Mechanical lubricating oil control safety valve assembly

The technology of one type lubricating oil and safety valve, applied in the field of high-pressure common rail fuel system, can solve the problems of lubricating oil protection function failure, cost reduction, engine friction failure, etc., to reduce the difficulty of seat surface processing, save materials, avoid The effect of pulling the cylinder and biting the card

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

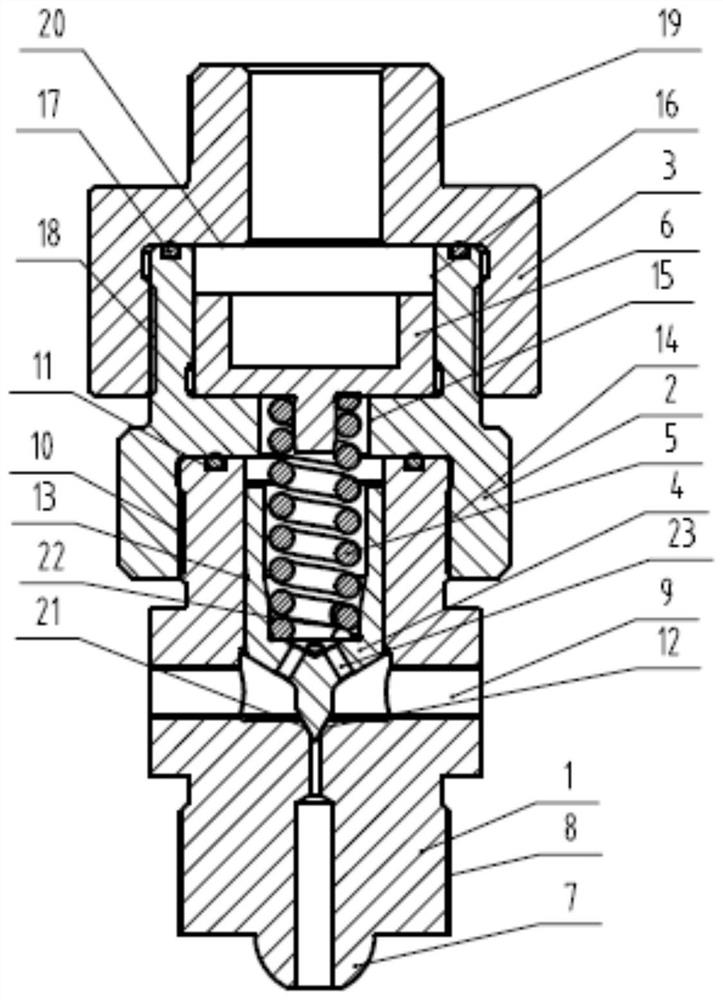

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] This embodiment provides a mechanical lubricating oil control safety valve assembly, whose function is to release the high-pressure common rail pressure when the oil pressure drops, so that the fuel injector stops spraying because the pressure is lower than the opening pressure, and then the engine stops. Prevent lubrication failure problems such as bearing bush holding the shaft and piston scuffing caused by the system running without oil. When the lubricating oil pressure is normal, if the fuel pressure in the high-pressure common rail exceeds the standard, the valve will open to release part of the pressure, so that the system can operate at low working conditions under part of the pressure.

