Patents

Literature

30results about How to "Reduce surplus factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-nitrogen burner

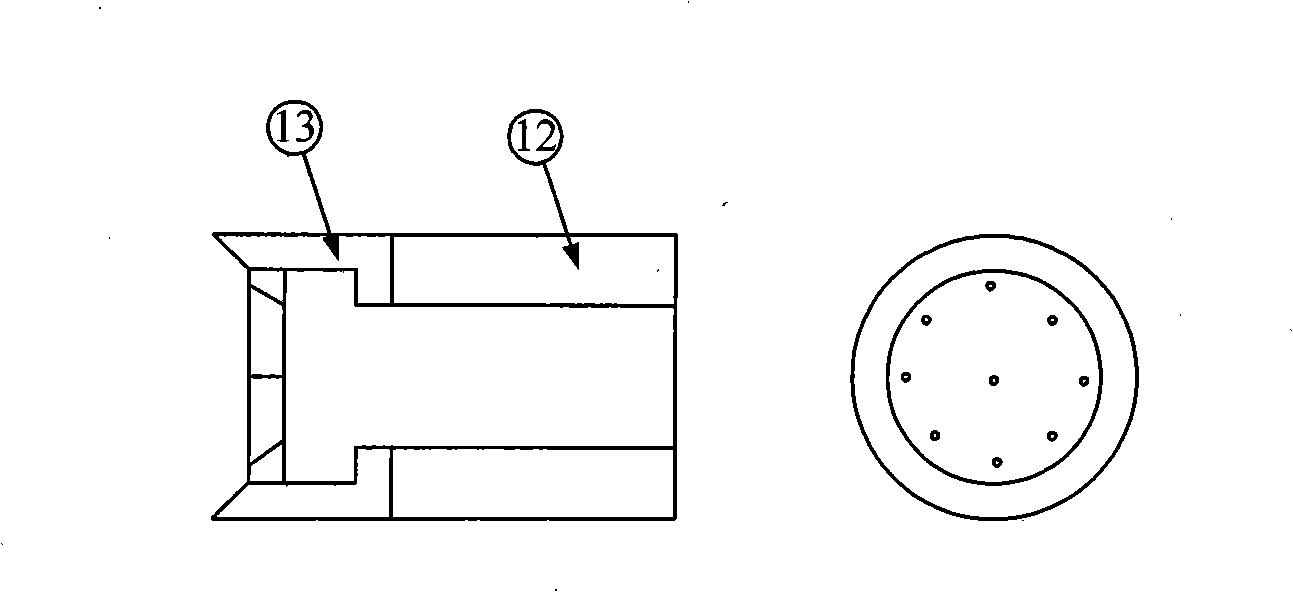

The invention discloses a low-nitrogen burner. According to the technical scheme, the low-nitrogen burner is characterized in that a mixer of the low-nitrogen burner comprises a barrel and a gas inlet, wherein an inner barrel and burning-supporting air swirling pieces arranged on the inner wall of the inner barrel are arranged at the gas inlet front end inside the barrel; an air inlet barrel located on the back side of the burning-supporting air swirling pieces in the air inlet direction is arranged at one end, close to the gas inlet back side, of the inner barrel; the air inlet barrel, the inner barrel and the inner wall of the barrel are connected in a sealed manner to form a gas sub-cavity; inclined flow guiding holes are formed in the air inlet barrel; a primary swirling impeller is arranged in the position, located on the air inlet back side of the inner barrel, inside the barrel; and the primary swirling impeller and the air inlet barrel form a primary mixing chamber. Through the arrangement, gas is ejected via the gas sub-cavity from the inclined flow guiding holes, the ejected gas can form multiple single, short and powerful gas flows, air flows sent by a fan pass through the burning-supporting air swirling pieces to form short and powerful rotating air flows, and the rotating air flows are circular and impact the multiple single gas flows, so that the air and the gas of the primary mixed gas reach the air-fuel ratio in the complete burning theory.

Owner:BEIJING SHENKEBOSI THERMAL ENERGY ENG TECH CO LTD

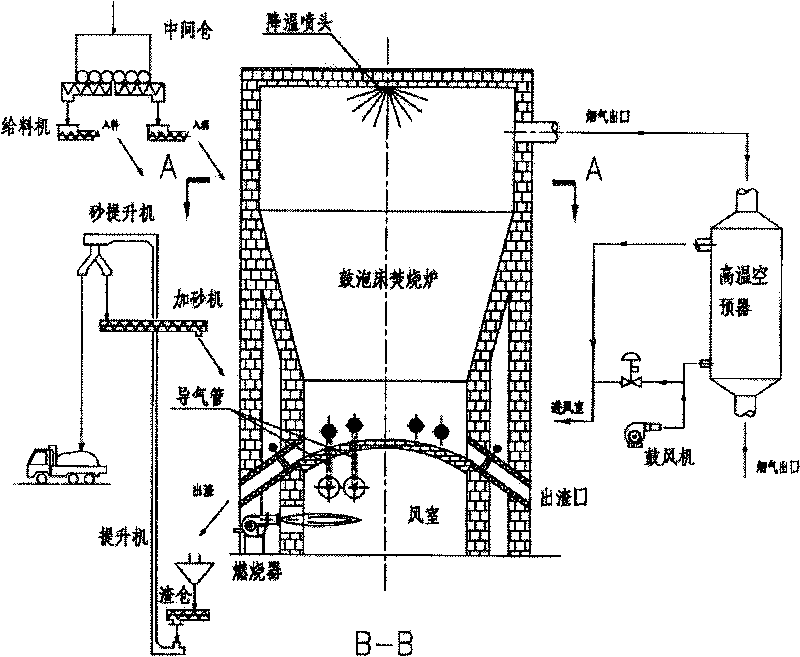

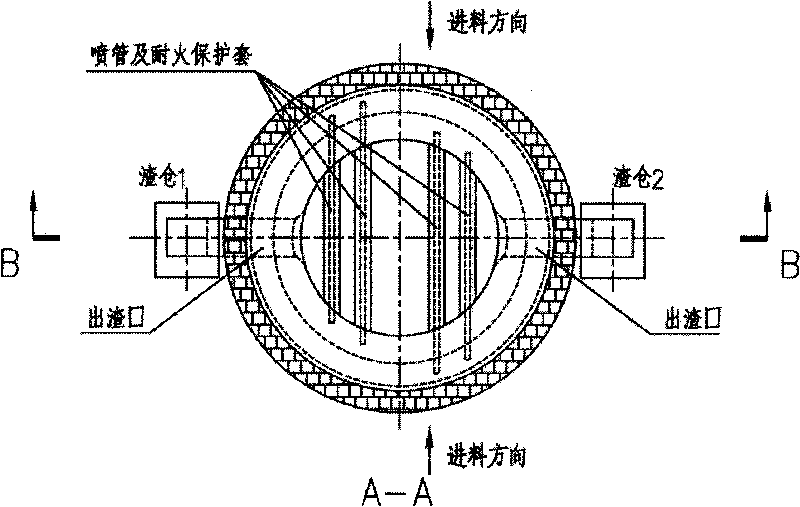

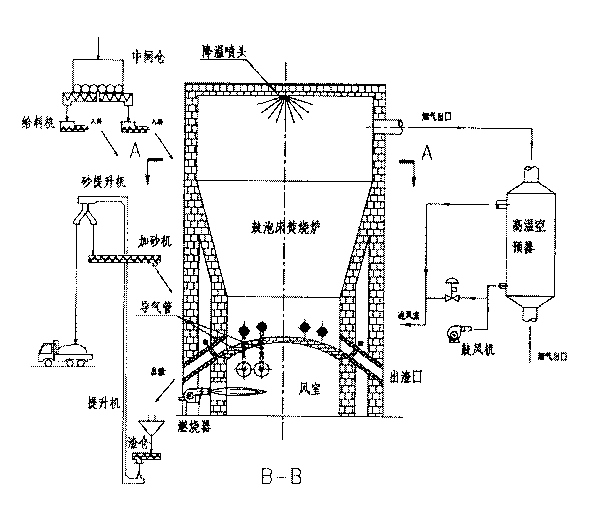

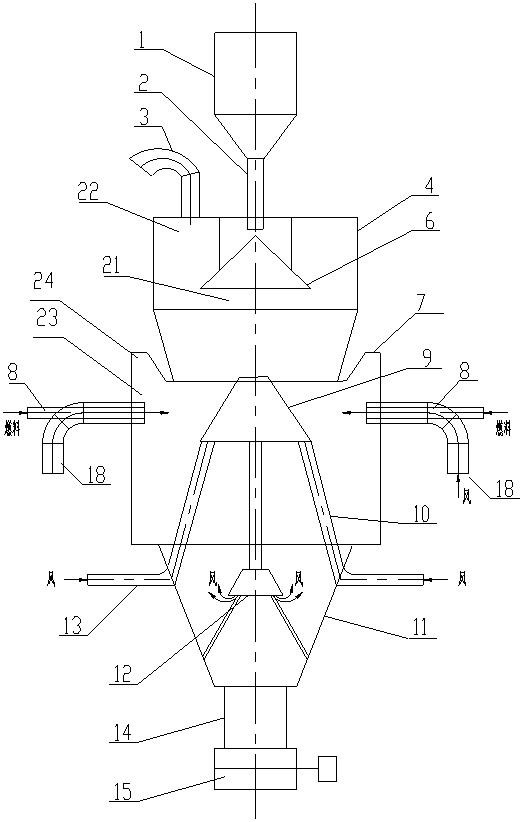

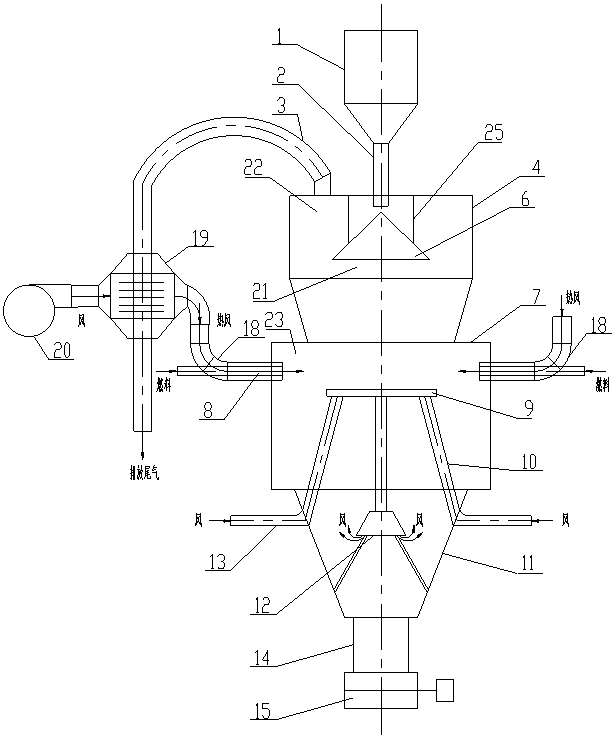

Sludge incinerator with no auxiliary fuel

InactiveCN101713543AIncineration stableMass transfer speedSludge treatment by oxidationByproduct vaporizationAir preheaterFailure rate

The invention relates to the field of environmental engineering, in particular to sludge incineration technology. The sludge incinerator with no auxiliary fuel overcomes the disadvantage that sludge incineration in the prior art requires the auxiliary fuel such as coal. The sludge incinerator with no auxiliary fuel mainly comprises a boiling section, a suspension chamber, a spray pipe, a gas-guide pipe, a support arch, a slag outlet, a cooling spray nozzle, a combustor, an air chamber and a high-temperature air pre-heater, a slag cabin, a sand hoisting machine, a sand feeder, a middle cabin and a feeding machine. The sludge incinerator with no auxiliary fuel has the following advantages that: the incinerator adopting the technology can realize stable incineration of the sludge under the condition of not adding the coal so as to achieve innocent treatment of the sludge; the sludge incinerator using the technology can store a large amount of heat inside, and a bed has a uniform reaction temperature, so that partial overheat phenomenon is prevented and the temperature in the bed is easy to be controlled; the sludge incinerator is also safe for treating sludge containing a lot of volatile substances (such as oil-containing sludge); a fluidized bed has a simple structure, a low failure rate and a low construction cost, and is provided with a mechanical transmission component; the sludge incinerator can lower the coefficient of excess air and can reduce power consumption; the sludge incinerator has wide fuel adaptability so as to realize controlling harmful gases, such as SO2, NOx and the like easily and to obtain higher combustion efficiency; and ash produced by sludge incineration has a plurality of applications.

Owner:刘沪滨

Oxygen-enriched combustion process for improving cement kiln clinker calcining temperature and apparatus thereof

InactiveCN101407381AQuality assuranceRaise the ignition temperatureTemperature resistanceCement kiln

The invention relates to an oxygen-enriched combustion technical method for improving heating power of a cement kiln and a device thereof. During the process of cement clinker calcination, the invention is characterized in that: 1) a pure oxygen (over 90 percent) feeding device is added at a coal dust combustion zone of the cement kiln so as to lead the combustion zone to form a local thermonuclear area, and with the gradual diffusion of high temperature at the thermonuclear area, the heating power of the whole cement kiln is further improved and stably controlled; and 2) an oxygen feeding device is added at a combustion area of the cement kiln so as to improve and stably control the oxygen content in combustion air within the range of 21.8-33 percent at the combustion area. In a coal supplying system and an air supplying system of the cement kiln, an oxygen-enriched combustion system is formed by arranging at least one high temperature resistance oxygen jet, a pipeline for transmitting oxygen, an oxygen generation device, an oxygen supply-quantity regulating device, a DCS control device and the like inside each independent combustion area of the cement kiln. The invention has the advantages of improving combustion efficiency of faulty coal and the heating power of the cement kiln, and stabilizing thermal regulation of the kiln so as to enhance the quality of the cement and prolong the service life of various heating equipment of the cement kiln.

