Formula and process of crystal ceramic fluid for high-silicon aluminum alloy piston surface treatment of engine

A high-silicon aluminum alloy and surface treatment technology, which is applied in the coating process of metal materials, coatings, etc., can solve the problems of increased cost of ceramic skeletons, falling blocks, peeling, scuffing, small thermal shock deformation, etc., to achieve heat insulation Good effect, reduced production cost, strong thermal corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

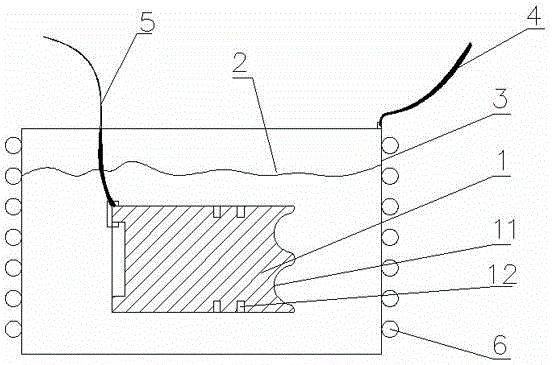

[0025] Such as figure 1 As shown, an engine high-silicon aluminum alloy piston surface treatment process is made according to the following steps:

[0026] 1. Clean the piston workpiece 1 with a metal cleaner to remove oil stains;

[0027] 2. Add the prepared crystal porcelain solution 2 into the treatment tank 3. The crystal porcelain solution 2 adds a positive electrode, connects the positive electrode wire 4, the piston workpiece 1 adds a negative electrode, connects the negative electrode wire 5, and the power supply Use alternating power supply;

[0028] 3. A circulating cooling water pipe 6 is installed outside the treatment liquid 3 to control the temperature of the crystal enamelizing solution 2, which is below 60°C;

[0029] 4. The power supply voltage is 120V, the current is 150A, the frequency conversion rate is 500Hz, and the crystallizing time is 50 minutes;

[0030] 5. Take out the piston workpiece 1, dry, and polish the combustion chamber 11 and piston ring groove 12 of...

Embodiment 2

[0034] The crystal porcelain solution formula of this embodiment is prepared according to the following weight percentages:

[0035] EDTA: 6%, SDBS: 4%, KOH: 8%, VCl 3 : 4%, TiO 3 : 4%, Nb-Re: 4%, NaPO 3 : 4%, the rest is water.

Embodiment 3

[0037] The crystal porcelain solution formula of this embodiment is prepared according to the following weight percentages:

[0038] EDTA: 5%, SDBS: 3%, KOH: 5%, VCl 3 : 3%, TiO 3 : 2%, Nb-Re: 2%, NaPO 3 : 3%, the rest is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com