Methods and systems for hybrid vehicle power delivery

A hybrid vehicle and vehicle technology, applied in the field of power transmission and systems for hybrid vehicles, can solve problems such as increased noise and vibration discomfort, insufficient engine to satisfy the driver, and impact on vehicle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

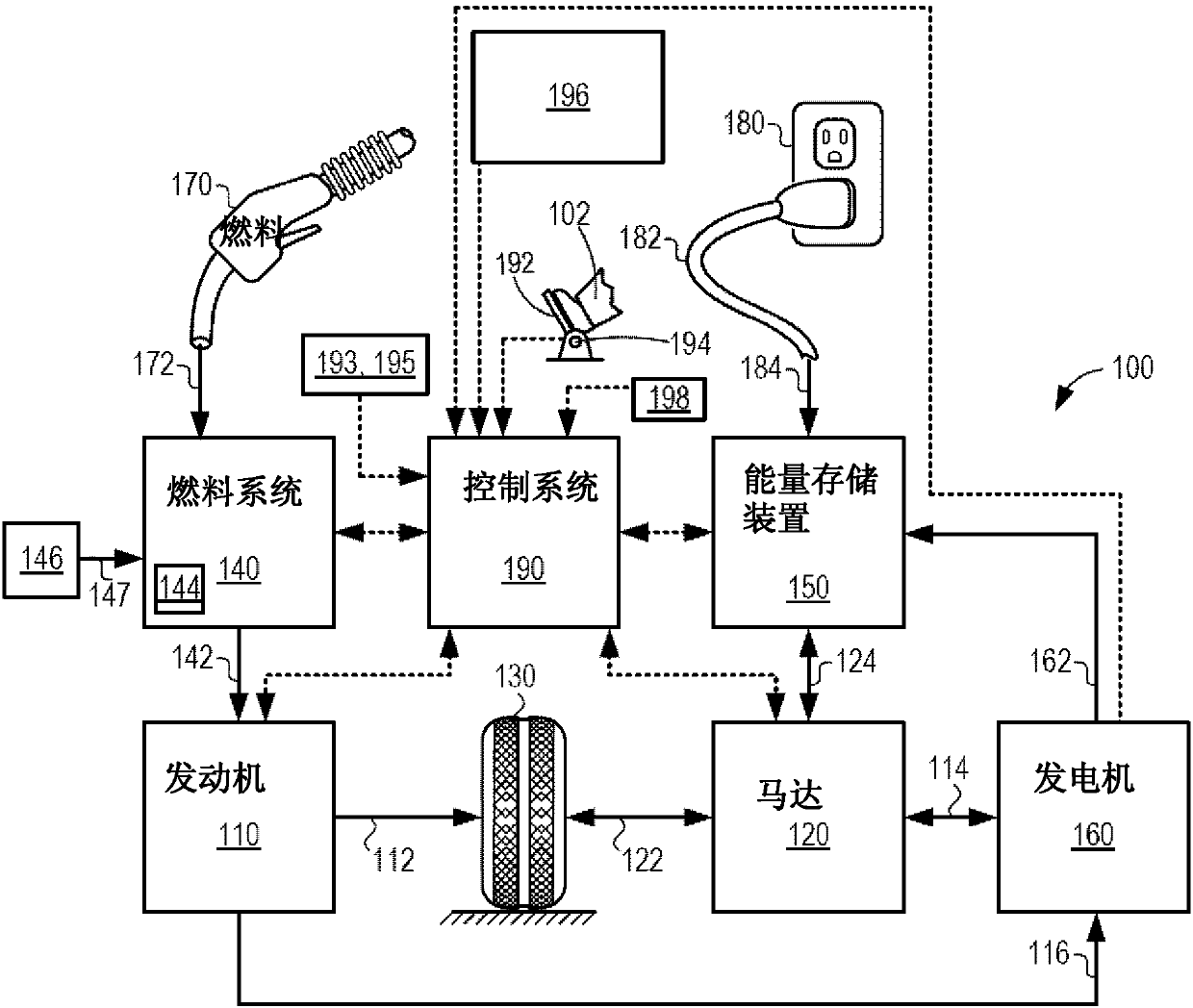

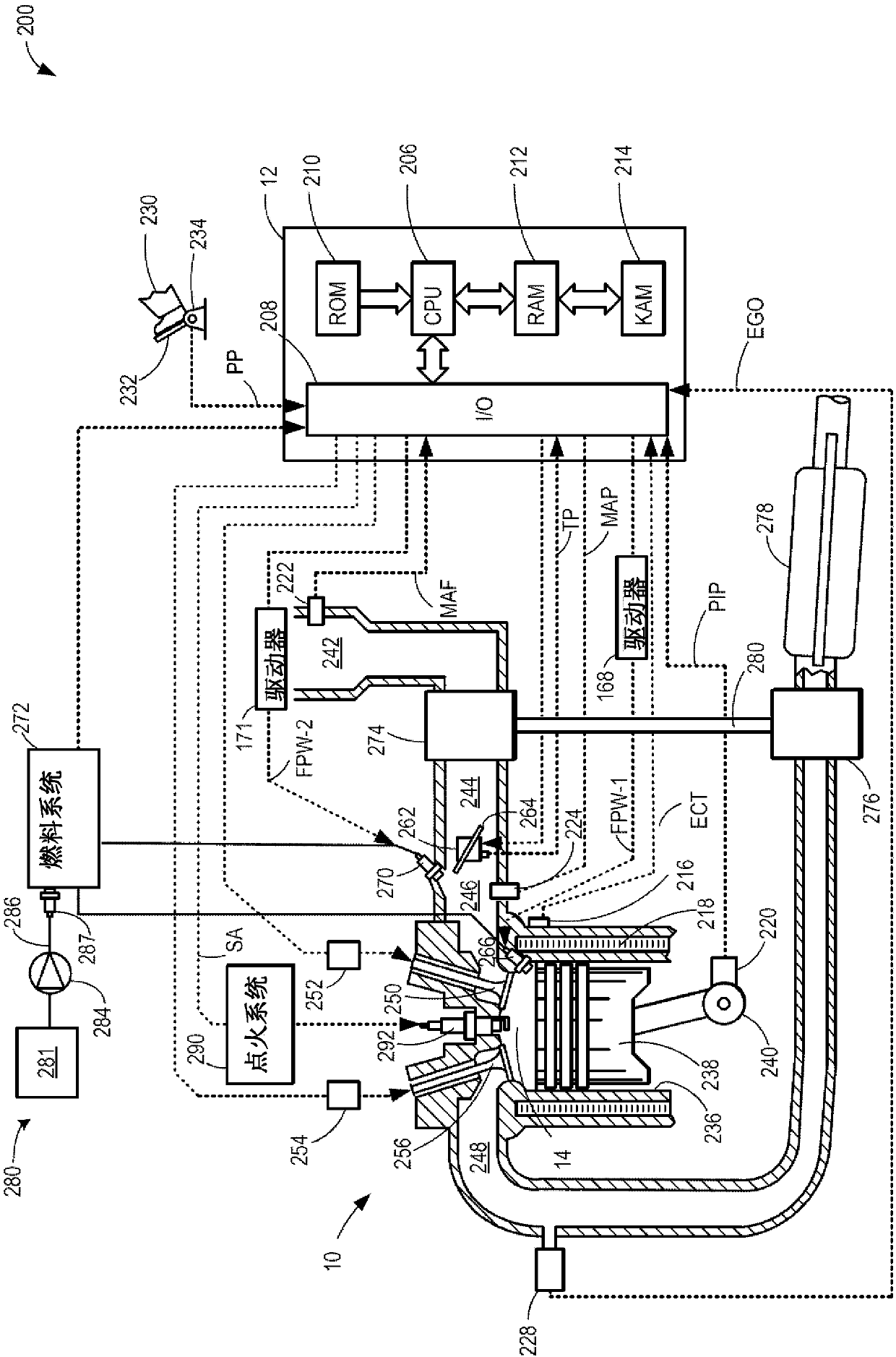

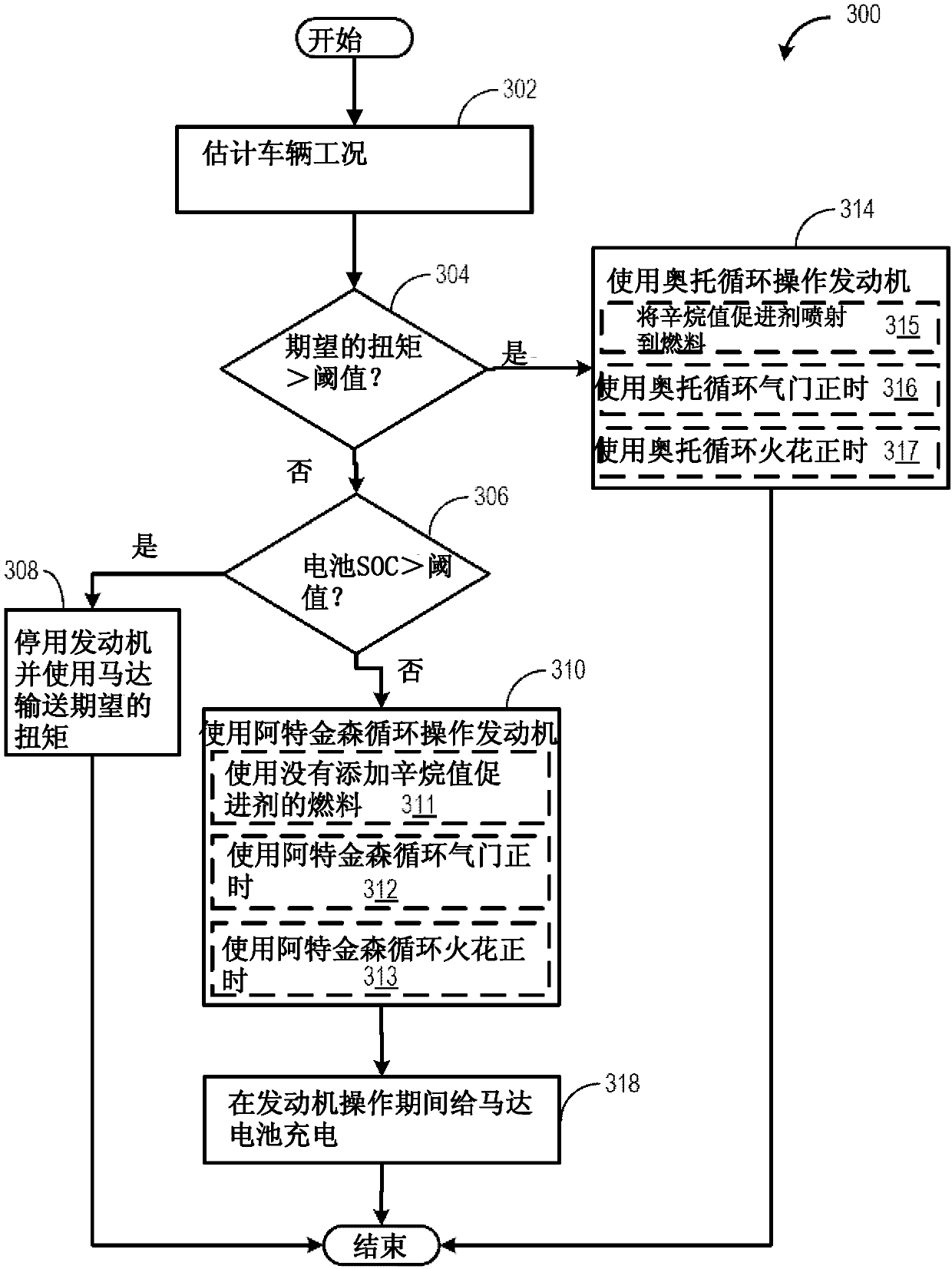

[0013] The following description relates to systems and methods for increasing the power output of a hybrid vehicle. An exemplary vehicle system with an engine and an electric motor is figure 1 shown in , and in figure 2 A detailed description of an engine system including a fuel system and an octane booster system is shown in . The engine controller can be configured to execute control routines such as image 3 An exemplary routine of ) to adjust engine operation to deliver a desired torque output while improving fuel efficiency. exist Figure 4 Exemplary engine operation to deliver a desired torque output is shown in .

[0014] figure 1 An exemplary vehicle propulsion system 100 is shown. For example, vehicle system 100 may be a hybrid electric vehicle or a plug-in hybrid electric vehicle. However, it should be understood that although figure 1 A hybrid vehicle system is shown, but in other examples, vehicle system 100 may not be a hybrid vehicle system and may be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com