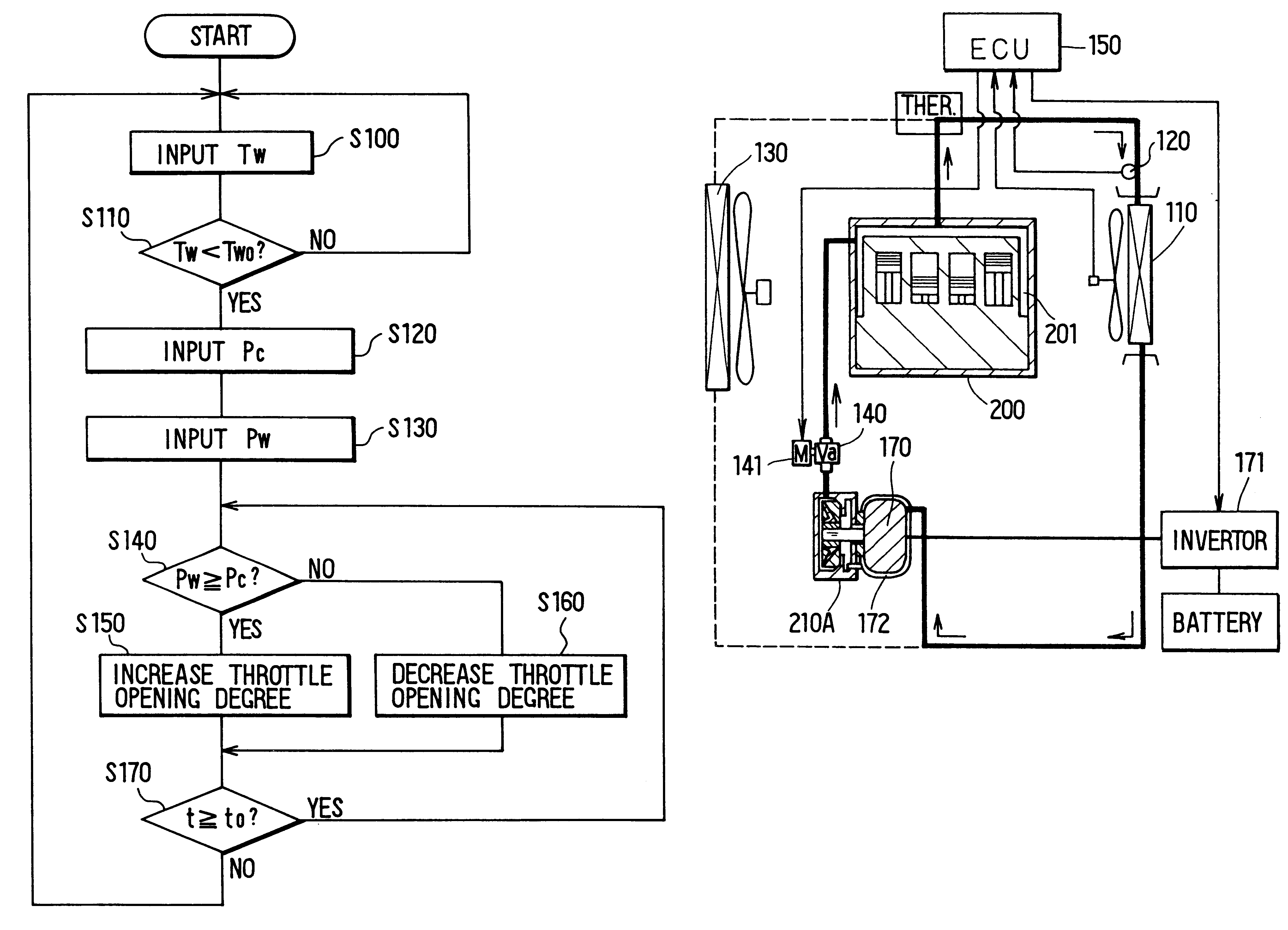

Control method of thermostatic system

InactiveUS6648235B2Easy to controlDegree of opening is decreasedFluid heatersFuel supply regulationThermal waterElectromagnetic valve

Owner:GUARD SOUND IND CO LTD

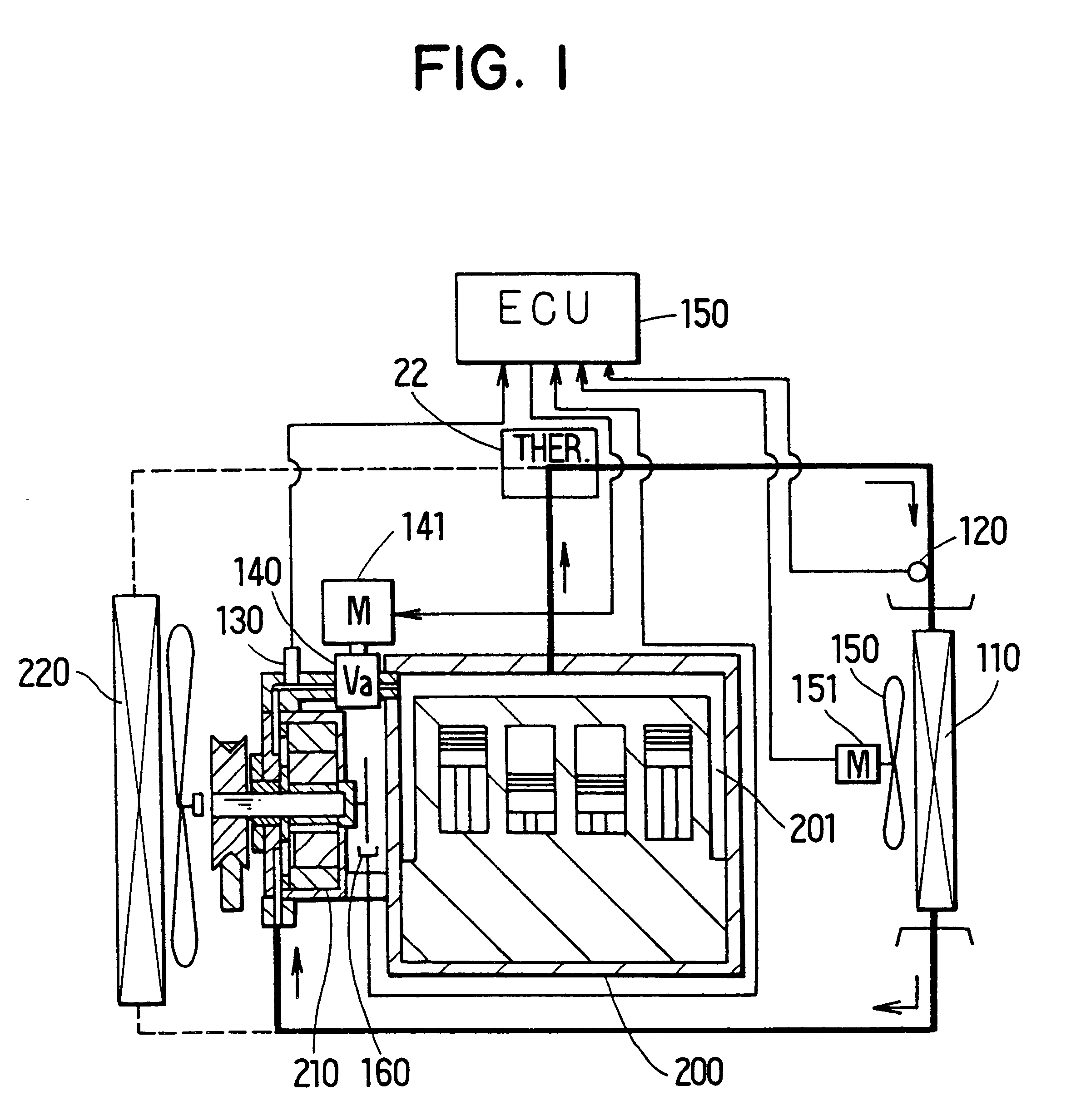

Heating apparatus for vehicle

InactiveUS6260766B1Improve the heating effectSolve insufficient capacitySteam generation using mechanical energyLiquid coolingEngineeringThrottle

A heating apparatus for a vehicle includes a pump for circulating cooling water in a cooling water circuit, a heating heat exchanger for heating air blown into a passenger compartment of the vehicle using cooling water as a heating source, and a throttle valve disposed at a discharge side of the pump. In the heating apparatus, when the temperature of cooling water is low and heating capacity for heating the passenger compartment is insufficient, an opening degree of the throttle valve is reduced by a control unit. Therefore, heat is generated from the throttle valve and the pump so that the temperature of cooling water is increased. Thus, heating capacity of the heating apparatus can be improved without using a manual operation.

Owner:DENSO CORP

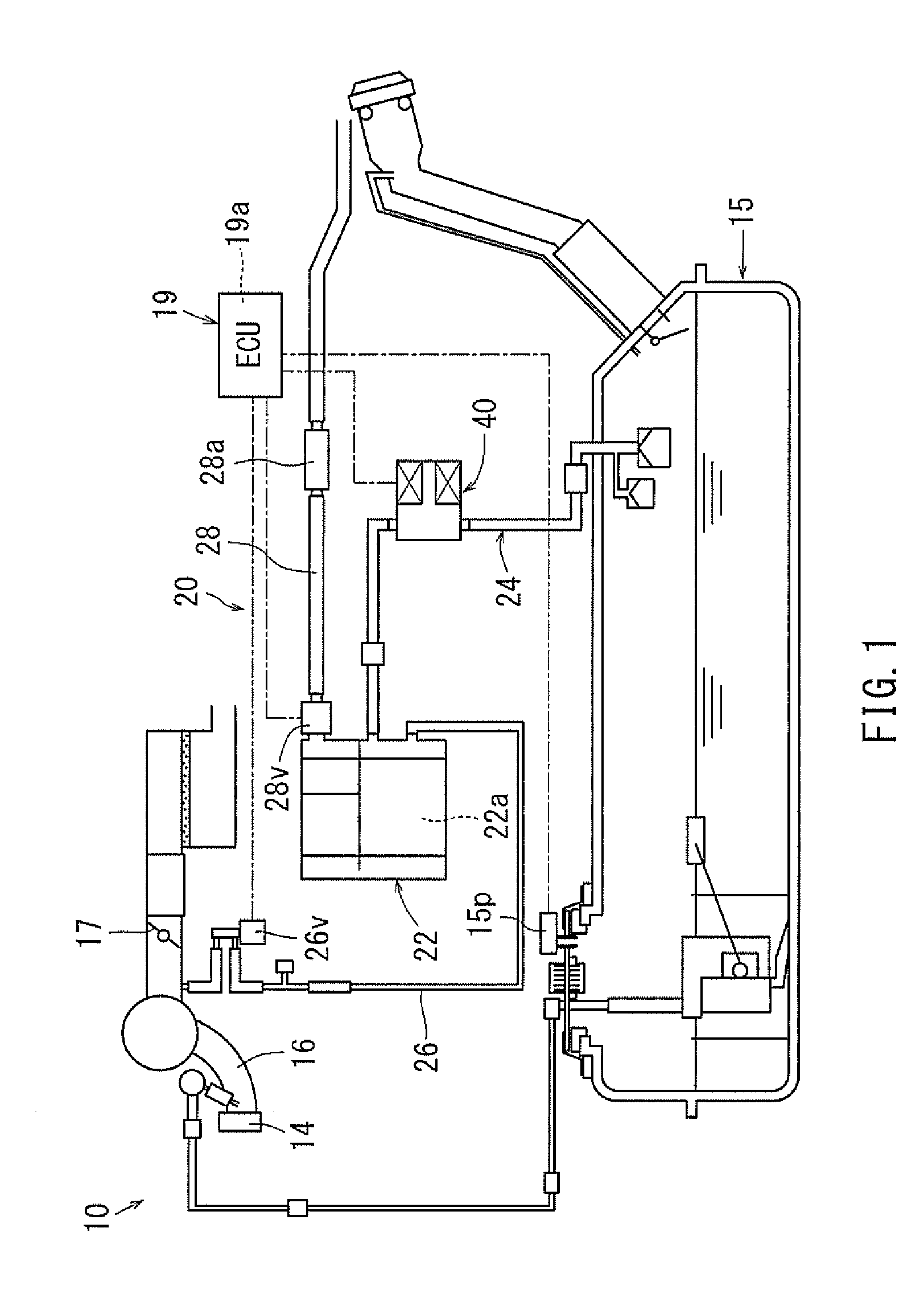

Reverse operation of a vehicle

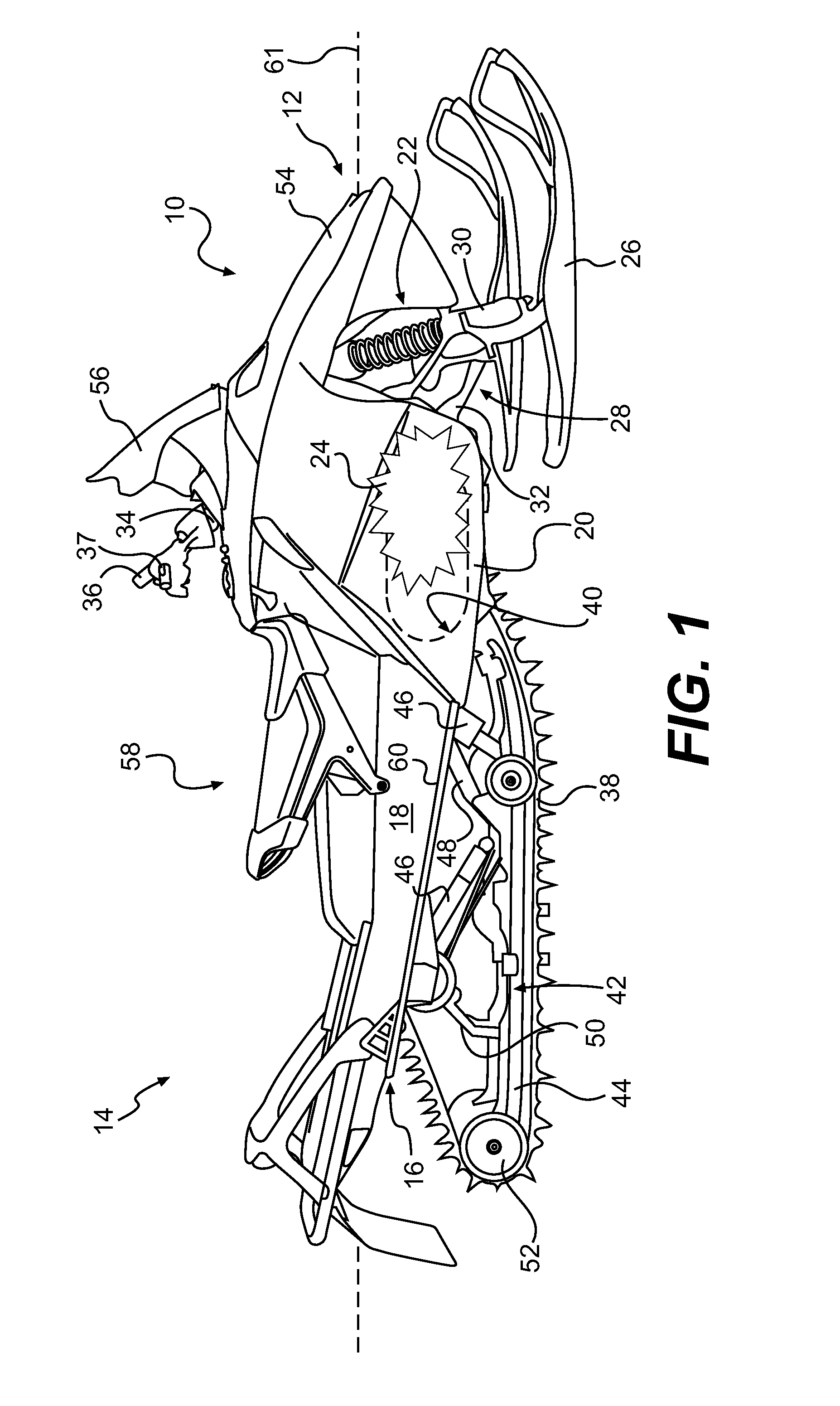

ActiveUS7380538B1Reduce opening degreeDegree of opening is decreasedElectrical controlVehicle fittingsThrottlePosition sensor

A vehicle has a vehicle body, a seat, an engine, an ECU, a throttle body, a throttle valve, a throttle valve actuator, a throttle operator, and a throttle operator position sensor. A shifter is disposed on the vehicle in proximity to the seat for selecting a vehicle operation direction between a forward direction and a reverse direction. A vehicle operation direction sensor senses the vehicle operation direction. The ECU limits a maximum speed of the vehicle when it operates in the reverse direction. In another aspect, the ECU limits the degree of opening of the throttle valve when it operates in the reverse direction. Methods of controlling an engine are also disclosed.

