A method for preventing engine from scuffing

An engine, engine output technology, applied in engine components, engine control, machine/engine, etc., can solve problems such as difficult intake air temperature, oil temperature, cylinder pulling, intake air temperature, water temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

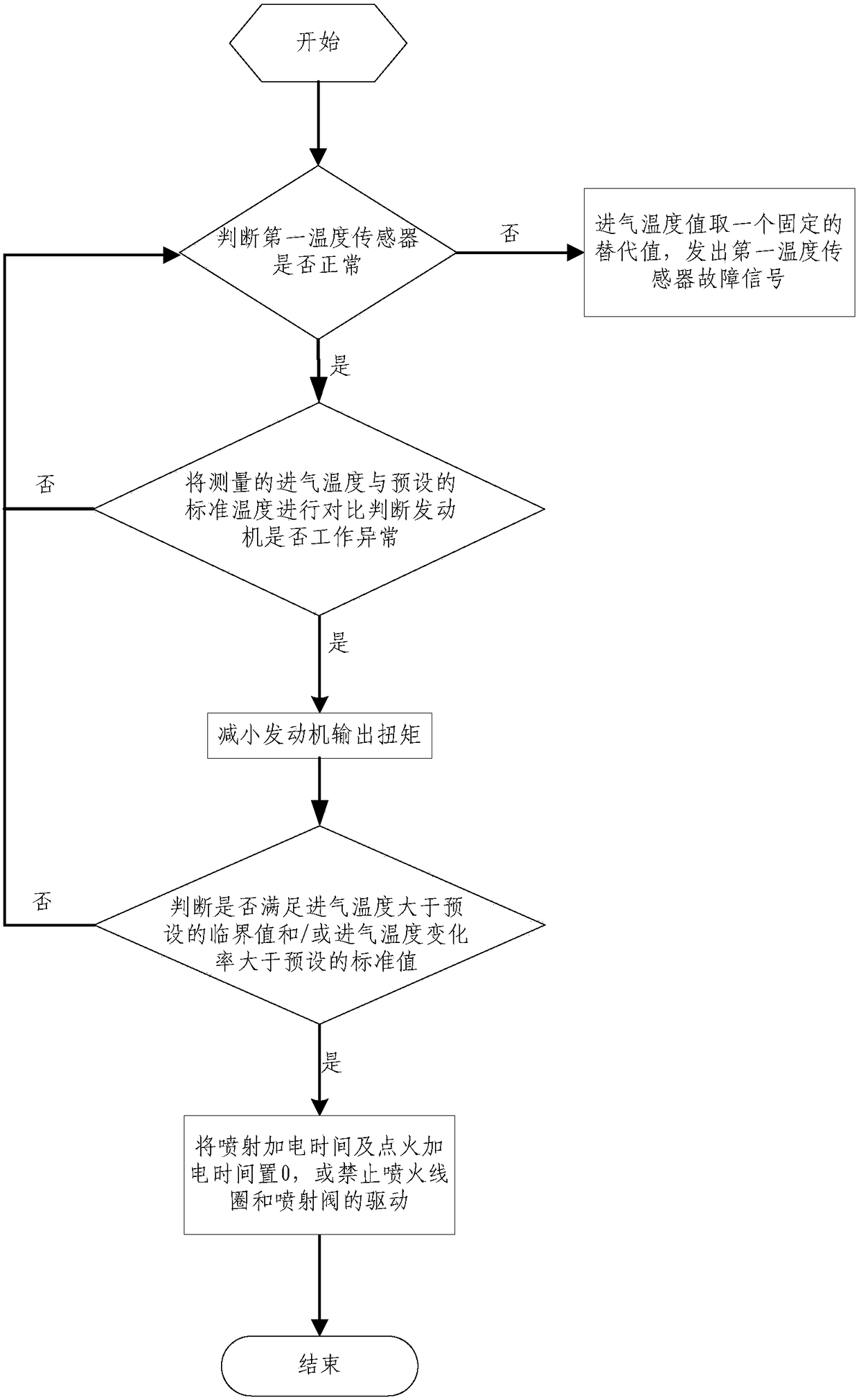

Embodiment 1

[0033] This embodiment provides a method for preventing the engine from scuffing, such as figure 1 As shown, step S1 is included to detect the performance parameters of the engine and compare them with preset standard parameters to determine whether the engine is in an abnormal working state. Preferably, the detected performance parameters are the intake air temperature of the engine, and the intake air The temperature is the temperature value collected by the first temperature sensor after the throttle valve in the natural gas engine. The first temperature sensor is close to the intake manifold. When the first temperature sensor is normal, it can accurately reflect the intake air temperature of the engine; When the air temperature is high, the electronic control unit judges whether the first temperature sensor installed behind the engine throttle is normal according to the obtained first temperature sensor voltage signal and internal diagnostic logic; when the first temperatur...