Owner:昆明阳光基业股份有限公司

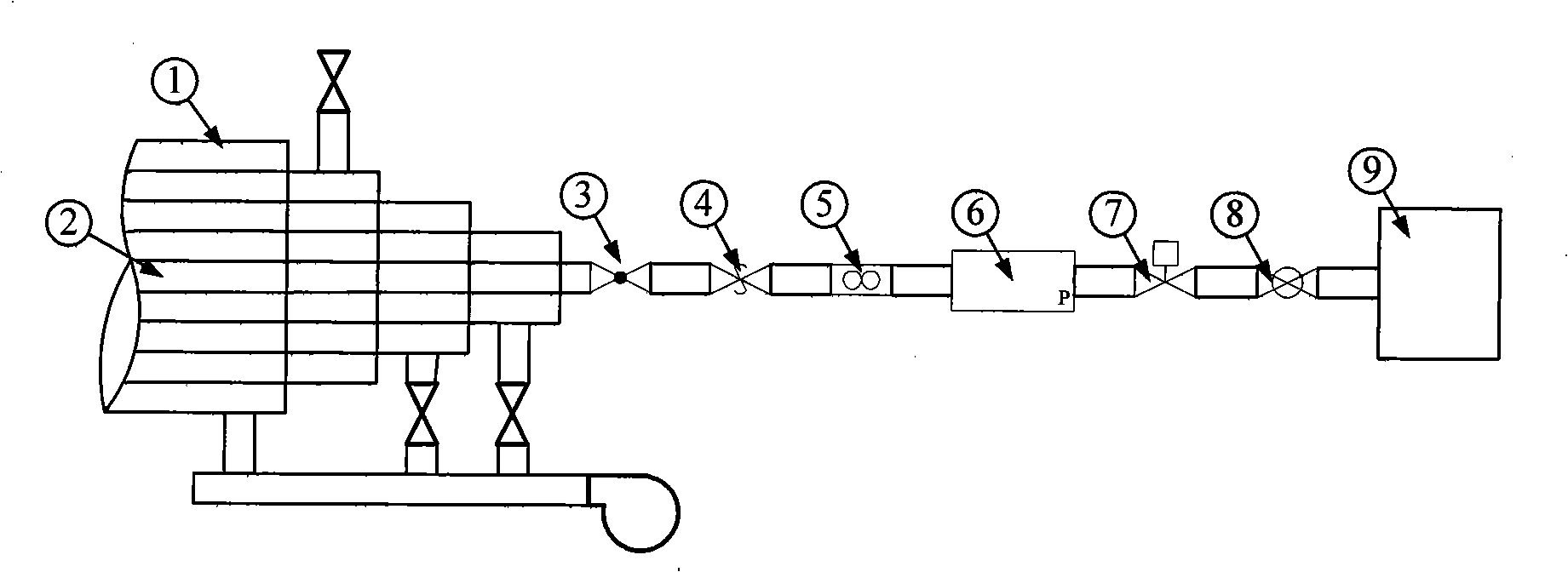

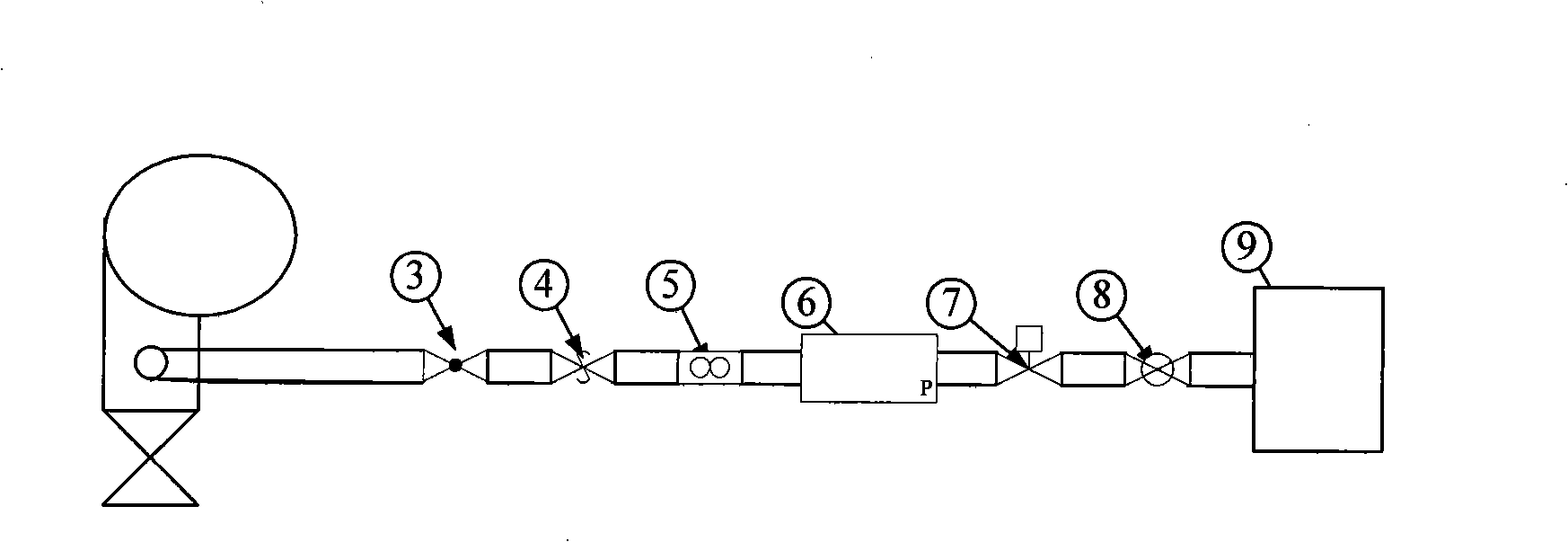

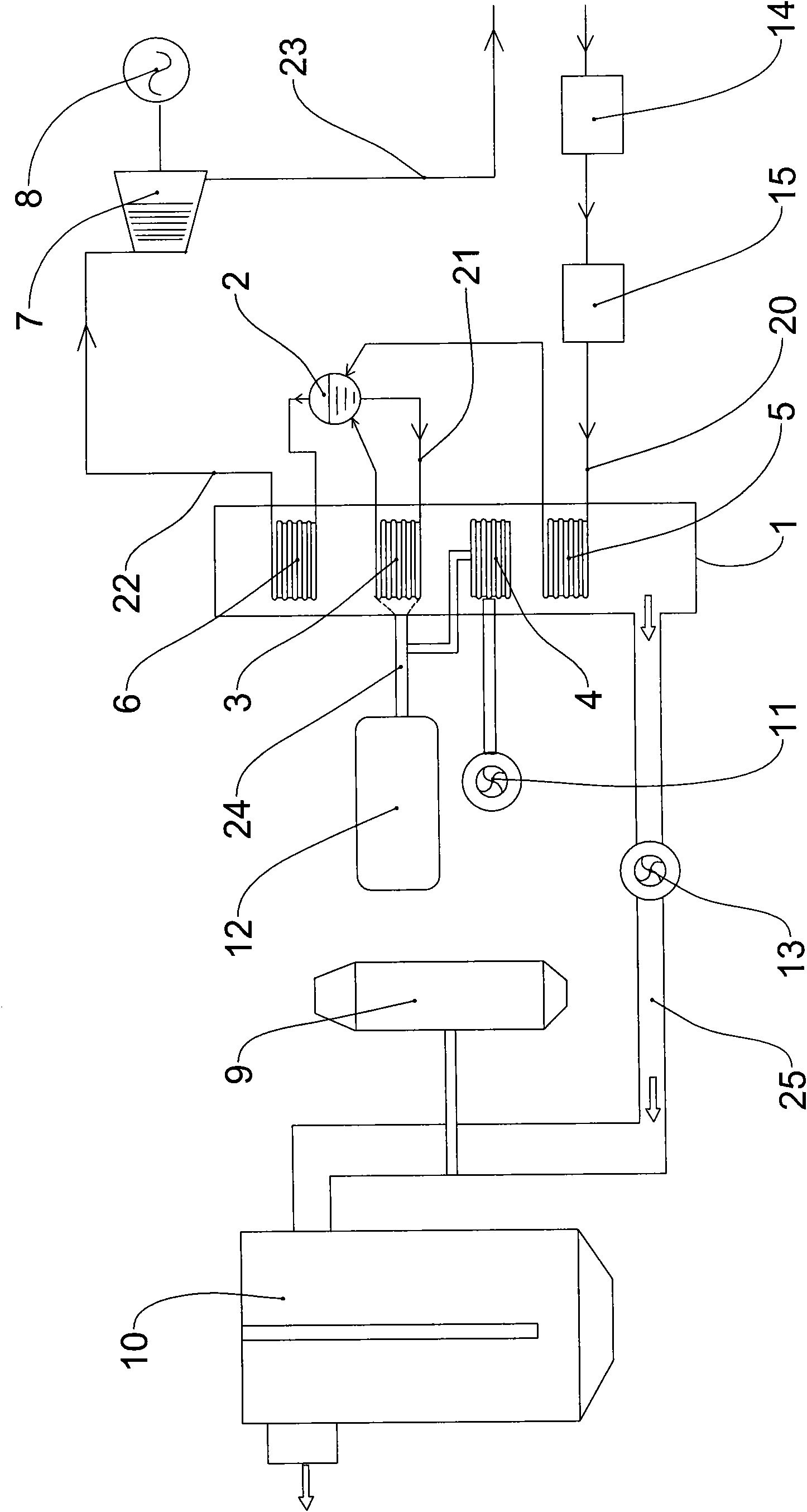

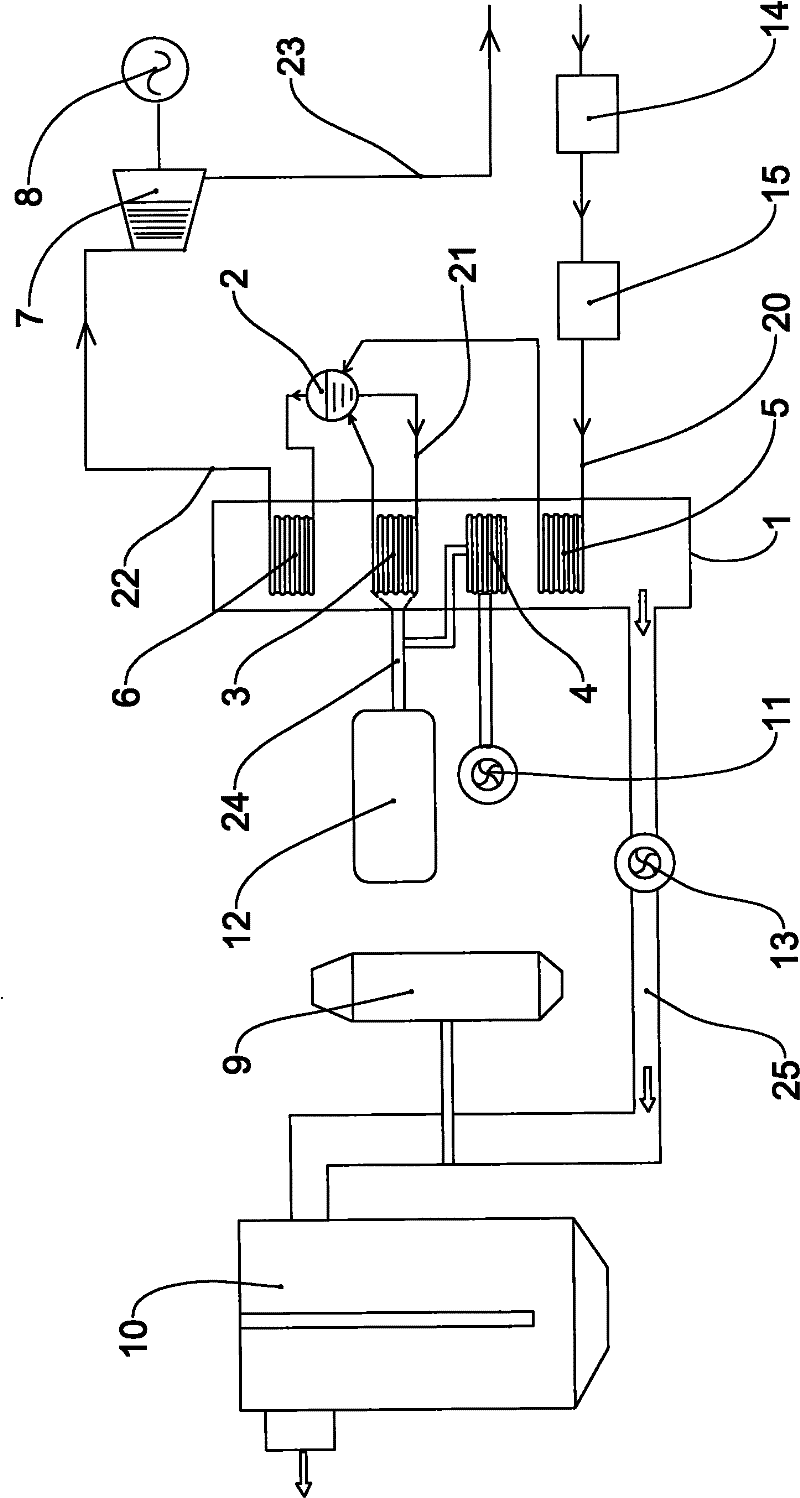

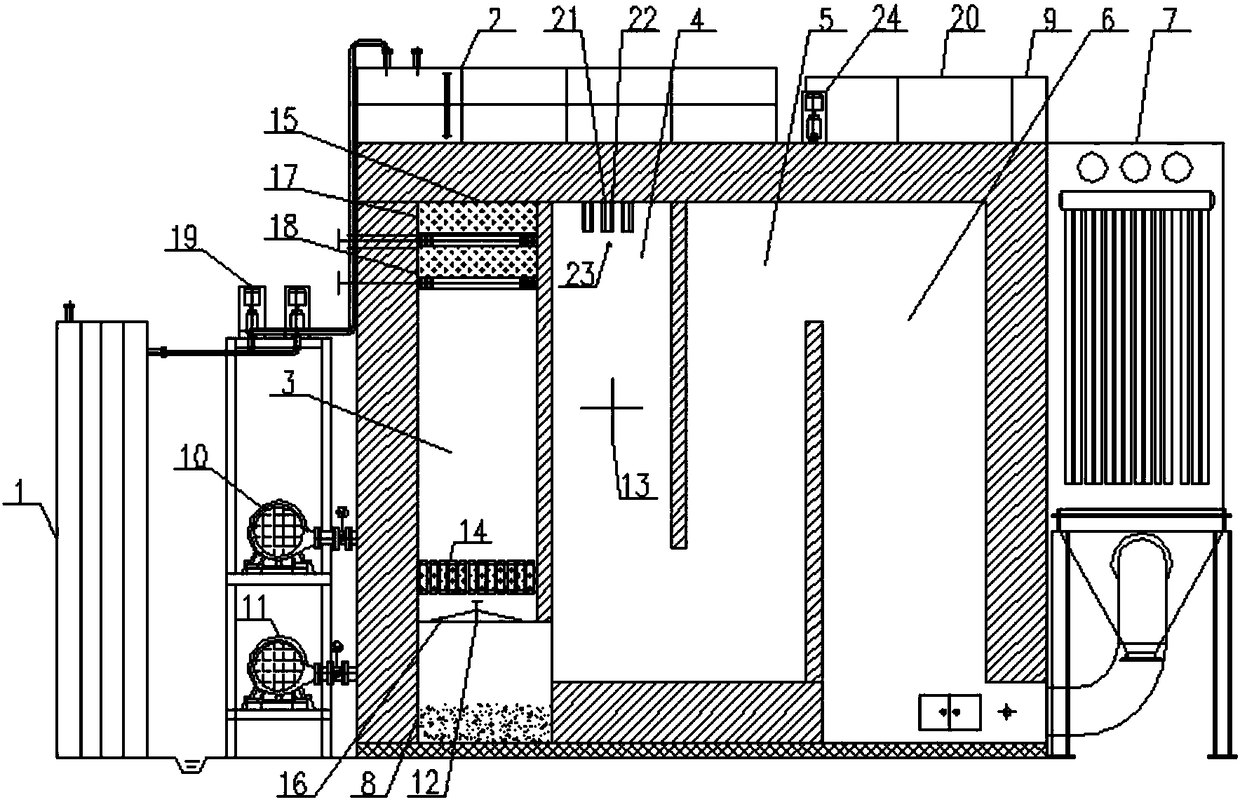

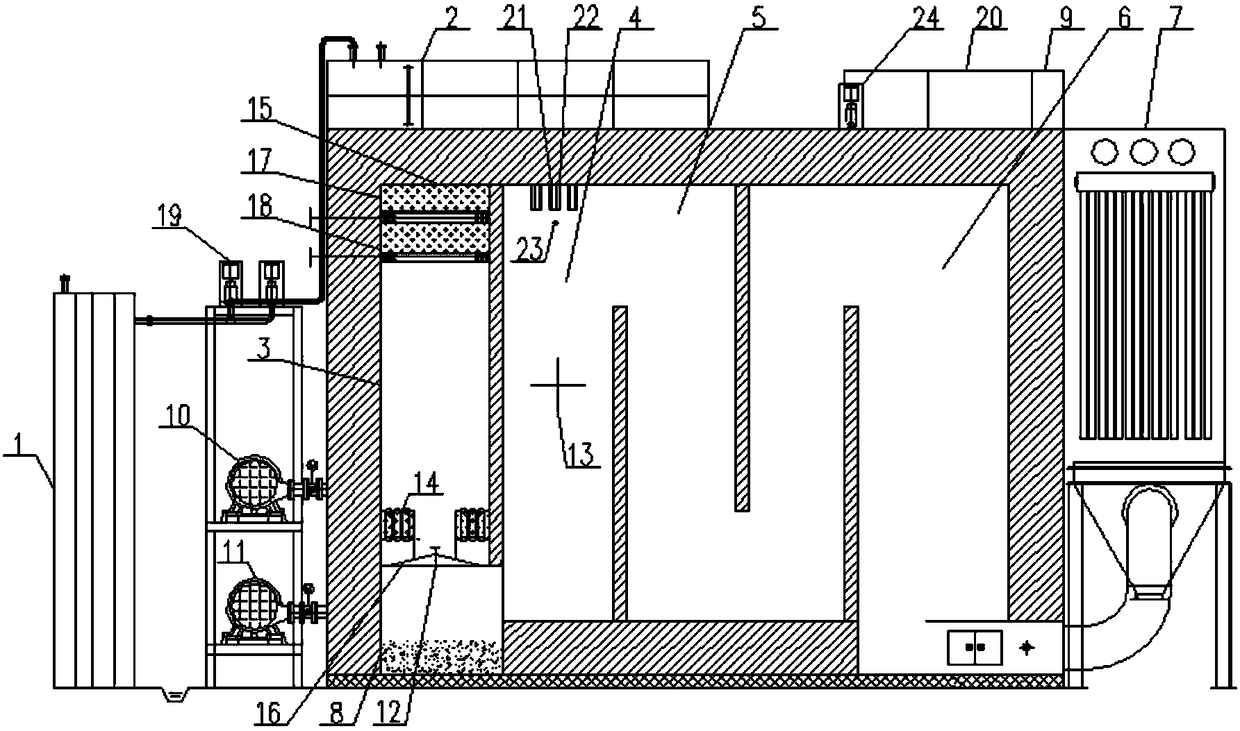

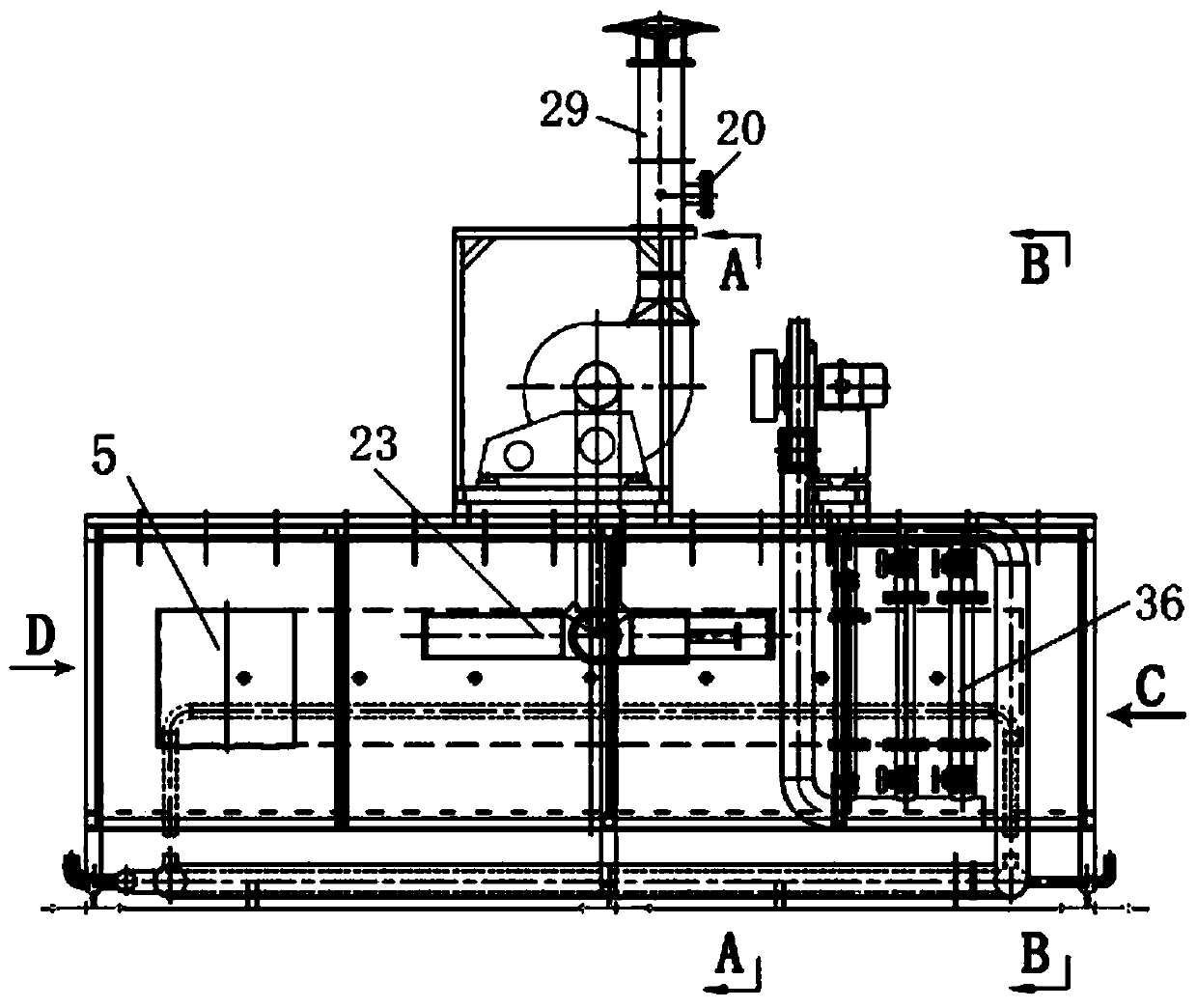

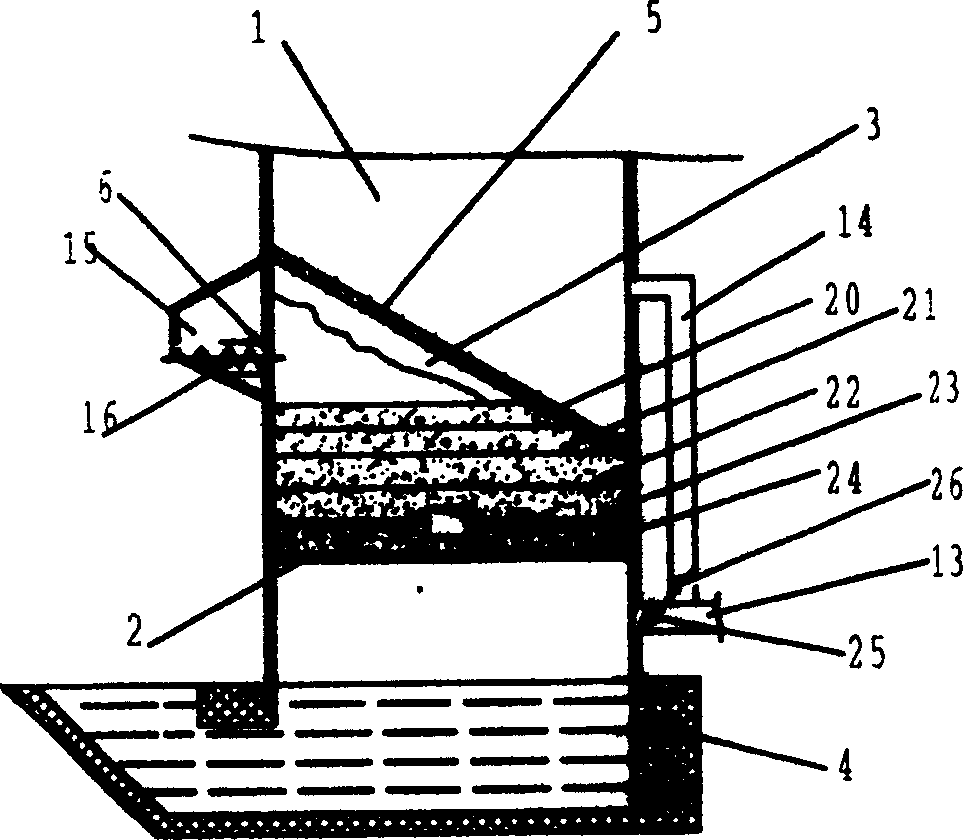

Integrated low-carbon micro-discharge energy-saving and emission-reduction boiler system

ActiveCN101986025AObvious superiorityLower discharge temperatureSteam generation plantsIndirect carbon-dioxide mitigationCombustionEngineering

The invention discloses an integrated low-carbon micro-discharge energy-saving and emission-reduction boiler system. The system comprises a boiler body (1), a steam drum (2), a heat exchanger (3), a preheater (4), an economizer (5), a superheater (6), a steam turbine (7), a generator (8), a secondary smoke combustion device (9), a desulfuration and dust collect unit (10), an air blower (11) and a smoke exhauster (13), wherein the steam drum (2) and the heat exchanger (3) constitute a hot-water heating circulation loop, the economizer (5) is connected with the steam drum (2), and the air blower (11) feeds air to the preheater (4); the steam drum (2) is connected with the superheater (6), and then connected with the steam turbine (7) by a superheated steam pipe (22); the steam turbine (7) is connected with a low-pressure steam pipe (23), and the generator (8) is linked with the steam turbine (7); and the outlet of a gas duct of the boiler body (1) is connected with a smoke pipe (25), and the smoke exhauster (13) is arranged on the smoke pipe (25), and sequentially feeds smoke into the secondary smoke combustion device (9) and the desulfuration and dust collect unit (10) so as to process and discharge the smoke.

Owner:慧生能源科技有限公司

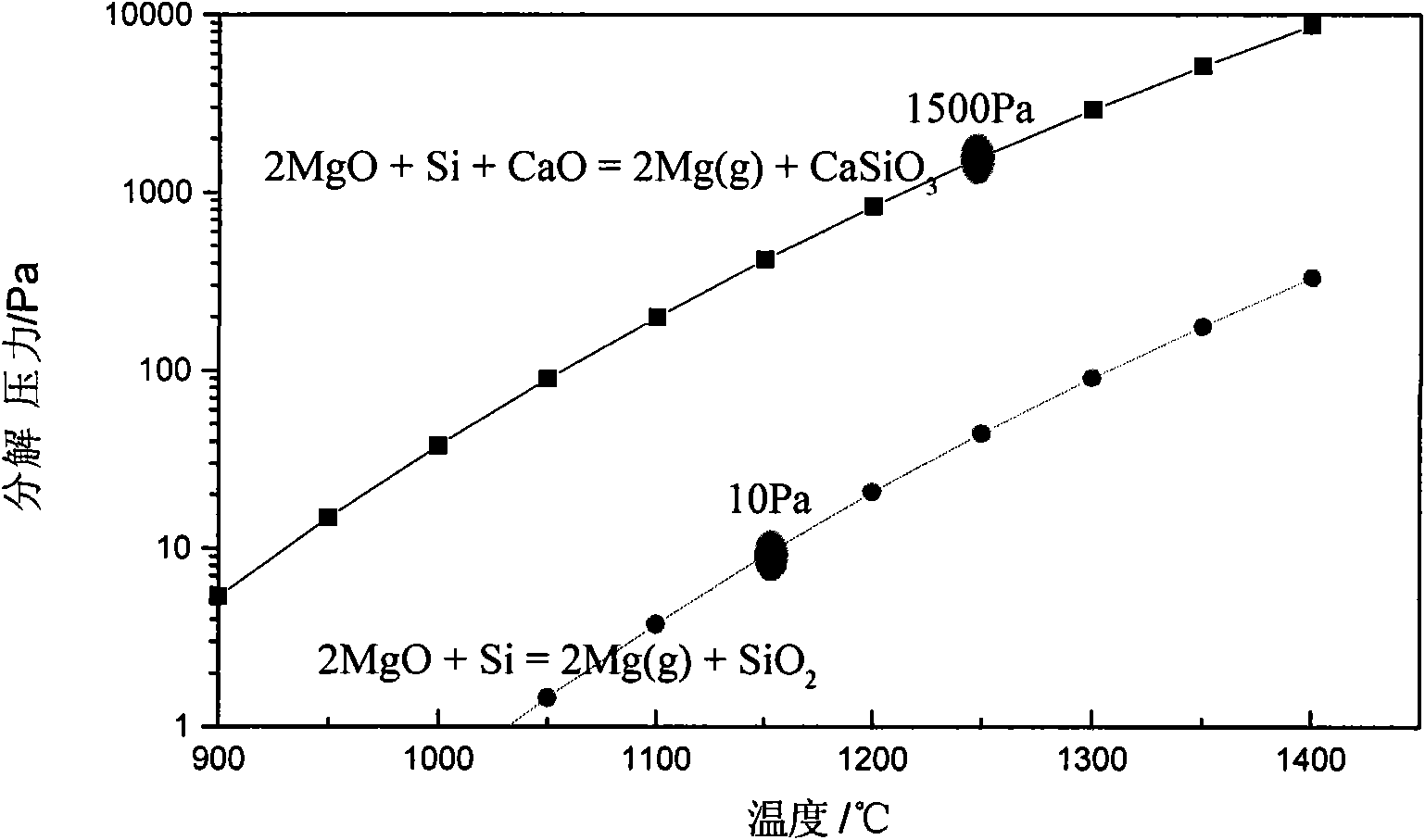

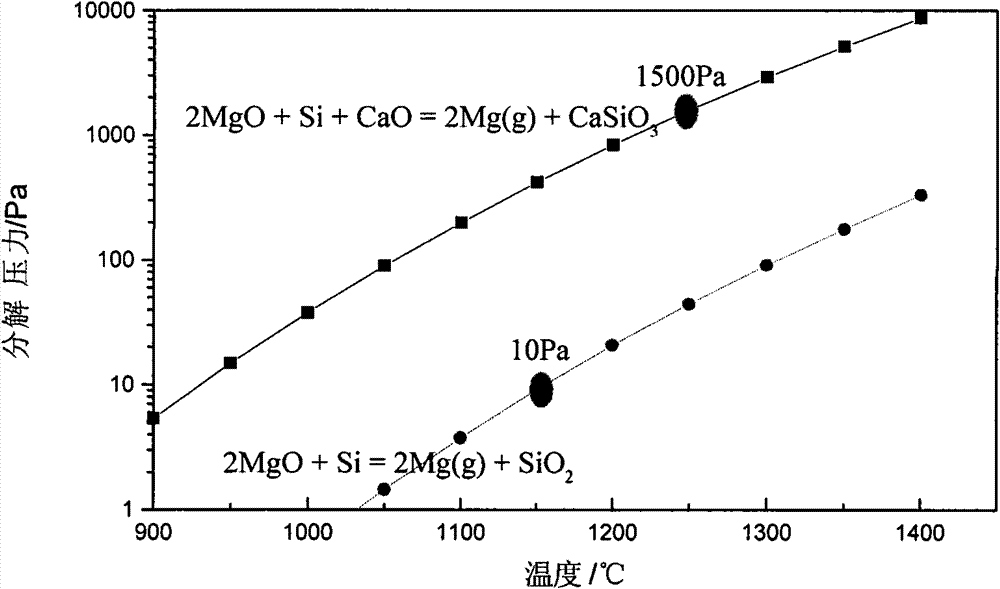

Method for smelting magnesium by decomposition in vacuum through microwaves

The invention relates to a method for smelting magnesium by decomposition in vacuum through microwaves, and belongs to the field of magnesium smelting. The method comprises the following steps: firstly, crushing raw materials of magnesia, lime and ferrosilicon, then evenly mixing the crushed materials according to the proportions, pressing into balls, carrying out microwave-heating in a microwavevacuum reactor to resolve the magnesia into gaseous magnesium, and condensing to obtain crude magnesium. The invention is characterized in that the technical parameters are as follows: the reaction temperature in the microwave vacuum reactor is 1250-1450 DEG C, and the vacuum degree is 20-1000 Pa; the proportion of the lime to the magnesia is 0.5:1-1.5:1, and the proportion of ferrosilicon to themagnesia is 0.44-0.65:1; and the heating time is 1-5 hours. Compared with the prior Pidgeon process for smelting magnesium, the invention has the characteristics of high efficiency, low energy consumption, low pollution, low production cost, low fixed investment and the like.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

Three-dimensional vortex burner

InactiveCN108662581AEasy to adjustAvoid damageNon-combustible gases/liquids supplyGaseous fuel burnerThermal energyNitrogen oxide

The invention relates to a three-dimensional vortex burner and belongs to the technical field of thermal power engineering. The three-dimensional vortex burner is primarily characterized by being provided with an air inlet and a coal gas inlet entering tangentially, a catenary convoluted rectifying room, a primary air nozzle and a secondary air nozzle which are arranged in layers and different indirection and a diversion trench reinforcing throat, so that air is supplied to form conical spiral vortexes to inject the coal gas to fit an extremely low coal gas pressure and staged burning and thick and light burning are achieved to reduce emission of nitric oxide. The three-dimensional vortex burner is full in burning and small in resistance loss, and is particularly suitable for various industrial kilns which are high in power, low in coal gas calorific value, low in coal gas pressure, great in pressure fluctuation and high in demand on emission of nitric oxide. Energy conservation and emission reduction are achieved.