Owner:BOMBARDIER RECREATIONAL PROD INC

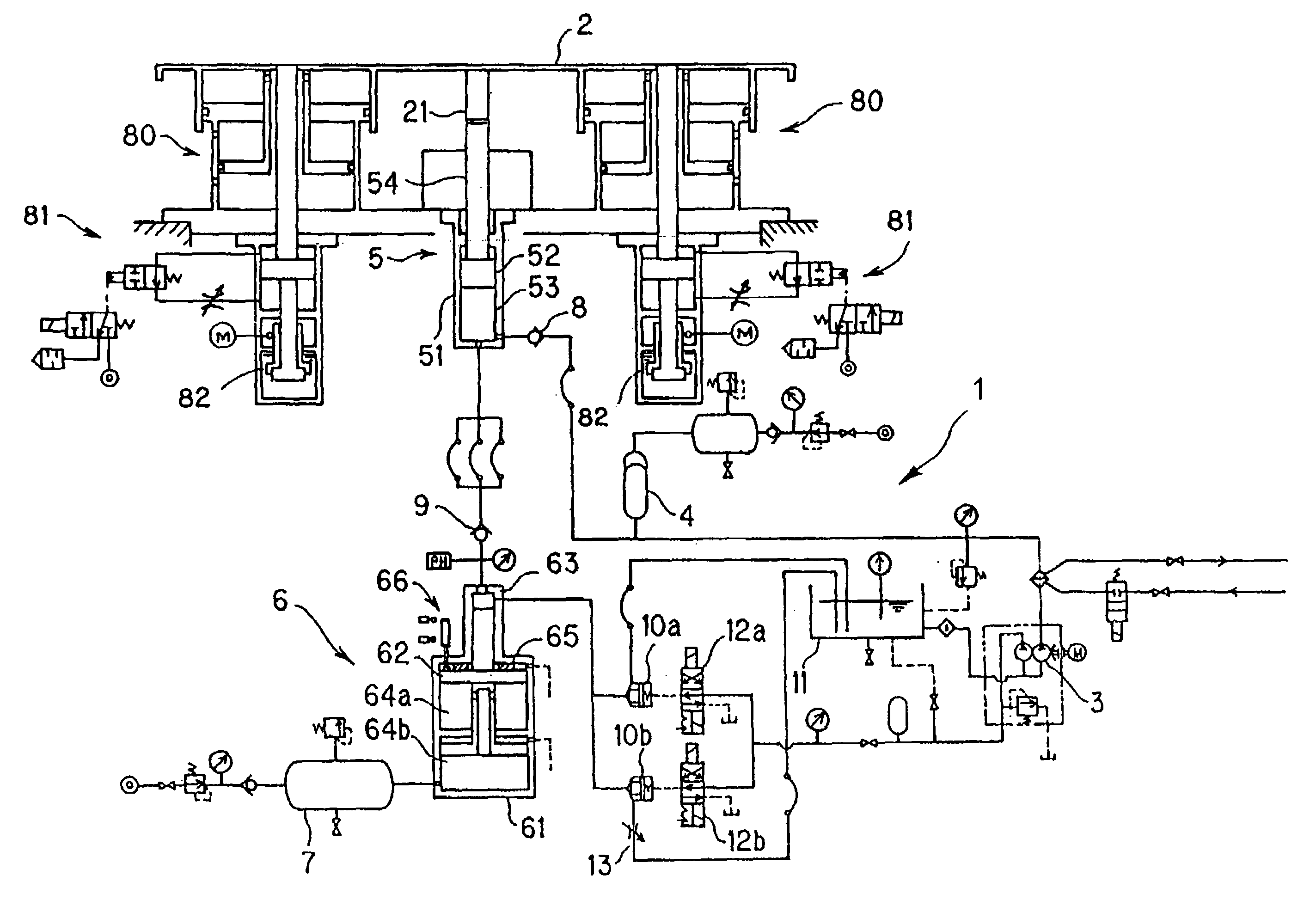

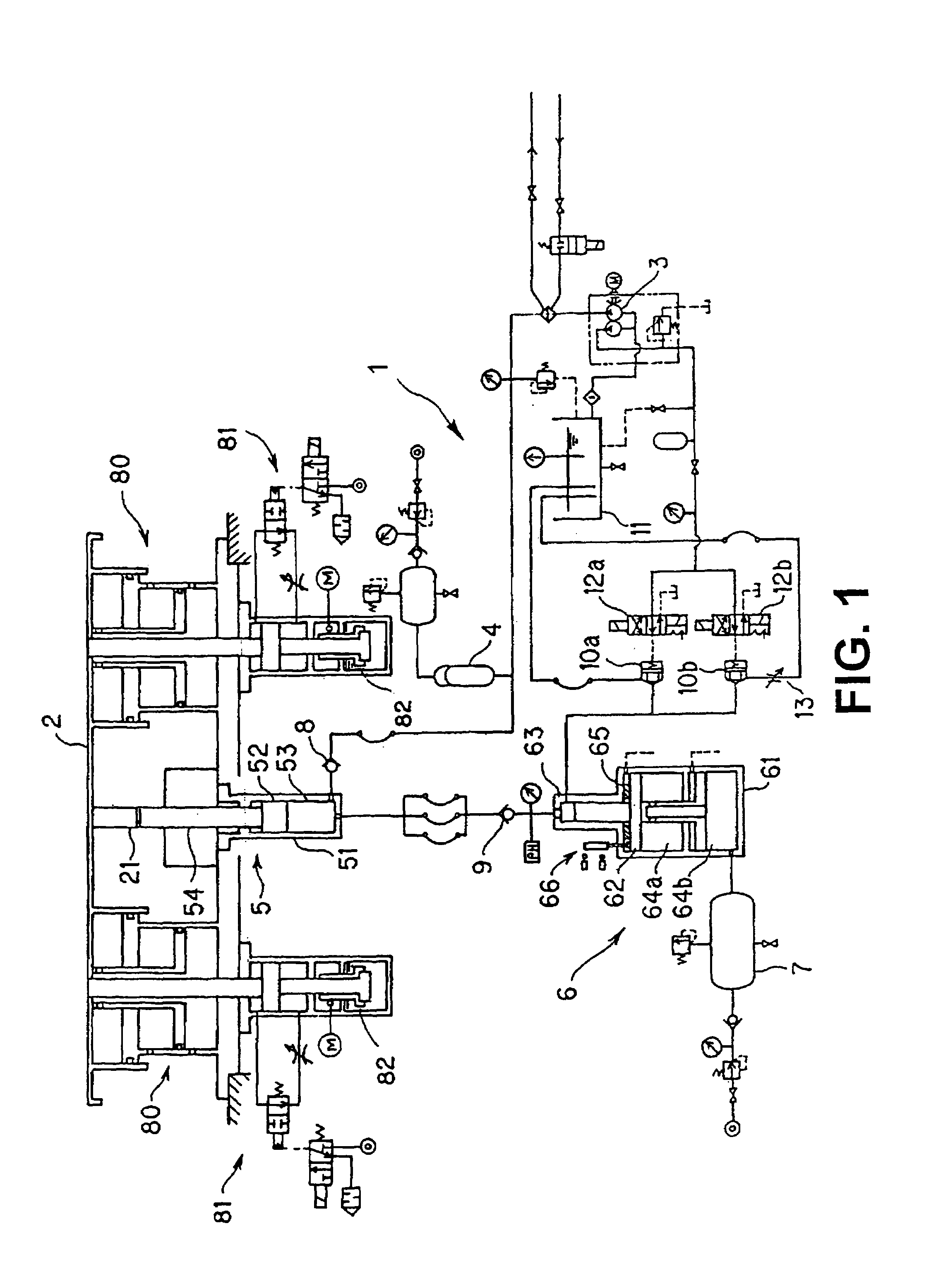

Die cushion apparatus of a press machine and surge pressure reduction method for a die cushion apparatus

InactiveUS7197910B2Simple configurationReduce surge pressureSpringsNon-rotating vibration suppressionPistonPush out

In a die cushion apparatus, a pressurizing force acting on a die cushion pad is applied to a first piston of a hydraulic cylinder unit by the operation of a slide, the first piston slides inside a first cylinder and pressure oil in a first hydraulic chamber is pressurized. The first hydraulic chamber is linked to a second hydraulic chamber of a booster cylinder unit via a second check valve, so that the pressure oil of the first hydraulic chamber is pushed out into the second hydraulic chamber. When the pressure of the first hydraulic chamber is applied to a second piston, the second piston slides inside the second cylinder and gas of a gas pressure chamber is compressed, whereby a surge pressure is reduced.

