Engine limit load control method and device

A technology of limit load and control method, applied in engine control, machine/engine, non-electrical control, etc., can solve problems such as engine flameout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

[0021] As a first aspect of the present invention, an engine limit load control device is provided, in particular, it can be used to implement the engine limit load control method in the present invention.

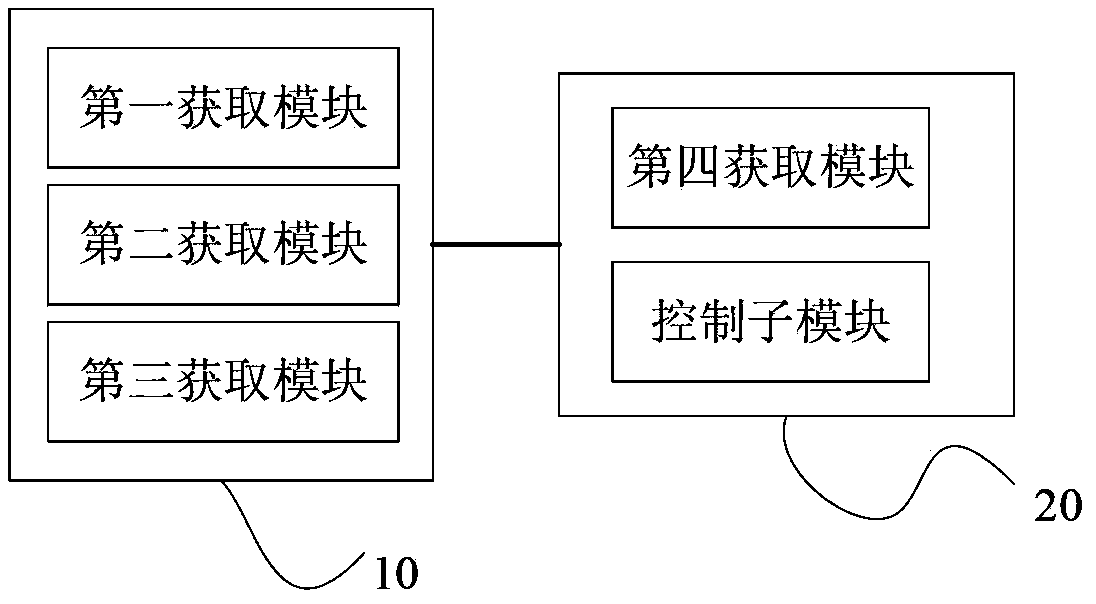

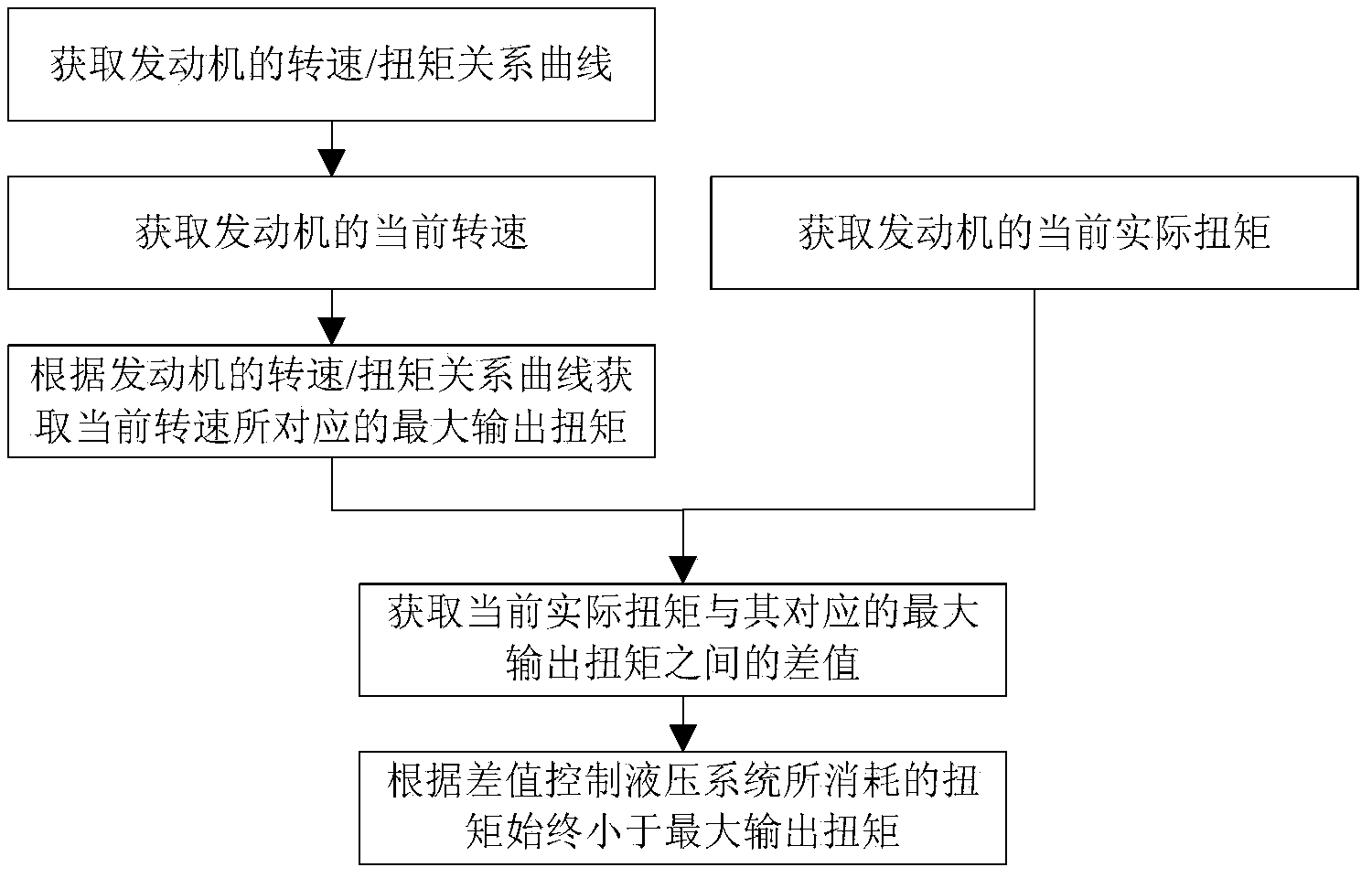

[0022] Please refer to figure 1 , the engine limit load control device includes: an acquisition module 10 and a control module 20 . Wherein, the obtaining module 10 is used for obtaining the maximum output torque of the engine in real time; the control module 20 is used for controlling the torque consumed by the hydraulic system driven by the engine to always be smaller than the maximum output torque.

[0023] At a certain moment, the engine of the engineering equipment has a first rotational speed, and has a maximum output torque corresponding to the first rotational speed, that is, when the engine is running...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com