Owner:姜凤山

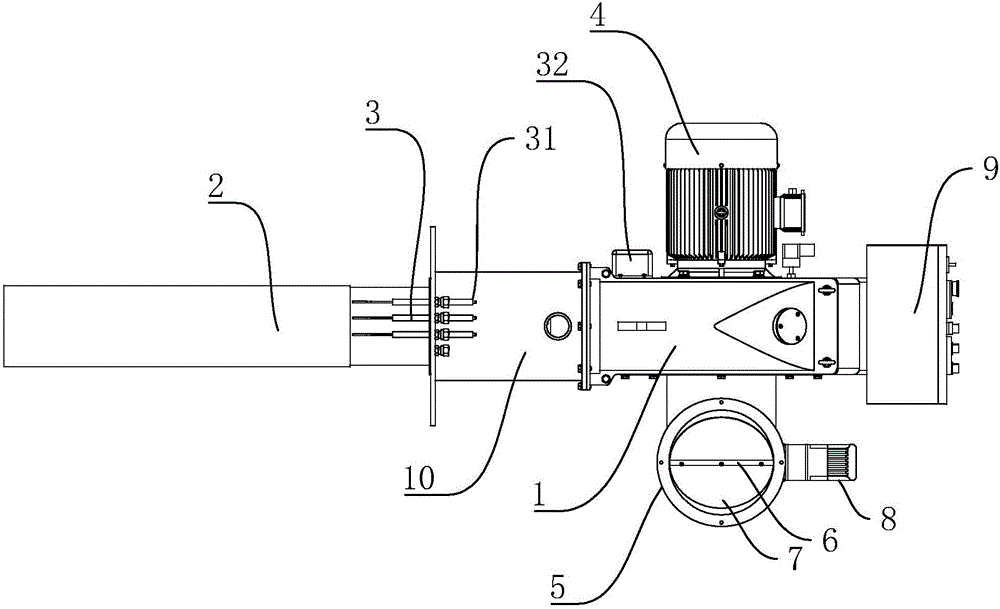

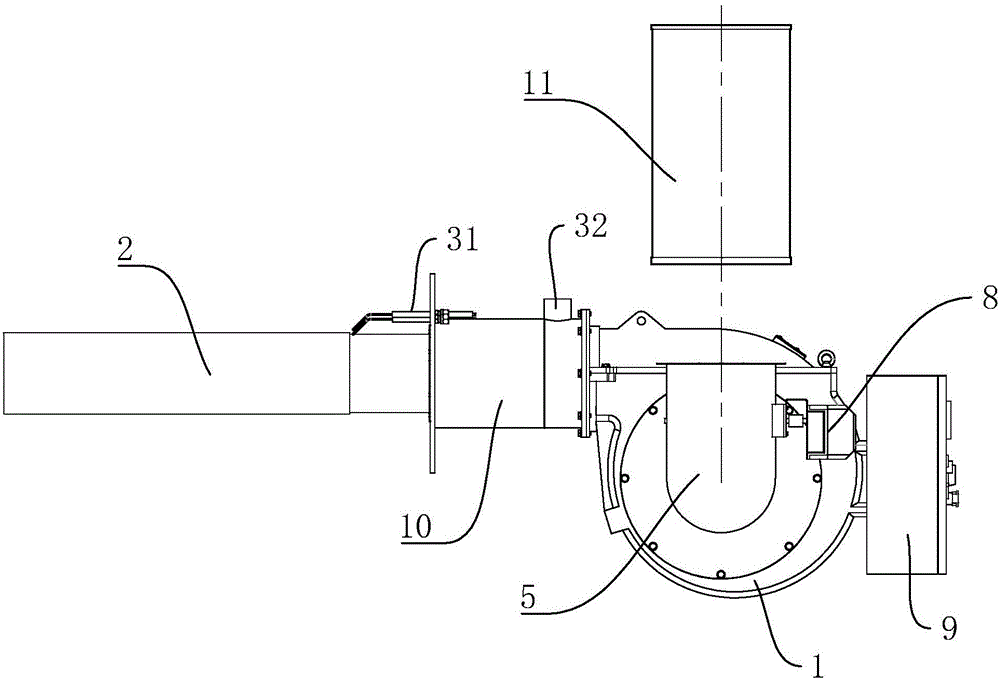

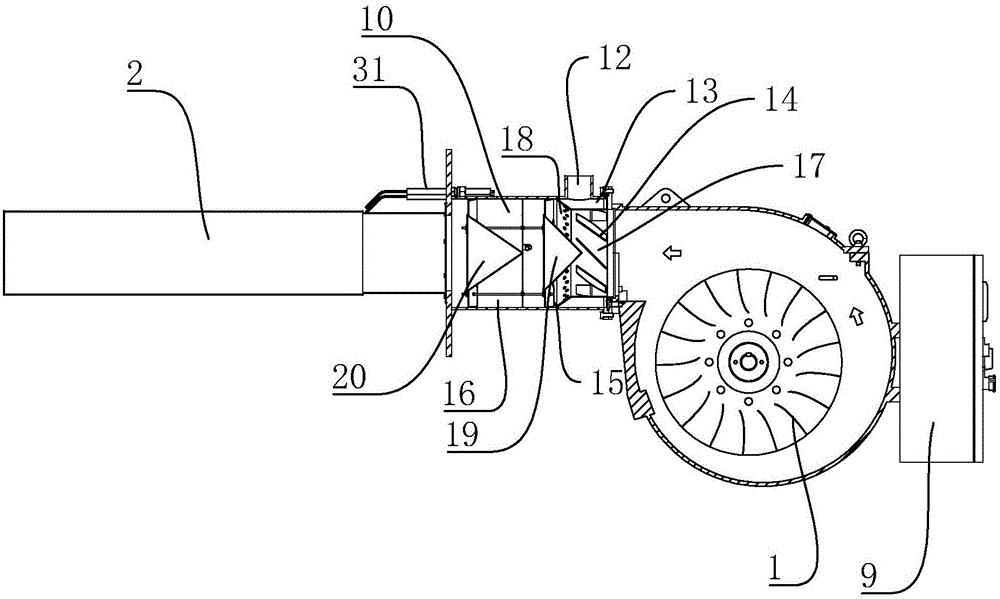

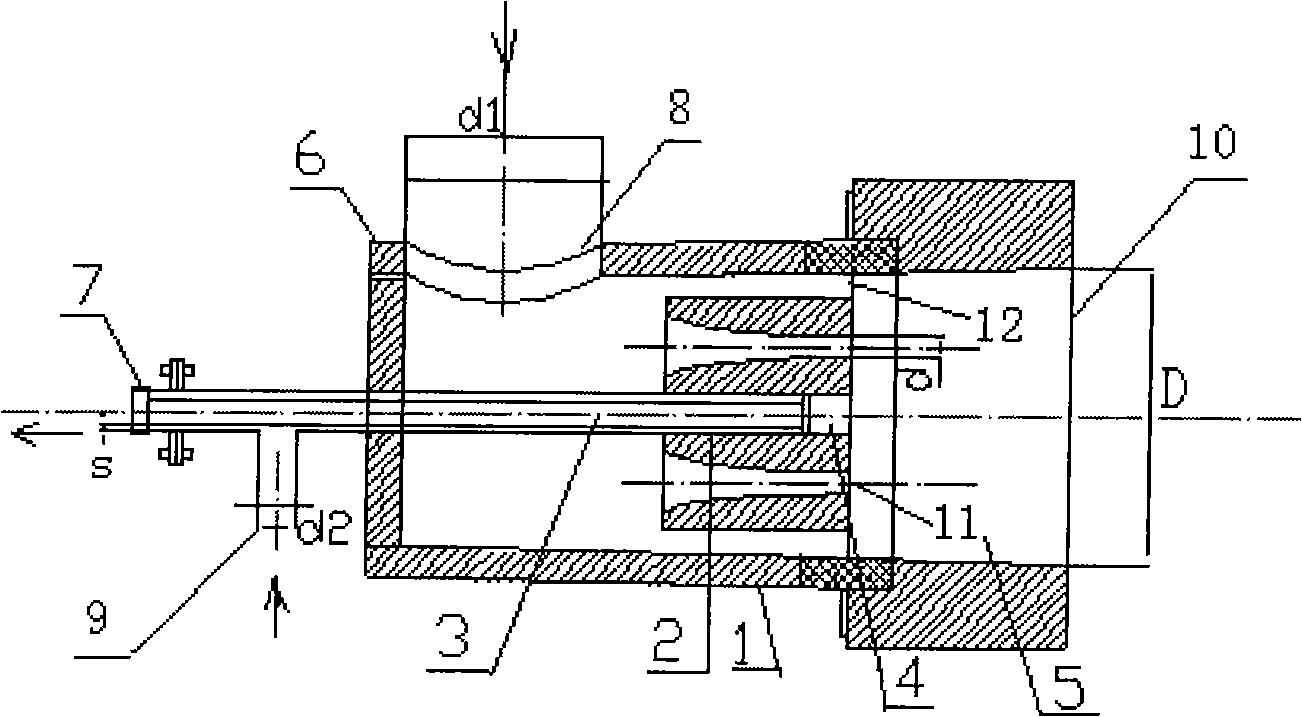

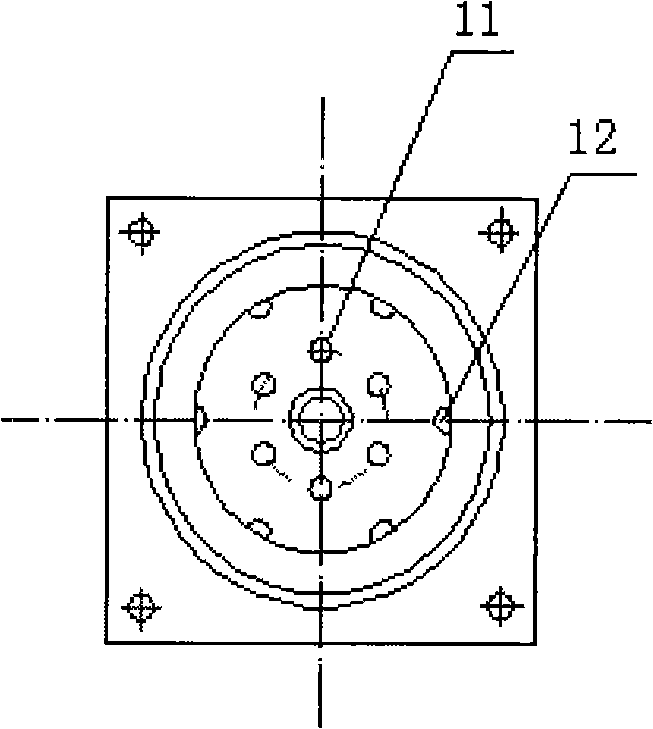

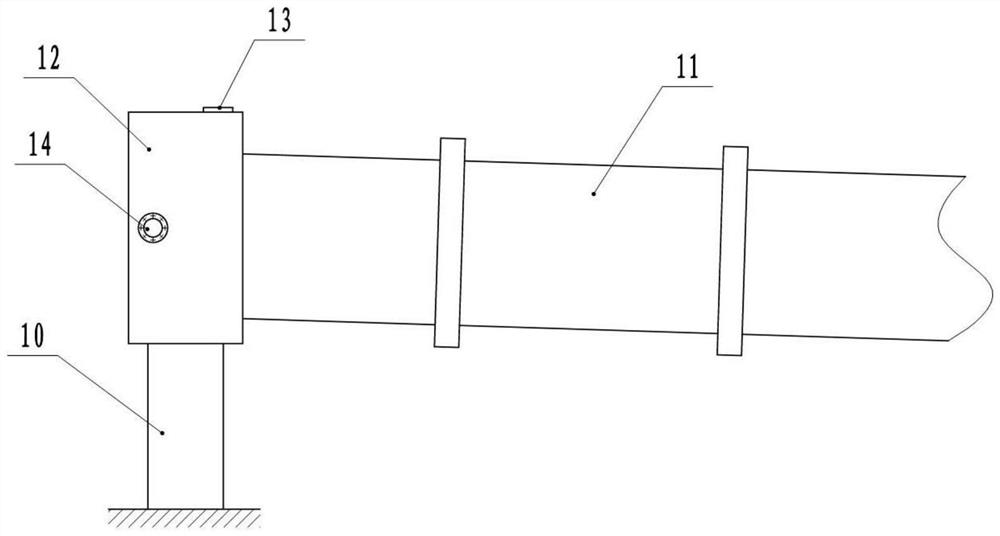

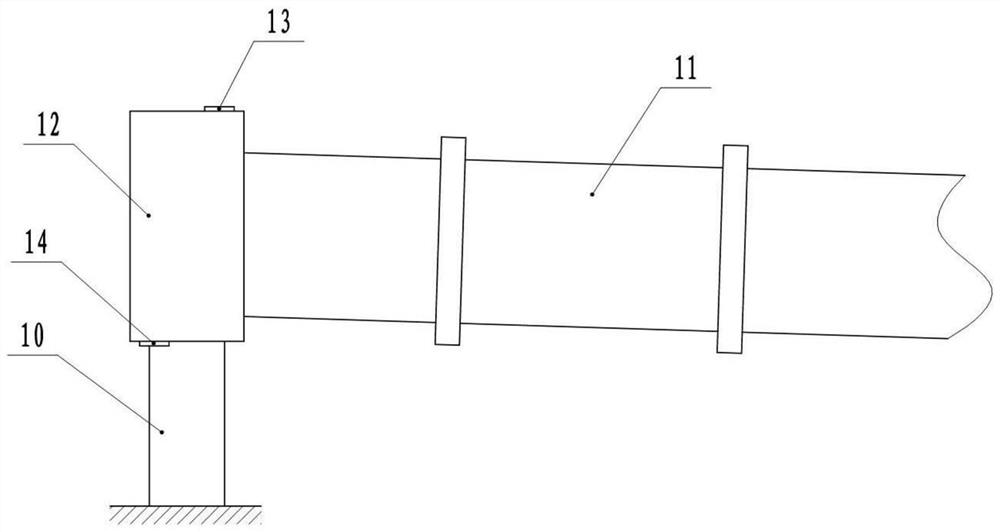

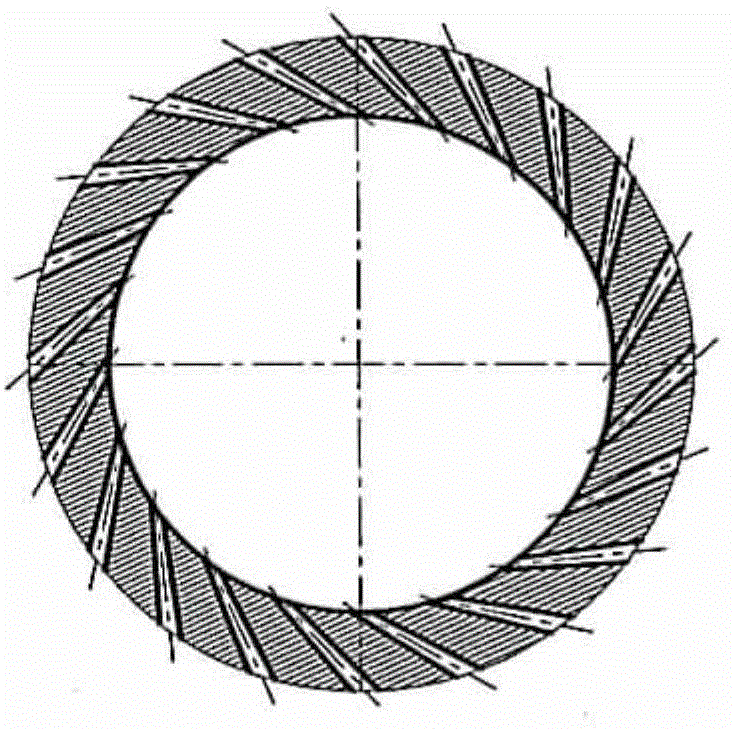

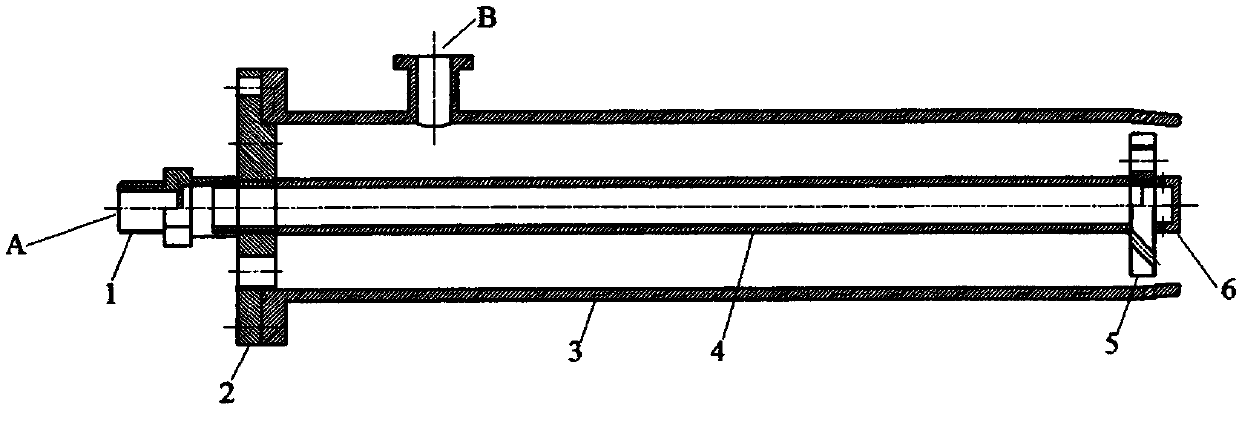

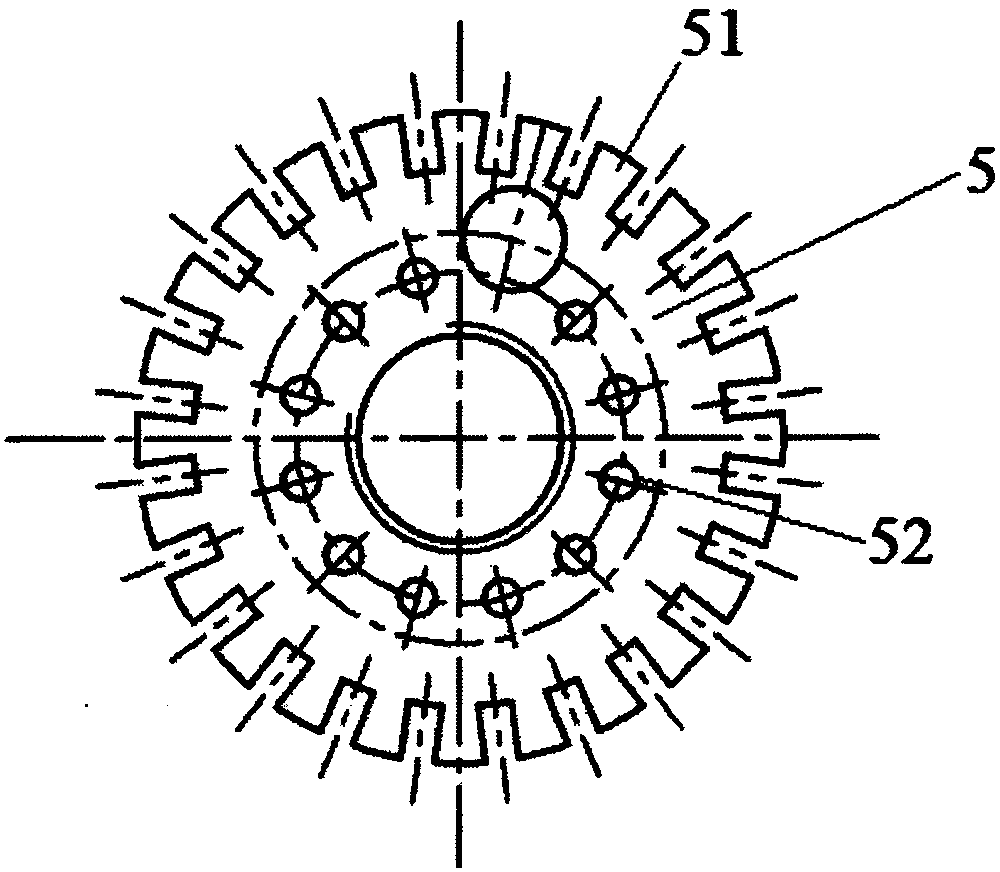

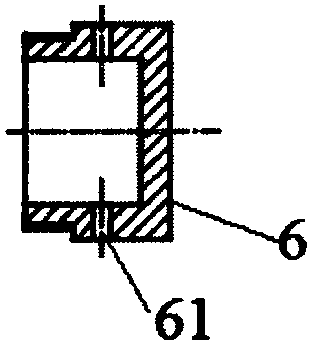

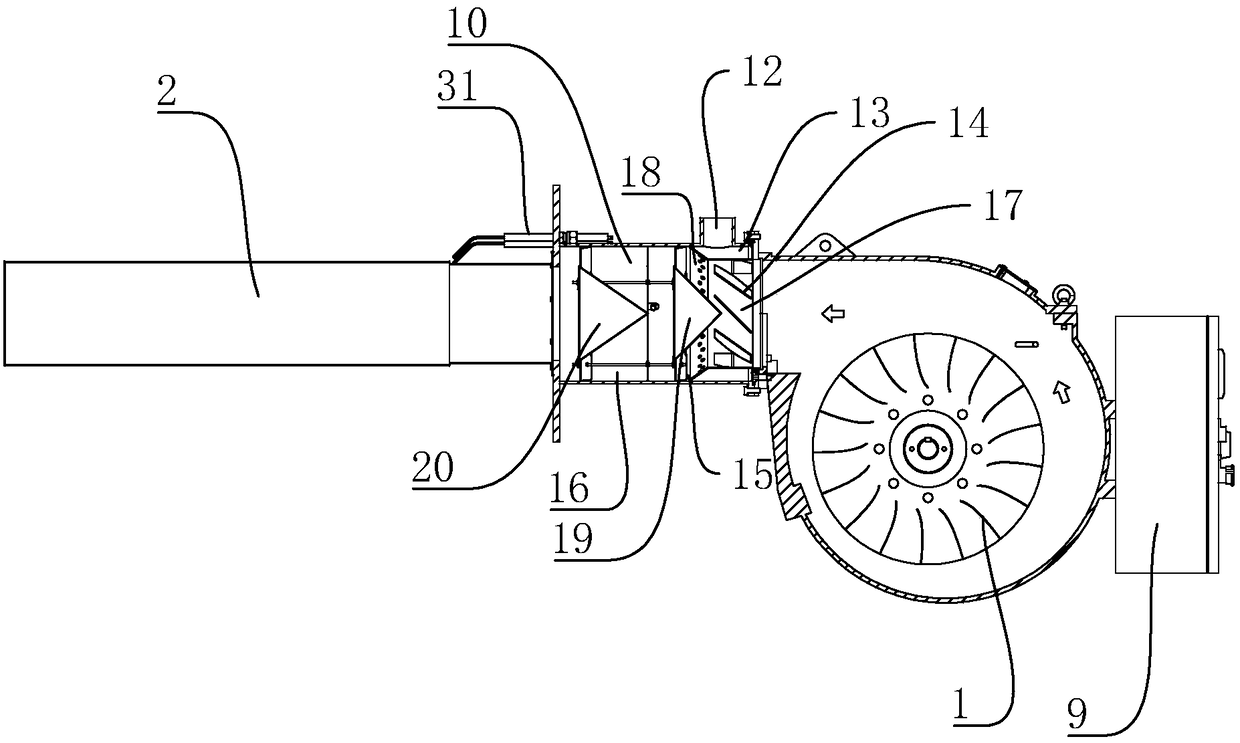

Axial rotational flow stepless regulation low-nitrogen combustor

ActiveCN106871116AAdapt to swirl intensityAdapt to requirementsPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationSet screwThermodynamics

The invention discloses an axial rotational flow stepless regulation low-nitrogen combustor in the field of combustors. The combustor comprises an oil gun, a center air pipe, a gas pipe, a coal air pipe and an axial flow air pipe which are arranged from inside to outside in a sleeved manner; a gas channel is formed between the gas pipe and the center air pipe, a rotational flow air adjusting mechanism is arranged in the gas channel and comprises a plurality of rotational flow air adjusting fan plates evenly arranged on the periphery of the center air pipe, the rotational flow air adjusting fan plates are mounted on the periphery of the center air pipe through positioning screws, and can swing around the positioning screws, the tails of the rotational flow air adjusting fan plates are connected to a rotational flow air adjusting ring through flexible shafts, the rotational flow air adjusting ring is rotatably arranged on the periphery of the center air pipe in a sleeving manner, and the tail of the rotational flow air adjusting ring is connected with a first adjusting rod used for controlling the rotational flow air adjusting ring to rotate. The rotational flow air outlet air speed adjusting and blade angular stepless adjusting are achieved, the combustor meets the requirements of different stations for the rotational flow strength and the rotational flow angle of the combustor, and the combustor can be used for work of combustion of various kinds of industrial furnaces.