Owner:KOMATSU LTD

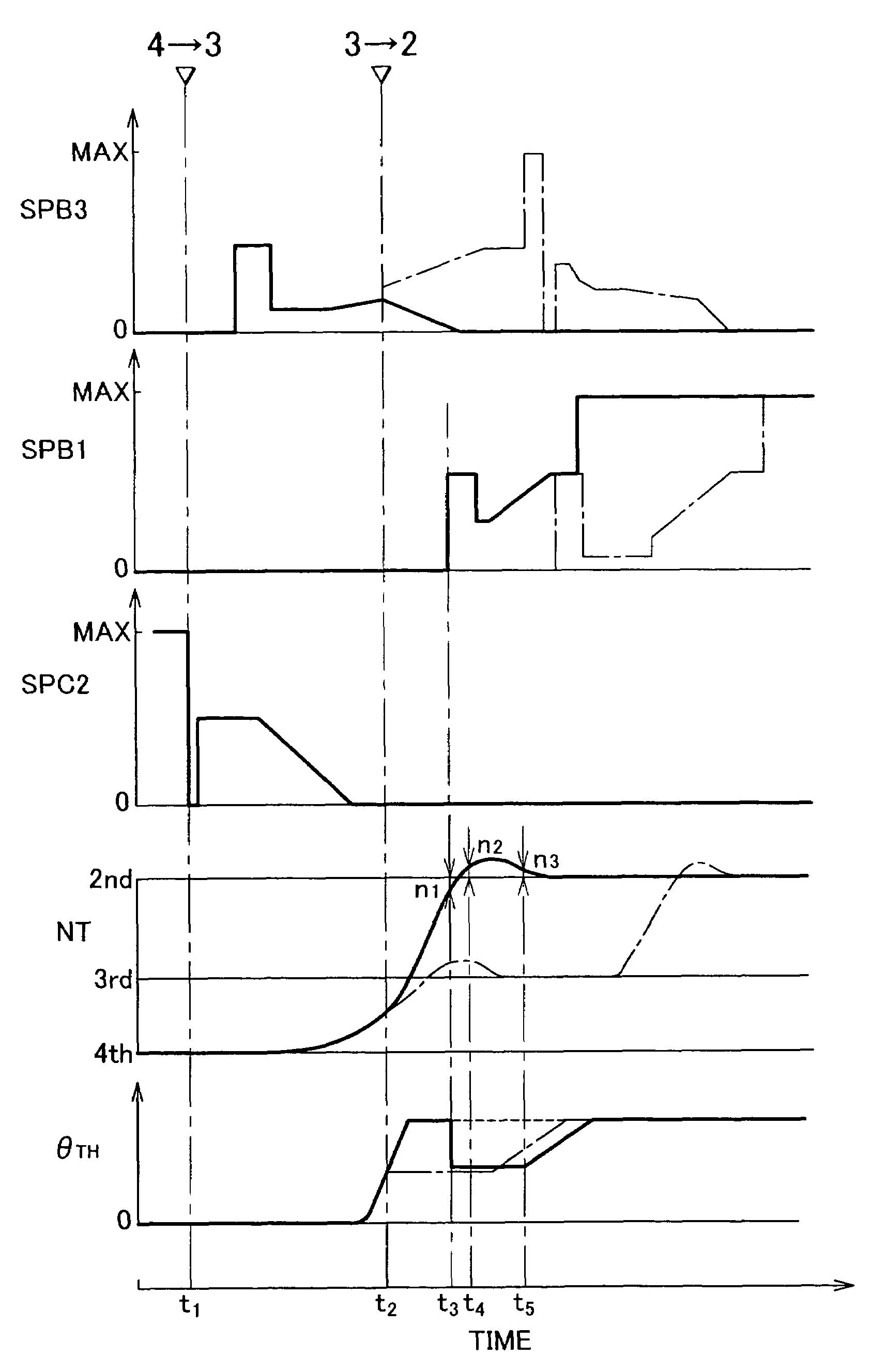

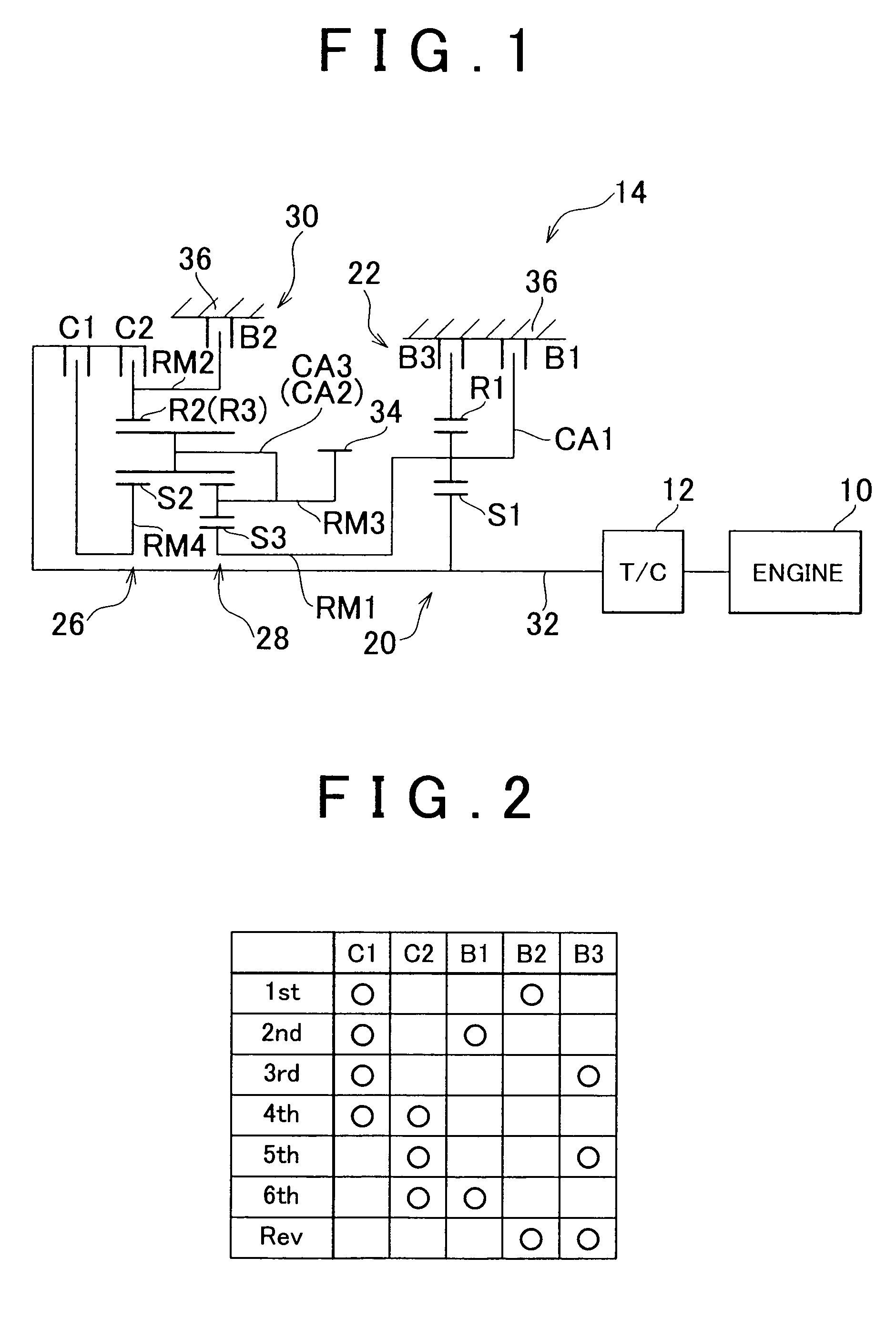

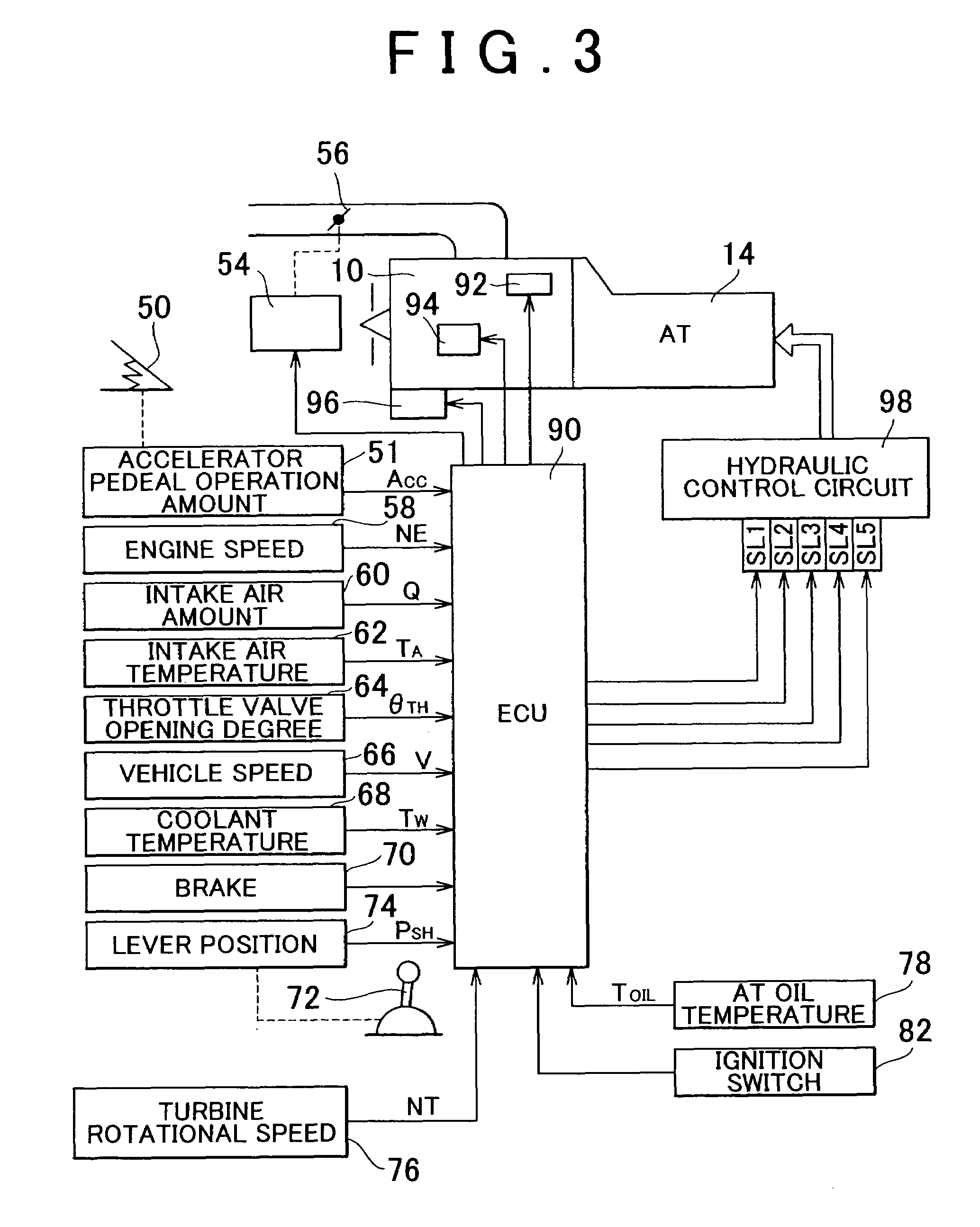

Shift control apparatus and shift control method of automatic transmission of vehicle

InactiveUS7549946B2Prevent speedingQuick changeElectrical controlGearing controlAutomatic transmissionExecution unit

The invention relates to a shift control apparatus for an automatic transmission, that executes a torque reduction control when the transmission executes a second downshift in response to a second downshift determination made during first downshift. The shift control apparatus includes a multiple shift execution unit that starts the second downshift operation in response to the second downshift determination, and a torque reduction control execution unit that executes a torque reduction control when the rotational speed of the input member is increased to at least a predetermined first determination speed, which is determined in accordance with a shift ratio of a gear stage after the second downshift operation, after the second downshift starts. This allows the rotational speed of the input shaft to be quickly changed to the appropriate synchronous rotational speed. Thus, the desired driving force is provided upon completion of the second downshift without overspeeding the engine.

Owner:TOYOTA JIDOSHA KK

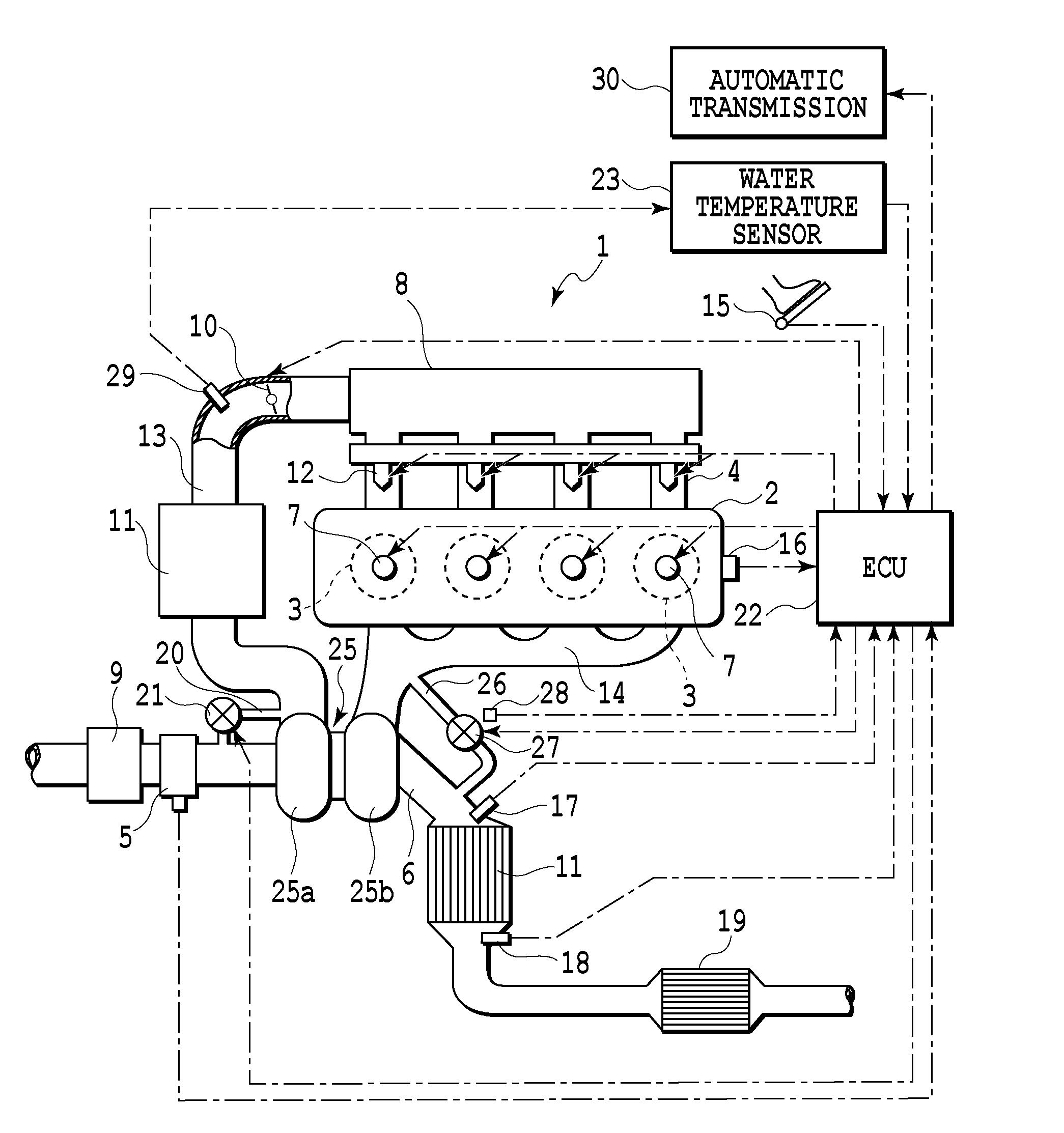

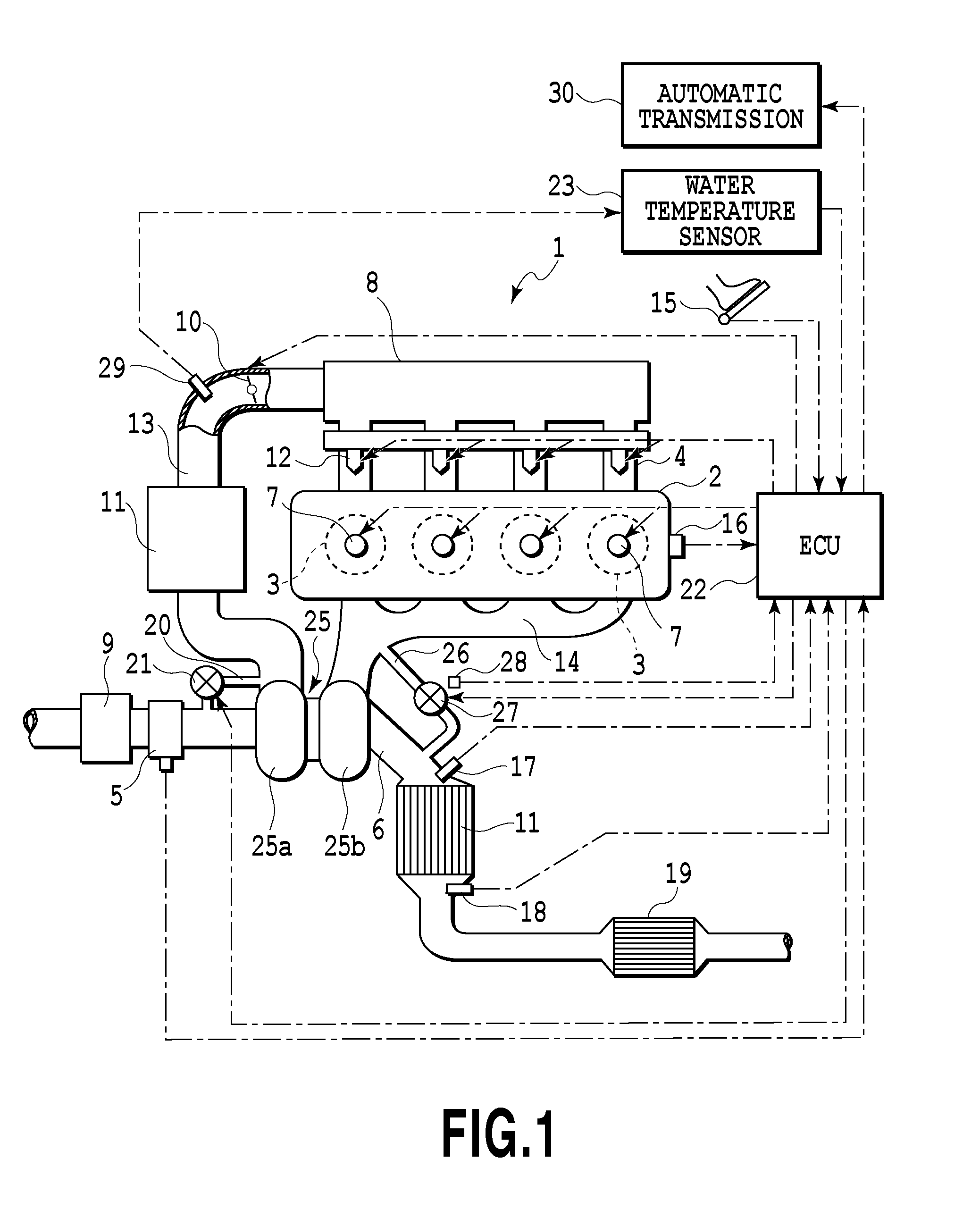

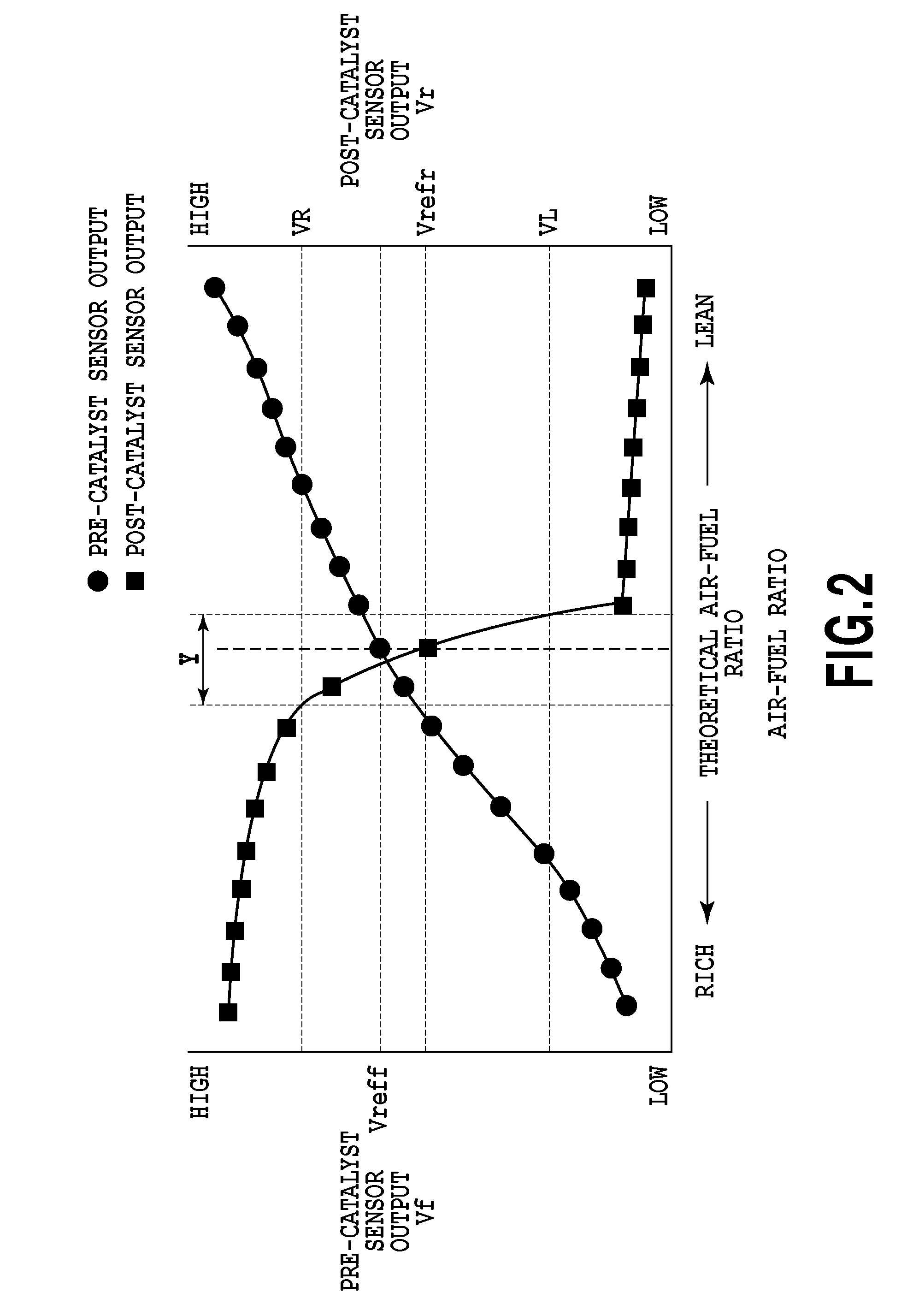

Apparatus for detecting inter-cylinder air-fuel ratio imbalance in multi-cylinder internal combustion engine

ActiveUS20150292422A1Accurately performLow rotational speedElectrical controlInternal combustion piston enginesAir–fuel ratioEngineering

An apparatus for detecting inter-cylinder air-fuel ratio imbalance in an engine is provided. The apparatus includes a turbocharger, a bypass passage configured to bypass a turbine of the turbocharger, a waste gate valve configured to selectively close the bypass passage, an air-fuel ratio sensor installed in a portion of an exhaust passage which portion is located on a downstream side of a junction between a downstream side of the turbine and a downstream side of the bypass passage, and a determination unit programmed to compare a value of a degree of fluctuation in an output from the air-fuel ratio sensor or a parameter correlated therewith with a predetermined threshold to perform inter-cylinder air-fuel ratio imbalance determination. The determination unit is programmed not to perform the imbalance determination when an opening degree of the waste gate valve is equal to or higher than a predetermined reference value.

