Cylinder body of a hydraulic breaker and its manufacturing method

A technology of hydraulic breaker and manufacturing method, which is applied in forging/pressing/hammer device, forging/pressing/hammering machinery, manufacturing tools, etc., which can solve the difficulty of processing and production and the increase of product failure rate, and cannot maintain the hydraulic breaker. Performance, breaking hammer can not work normally, etc., to achieve the effect of strong adhesion, prevent strain, and strengthen structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

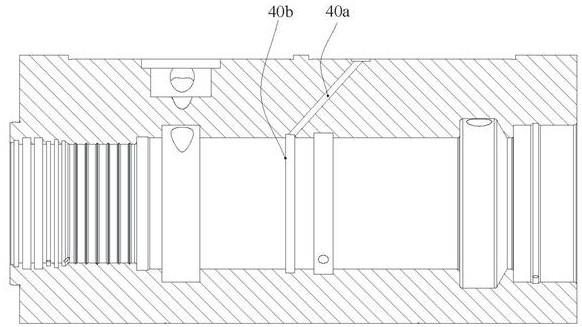

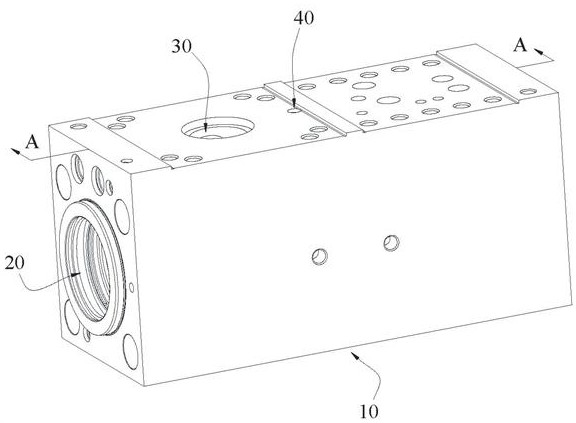

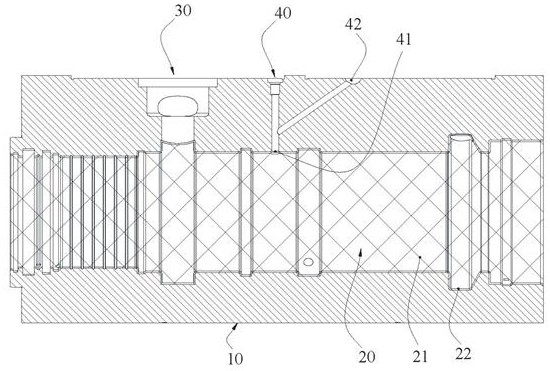

[0037] Such as Figure 2 to Figure 3 The middle cylinder of the hydraulic breaker shown includes a middle cylinder body 10, the middle cylinder body 10 is provided with a piston chamber 20 along its length, and an energy storage chamber 30 communicating with the piston chamber 20 is also arranged on the cylinder body. And the control valve signal passage 40 communicated with the piston chamber 20; here it should be pointed out that the middle cylinder body 10 also has an oil inlet and oil return passage communicated with the energy storage chamber 30, because the oil inlet and oil return passage are connected with the actual The technology is the same, so it will not be repeated here, and the embodiment part of the present invention only introduces the improvement points in detail;

[0038] Such as image 3 As shown in , the piston chamber 20 has a textured structure 21, the textured structure 21 is uniformly distributed throughout the inner cavity of the piston chamber 20, a...

Embodiment 2

[0054] In another embodiment of the present invention, another coating method, that is, an electrostatic spraying method, is also used. Specifically: when the soft film 22 is coated on the inside of the piston chamber 20, the piston chamber is sprayed by electrostatic spraying. The inner wall of 20 is incompletely sprayed, and then heated and cured, so that the surface of the cured flexible film 22 has pores, and then electrostatic sprayed several times, so that the thickness of the flexible film 22 reaches 1.8-2.0mm. The advantage of electrostatic spraying is that it can accurately control the thickness of the coating and the control of the pores. The incomplete spraying here means that the graphite powder does not completely cover the inner wall of the piston chamber 20 when spraying, so that there are pores on the surface of the coating when it is heated and fluidized. , and a multi-layer porous coating structure can be formed by multiple spraying methods, which further impr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com