Owner:江苏炬烽热能科技有限公司

Glass kiln natural gas oxygen-enriched combustor

InactiveCN101303124AIncrease profitReduce surplus factorIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorEngineering

The invention relates to a natural gas oxygen-enriched burner with a glass kiln. Based on the normal natural gas burner, by adopting oxygen enrichment technology, the original larger air port is changed to a relatively smaller oxygen-enriched air port according to the oxygen content of the oxygen-enriched air so as to heighten the temperature of flame, reduce air displacement after combustion, promote heat utilization ratio and lower excess air coefficient.

Owner:SHANGHAI INST OF TECH

Industrial calcination shaft kiln

PendingCN108088236AEqual temperatureEasy to achieve uniform temperature requirementsControl devices for furnacesVertical furnacesCombustionPulp and paper industry

The invention discloses an industrial calcination shaft kiln. According to the industrial calcination shaft kiln, gas, liquid or power are taken as fuel, the calcination temperature is more even, theproduct quality is better, energy conservation and environmental protection are achieved, the automation degree is high, and massive or granular or ball-shaped materials can be calcined. The industrial calcination shaft kiln comprises a cylinder body, a material adding device used for adding materials to the interior of the cylinder body and an exhaust device used for exhausting tail gas are arranged on the upper portion of the cylinder body; a combustion-supporting wind device used for sending combustion-supporting wind to the interior of the cylinder body and an unloading device used for discharging the material in the cylinder body are arranged on the lower portion of the cylinder body, at least a sudden-changed section is arranged at the position, between the material adding device andthe combustion-supporting wind device, of the cylinder body, the size of the part, on the upper portion of the sudden-changed section, of an inner cavity of the cylinder body is small in the horizontal direction, the size of the part, on the lower portion of the sudden-changed section, of the inner cavity of the cylinder body is large in the horizontal direction, and when the materials flow downwards in the cylinder body, a cavity which the materials cannot reach naturally is formed on the lower portion of the sudden-changed section; and an outlet of a combustion nozzle in a fuel combustion device communicates with the cavity, and materials are sprayed out from the combustion nozzle.

Owner:NANJING SUYE CALCIUM IND TECH

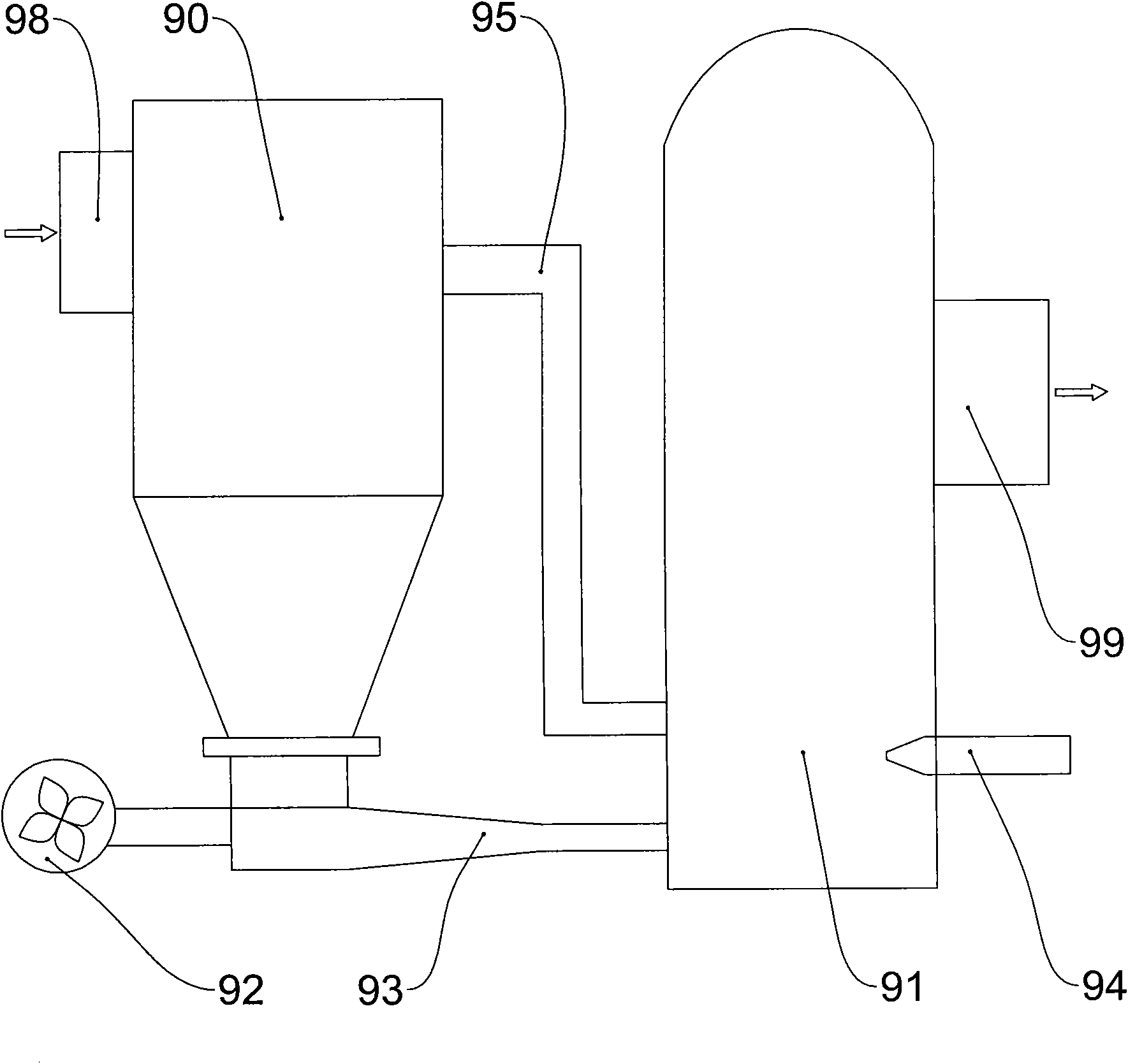

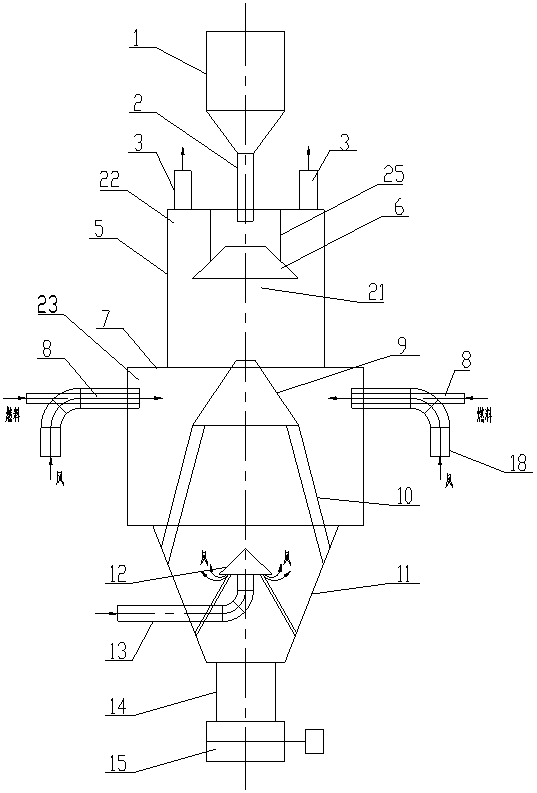

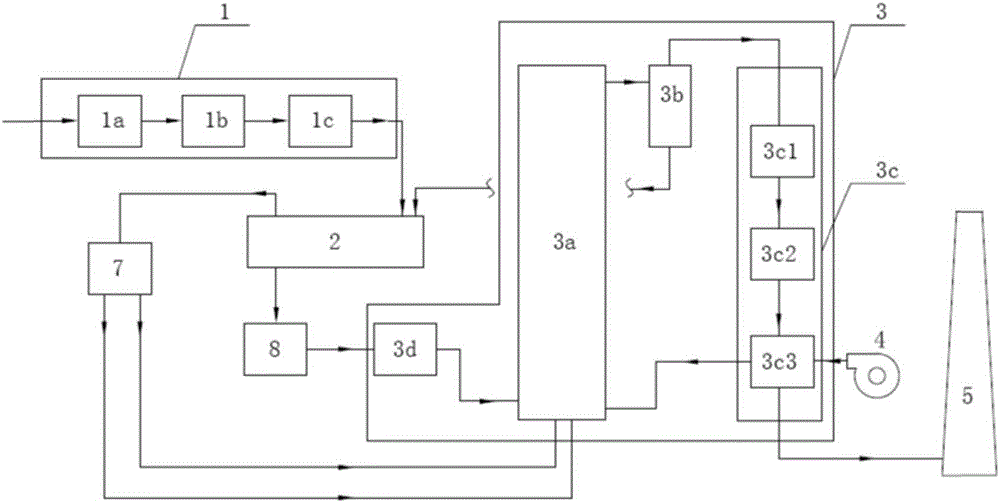

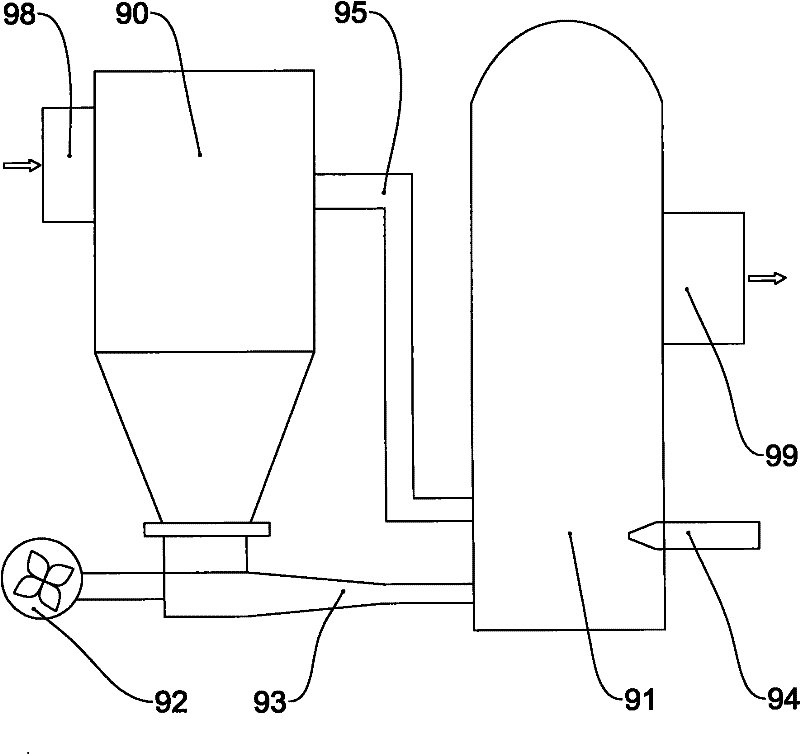

Anaerobic pyrolysis treatment system and method for garbage

The invention discloses an anaerobic pyrolysis treatment system for garbage. The Anaerobic pyrolysis treatment system comprises a pyrolysis device, a solid thermal carrier furnace, a purification device and an intermediate bunker, wherein a pretreatment unit comprises a separation unit, a crushing unit and a drying unit; the separation unit, the crushing unit and the drying unit are sequentially connected in series; the drying unit is connected with the pyrolysis device; the pyrolysis is connected with the purification device and the intermediate bunker respectively; the solid thermal carrier furnace comprises a hearth, a gas-solid separation device, a waste heat recycling unit and a return feeder; the waste heat recycling unit comprises an air preheater, an economizer and an over heater; the purification device is connected with the hearth of a combustion unit through two pipelines; the intermediate bunker is connected with the return feeder of the solid thermal carrier furnace; in the solid thermal carrier furnace, the return feeder is connected with the hearth; the hearth is connected with the gas-solid separation device; the gas-solid separation device is connected with the pyrolysis device and the waste heat recycling unit respectively; the waste heat recycling unit comprises the over heater, the economizer and the air preheater.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