Owner:TOYOTA JIDOSHA KK

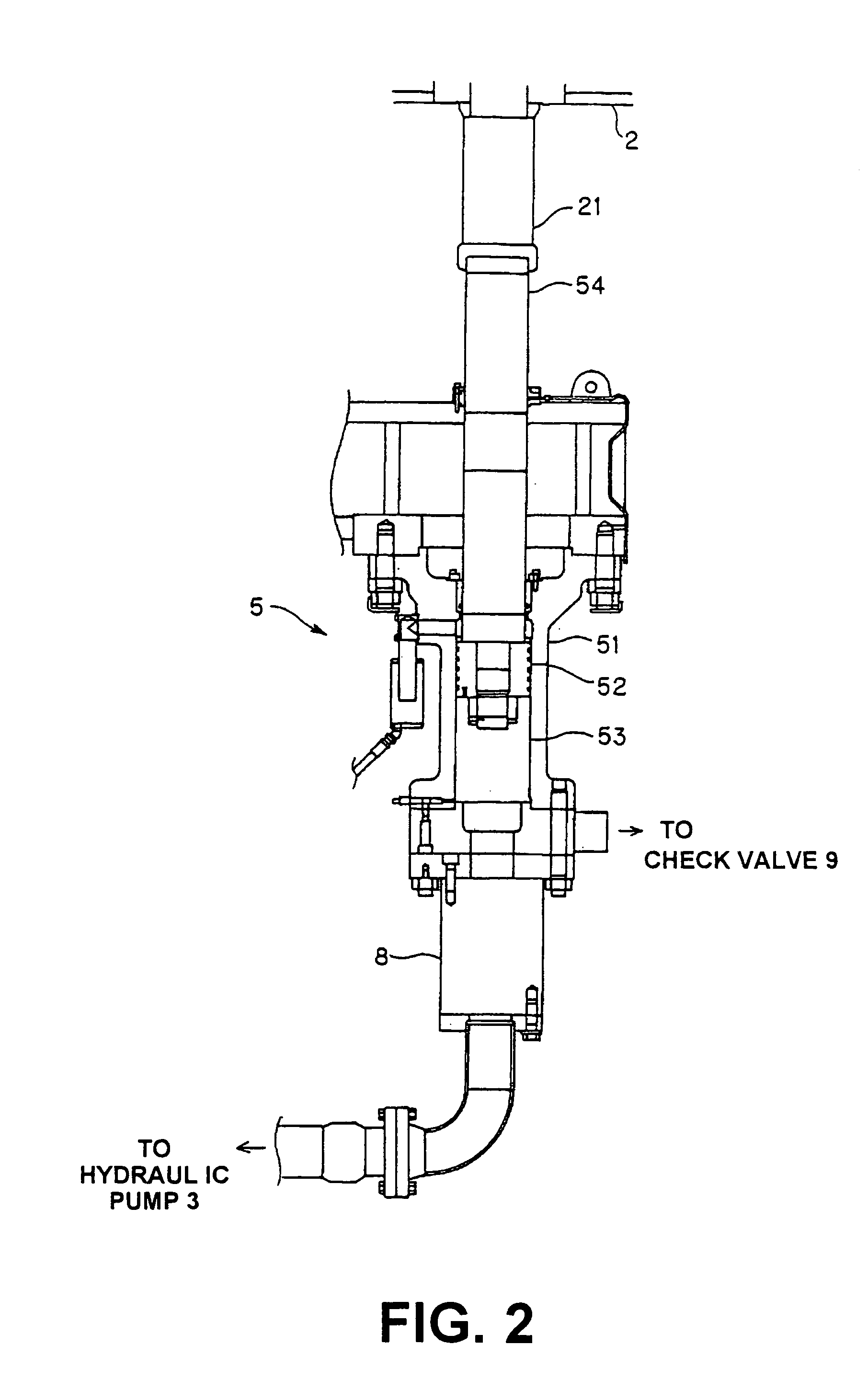

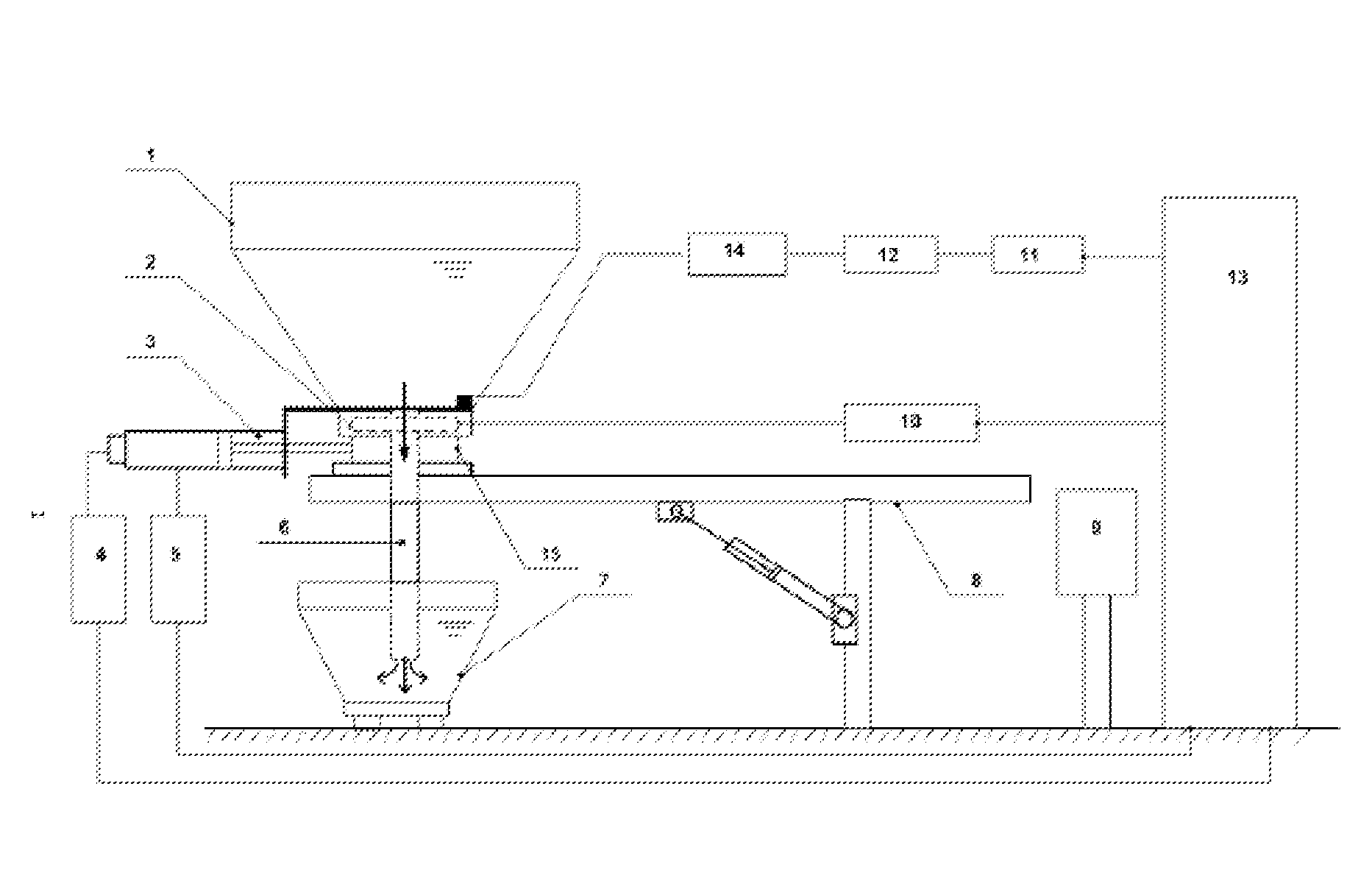

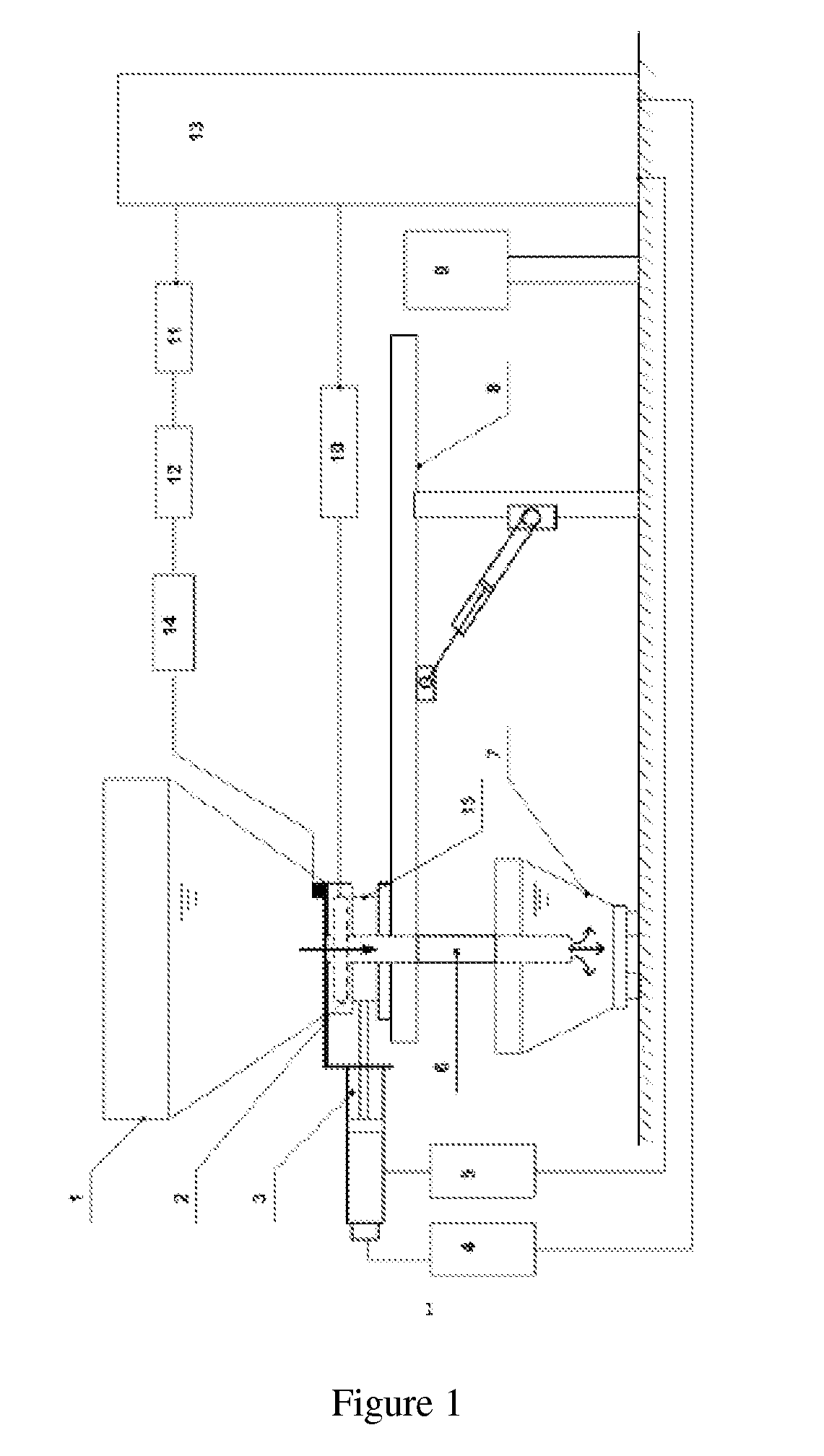

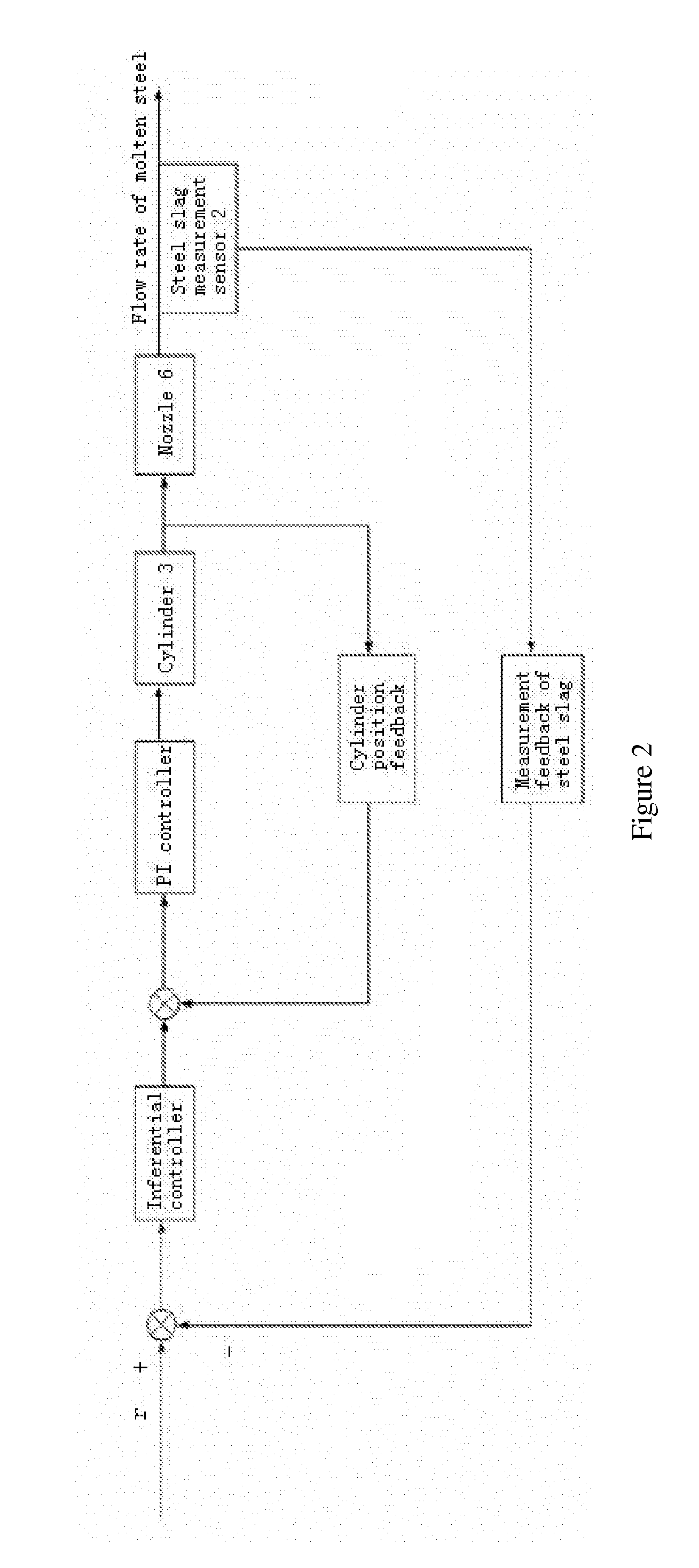

Control Method and Apparatus for Continuous Casting Steel Pouring

ActiveUS20150190863A1Improve yield rateImprove yieldMelt-holding vesselsMolten metal pouring equipmentsControl variableSlag

The present invention discloses a control method for continuous casting steel pouring, wherein: Step one: measuring and reading a steel ladle pouring position signal by a steel ladle position sensor (14) mounted on a turntable of a steel ladle; Step two: judging whether the pouring of the steel ladle (1) has begun therein by a steel pouring optimization control computer (13); Step three: feeding a data of a steel slag measurement sensor (2) mounted above a steel ladle sliding nozzle (15) to an inferential controller; Step four: in the inferential controller, conducting a comparison between the read data of the steel slag measurement and the manually set value of steel slag, and back to the former step if the measured value of the steel slag measurement is smaller than the manually set value of steel slag; if the current measured value of the steel slag measurement is greater than the manually set value of the steel slag, outputting and feeding a cylinder control variable to a PI controller; Step five: conducting a comparison between the cylinder position signal output by the inferential controller and a cylinder position signal actually measured and a calculation in the PI controller, and an output control of the cylinder driving unit (5) drives the cylinder (3) to move, thus reducing the opening degree of the sliding nozzle (15) of the steel ladle.

