In-mold cutting injection mold

An injection mold and in-mold cutting technology, applied in the field of molds, can solve the problems of reducing the service life of the mold, jamming, and inability to completely hide the incision, so as to achieve the effect of beautiful appearance and avoid pulling the cylinder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

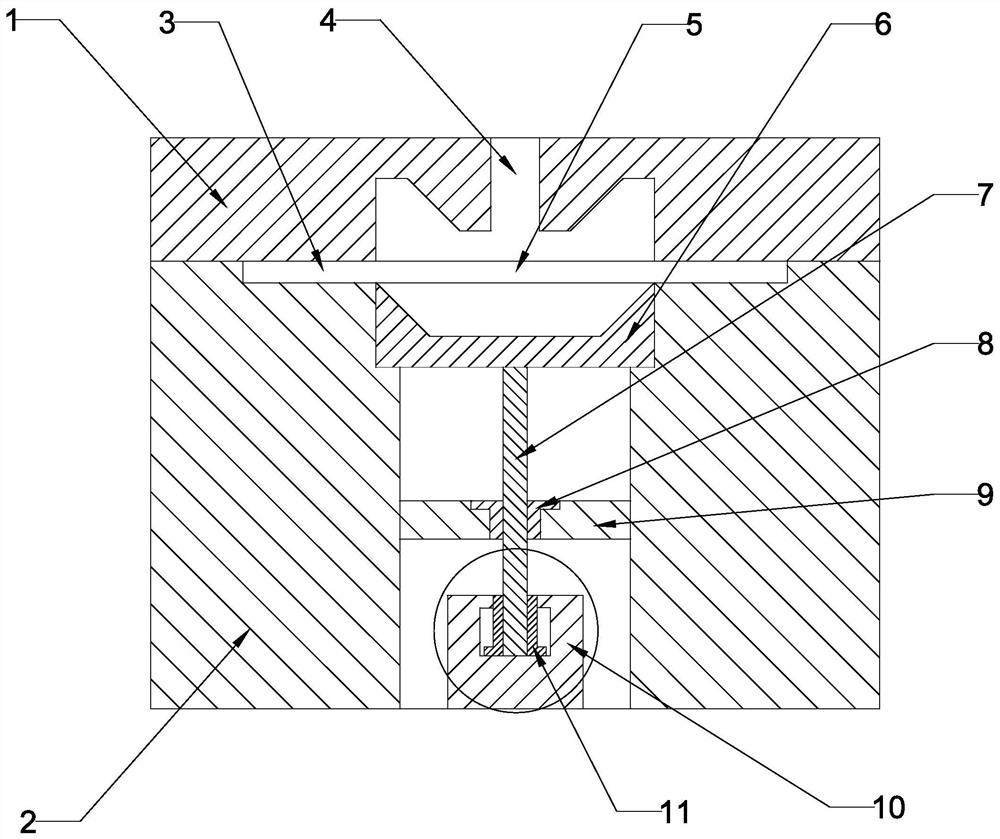

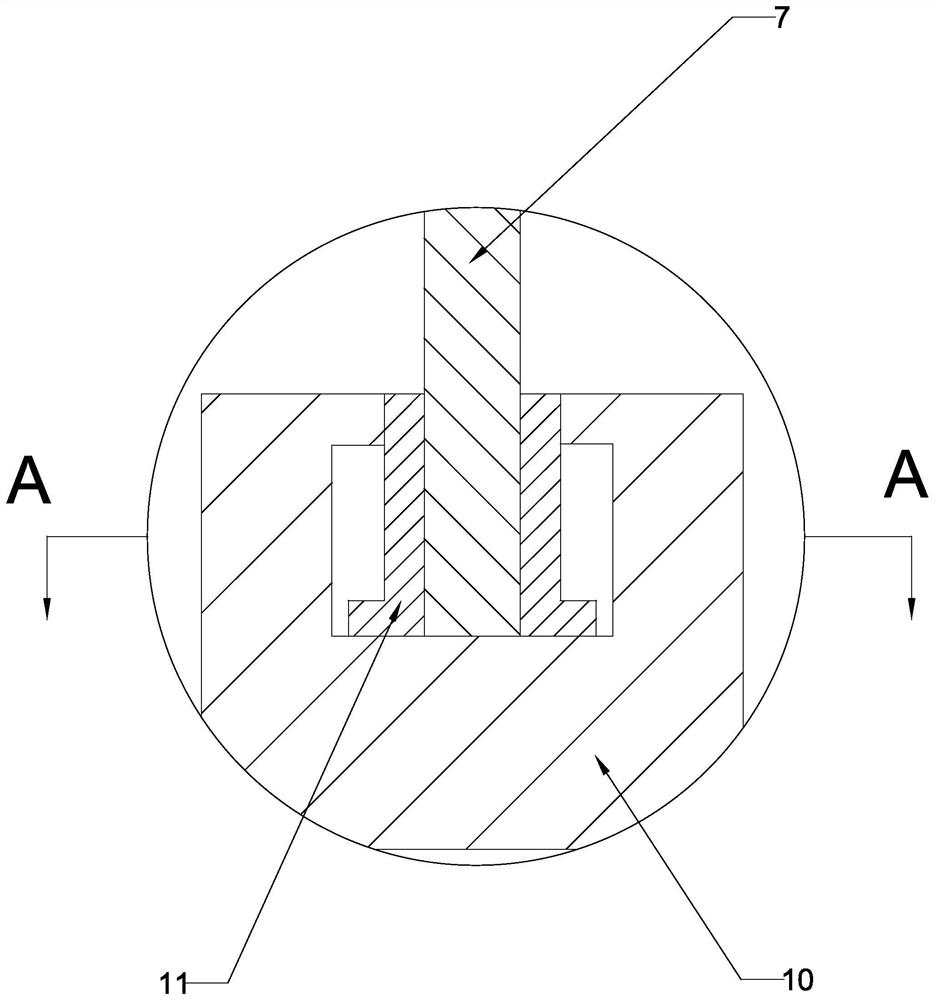

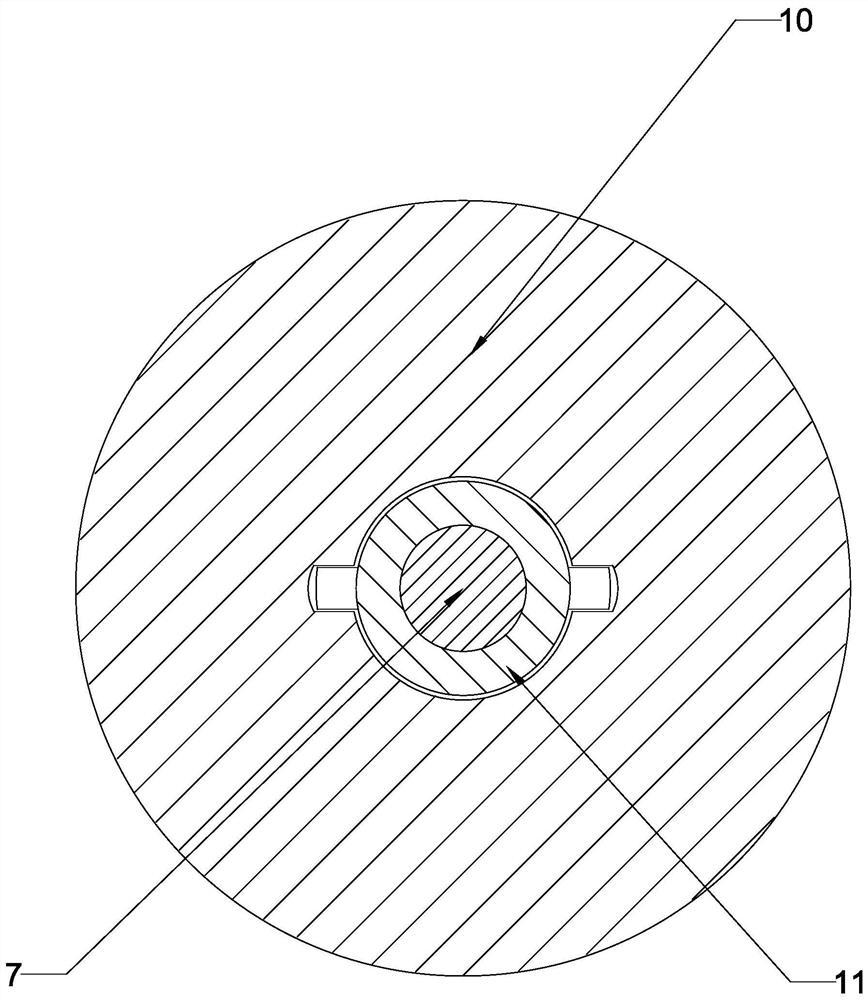

[0023] Such as figure 1 , figure 2 , image 3 In the shown embodiment, an in-mold cutting injection mold includes an upper mold core 1 and a lower mold core 2, and is characterized in that it also includes a cutting knife 6, and the cutting knife includes a cylindrical blade body. It also includes a cutter ejection mechanism, the cutter ejection mechanism includes an ejector rod assembly and a drive assembly, and a cutter ejection mechanism cavity is arranged inside the lower mold core. The ejector rod assembly includes a screw rod 7 and a nut 8 , a nut holder 9 is fixed in the cavity of the cutter ejection mechanism, and the nut 8 is fixed on the nut holder 9 . The drive assembly includes a hydraulic motor 10, a sleeve 11 is fixed at one end of the screw 7, and a positioning protrusion is arranged on the sleeve, and a sleeve cavity matching the sleeve 11 is connected to the output shaft of the hydraulic motor. , the sleeve cavity is provided with a sliding groove matching...

Embodiment 2