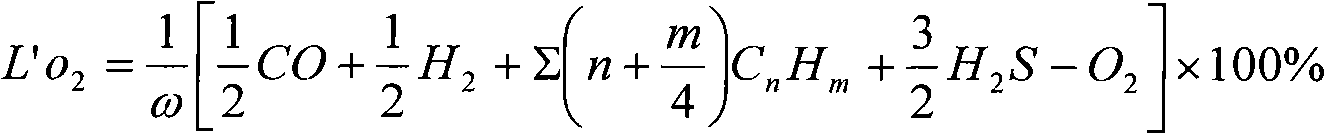

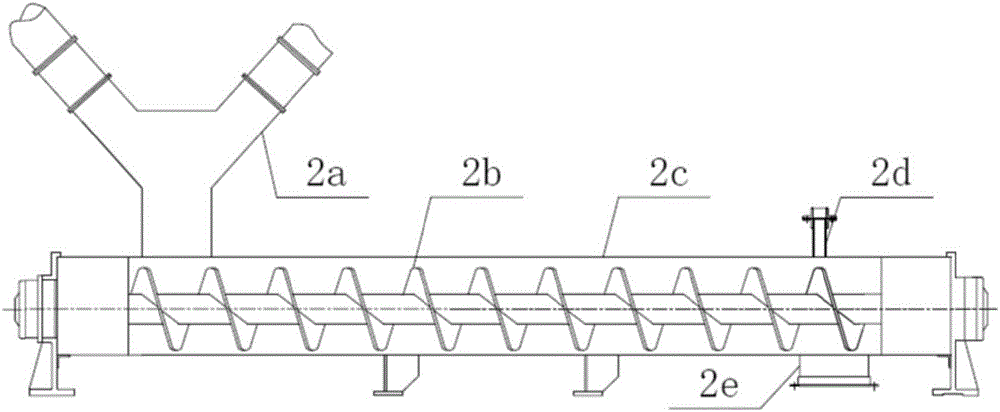

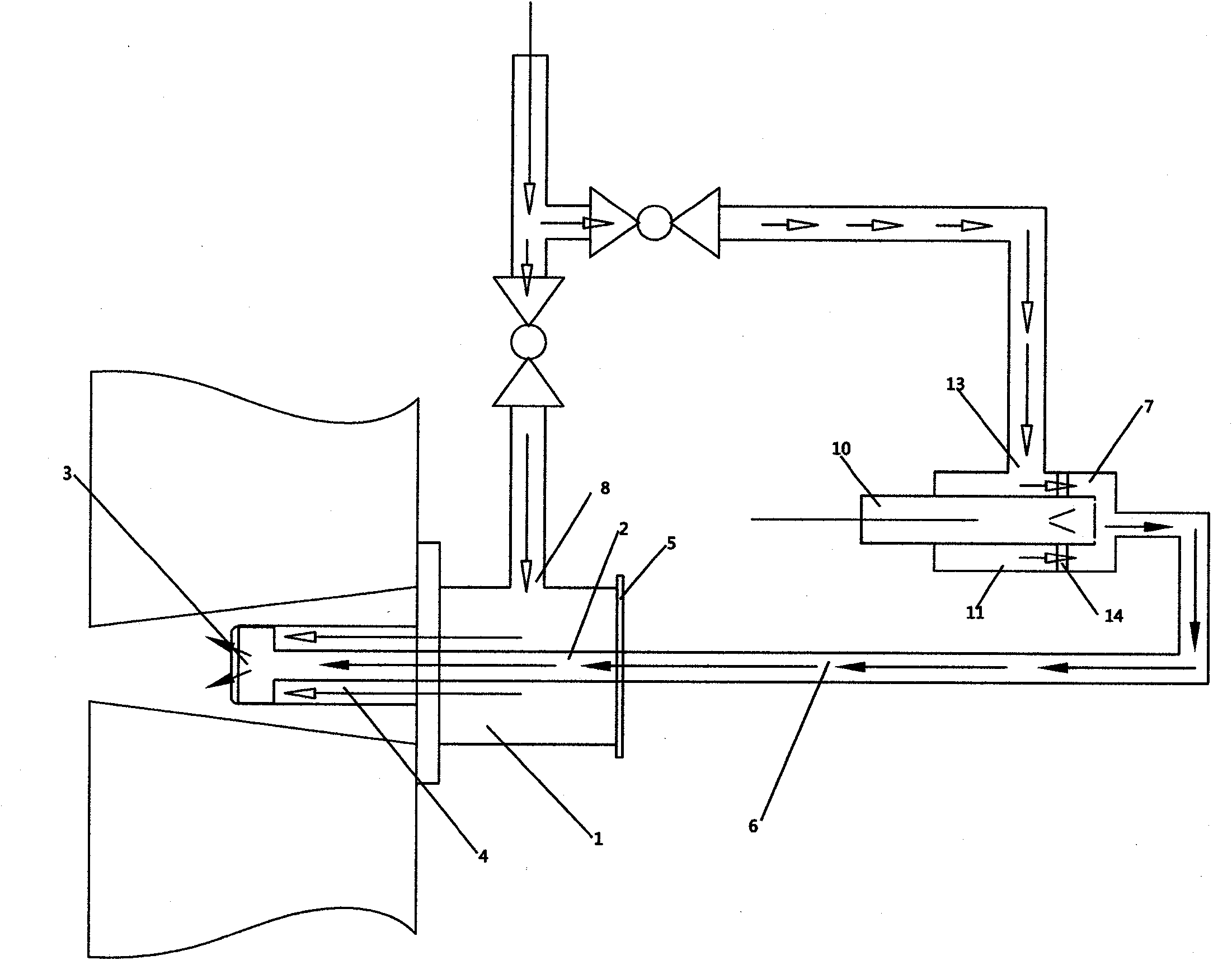

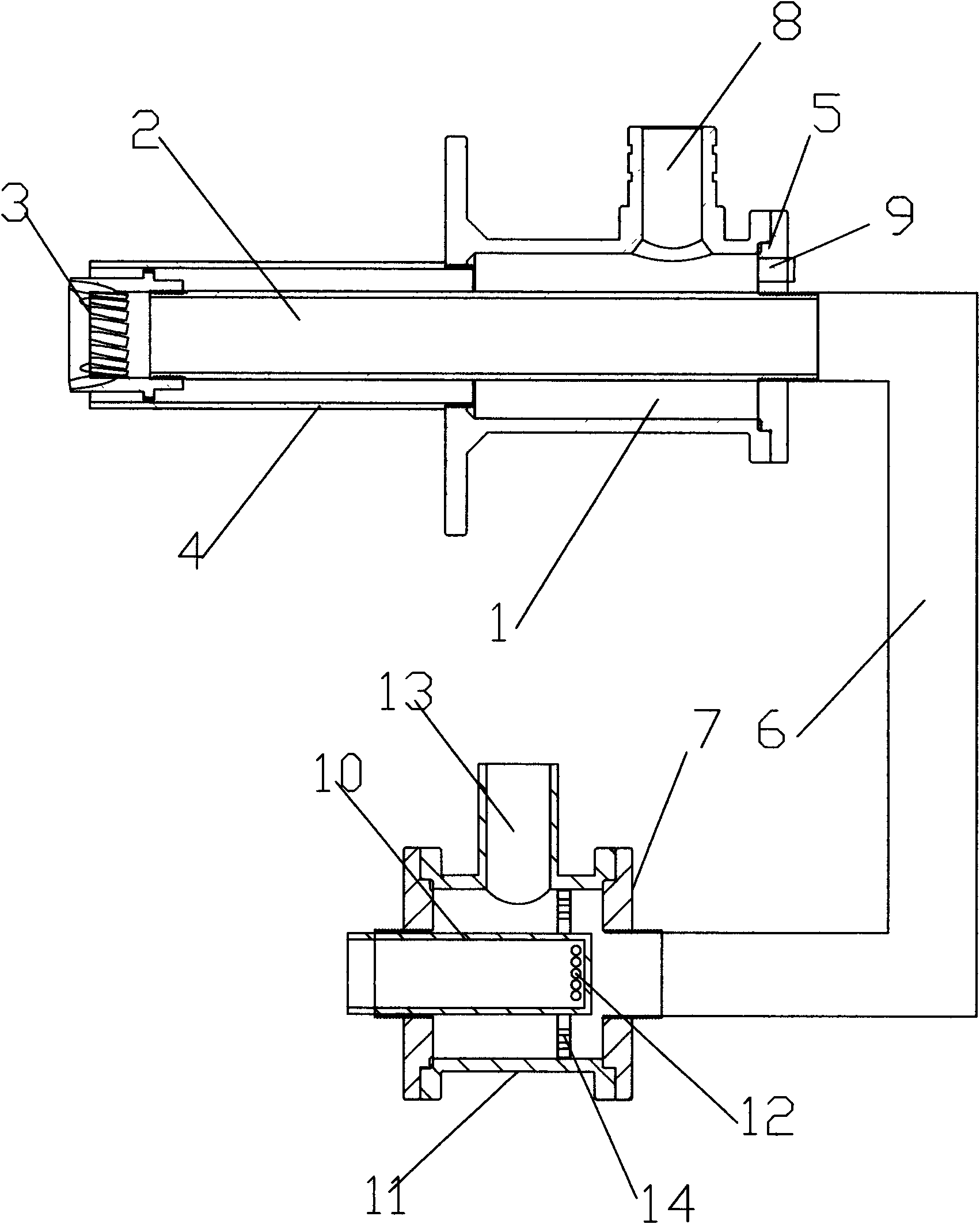

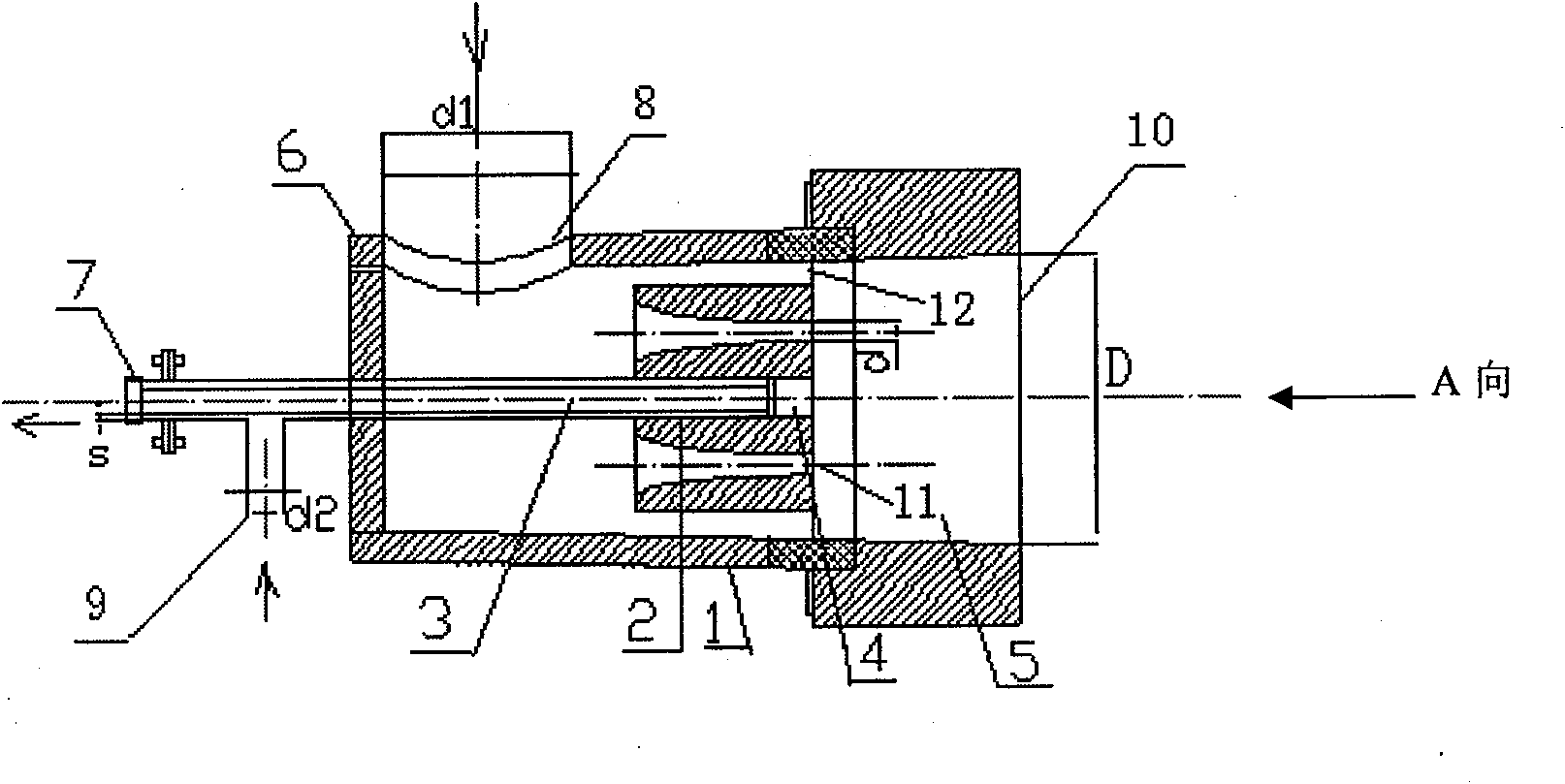

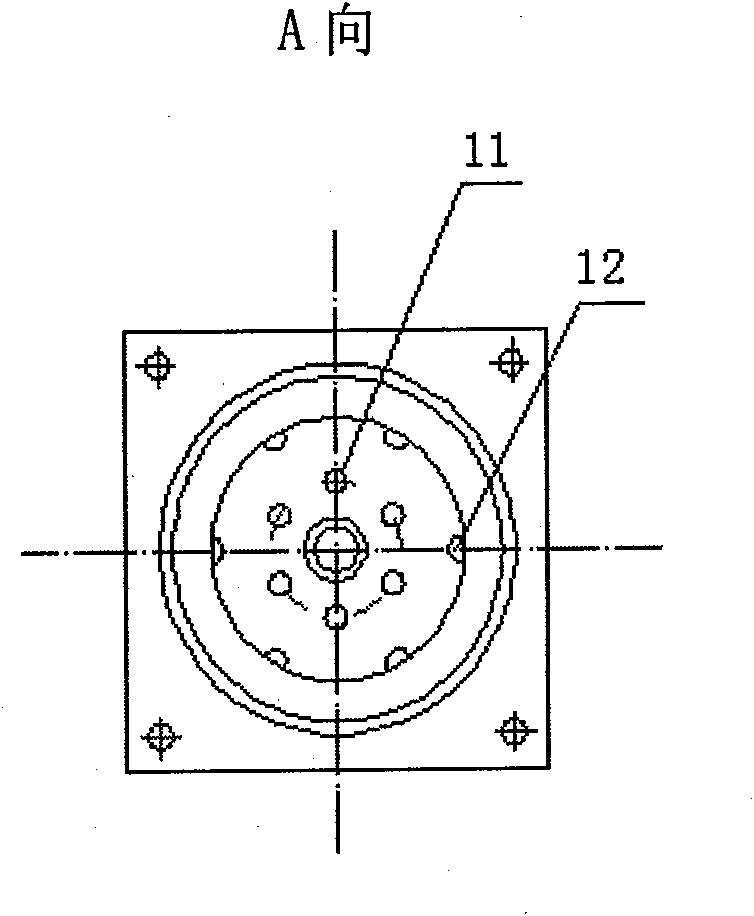

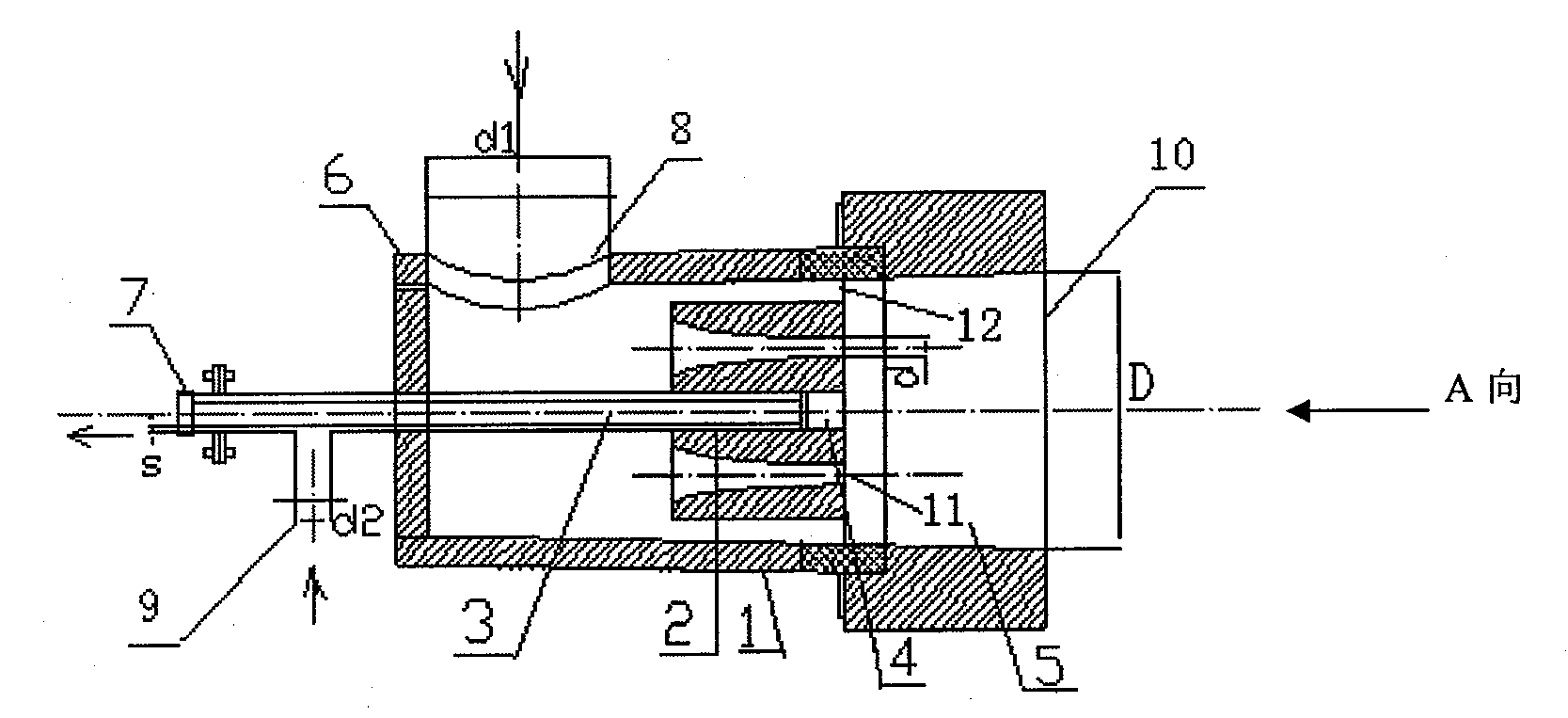

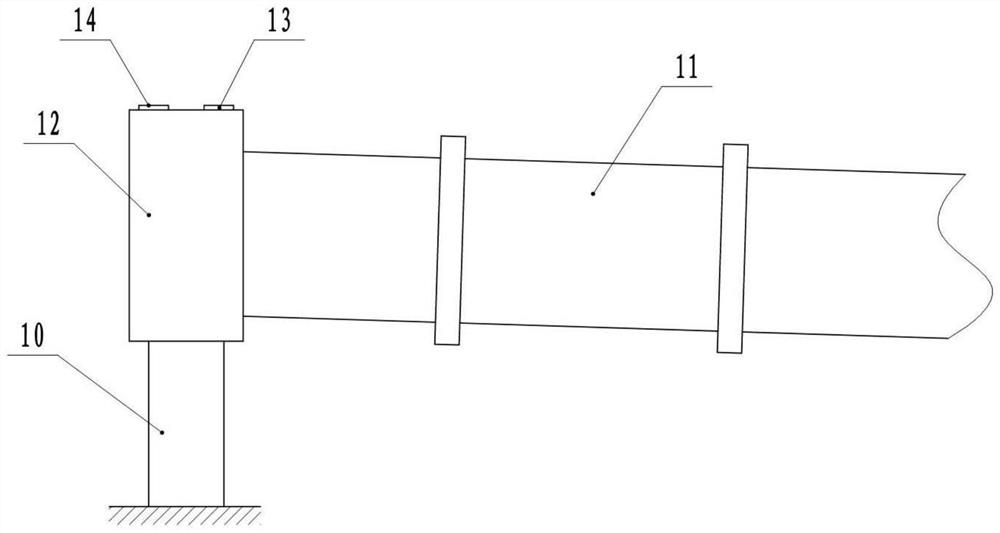

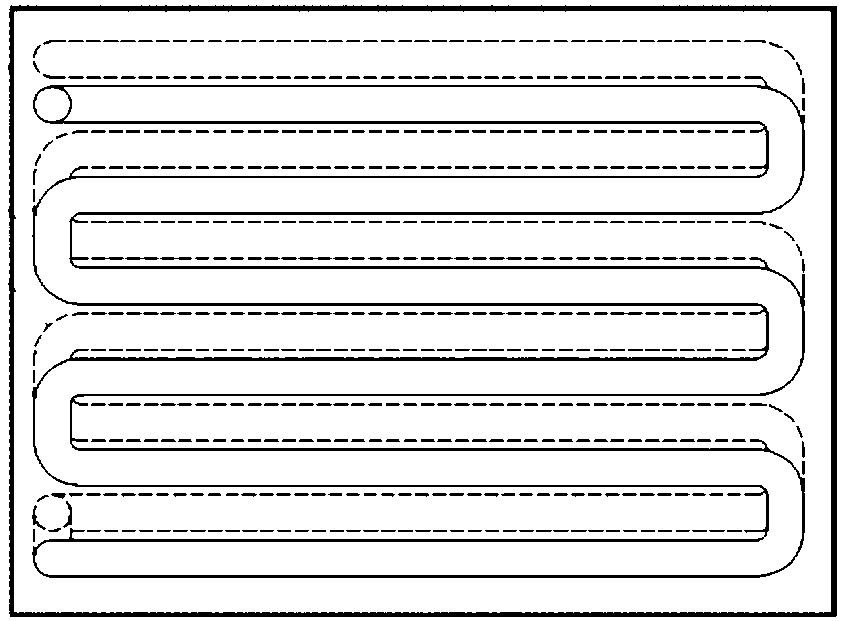

Working method and device of pre-mixing type secondary combustor

The invention discloses a working method and a device of a pre-mixing type secondary combustor. The invention aims at providing a working method and a device of a pre-mixing type secondary combustor capable of effectively saving the energy source. The method disclosed by the invention comprises the steps of: firstly, dividing the combustion air into two parts through a tee shunt, and respectively controlling the flow rates through valves; and then, conveying the combustion air (primary air) into a pre-mixer through a pipeline to be fully mixed with fuel gas to reduce the air coefficient of excess; conveying the pre-mixed mixed gas into a pre-mixing pipe through a pre-mixing connecting pipe and outputting the mixed gas through an output hole on a combustion nozzle; and finally, introducing the other part of the combustion air (secondary air) into a main body shell through a conveying pipe, conveying the combustion air to the combustion nozzle through a secondary air flow duct to be fully mixed with the mixed gas and to cool the combustion nozzle. The method disclosed by the invention is mainly applied to ceramic kiln combustors, nonferrous metal smelting furnaces, holding furnaces and industrial boilers.