Owner:BAOSHAN IRON & STEEL CO LTD

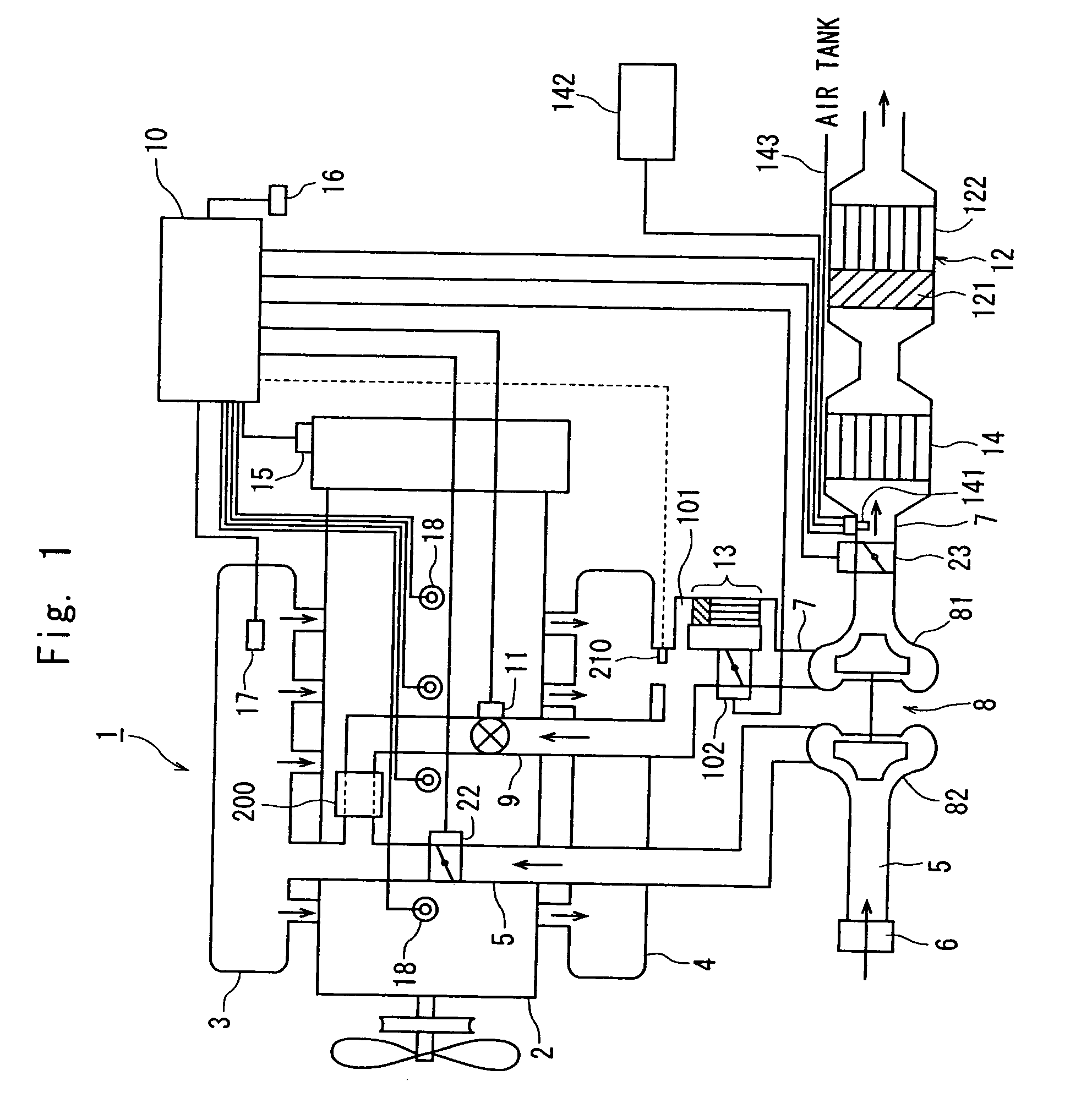

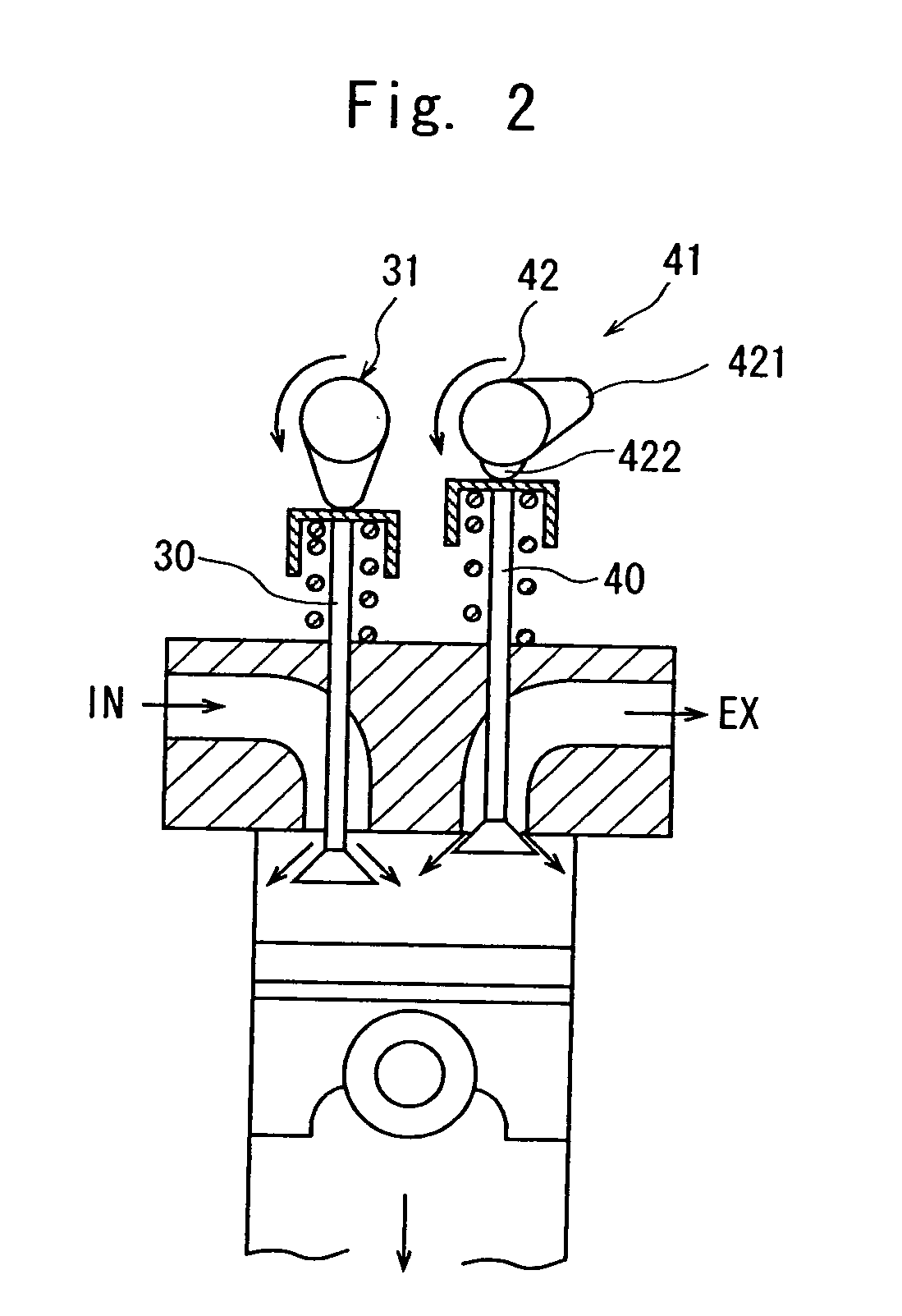

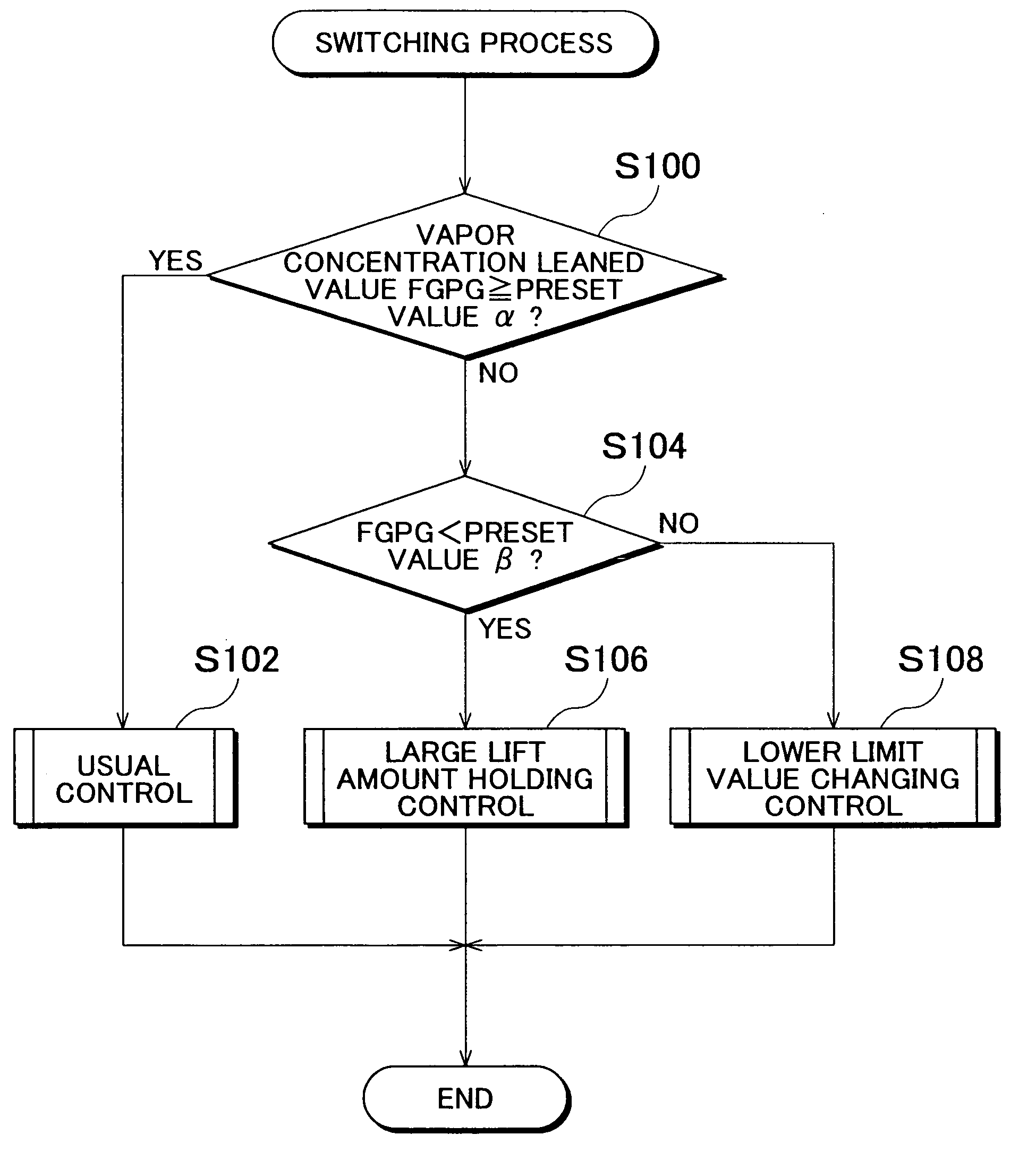

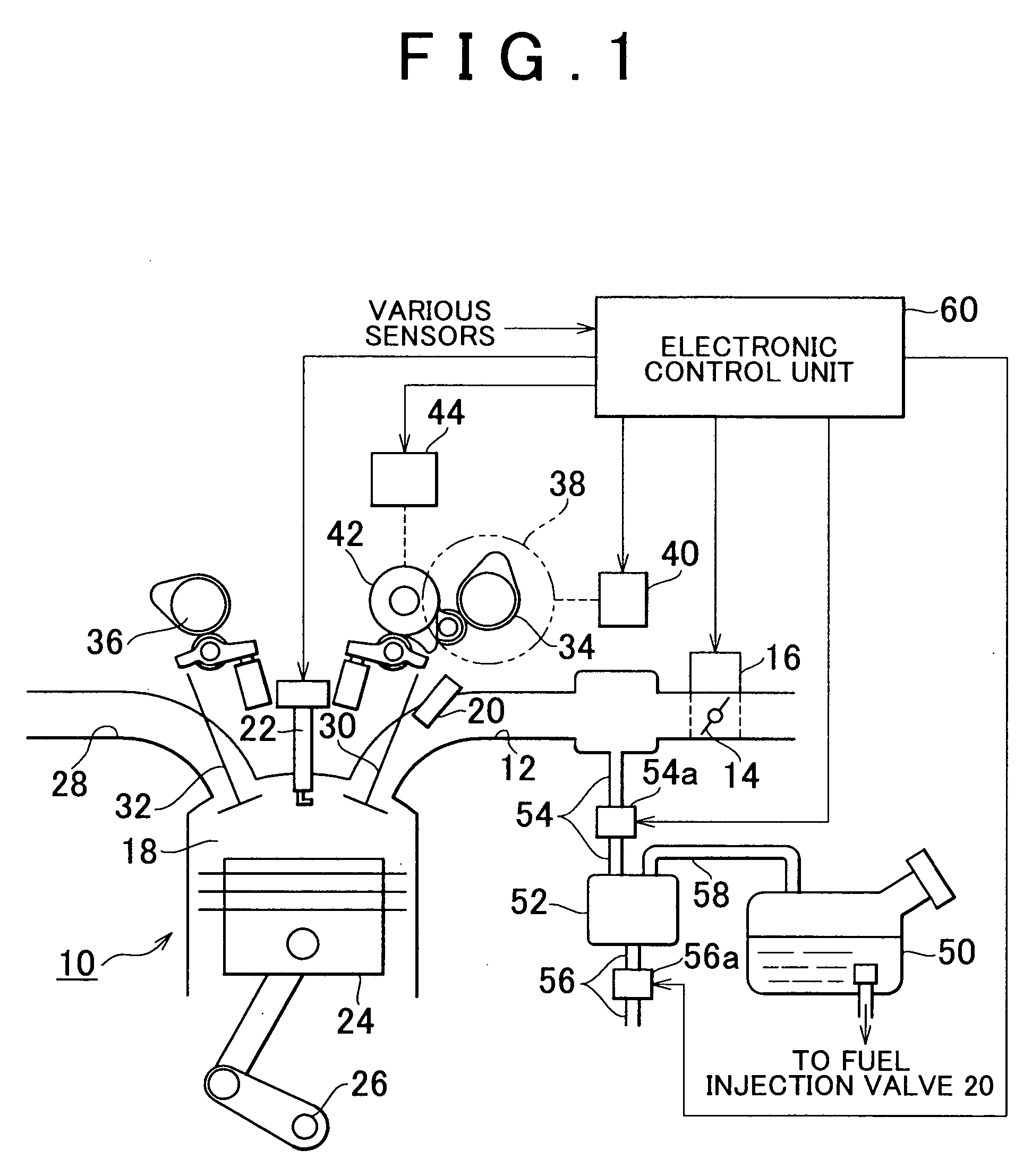

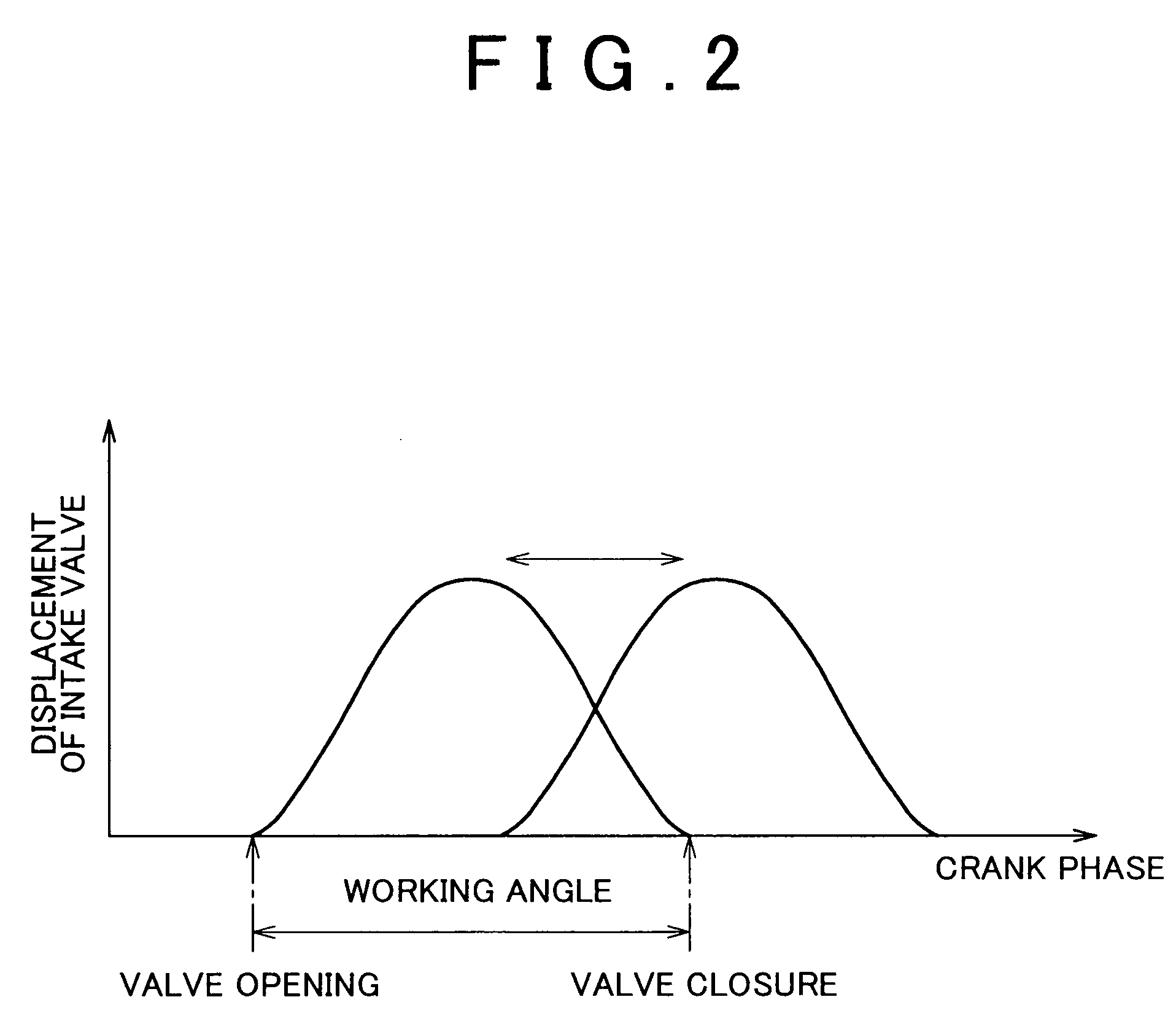

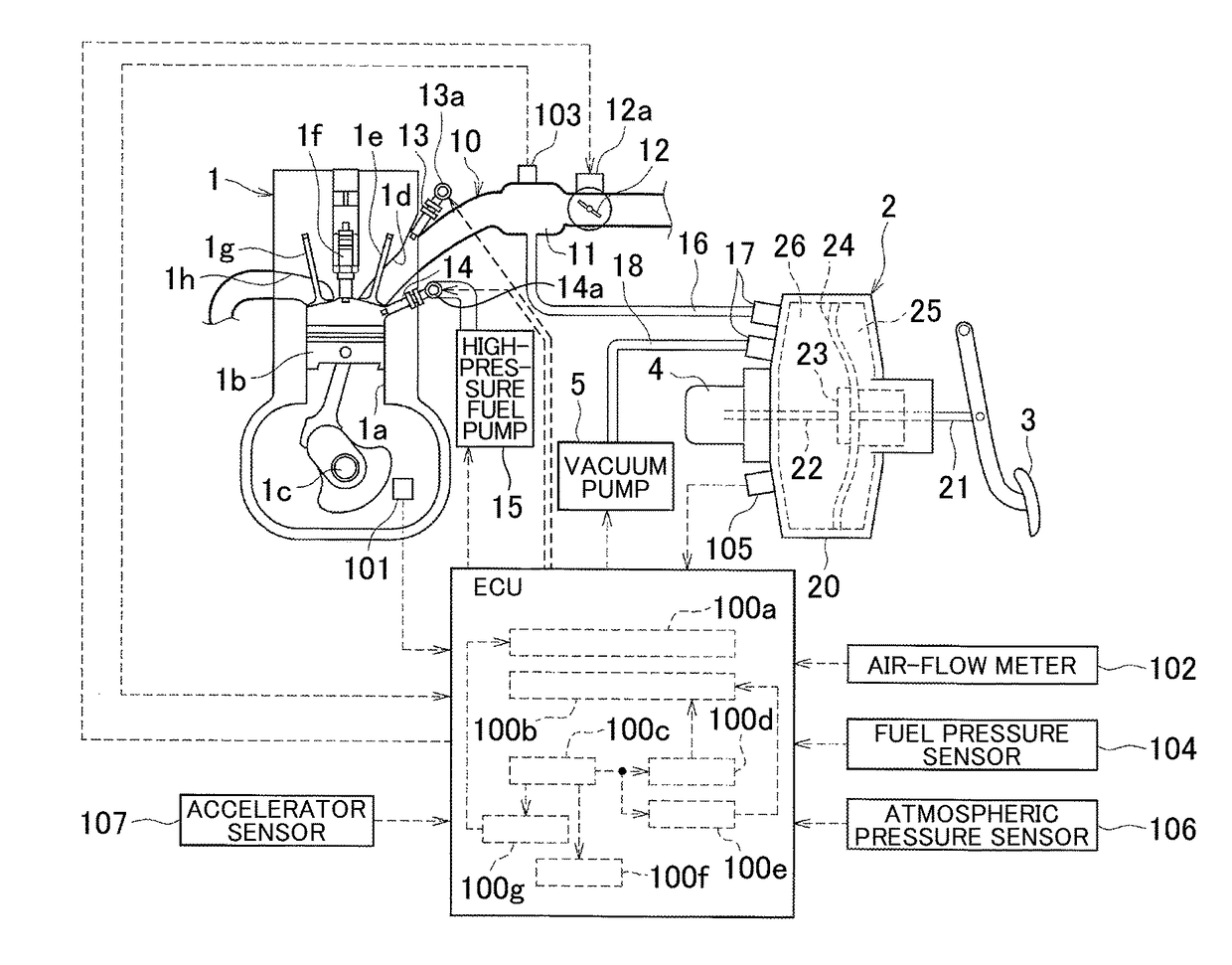

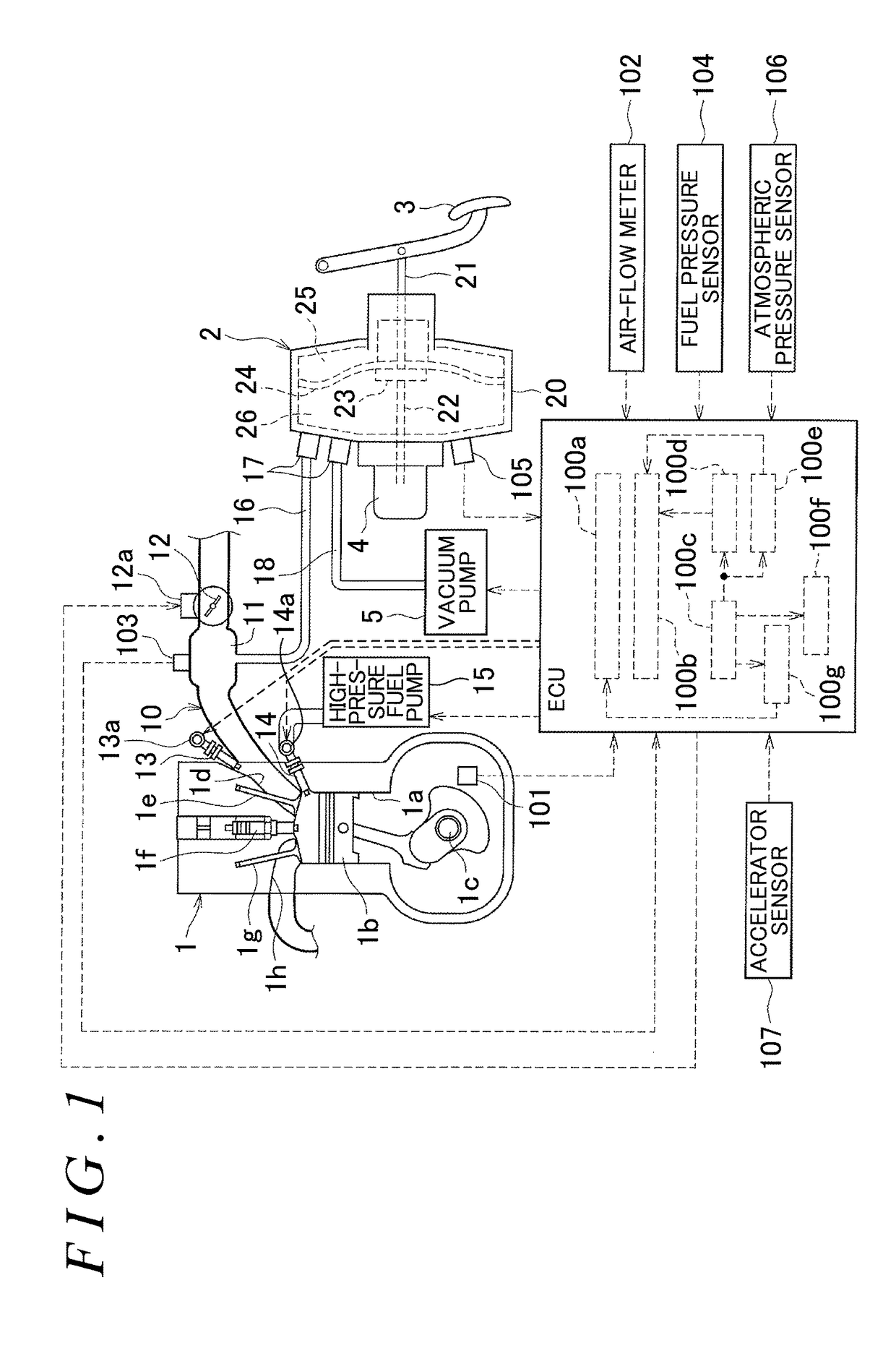

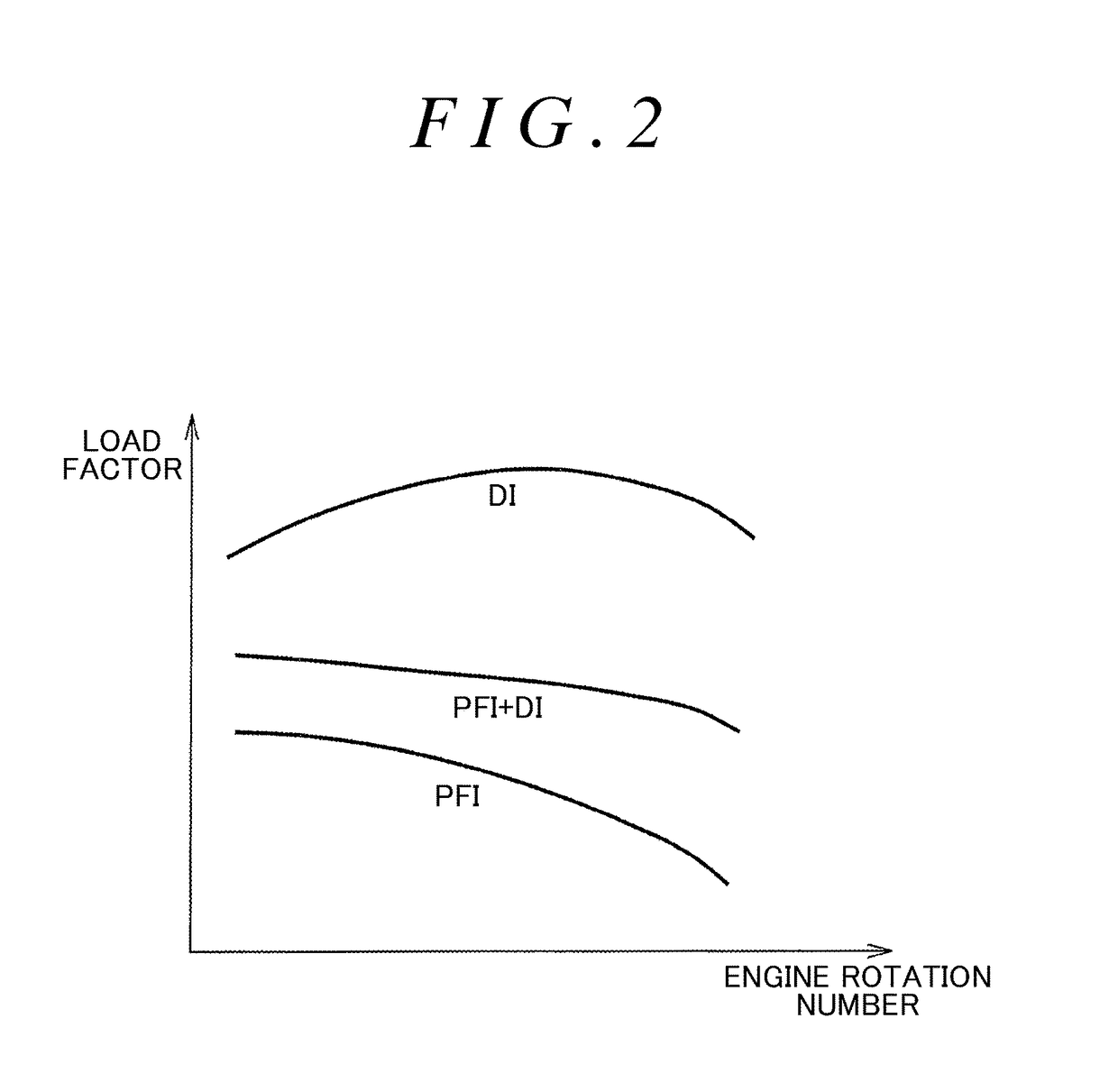

Control apparatus of internal combustion engine

InactiveUS20060090729A1Reduce pressureImprove fuel economyElectrical controlNon-fuel substance addition to fuelThrottleInternal combustion engine

a control apparatus for an internal combustion engine provided with a fuel vapor treatment system according to the invention includes a controller that discharges fuel vapor into an intake passageway by using the intake negative pressure, and which adjusts the amount of the intake air through the cooperative control of a variable control of at least one of the lift amount of an intake valve and the working angle of the intake valve, and a control of the degree of opening of a throttle valve. In addition, the control apparatus executes the variable control so that at least one of the lift amount and the working angle of the intake valve changes in accordance with the fuel vapor concentration in the fuel vapor treatment system.

