Two-stroke engine control

A two-stroke internal combustion engine and controller technology, applied in the direction of engine control, fuel injection control, electrical control, etc., can solve the problems of increasing engine emissions, increasing the amount of unburned fuel, etc., and achieve reduced wear, low implementation, and low complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Aspects of the present disclosure will now be described more fully with reference to the accompanying drawings. However, the different apparatus, computer programs and methods disclosed herein may be implemented in many different forms and should not be construed as limited to the aspects set forth herein. Like numbers refer to like elements throughout the drawings.

[0041] The terms used herein are used only to describe aspects of the present disclosure and are not intended to limit the present invention. As used herein, the singular forms "a", "an" and "the" are intended to include the plural forms as well, unless the context clearly dictates otherwise.

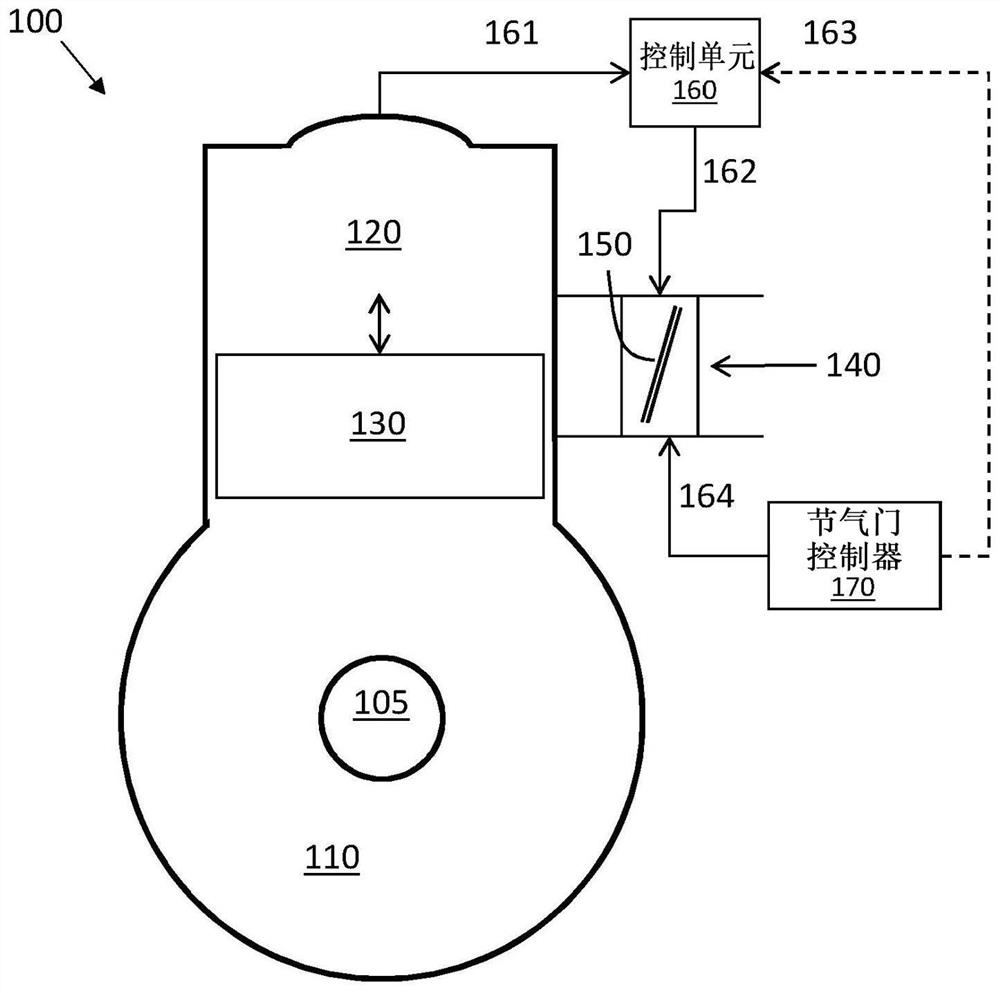

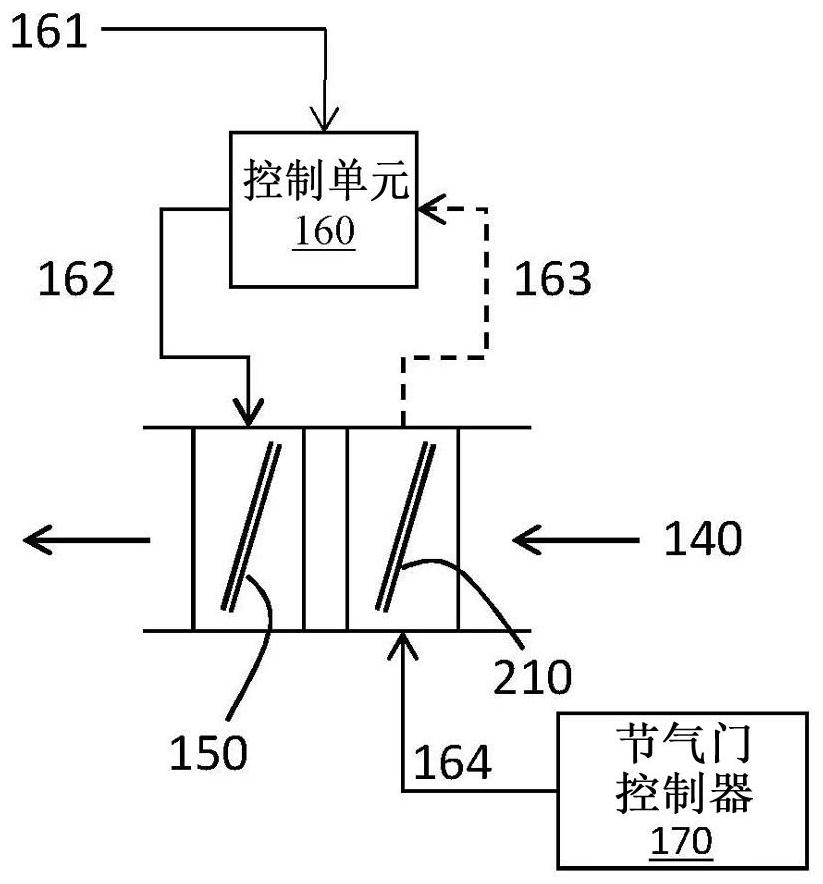

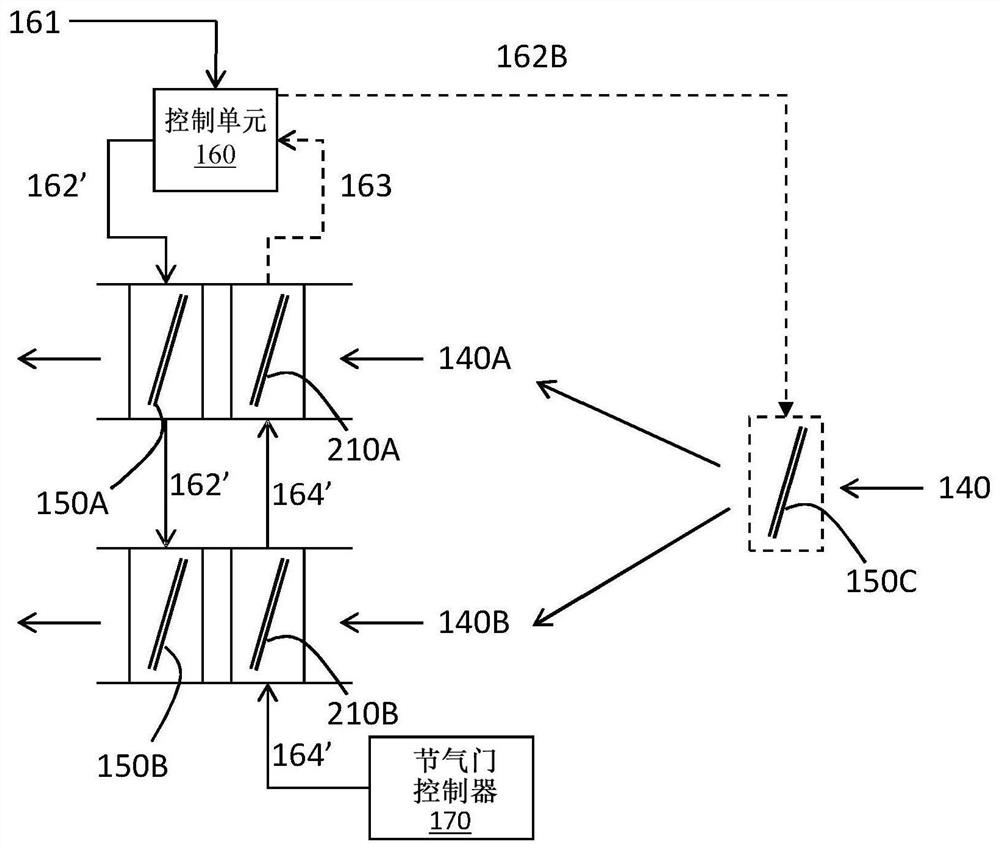

[0042] figure 1 A two-stroke engine 100 is shown schematically. Piston 130 is arranged to reciprocate in a cylinder including combustion chamber 120 . As the piston moves upward, a fuel / air mixture having a composition determined by the fuel setting is injected into chamber 120 . The fuel / air mixture is ignited...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com