Owner:FOSHAN QIDI ENERGY SAVING TECH

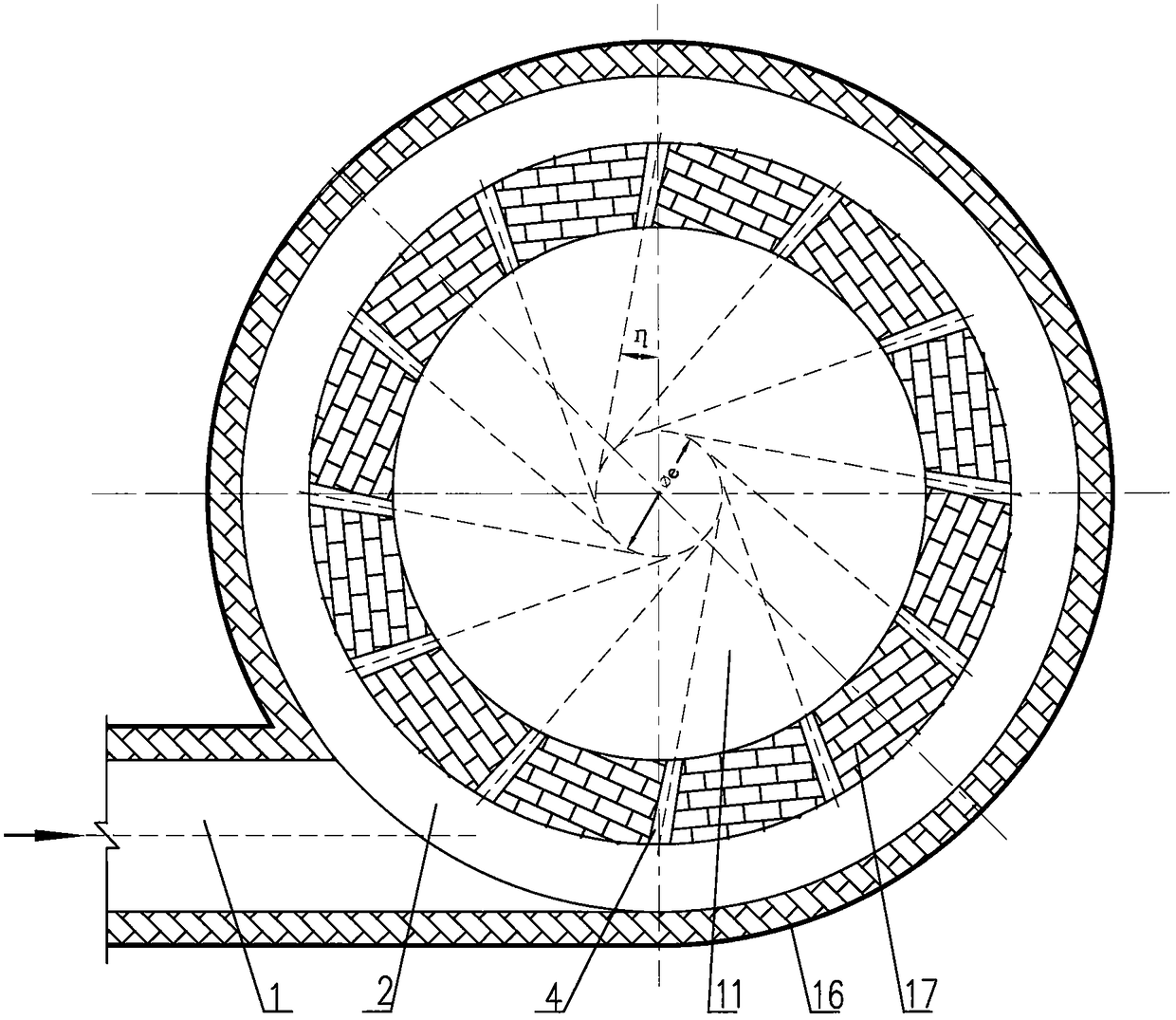

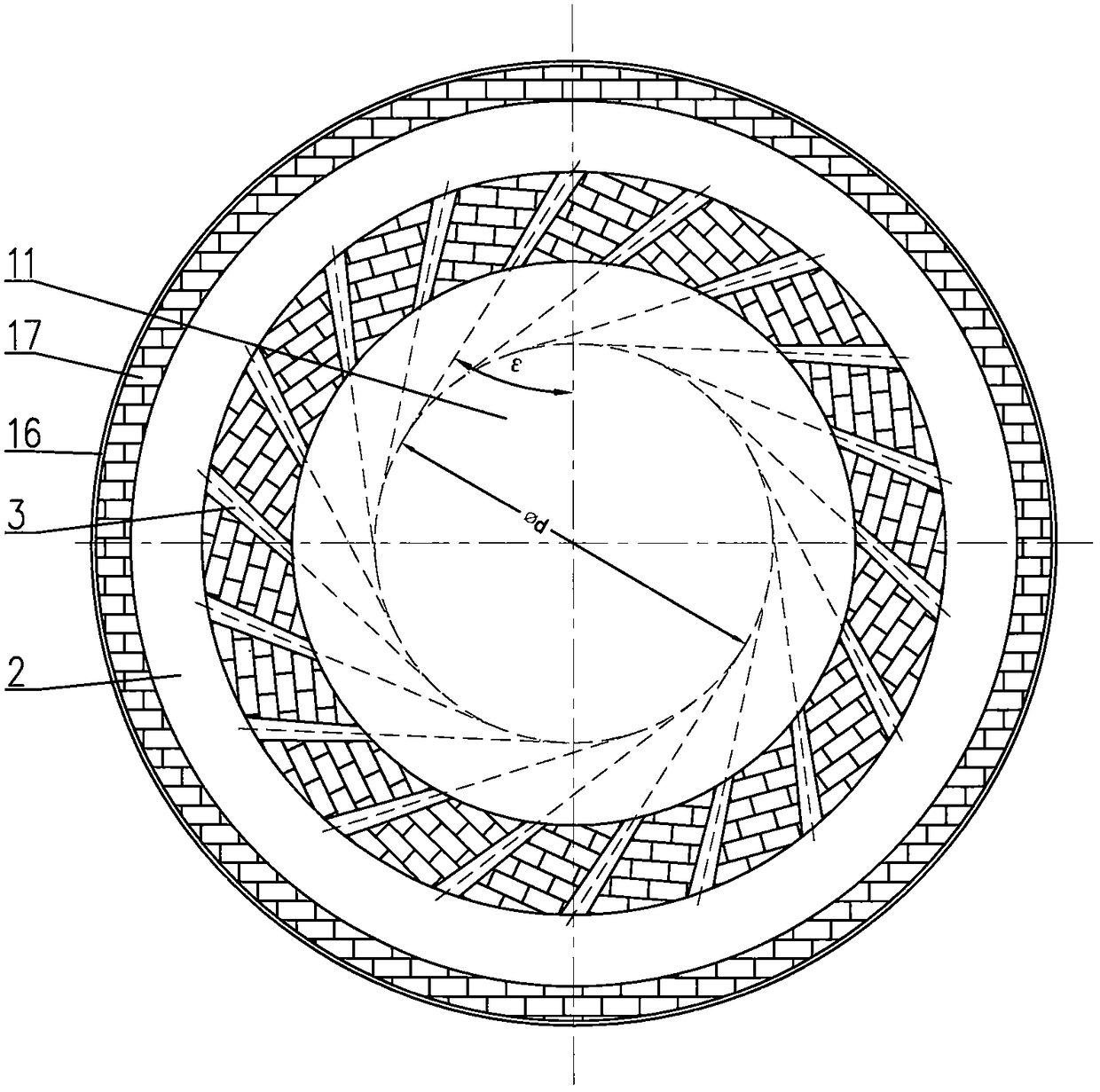

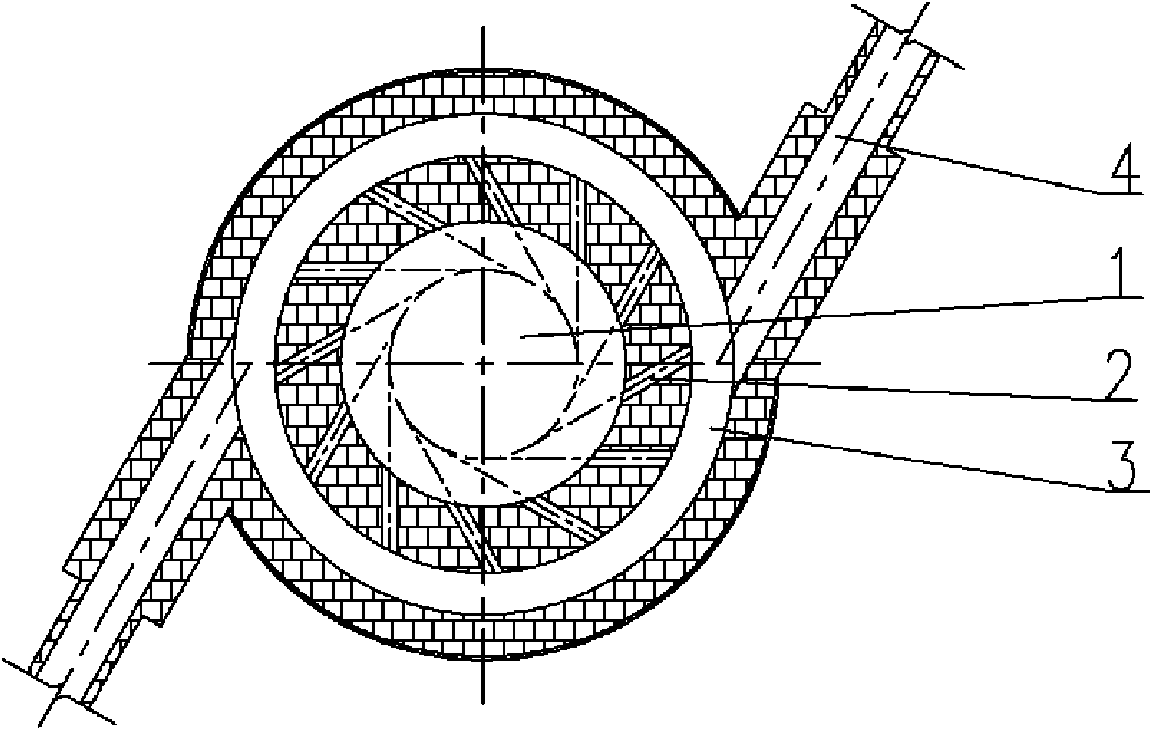

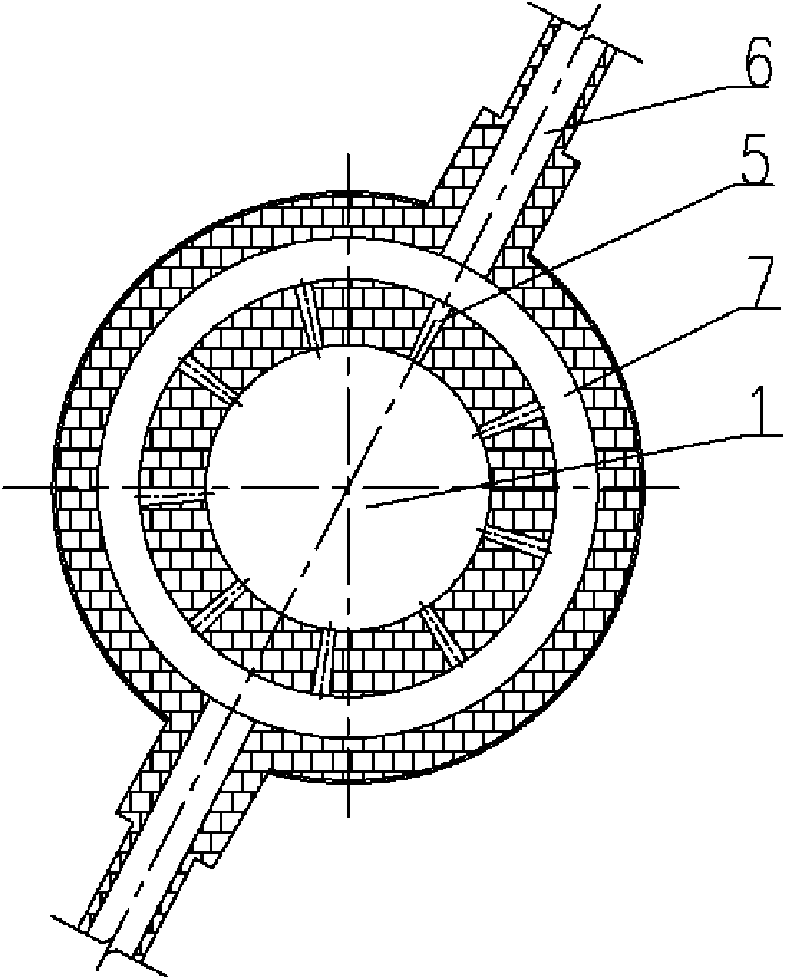

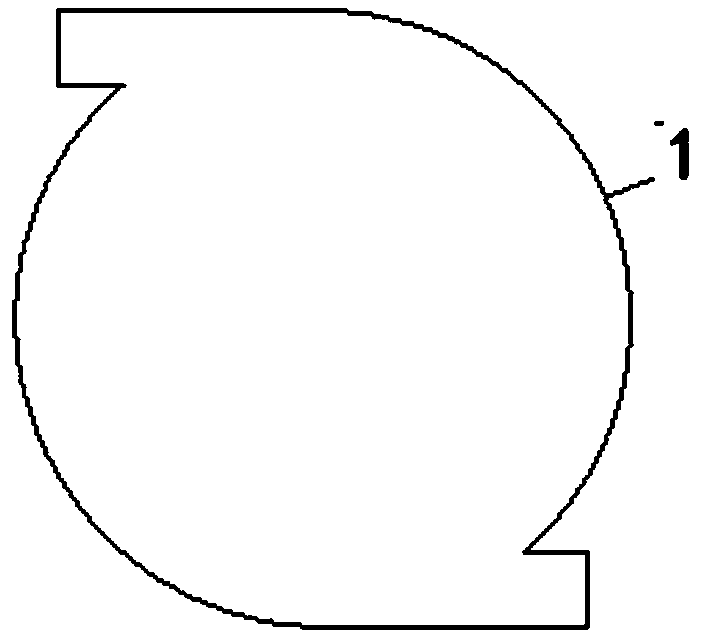

Double-channel vortex ceramic burner

The invention relates to a double-channel vortex ceramic burner (namely, the number of coal gas inlets is two and the number of air inlets is two) which is vertically installed at the upper part of a burning chamber of a hot air stove and comprises a vortex chamber 1, a throat mouth 8, coal gas inlets 4, a coal gas ring path 3, a coal gas nozzle 2, air inlets 6, an air ring path 7 and an air nozzle 5, wherein the vortex chamber 1 is positioned at a central area, and the throat mouth 8 is arranged between the vortex chamber 1 and the burning chamber; the coal gas nozzle 2 is arranged on the inner wall of the coal gas ring path 3, and two coal gas inlets 4 are arranged on the outer wall of the coal gas ring path 3; the air nozzle 5 is arranged on the inner wall of the air ring path 7; and the two air inlets 6 are arranged on the outer wall of the air ring path 7. The double-channel vortex ceramic burner can transform the top-burning hot air stove of the traditional level sleeve type burner into a vortex top-burning hot air stove under the condition that the burning chamber and the pipeline of the hot air stove is rarely transformed. The double-channel vortex ceramic burner has the characteristics of raising the hot air temperature, prolonging the service life of the hot air stove, reducing the burning consumption, and reducing the investment.

Owner:ZHENGZHOU ANNEC IND

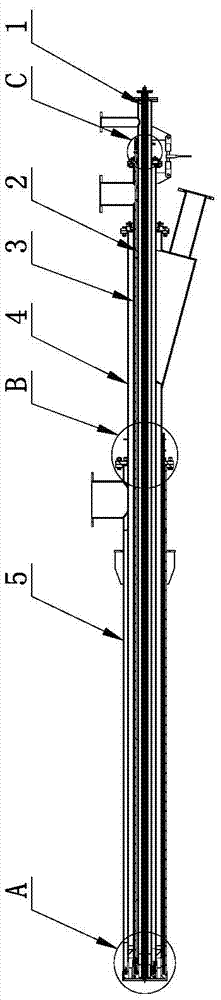

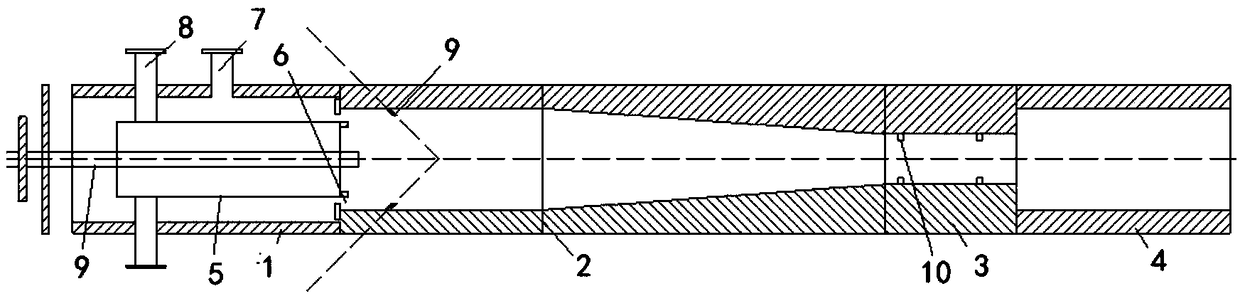

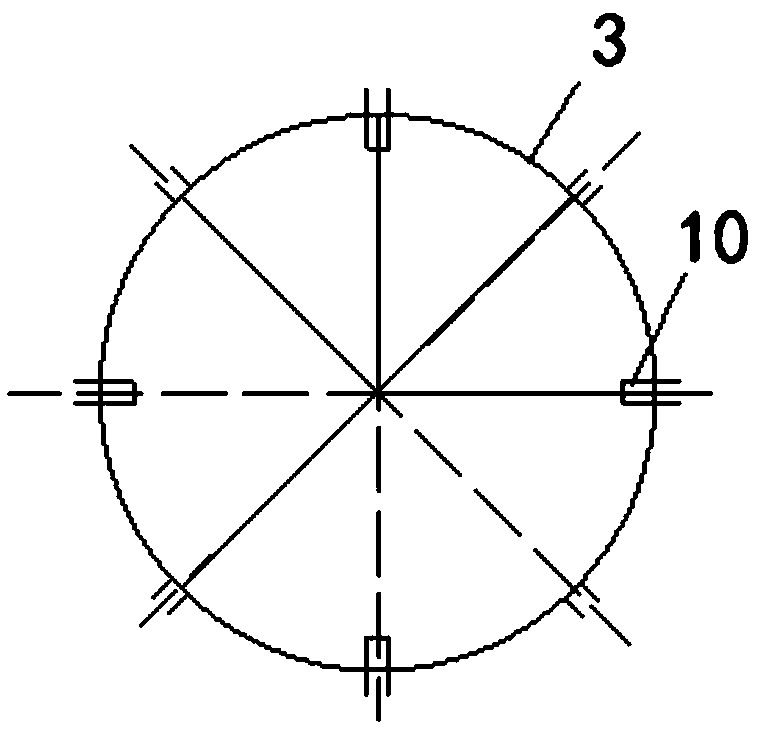

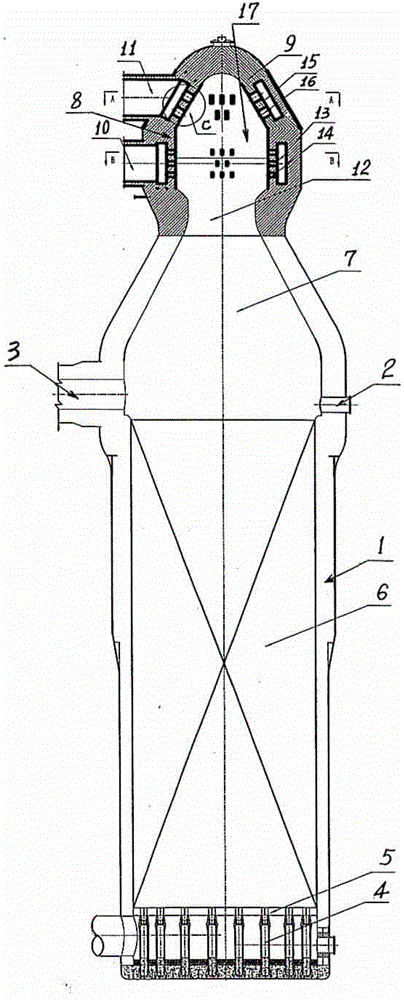

50,000 ton/year natural gas hard carbon black reaction furnace

PendingCN109135350AReduce surplus factorIncrease temperaturePigmenting treatmentFurnace temperatureReaction temperature

The invention relates to a 50,000 ton / year natural gas hard carbon black reaction furnace, one end of an air guide cylinder is connected with a panel of the reaction furnace, the other end of the airguide cylinder is connected with a combustion section, a ventilation opening is reserved on the joint of the air guide cylinder and the combustion section to form bypass air, a preheated air intake tube I is arranged on the middle section of an air distributor, and the preheated air of the preheated air intake tube I respectively forms a ventilation air path with the air guide cylinder and the ventilation opening respectively. The 50,000 ton / year natural gas hard carbon black reaction furnace has the technical effects that: the air distributor is designed and improved and is butted with a combustion straight section to form the bypass air, the inner wall of a hearth is protected, the air temperature and the furnace temperature are improved on the premise that the reaction furnace is effectively protected, two tangential air inlets are arranged at the end part of the air guide cylinder, the rotational flow is formed in the air guide cylinder, the turbulence degree of the preheated air is increased, so that the combustion is promoted, the reaction temperature of raw oil is increased, meanwhile, the coefficient of excess air is further reduced, the content of excess oxygen in the smoke produced in the combustion is reduced, and the consumption of the raw oil is reduced.

Owner:济宁黑猫炭黑有限责任公司

Integrated low-carbon micro-discharge energy-saving and emission-reduction boiler system

ActiveCN101986025BObvious superiorityLower discharge temperatureSteam generation plantsIndirect carbon-dioxide mitigationCombustionSuperheater

The invention discloses an integrated low-carbon micro-discharge energy-saving and emission-reduction boiler system. The system comprises a boiler body (1), a steam drum (2), a heat exchanger (3), a preheater (4), an economizer (5), a superheater (6), a steam turbine (7), a generator (8), a secondary smoke combustion device (9), a desulfuration and dust collect unit (10), an air blower (11) and asmoke exhauster (13), wherein the steam drum (2) and the heat exchanger (3) constitute a hot-water heating circulation loop, the economizer (5) is connected with the steam drum (2), and the air blower (11) feeds air to the preheater (4); the steam drum (2) is connected with the superheater (6), and then connected with the steam turbine (7) by a superheated steam pipe (22); the steam turbine (7) is connected with a low-pressure steam pipe (23), and the generator (8) is linked with the steam turbine (7); and the outlet of a gas duct of the boiler body (1) is connected with a smoke pipe (25), and the smoke exhauster (13) is arranged on the smoke pipe (25), and sequentially feeds smoke into the secondary smoke combustion device (9) and the desulfuration and dust collect unit (10) so as to process and discharge the smoke.

Owner:慧生能源科技有限公司

Method for smelting magnesium by decomposition in vacuum through microwaves

InactiveCN101892395BRaise the reaction temperatureReduction of energy consumptionMicrowaveHeating time

The invention relates to a method for smelting magnesium by decomposition in vacuum through microwaves, and belongs to the field of magnesium smelting. The method comprises the following steps: firstly, crushing raw materials of magnesia, lime and ferrosilicon, then evenly mixing the crushed materials according to the proportions, pressing into balls, carrying out microwave-heating in a microwavevacuum reactor to resolve the magnesia into gaseous magnesium, and condensing to obtain crude magnesium. The invention is characterized in that the technical parameters are as follows: the reaction temperature in the microwave vacuum reactor is 1250-1450 DEG C, and the vacuum degree is 20-1000 Pa; the proportion of the lime to the magnesia is 0.5:1-1.5:1, and the proportion of ferrosilicon to themagnesia is 0.44-0.65:1; and the heating time is 1-5 hours. Compared with the prior Pidgeon process for smelting magnesium, the invention has the characteristics of high efficiency, low energy consumption, low pollution, low production cost, low fixed investment and the like.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

Burner for horseshoe flame glass kiln, glass kiln and burning method

ActiveCN111072257BSlow down the intensity of burningReduce surplus factorGlass furnace apparatusThermodynamicsNitrogen oxides

The invention discloses a burner for a horseshoe flame glass kiln, a glass kiln and a combustion method. The tails of the gas cavity and the gas inner cavity are sealed, and the heads are open. The tail of the gas outer cavity is provided with a gas main inlet, and the gas inner cavity is provided with an inner cavity gas inlet that communicates with the gas outer cavity; The adjustment component of the cross-sectional opening ratio of the gas outer cavity. The horseshoe flame glass kiln burner of the present invention realizes a staged double-flame combustion mode combining long and short flames, delays the reaction speed of gas and combustion-supporting air, slows down the degree of violent combustion of gas, and avoids local high temperature in the flame space. At the same time, the excess air is reduced, the air excess coefficient is reduced, and the purpose of reducing the generation of nitrogen oxides is achieved.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

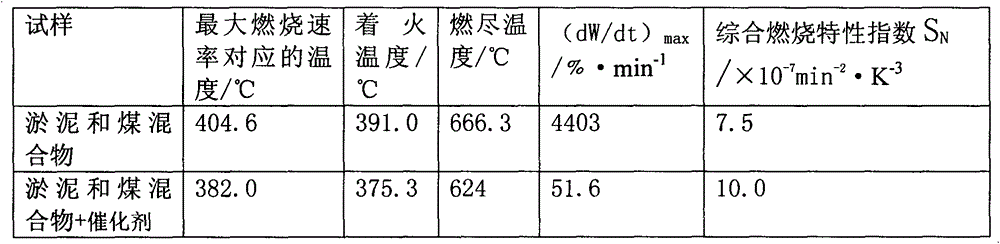

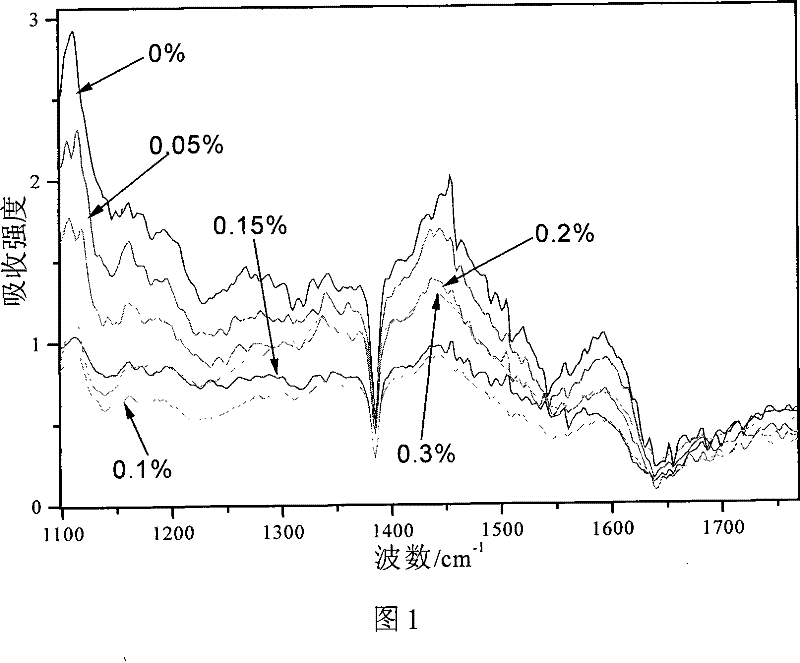

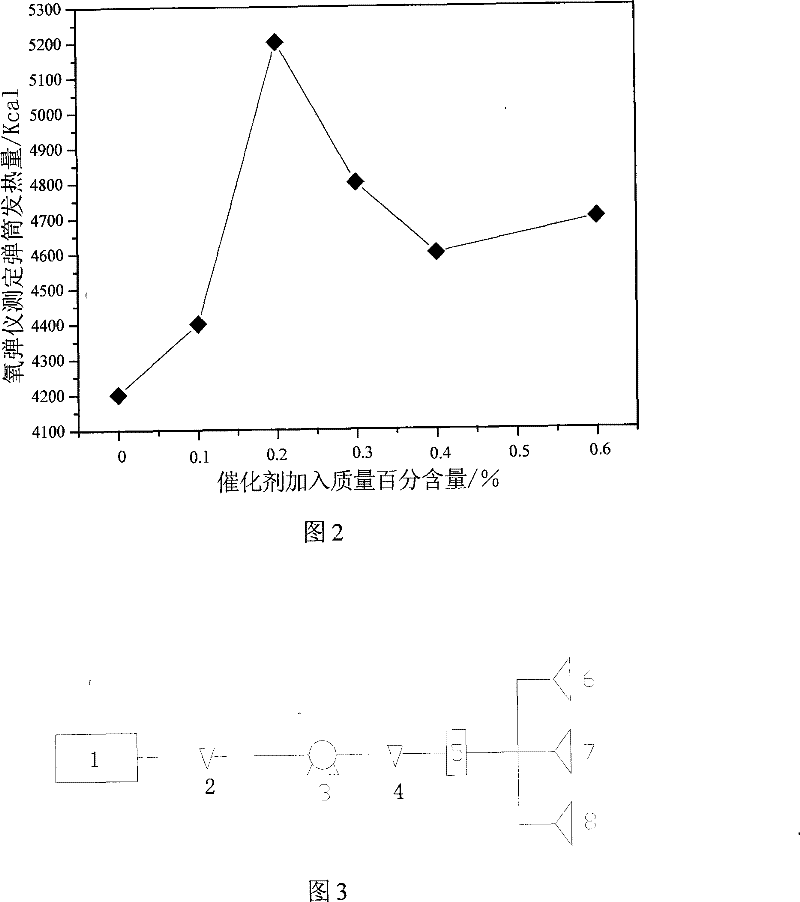

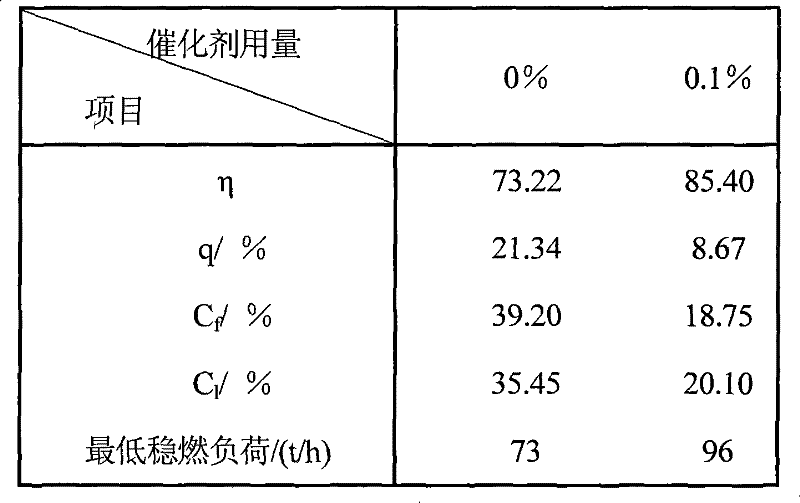

Catalyst capable of promoting burning of mixture of sludge and pulverized coal

InactiveCN103146459AImprove combustion efficiencyLow ignition temperatureSolid fuelsBrown coalSludge

The invention discloses a catalyst capable of promoting burning of a mixture of sludge and pulverized coal. The catalyst is characterized in that the mixture of the sludge and the pulverized coal and methylcyclopentadienyl manganese tricarbonyl and N,N-dimethylformamide are mixed for burning, thereby being capable of improving the burning efficiency of the sludge and pulverized coal mixture and reducing the firing temperature and the burnout temperature. In the catalyst, the sludge includes water supply sludge, domestic sewage sludge and industrial wastewater sludge, and the pulverized coal comprises lignite, bituminous coal and kikenny coal; and when the mass fraction of the sludge is 15-25% and the mass fraction of the pulverized coal is 75-85% in the mixture of the sludge and the pulverized coal, the catalytic effect is the best. The method and the product are hopefully applied to various large and small burning furnaces.