Owner:TOYOTA JIDOSHA KK

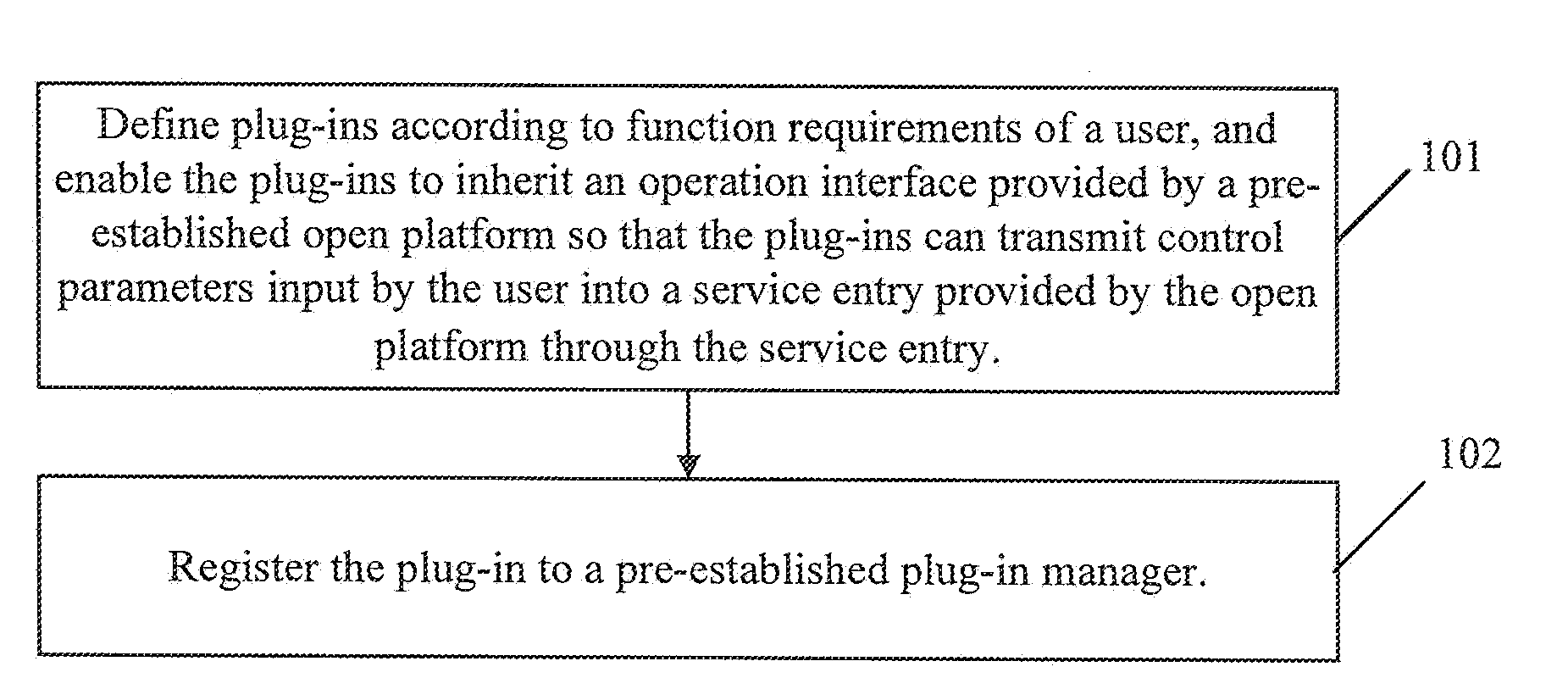

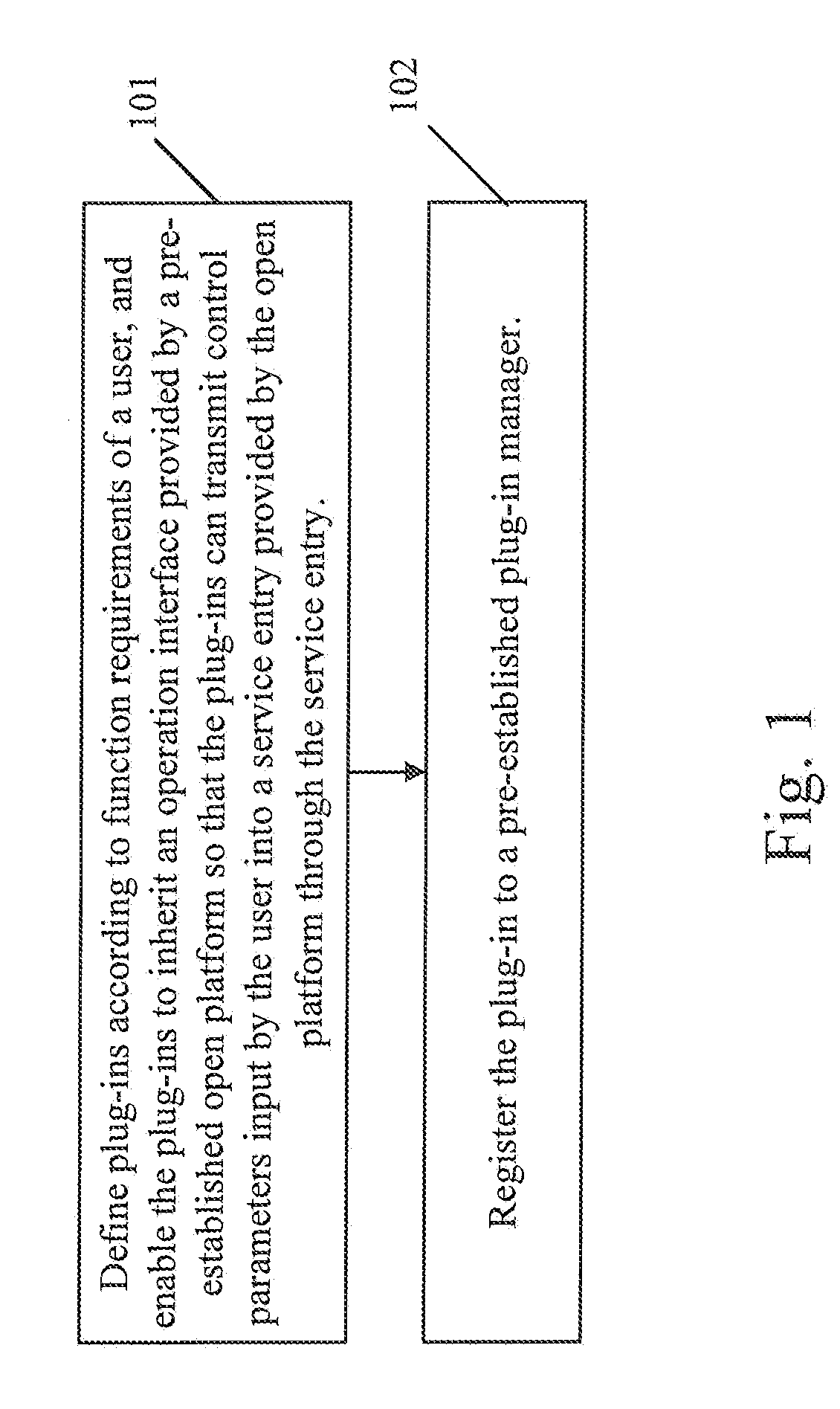

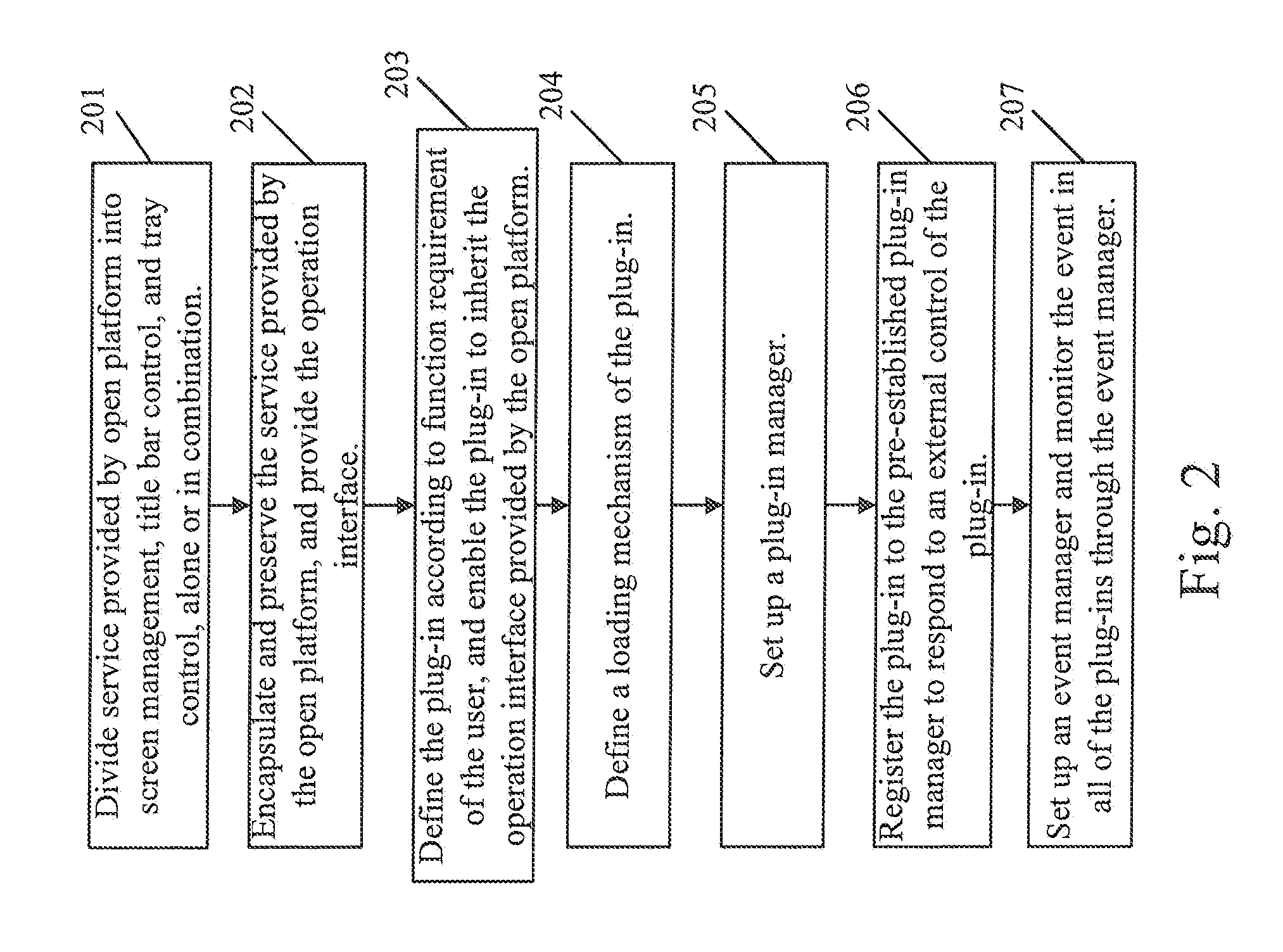

Method and System for Implementing Function Extension of Open Platform

ActiveUS20140317639A1Easy to manageImprove simplicityInterprogram communicationProgram loading/initiatingExtensibilityCoupling

Described are a method and a system for implementing function extension of an open platform. In the system, services that can be provided by an open platform are encapsulated and an operation interface is provided, so that plug-ins uniformly inherit the operation interface and transmit control parameters through the interface into a service entry to obtain the services. Therefore, the open platform has a simple framework and low coupling degree. Since the plug-ins are uniformly managed by a plug-in manager, the manageability and dynamic extensibility of the open platform are enhanced.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Evaporated fuel processing device

ActiveUS20160298577A1Easy to implementEasy to controlElectrical controlNon-fuel substance addition to fuelInternal pressureFuel tank

An evaporated fuel processing device has a canister, a vapor passage, a purge passage, a shutoff valve, a storage device and a control device. The canister includes an adsorbent material that adsorbs evaporated fuel generated in a fuel tank. The vapor passage connects the canister and the fuel tank. The purge passage connects the canister and an intake passage of an engine. The shutoff valve is provided in the vapor passage, and adjusts flow rate of gas flowing through the vapor passage. The storage device stores in advance a reference value for the shutoff valve corresponding to internal pressure of the fuel tank. The shutoff valve is controlled based on the reference value, which is obtained from the internal pressure of the fuel tank, and pressure release control is performed on the fuel tank.

Owner:AISAN IND CO LTD

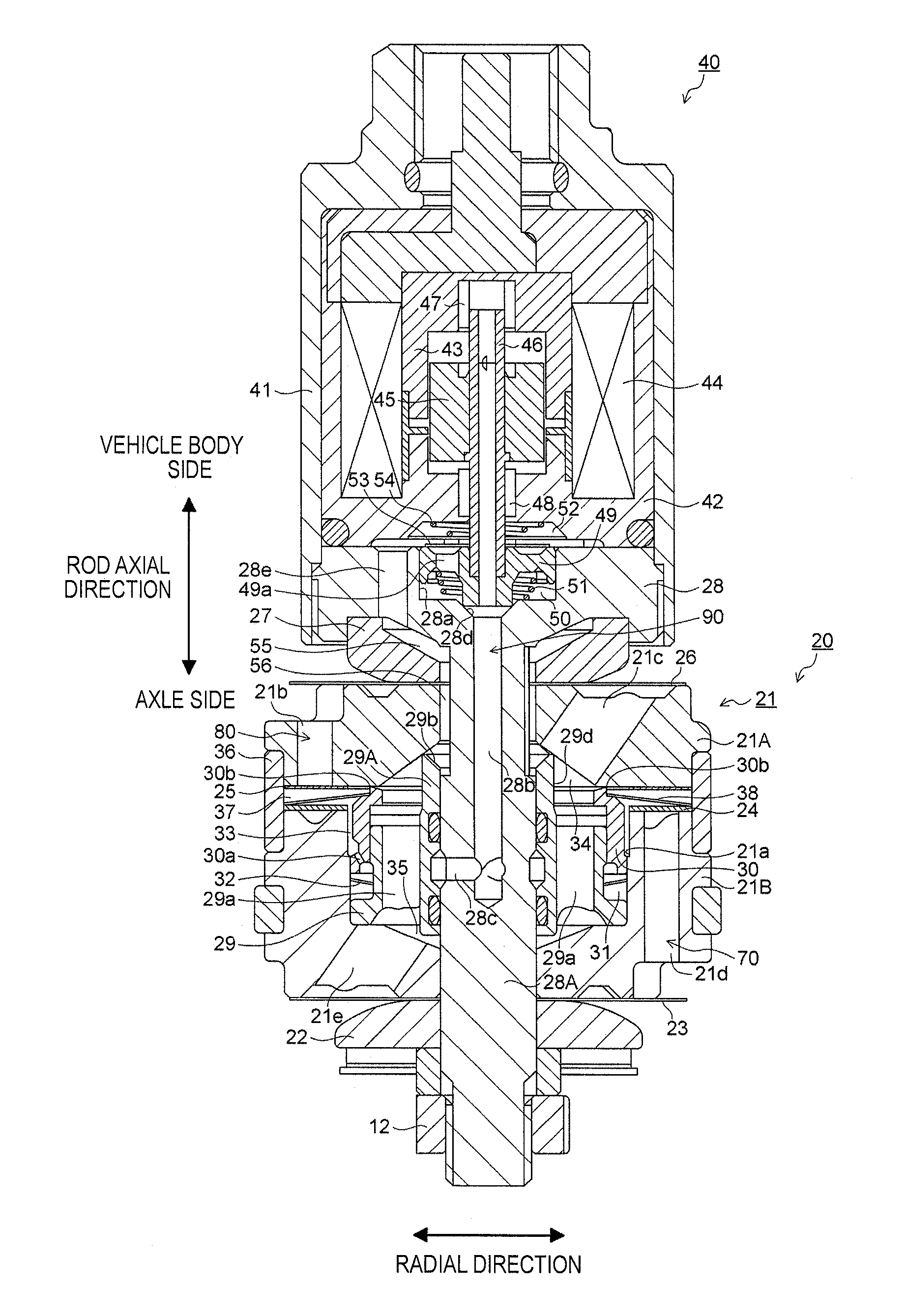

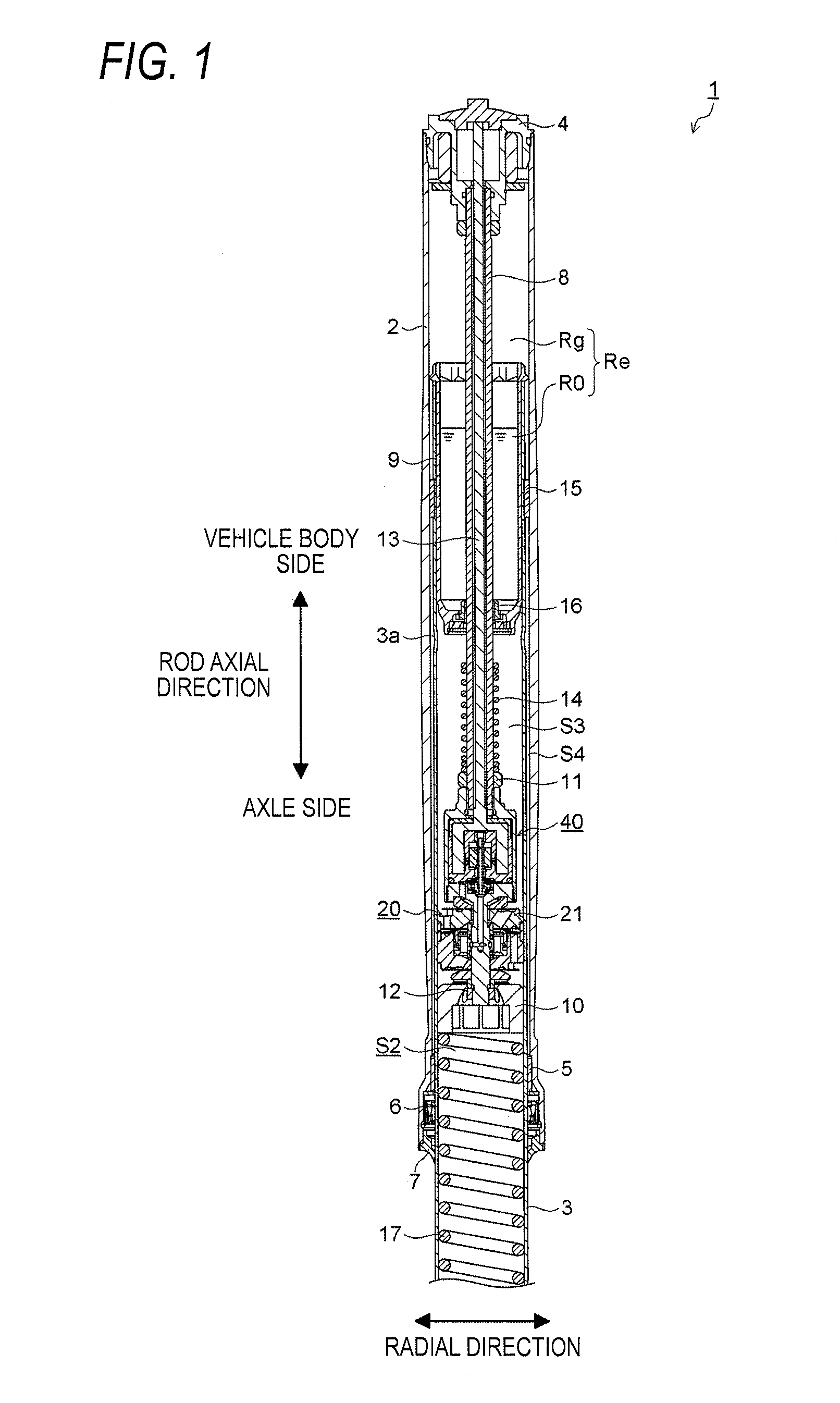

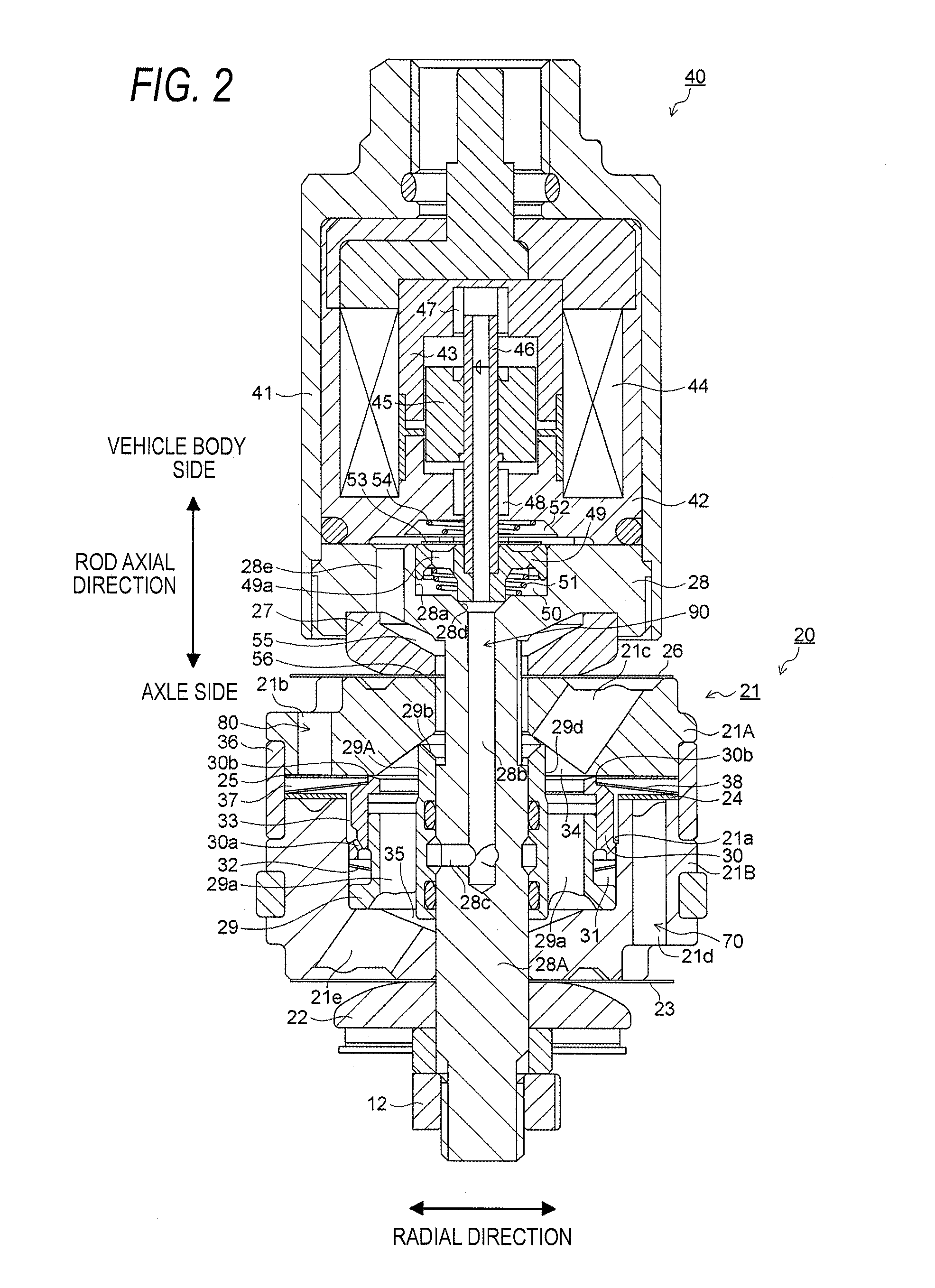

Shock absorber

ActiveUS20150276004A1Desired damping force characteristicExpand the adjustment rangeSpringsAxle suspensionsInternal pressureWorking fluid

A damping force generating apparatus of a shock absorber includes a main flow path through which a working fluid flows, a main valve which generates a damping force by controlling the flow of the working fluid by opening and closing the main flow path, a pilot chamber into which the working fluid branched from the main flow path flows and which applies an internal pressure in a valve closing direction to the main valve by a pressure of the working fluid, and a pilot flow path to which the working fluid flows out from the pilot chamber. In addition, a jet stream which is generated in a flow path narrowed by the main valve in the main flow path joins the flow of the working fluid which flows out from the pilot chamber via the pilot flow path.

