System and method for semi-coke blending combustion of coal-fired power plant with Brown gas for catalytic combustion supporting

A technology of coal-fired power station and Brown gas, which is applied to the system field of mixed-burning semi-coke in coal-fired power station to achieve the effects of solving flame retardancy, enhancing reducibility and solving poor burnout performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

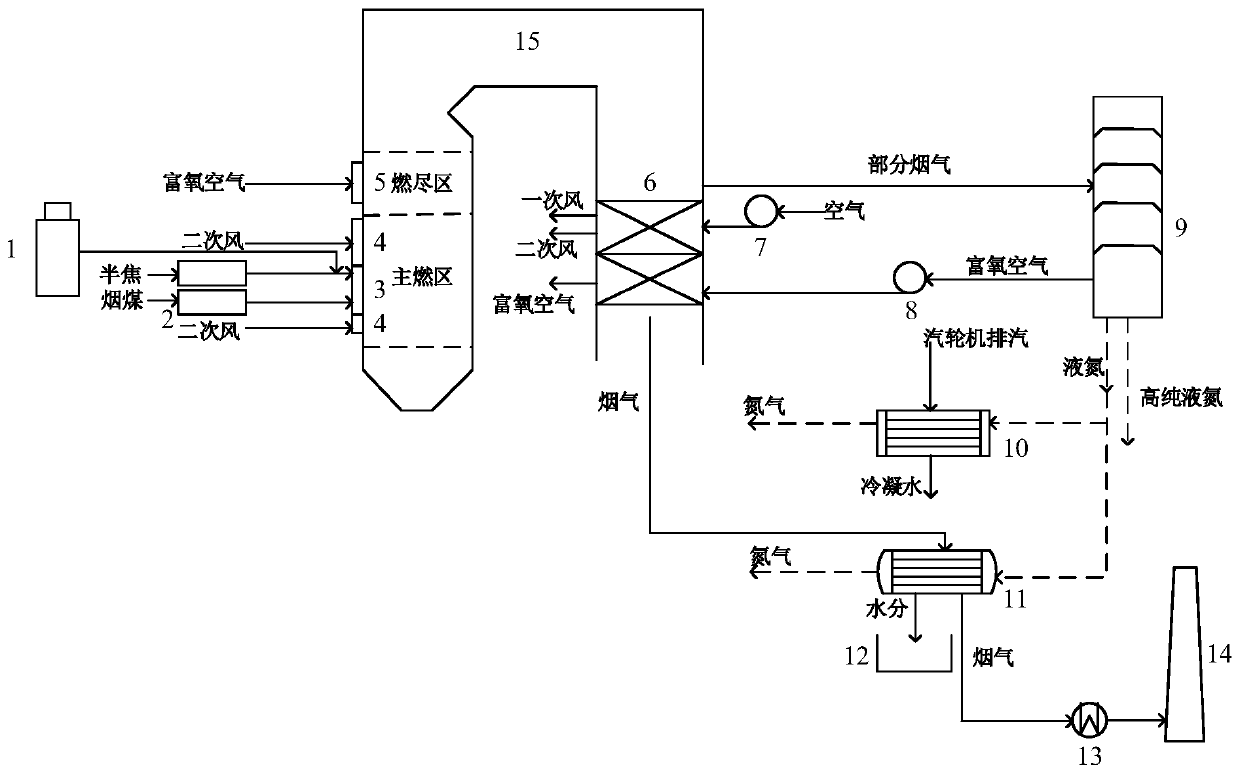

[0037] The present invention is described in further detail below in conjunction with accompanying drawing:

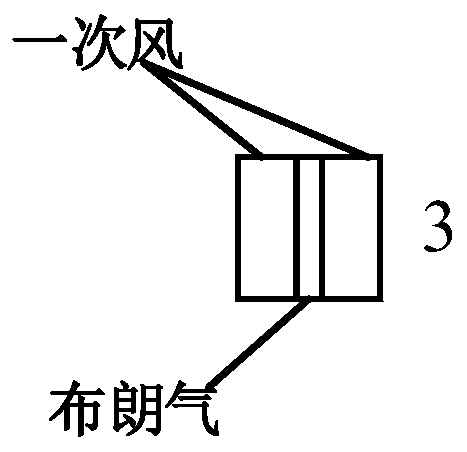

[0038] see figure 1 and figure 2 , a Brownian gas catalytic combustion-supporting coal-fired power station system for blending semi-coke provided by the present invention, comprising a Brownian gas generator 1, a coal mill 2, a primary air nozzle 3, a secondary air nozzle 4, and an overburned air nozzle 5 , air preheater 6, fan 7, pressurized conveying equipment 8, cryogenic air separation nitrogen generator 9, condenser 10, flue gas condenser 11, water collector 12, flue gas reheater 13, chimney 14 And the boiler body 15, and the main combustion zone and the burnout zone of the boiler arranged from bottom to top.

[0039] Among them, the primary air nozzle 3 and the secondary air nozzle 4 are respectively arranged in the main combustion zone of the boiler, the burnout air nozzle 5 is arranged in the boiler burnout zone, and the air preheater 6 is arranged in the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com