Owner:JIANGNAN UNIV

Glass kiln natural gas oxygen-enriched combustor

InactiveCN101303124BIncrease profitReduce surplus factorIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorEngineering

The invention relates to a natural gas oxygen-enriched burner with a glass kiln. Based on the normal natural gas burner, by adopting oxygen enrichment technology, the original larger air port is changed to a relatively smaller oxygen-enriched air port according to the oxygen content of the oxygen-enriched air so as to heighten the temperature of flame, reduce air displacement after combustion, promote heat utilization ratio and lower excess air coefficient.

Owner:SHANGHAI INST OF TECH

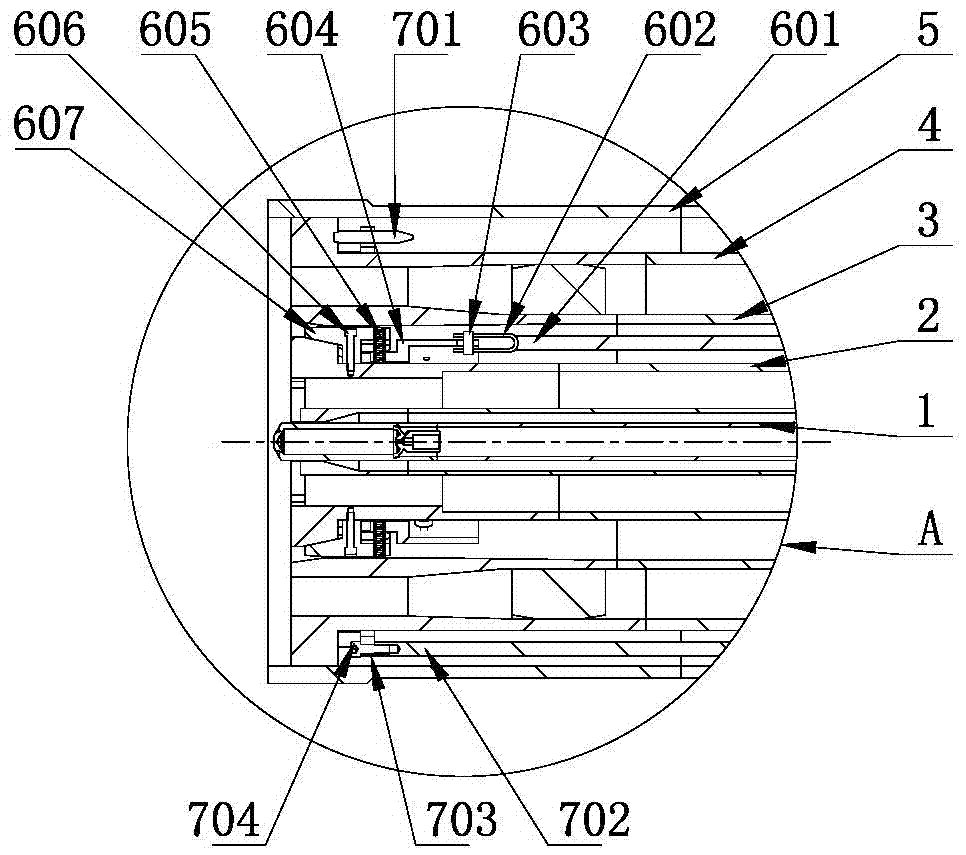

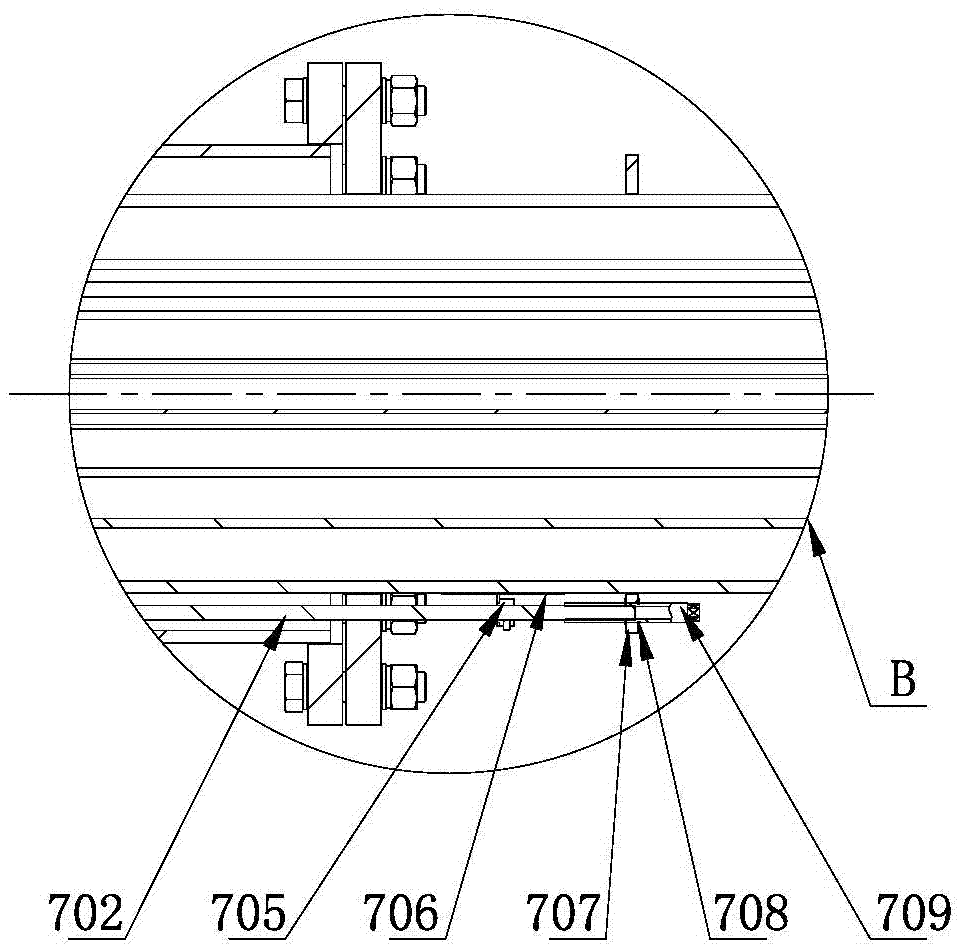

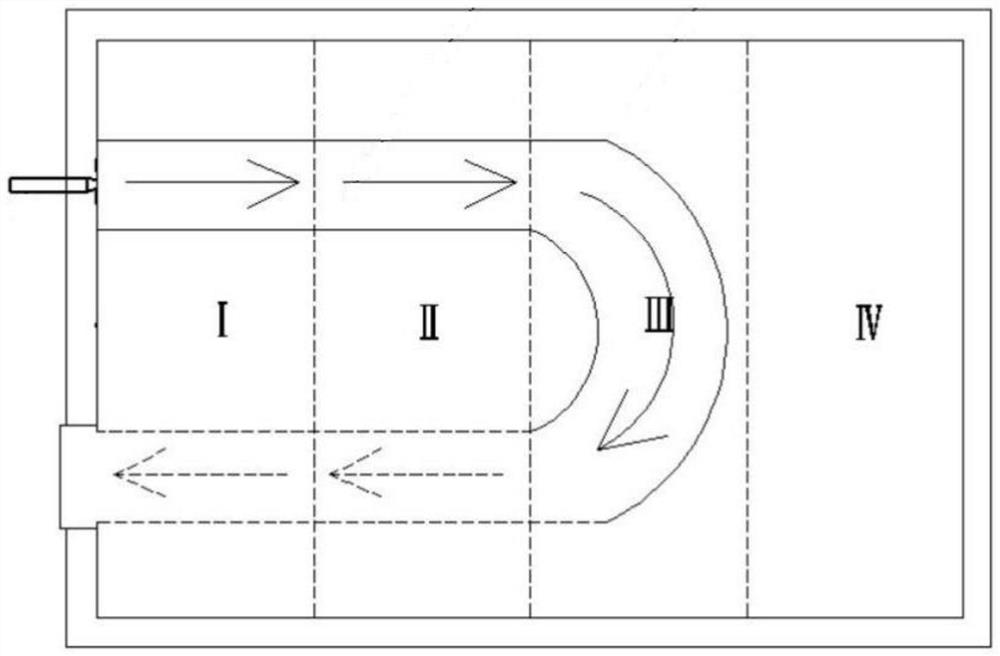

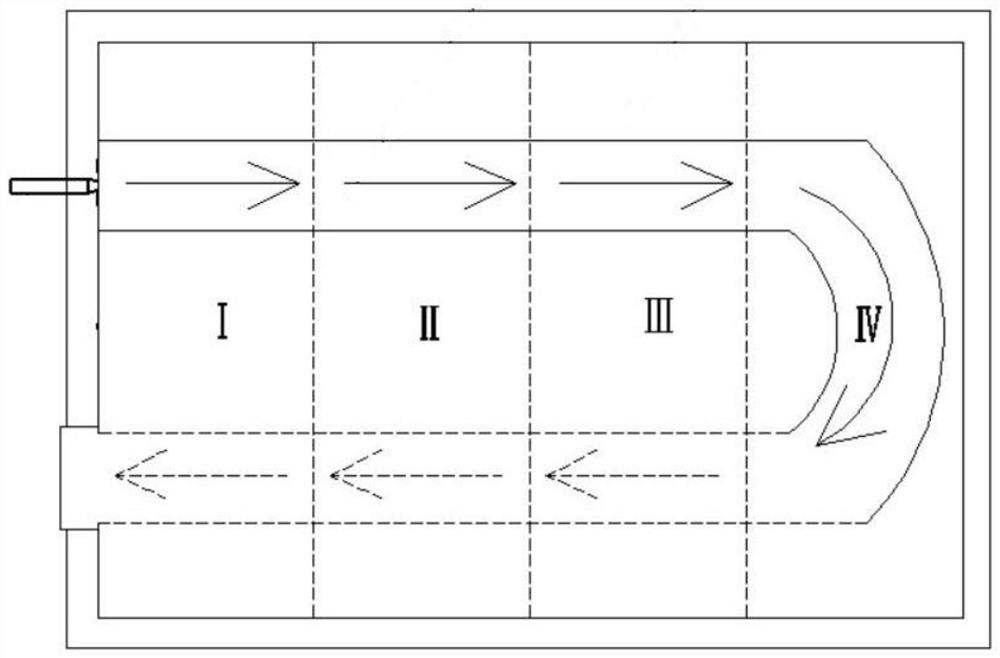

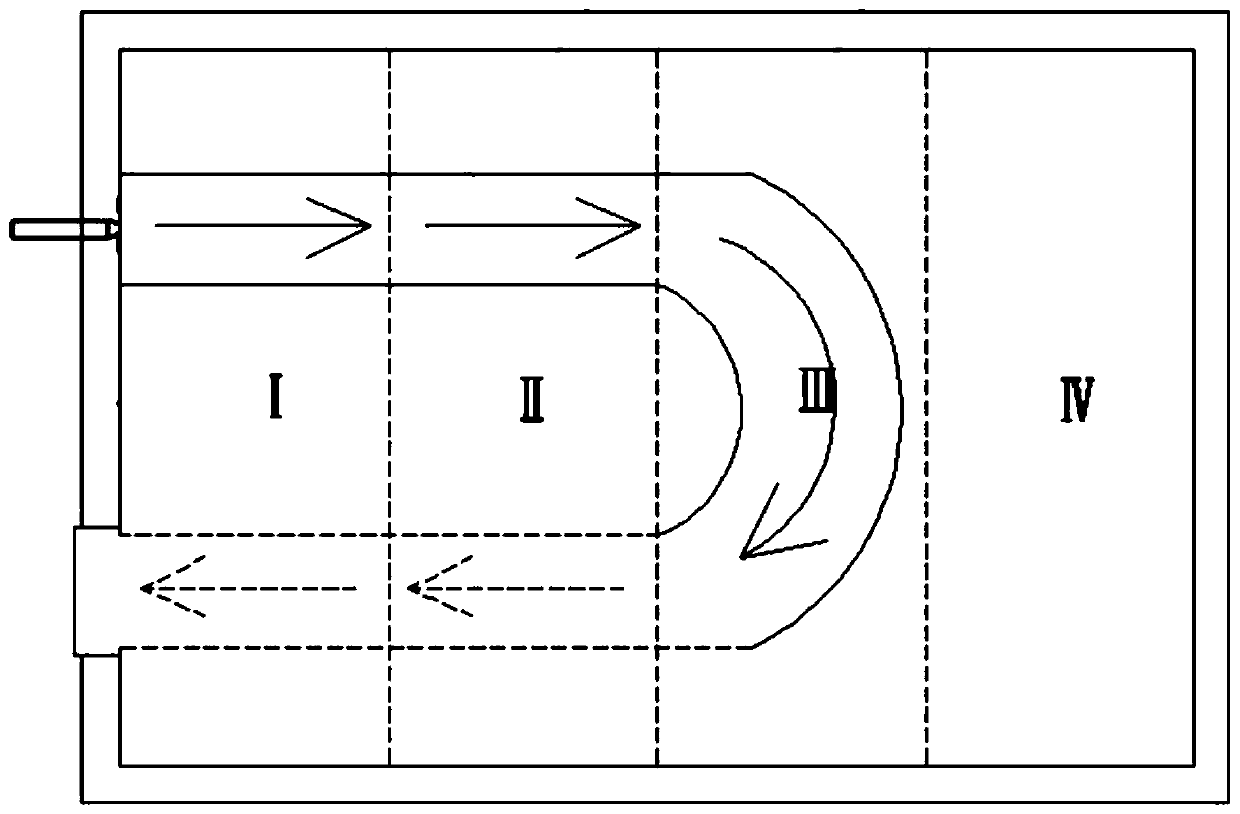

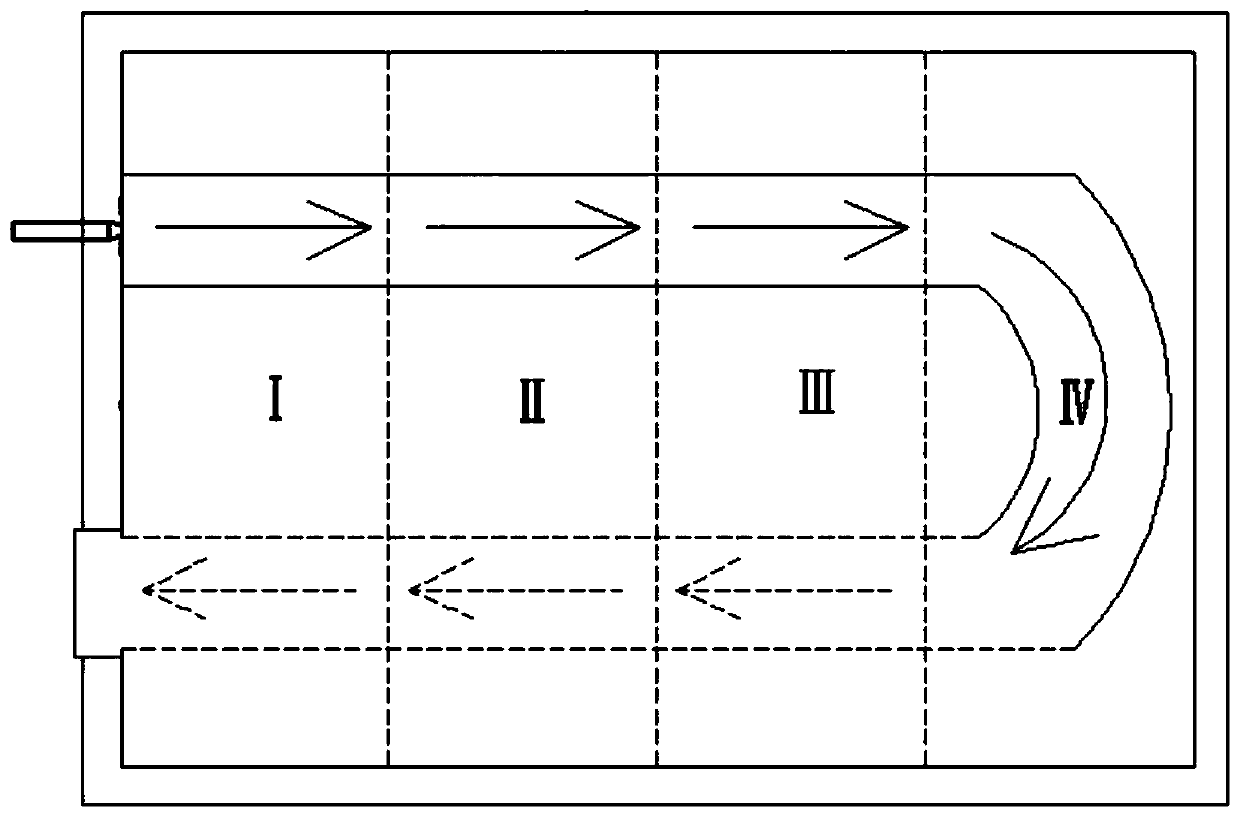

Hazardous waste incineration rotary kiln air supply structure

PendingCN112361353AReduce heat burn rateLow Air Excess SystemIncinerator apparatusEnvironmental engineeringMechanical engineering

The invention relates to the technical field of hazardous waste incineration, and particularly discloses a hazardous waste incineration rotary kiln air supply structure which comprises a supporting frame, a rotary drum and a kiln head cover. The rotary drum is rotationally connected to the supporting frame, the kiln head cover is fixed to the supporting frame, the rotary drum is rotationally connected with the kiln head cover in a sealed manner, the kiln head cover is cylindrical, and a main air hole and an auxiliary air hole are formed in the side wall of the kiln head cover; and the main airhole is located in the top of the kiln head cover, the main air hole and the auxiliary air hole are not located in the same circumferential line of the kiln head cover, the main air hole is close tothe rotary drum, and the auxiliary air hole is formed in the side far away from the rotary drum. According to the air supply structure, through model simulation, the air excess coefficient of hazardous waste incineration is controlled to range from 0.8 to 1.0 to adjust the air supply amount, a rotary turbulence flow field of the scheme is obtained through calculation, the hazardous waste incineration heat ignition loss rate of a rotary kiln can be lower than 3%, and it can be seen through the scheme that on the premise that the low excess coefficient is guaranteed, the lower ignition loss ratecan also be ensured, and the combustion rate is improved.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

A method and device for gasification, pyrolysis, catalytic regenerative combustion of organic matter

ActiveCN106196085BReduce productionEfficient decompositionIncinerator apparatusCombined combustion mitigationOrganic fuelIntegrated devices

The invention provides an organic matter gasification pyrolyzation catalysis heat storage burning method and device and belongs to the technical field of environment protection. Organic fuels enter a perforating type gasification pyrolyzation section through a feeding inlet, and generated gasification pyrolyzation gas enters a catalysis heat storage burning section; cross heat storage carriers are installed in the catalysis heat storage burning section, and the surfaces of the cross heat storage carriers are provided with catalysts, so that the gasification pyrolyzation gas can mix with air, is subjected to hypoxia superinsulated burning in a short time simultaneously, and is burned completely in a free reaction section; the high temperature smoke generated from burning enters a heat transfer section, the heat transfer section is divided into a plurality of districts to ensure sufficient heat transferring; the smoke enters a ceramic purification section to be purified after heat transferring; and ashes generated in the gasification pyrolyzation process are transported to a sealed dry-type ash discharging section through a vertical spiral ash removing and air supplying integrated device. The organic matter gasification pyrolyzation catalysis heat storage burning device can be used as various reactors such as hot water boilers, steam boilers and hot blast heaters and has the advantages that the application range of organic matters is wide; burning reaction time is short; heat transferring is complete; the volume of the entire device is small; and tail gas does not need to be deacidified or subjected to oxynitride removing.