Owner:HITACHI ASTEMO LTD

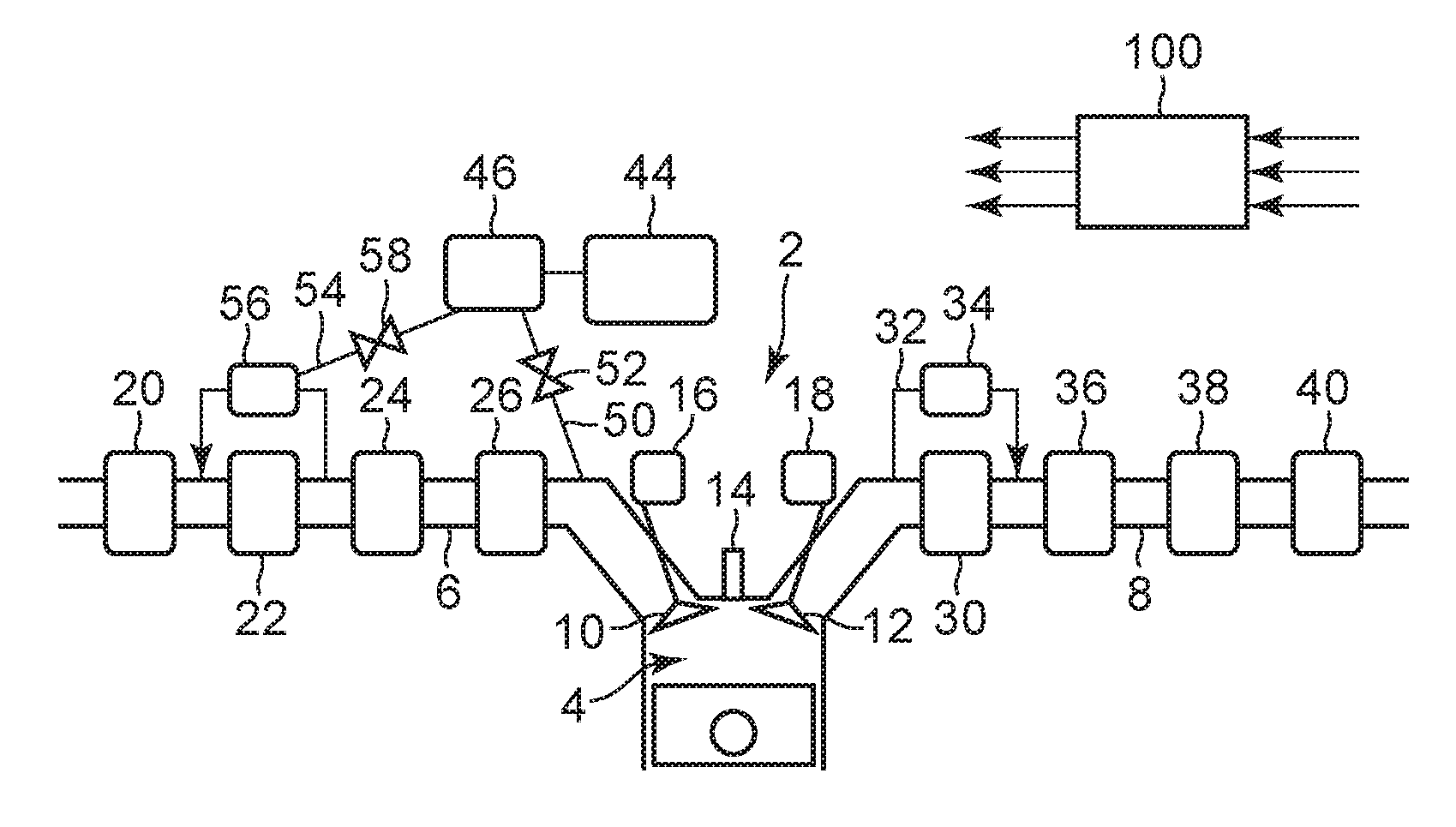

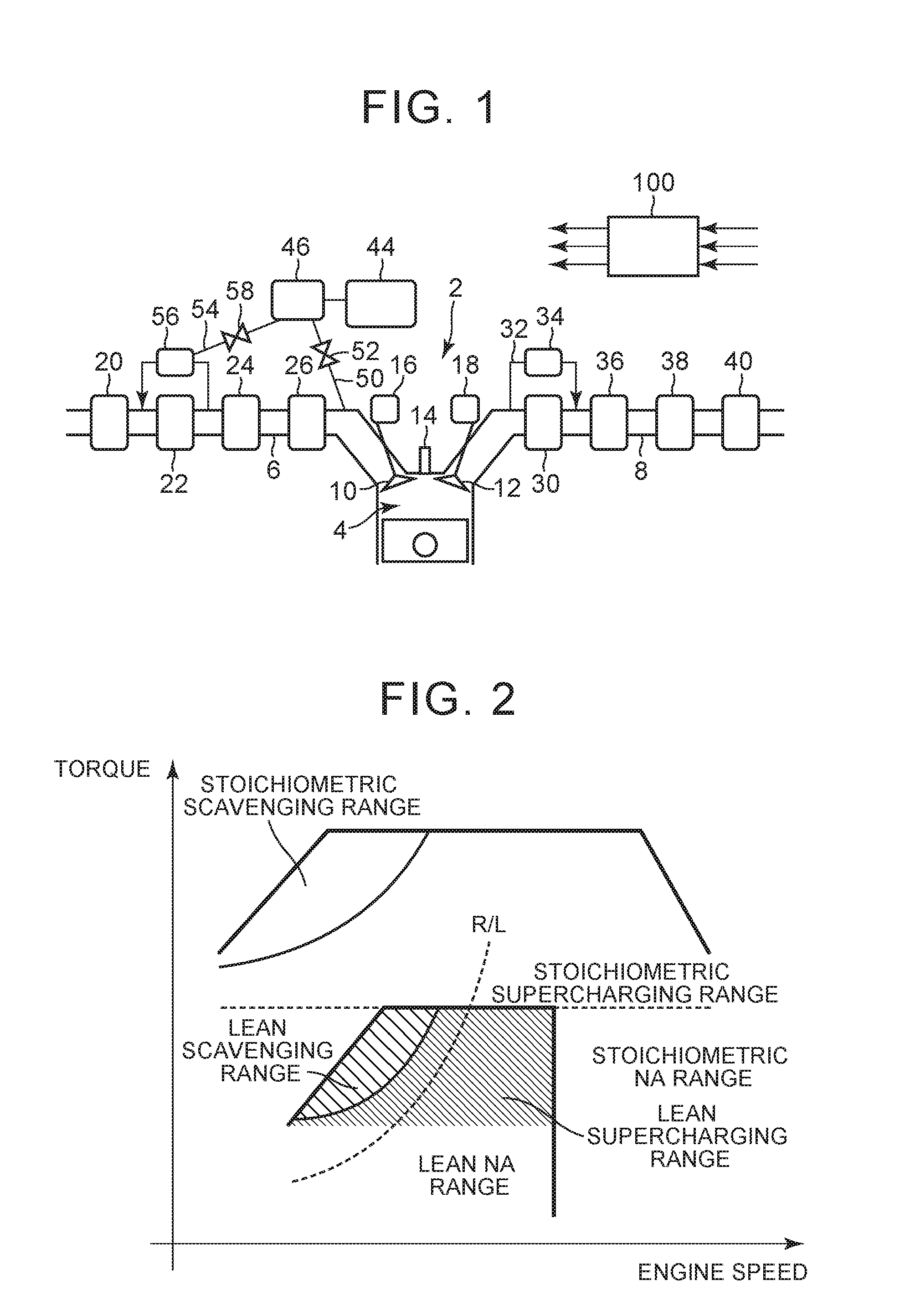

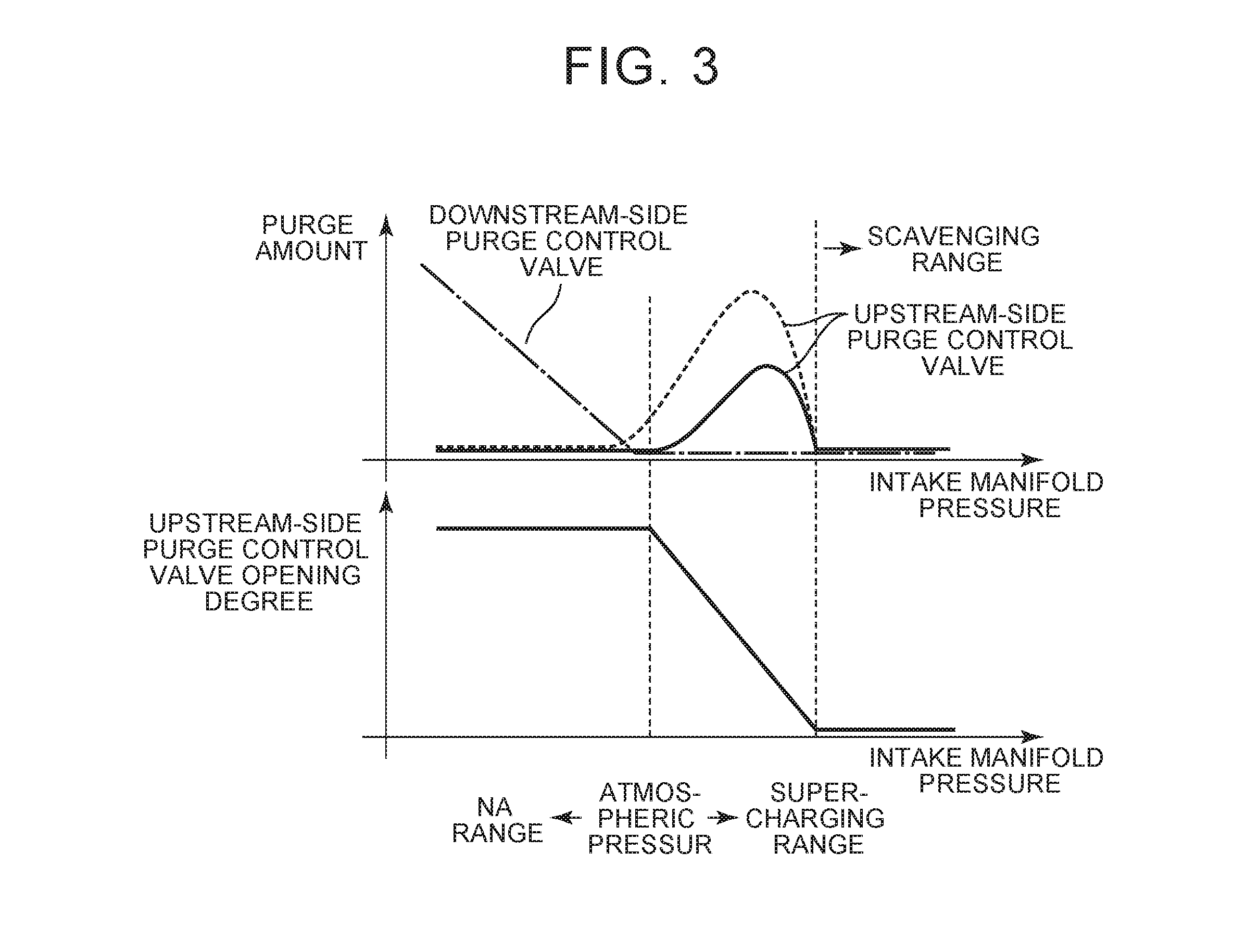

Controller for internal combustion engine

ActiveUS20160273494A1Increase in purge amount can be suppressedPrevent degradationElectrical controlNon-fuel substance addition to fuelExternal combustion engineControl valves

A controller for an internal combustion engine is provided. The engine includes a compressor, a three way catalyst, a canister, an evaporated fuel passage, an ejector, and a purge control valve. The controller includes an ECU. The ECU is configured to decrease an opening degree of the purge control valve in response to an increase in pressure on the downstream side of the compressor in a lean supercharging range. The is a range in which an operation air-fuel ratio of the internal combustion engine is leaner than a theoretical air-fuel ratio of the internal combustion engine, and in which the pressure on the downstream side of the compressor is higher than pressure on the upstream side of the compressor.

Owner:TOYOTA JIDOSHA KK

Brake negative pressure control device for vehicle

InactiveUS20170166179A1Restrain insufficiency of negative pressureImprove intake capacityElectrical controlInternal combustion piston enginesEngineeringPressure controlled ventilation

A brake negative pressure control device for a vehicle includes an ECU. The ECU is configured to (i) control a first fuel injection valve and a second fuel injection valve, when the ECU determines that a negative pressure in a negative pressure chamber is insufficient, such that a ratio of a fuel injection amount by the first fuel injection valve is decreased and a ratio of a fuel injection amount by the second fuel injection valve is increased; and (ii) control an opening degree of the throttle valve, when the ECU determines that the negative pressure in the negative pressure chamber is insufficient, such that the opening degree of the throttle valve at the time when the ECU determines that the negative pressure is insufficient is smaller than an opening degree of the throttle valve at the time when the ECU determines that the negative pressure is not insufficient.

Owner:TOYOTA JIDOSHA KK

Displacement control mechanism for variable displacement compressor

InactiveUS7559208B2Increase the differential pressureDegree of opening is decreasedCompression machines with non-reversible cycleFluid circulation arrangementDisplacement controlEngineering

A displacement control mechanism for a variable displacement compressor includes a first valve hole, a first valve body, a pressure sensing means operable to sense pressures of first and second points in a discharge pressure region to adjust a position of the first valve body, and a pressure-difference-increasing means operable to increase pressure difference between the first and second points when the pressure of a suction pressure region falls below a predetermined standard pressure. The pressure sensing means displaces the first valve body to increase an opening degree of the first valve hole according to increase of the pressure difference when the first valve hole is part of a supply passage. The pressure sensing means displaces the first valve body to decrease the opening degree of the first valve hole according to the increase of the pressure difference when the first valve hole is part of a bleed passage.

Owner:TOYOTA IND CORP +1

Displacement control mechanism for variable displacement compressor

InactiveUS7523620B2Increase speedExtensive operationFluid parameterCompression machines with non-reversible cycleEngineeringDisplacement control

A displacing device is incorporated in a displacement control valve. The displacing device includes a first pressure chamber, a second pressure chamber, a second bellows, a transmission rod, and an urging spring. The second pressure chamber communicates with a suction chamber. The interior of the second pressure chamber is a suction pressure zone. When the pressure in the suction pressure zone is less than or equal to a predetermined reference pressure, the transmission rod moves an actuation rod (valve body) to open a valve hole. Therefore, a variable displacement compressor is prevented from operating with a large displacement when there is insufficient amount of refrigerant or when the speed of the compressor is high.

Owner:TOYOTA IND CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com