Systems and methods for engine

An engine system and engine technology, applied in the direction of engine lubrication, engine components, engine control, etc., can solve problems such as not considering engine thickening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

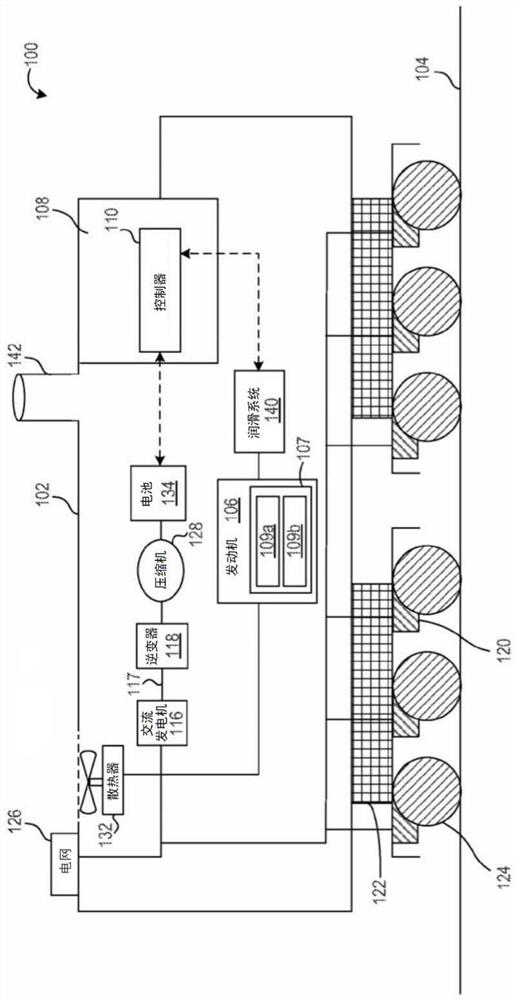

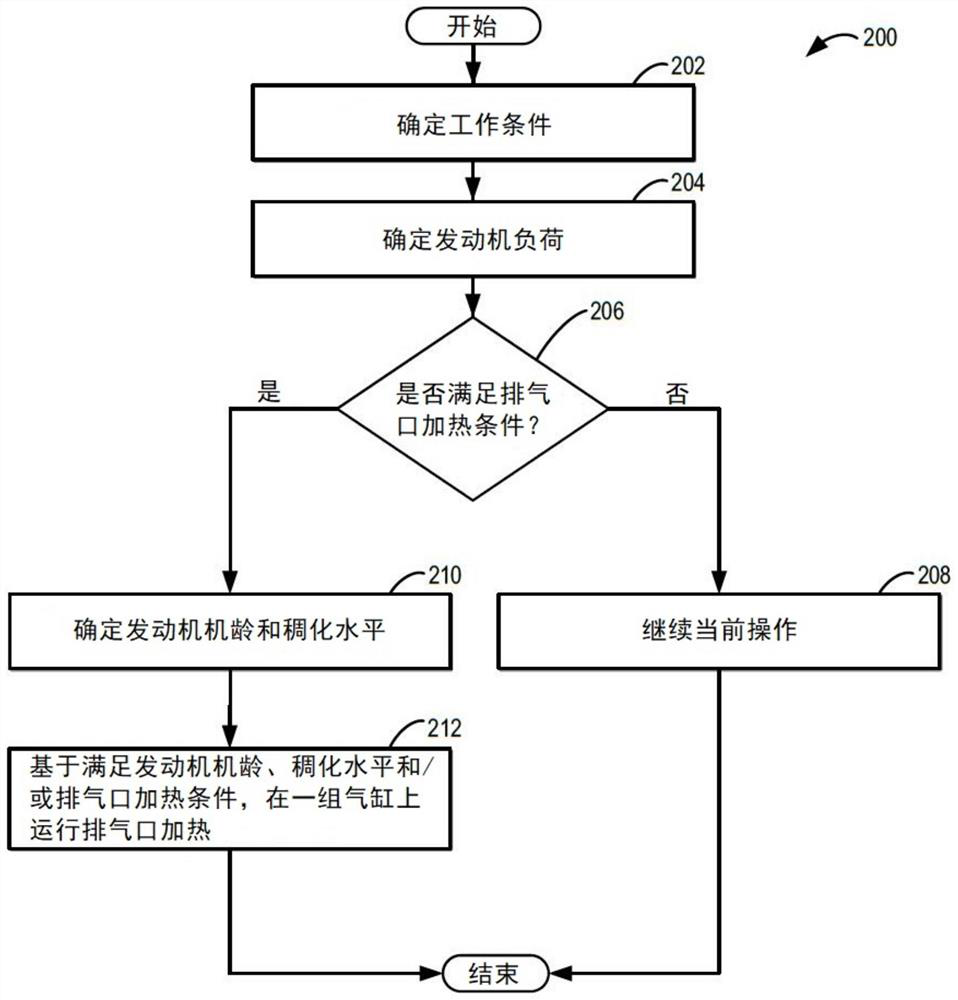

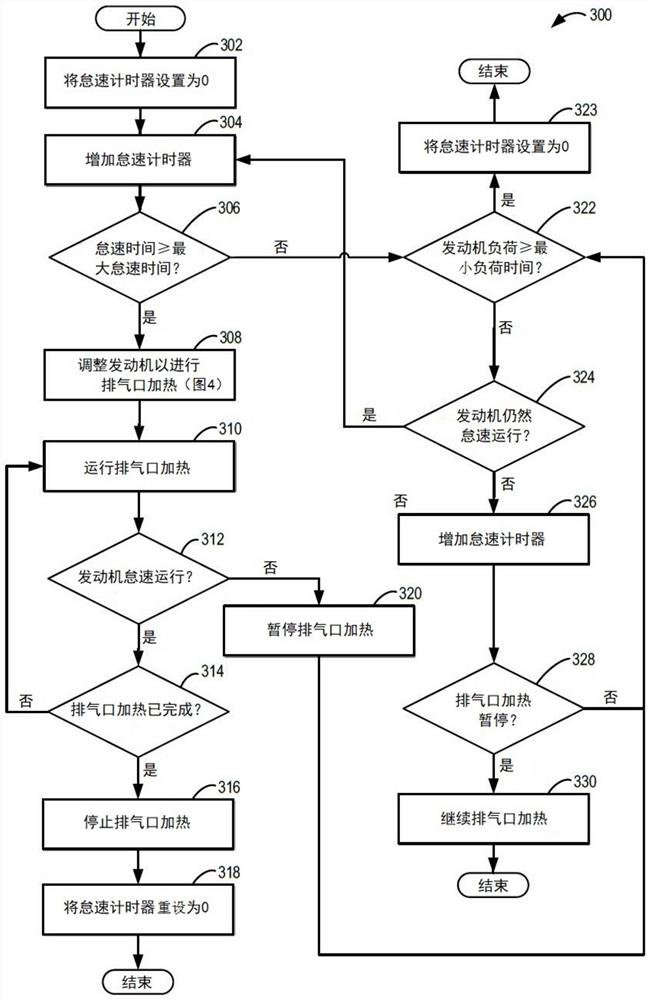

[0015] An engine may have a lubrication system that provides oil for lubricating the valve train, pistons, and other related engine components. During engine operation, unburned oil and / or fuel may accumulate in the engine exhaust manifold. The lubrication system may interact with the engine controlled by the engine control system to burn off unburned oil and / or fuel to reduce fouling of the engine exhaust system. refer to figure 1 An example of such a configuration is shown in which a lubrication system interacts with a locomotive engine to provide lubrication during engine operation, and an engine controller enables periodic exhaust maintenance.

[0016] In one embodiment, the engine controller can switch the engine between different operating modes. Examples of operating modes may include normal operating mode, low load, high load, high heat mode, startup mode, limited oxygen mode, and the like. Under normal operating conditions, the oil used to lubricate the pistons is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com