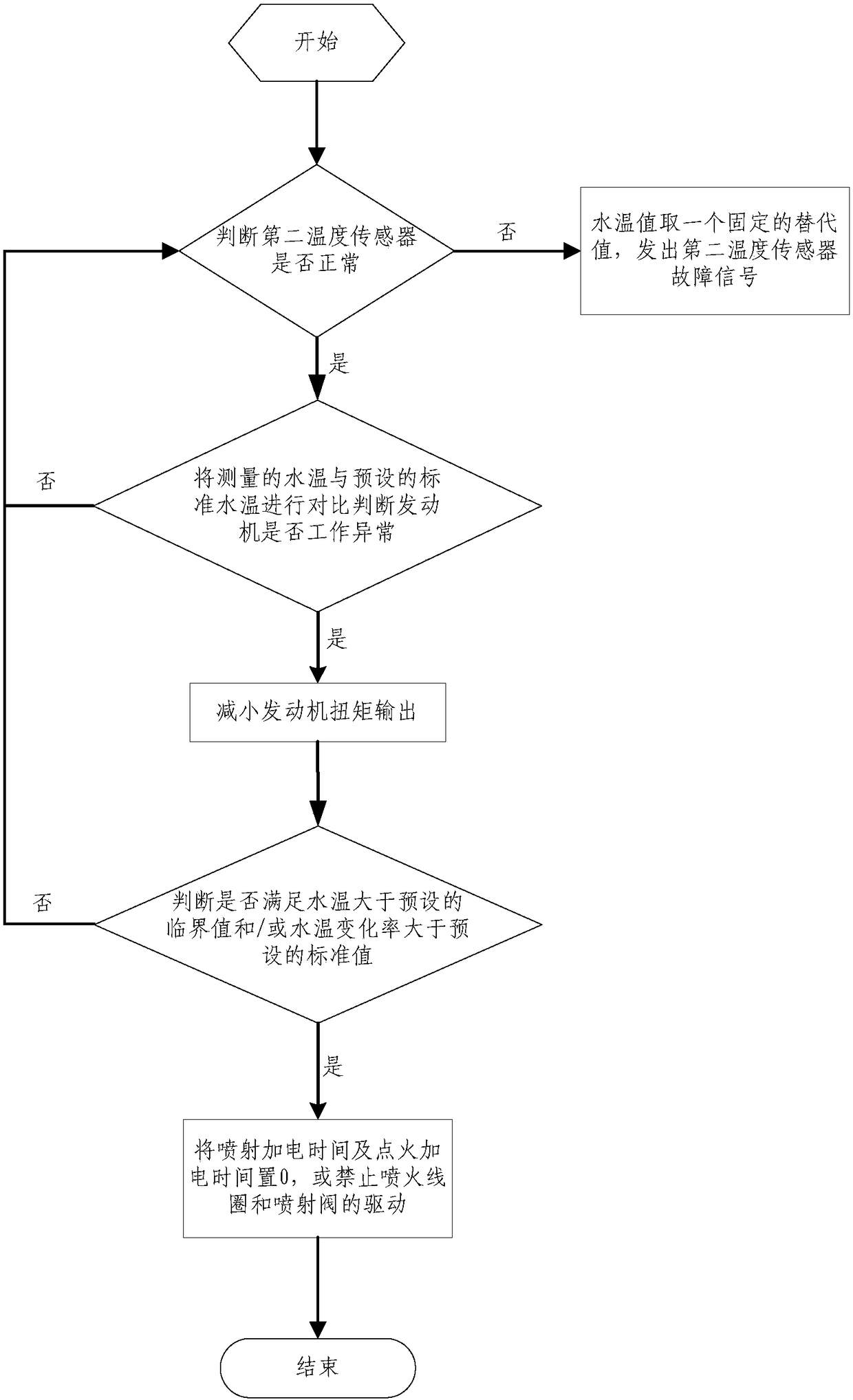

Embodiment 2

[0038] The technical solution of this embodiment is substantially the same as that of Embodiment 1, and the main difference is that the engine energy parameter measured in this embodiment is water temperature (ie: engine temperature), such as figure 2 As shown, the specific steps are: S1, detect the engine water temperature, wherein the engine water temperature is measured by the second temperature sensor, and when detecting the engine water temperature, the electronic control unit obtains the voltage signal of the second temperature sensor and the internal diagnostic logic to judge whether the second temperature sensor is normal; when the second temperature sensor is normal, the electronic control unit obtains the water temperature of the engine according to the voltage value measured by the second temperature sensor, and compares the obtained water temperature with the preset standard water temperature to judge whether the engine Whether it is in an abnormal working state; w...

