The method of adjusting the cross-sectional area of the nozzle to keep the wind speed constant

A cross-sectional area and nozzle technology, which is applied in the field of power plant boilers and boilers, can solve the problems of different loads, large ash content, low calorific value of thermal coal chemical coal, etc., and achieve the effect of increasing contact opportunities, good combustion state, and ensuring combustion state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

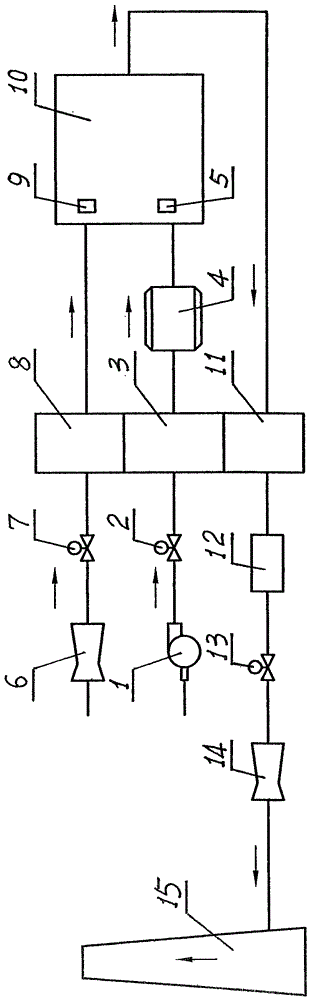

[0069] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0070] A device for adjusting the cross-sectional area of the nozzle to ensure constant wind speed, which consists of primary fan 1, A valve 2, preheater A3, coal mill 4, burner A5, secondary fan 6, B valve 7, preheater B8, Composed of burner B9, furnace 10, preheater C11, dust collector 12, C valve 13, fan 14, and chimney 15;

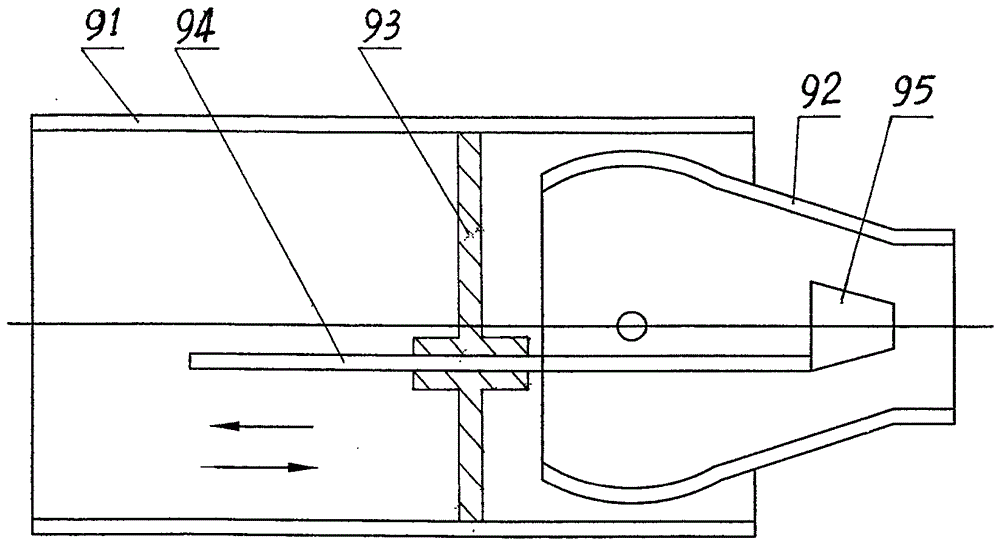

[0071] The burner B9 is selected from a blunt telescopic burner, a swing burner with an upper and lower nozzle, and a swing burner with blades;

[0072] The blunt telescopic burner is composed of a frame body 91, a spout 92, a support 93, a pull rod 94, and a blunt body 95;

[0073] The upper and lower spout swing type burner consists of an outer frame 901, an upper spout 902, a lower spout 903, a rotating shaft 904, an upper shaft 905, a lower shaft 906, an upper pull block 907, a pull block 908, an...

specific Embodiment approach 2

[0093] Carry out according to specific embodiment one, just: described primary fan 1, A valve 2, preheater A3, coal mill 4, burner A5 are fixedly connected by pipeline and secondary fan 6, B valve 7, preheater B8, burner B9 is fixedly connected by pipelines, replaced by secondary air blower 6, B valve 7, preheater B8, after the said preheater B8 is paralleled with burner B9 and coal mill 4 and behind coal mill 4 All burners A5 are fixedly connected by pipes. The expected good effect was also obtained.

specific Embodiment approach 3

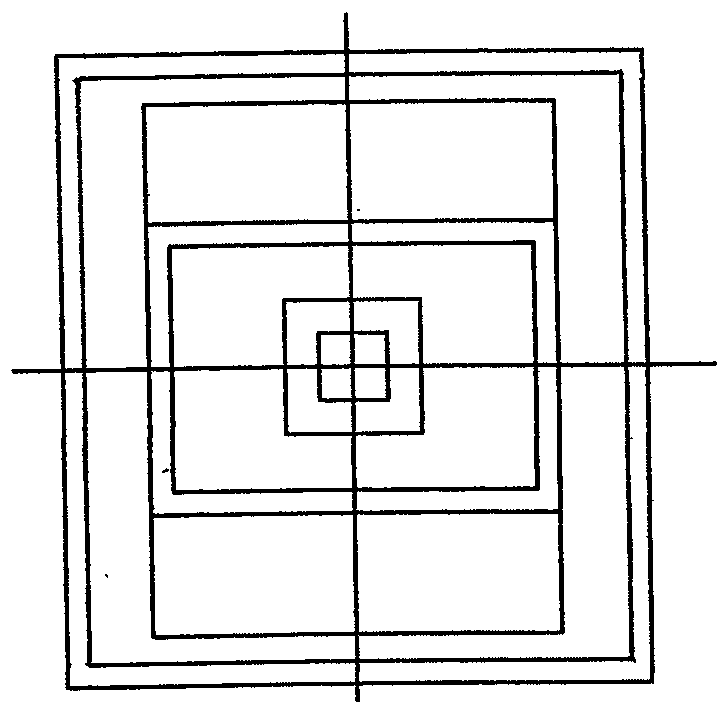

[0095] Carry out by specific implementation mode one, just: just as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the blunt telescopic burner has been implemented, the frame 91 and the spout 92, the frame 91 and the support 93, one end of the pull rod 94 and the blunt body 95 are all fixedly connected and the support 93 and the pull rod 94 slide left and right live connection; also obtained the expected good results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com