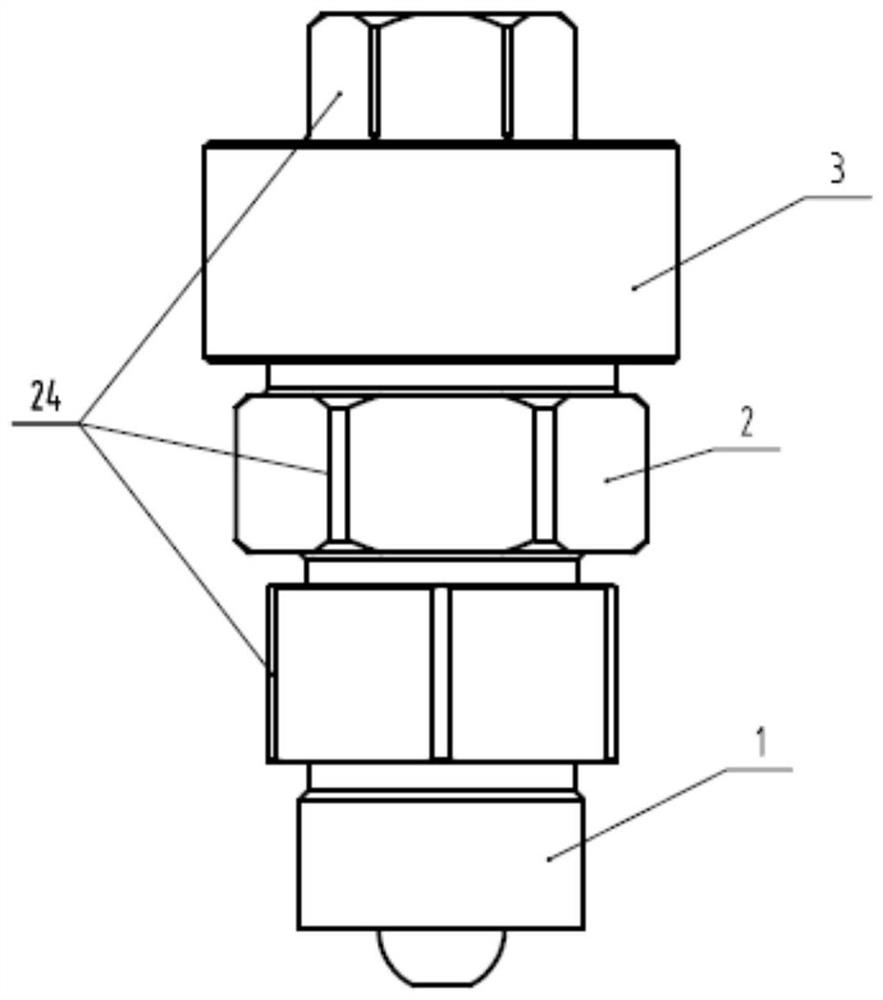

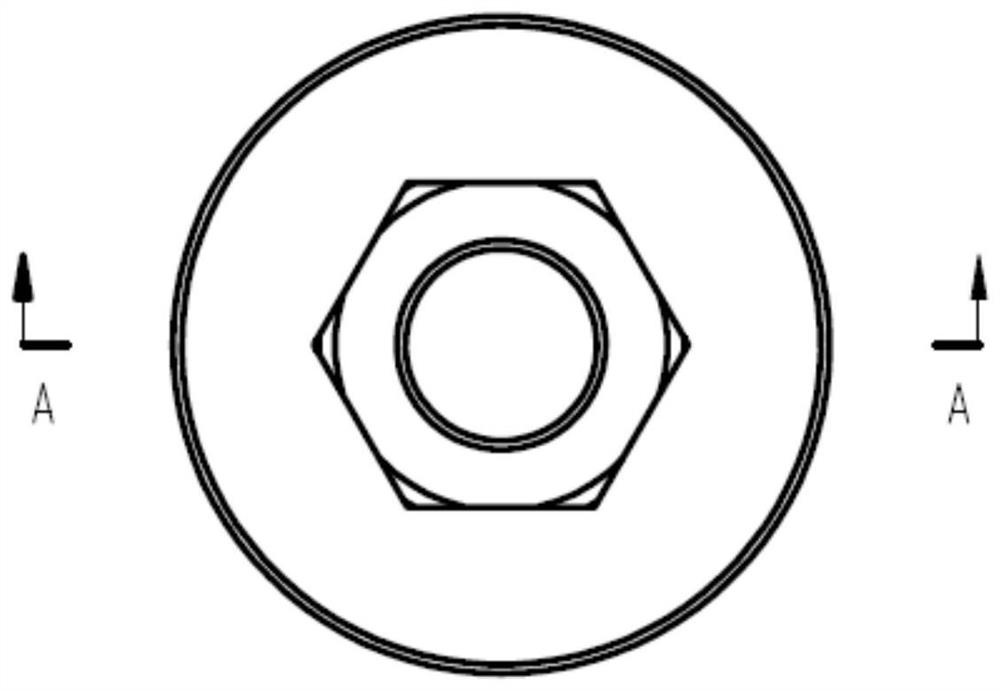

[0035] Such as Figure 1 to Figure 4 The mechanical lubricating oil control safety valve assembly shown is composed of a lower joint 1, a valve body 2, an upper join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com