A control method and system for a turbocharger, based on position sensor learning

A technology for controlling equipment and control methods, which is applied in the direction of electrical control, mechanical equipment, non-electrical control, etc., and can solve problems such as return value deviation and accuracy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

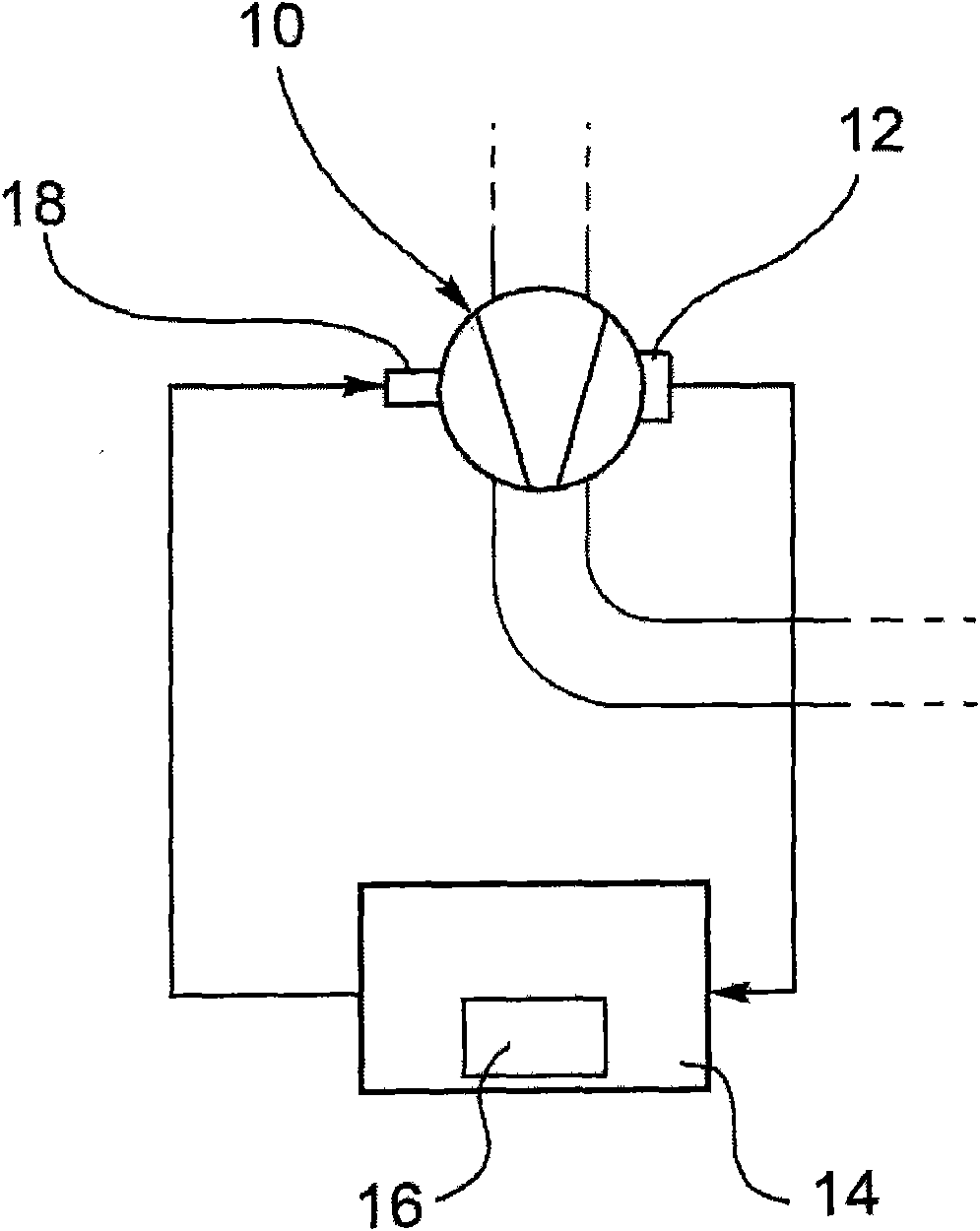

[0012] refer to figure 1 , a brief description of a control system for a fluid control device, in particular for an internal combustion engine.

[0013] In an exemplary embodiment of the fluid control device, a variable geometry turbocharger (VGT) 10 is considered here. A variable geometry turbocharger has adjustable deflector vanes adapted to adopt multiple operating positions for continuously varying the clearance through which the exhaust gas flows through to reach the turbine of the turbocharger, thereby controlling the flow through the turbine. Air velocity.

[0014] The control system comprises a position sensor 12 , such as a vane angular position sensor, arranged for continuously detecting the operating position of the variable turbine geometry of the turbocharger 10 . The sensor 12 comprises a converter portion adapted to convert a physical entity value representative of the angular position of the deflected blade into an electrical parameter value, and detection me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com