[0025] Such as Figure 4 In the above embodiment, the difference from the first embodiment is that the driving assembly includes an oil cylinder 12 , and the screw rod 7 is connected to the oil cylinder 12 through a bearing 13 by sliding. The oil cylinder can drive the screw to eject and retract, and at the same time, under the action of the fixed nut, the screw can rotate to realize rotating ejection and rotating retraction, effectively avoiding the phenomenon of cylinder pulling and knife jamming.

Embodiment 3

[0026] Embodiment 3: Different from the embodiment, the drive assembly includes a motor, a sleeve is fixed at one end of the screw, a positioning protrusion is provided on the sleeve, and the output shaft of the motor is connected with the A sleeve cavity of the sleeve, the sleeve cavity is provided with a slide groove matching the positioning protrusion. The motor can drive the screw to rotate, and at the same time, under the action of the fixed nut, the screw moves up and down to realize the ejection and retraction actions.

[0027] As a preference,

[0028] The cylindrical cutter can directly form products with round holes while cutting the nozzle, eliminating the process of digging holes. At the same time, it can completely hide the nozzle and make the appearance more beautiful.

[0029] The usual ejection mechanism is driven by the cylinder to eject the ejector rod, which is prone to cylinder pulling and knife jamming. The screw nut is a ball screw structure, the screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com