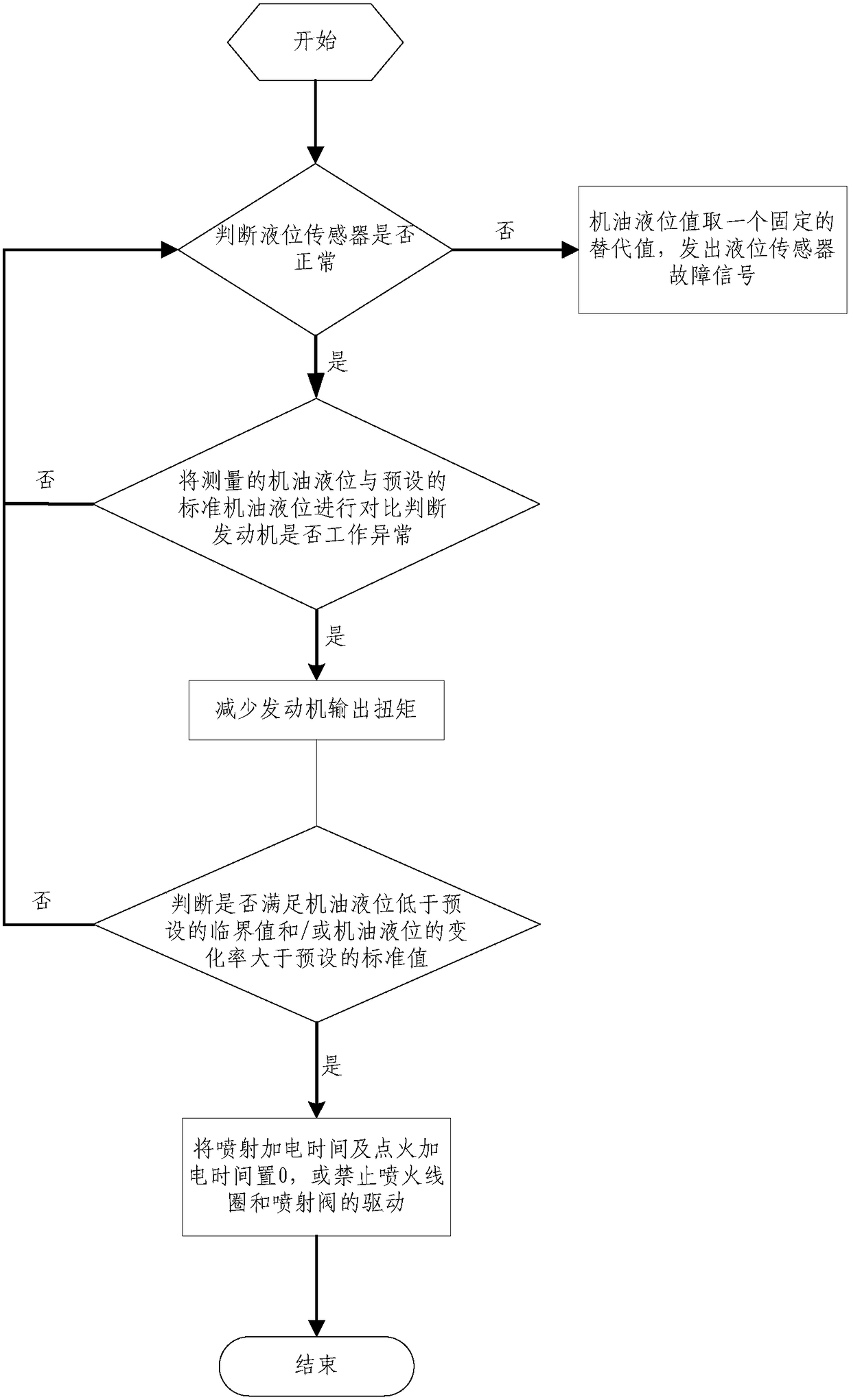

Embodiment 3

[0043] This embodiment is substantially the same as the technical solution in Embodiment 1, and its main requirement is that the engine performance parameter measured in this embodiment is the oil level, such as image 3 As shown, the specific steps are: S1, detect the oil level in the engine, wherein the engine oil level is measured by a liquid level sensor, and when detecting the engine oil level, the electronic control unit obtains the oil level according to the liquid level sensor The voltage signal of the liquid level sensor and the internal diagnostic logic are used to judge whether the liquid level sensor is normal; when the liquid level sensor is normal, the electronic control unit obtains the engine oil level according to the voltage value measured by the liquid level sensor, and compares the obtained oil level with the preset value. Compared with the set standard oil level, it is judged whether the engine is in an abnormal working state; when the liquid level sensor f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com