Owner:DALIAN UNIV OF TECH

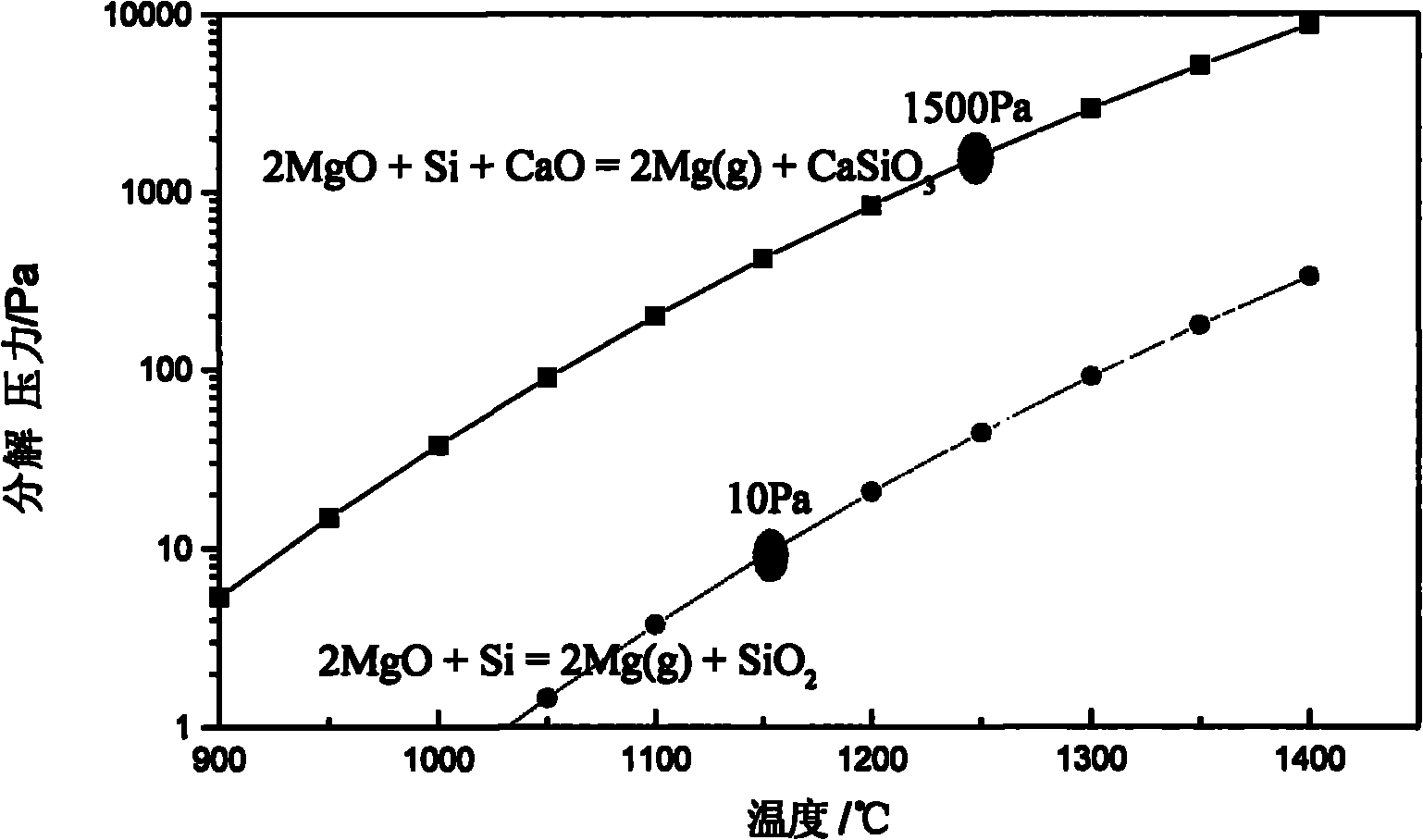

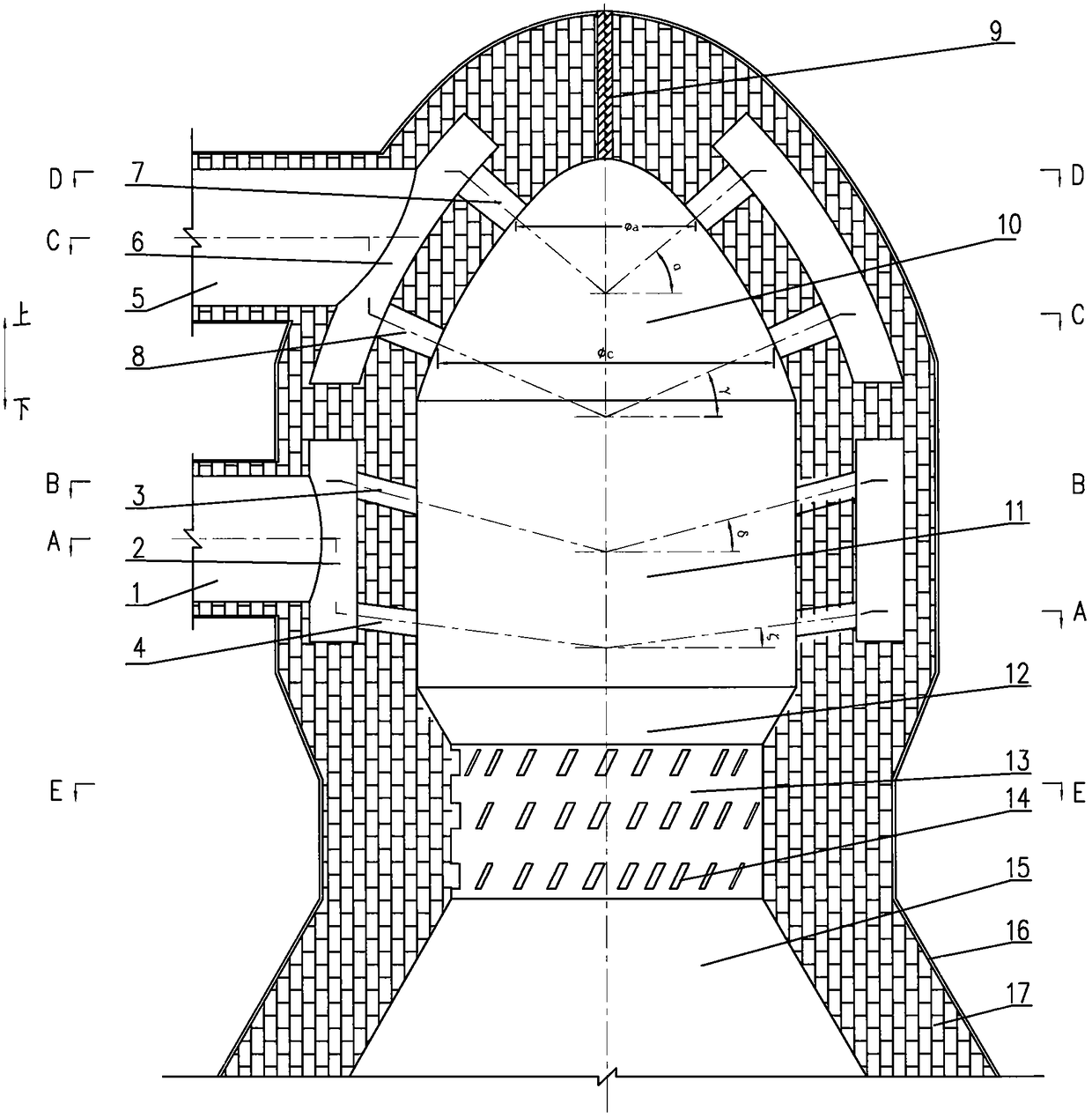

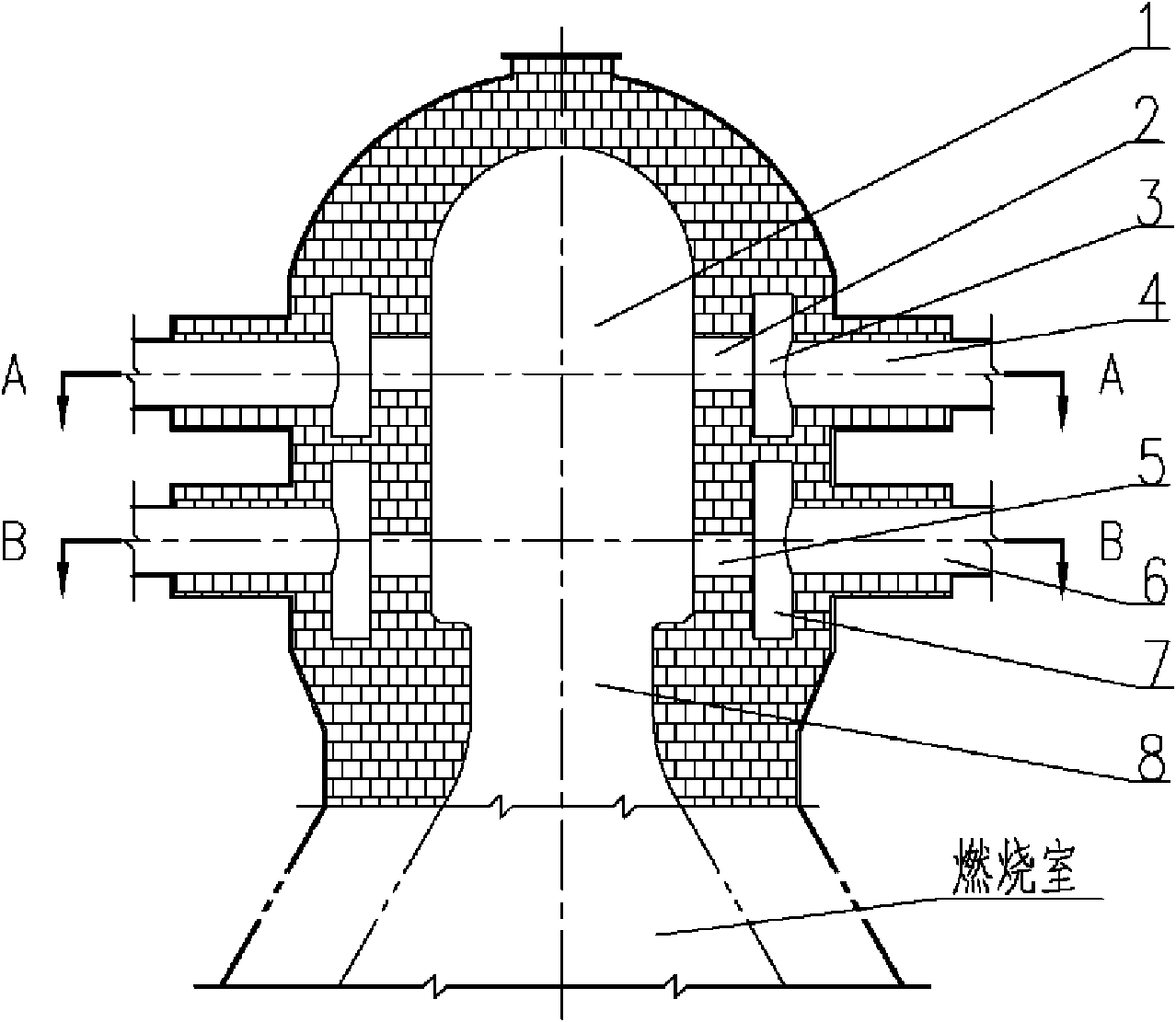

Top-burning hot-blast stove with cone-column composite vault structure

The invention discloses a top-burning hot-blast stove with a cone-column composite vault structure, and belongs to the field of heat energy technology. The top-burning hot-blast stove with the cone-column composite vault structure comprises a stove body and a combustor, wherein the stove body is composed of an inlet, a hot wind outlet, supporting columns, a grate, a regenerative chamber, and a combustion chamber; column chamber walls above the combustor and cone top walls are integrated to form a mixing chamber; one side of the column chamber walls is provided with an air inlet, the column chamber walls are provided with an air circuit, and the inner side of the air circuit is provided with air nozzles; and one side of the cone top walls is provided with a gas inlet, the cone top walls are provided with a gas circuit, and the inner side of the gas circuit is provided with gas nozzles. The top-burning hot-blast stove is used for heat accumulation of wind supply to blast furnaces. Combustion is sufficient, thermal efficiency is high, and cost is low.

Owner:ZHENGZHOU ANNEC IND

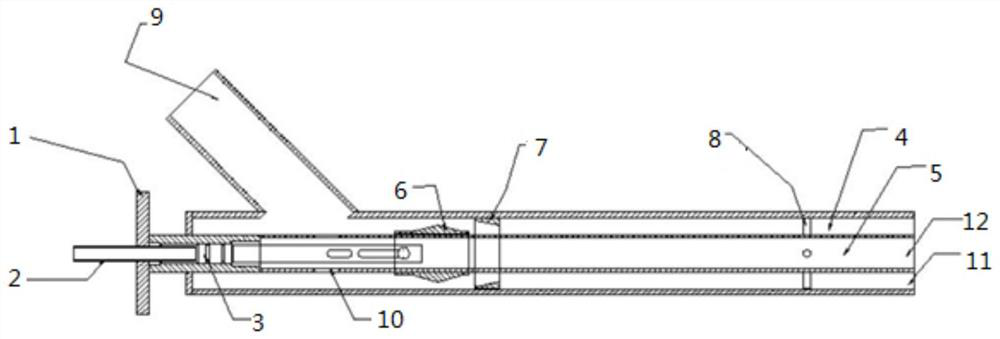

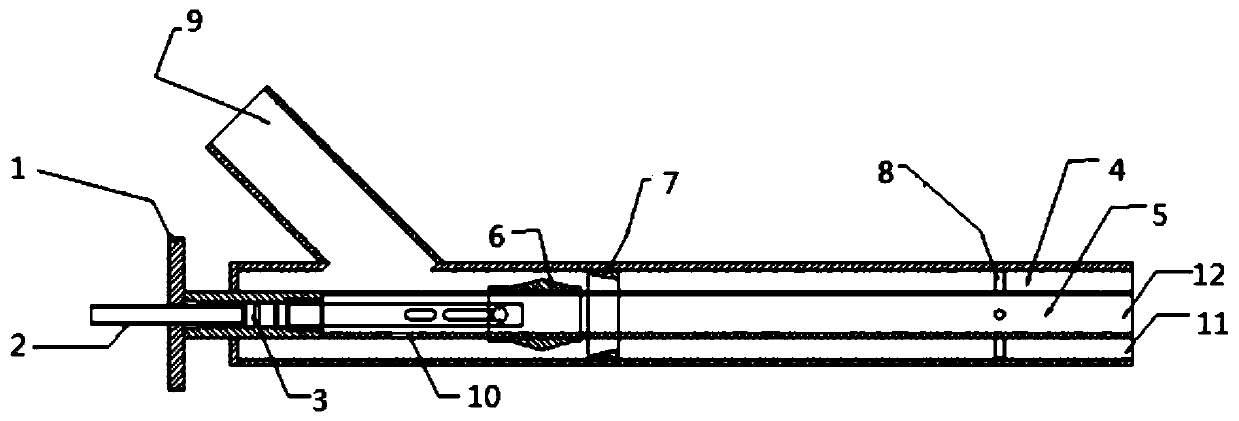

Oxygen increasing energy-saving spray gun for industrial furnace

PendingCN107860002AReduce surplus factorEmission reductionIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyEngineeringOxygen

The invention provides an oxygen increasing energy-saving spray gun for an industrial furnace. The top of a fuel channel connection pipe penetrates a rotary air plate to be connected with a nozzle head of the spray gun, the tail of the fuel channel connection pipe penetrates a baffle at the rear end of the spray gun to be connected with a fuel opening connector, and the fuel opening connector is provided with a fuel inlet. An outer shell of the spray gun is coaxially arranged on the outer side of the fuel channel connection pipe, and the outer shell of the spray gun is provided with an air combustion supporting air inlet. An oxygen increasing channel outer sleeve is coaxially arranged between the outer shell of the spray gun and the fuel channel connection pipe, the top end of the oxygen increasing channel outer sleeve is connected with the rotary air plate, and the tail end of the oxygen increasing channel outer sleeve and the tail end of the outer shell of the spray gun are connectedwith the baffle at the rear end of the spray gun through oxygen increasing inlet flanges. By means of the oxygen increasing energy-saving spray gun for the industrial furnace, fuel can be greatly saved, the amount of air for reaching the original same combustion temperature is reduced, the amount of combustion-supporting air for combustion is reduced, the coefficient of excess air is reduced, andthe smoke exhausting amount and the SO2 and NOx exhausting amount are reduced; and the energy saving and environment protecting effects are improved, the running cost is reduced, and the service lifeis prolonged.

Owner:SHANGHAI SHENGLIANG ENERGY SAVING TECH DEV

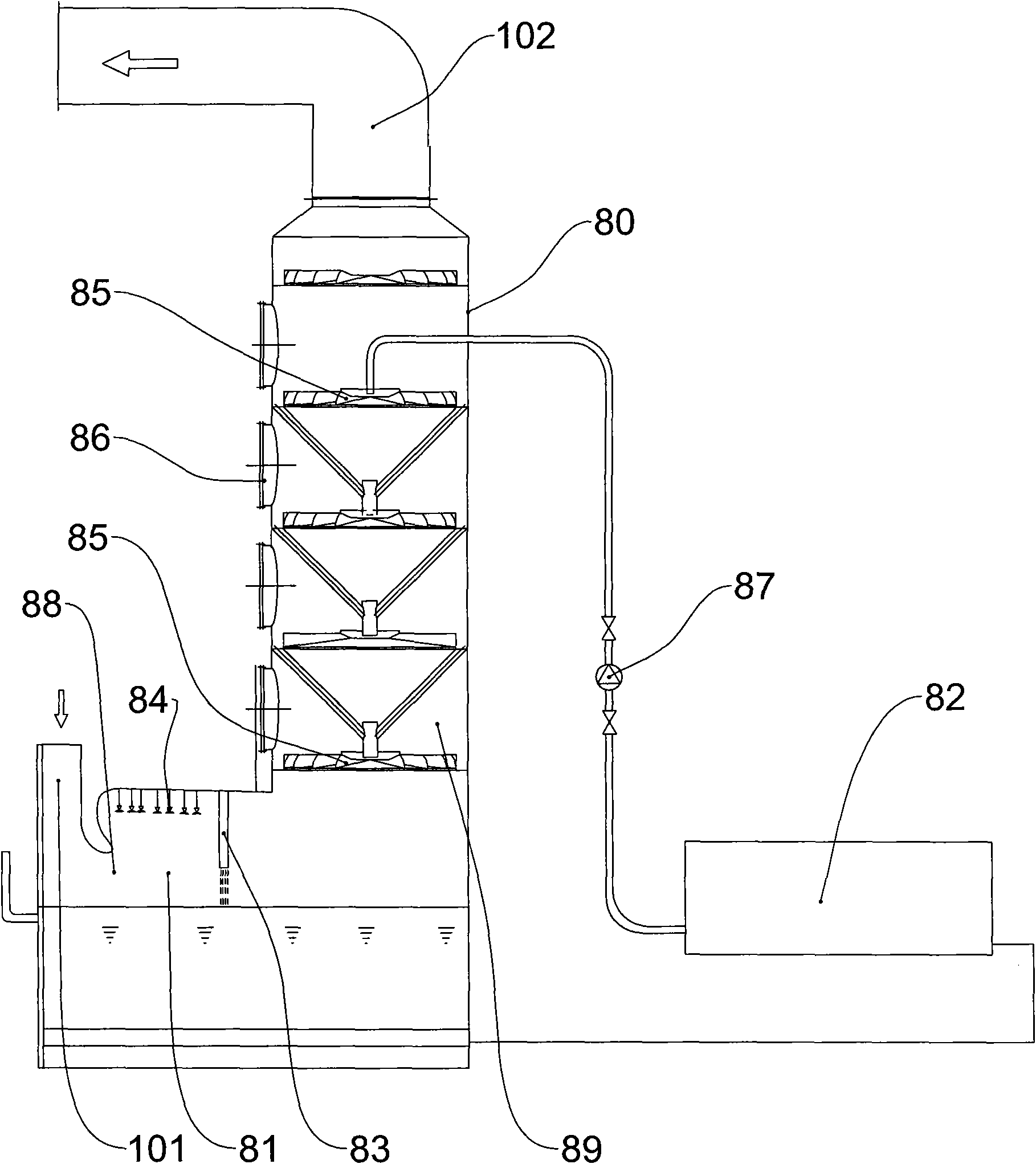

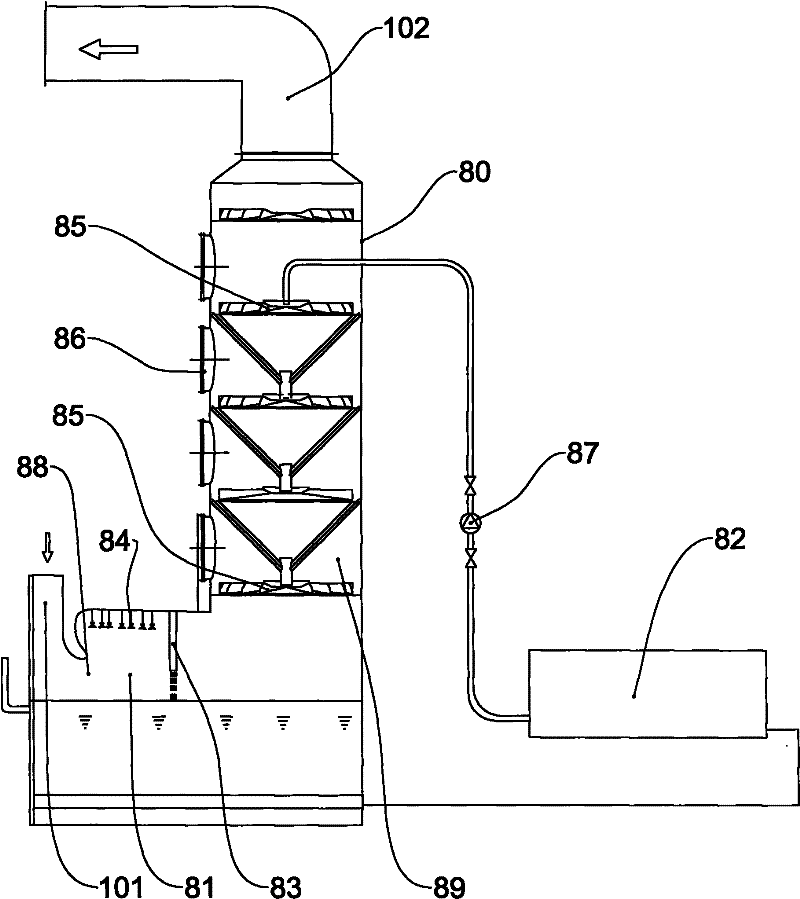

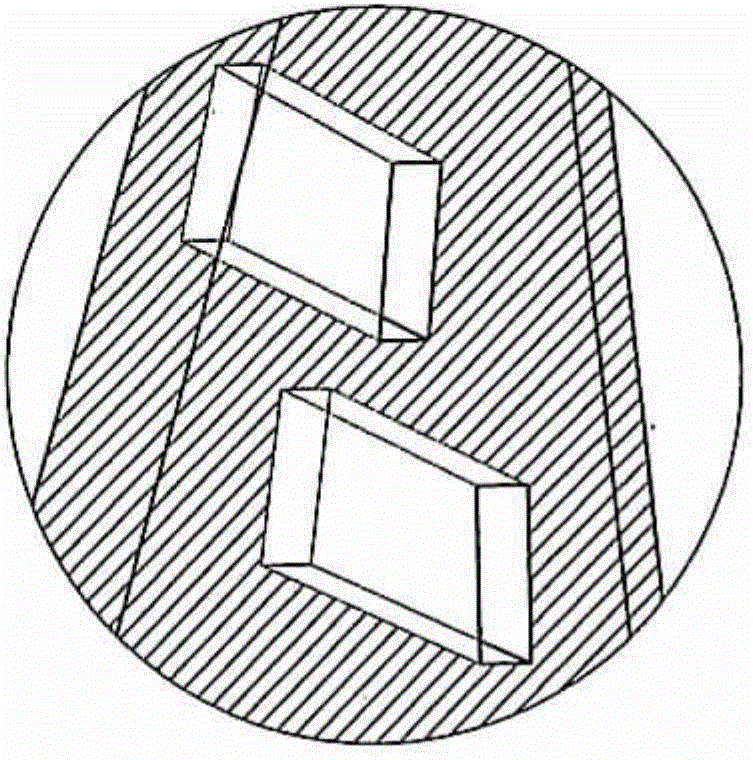

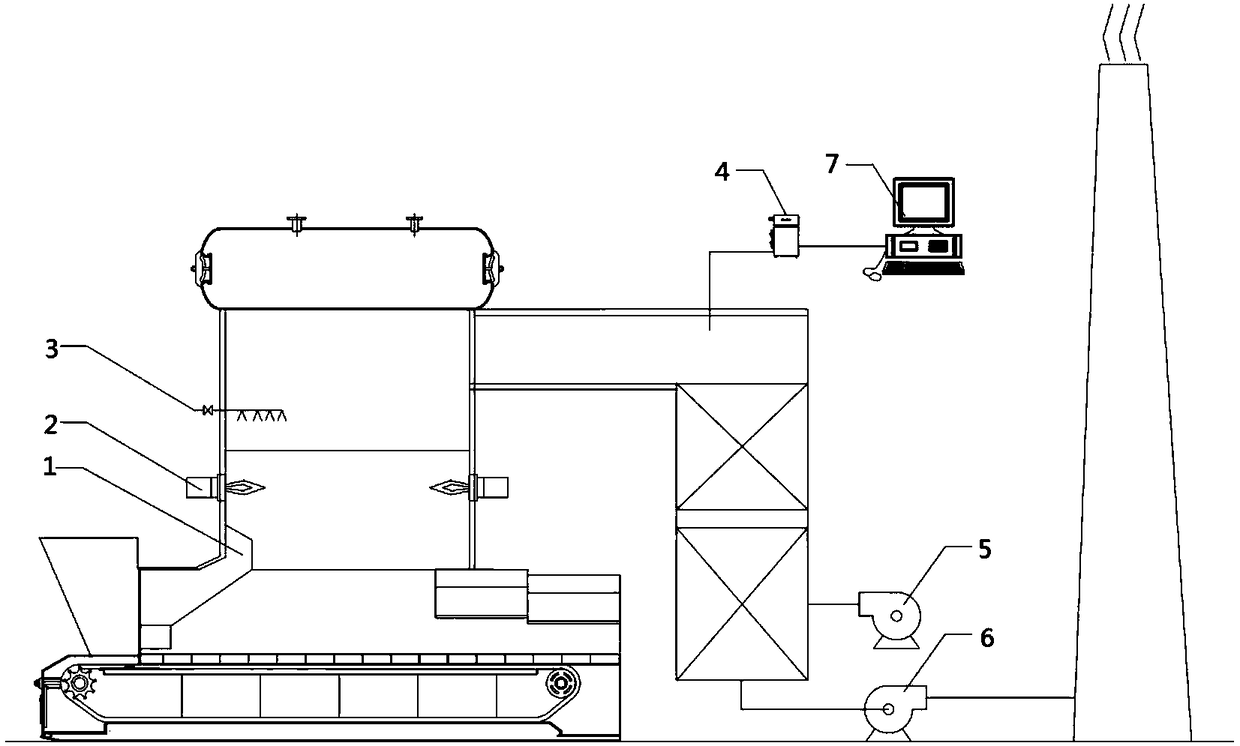

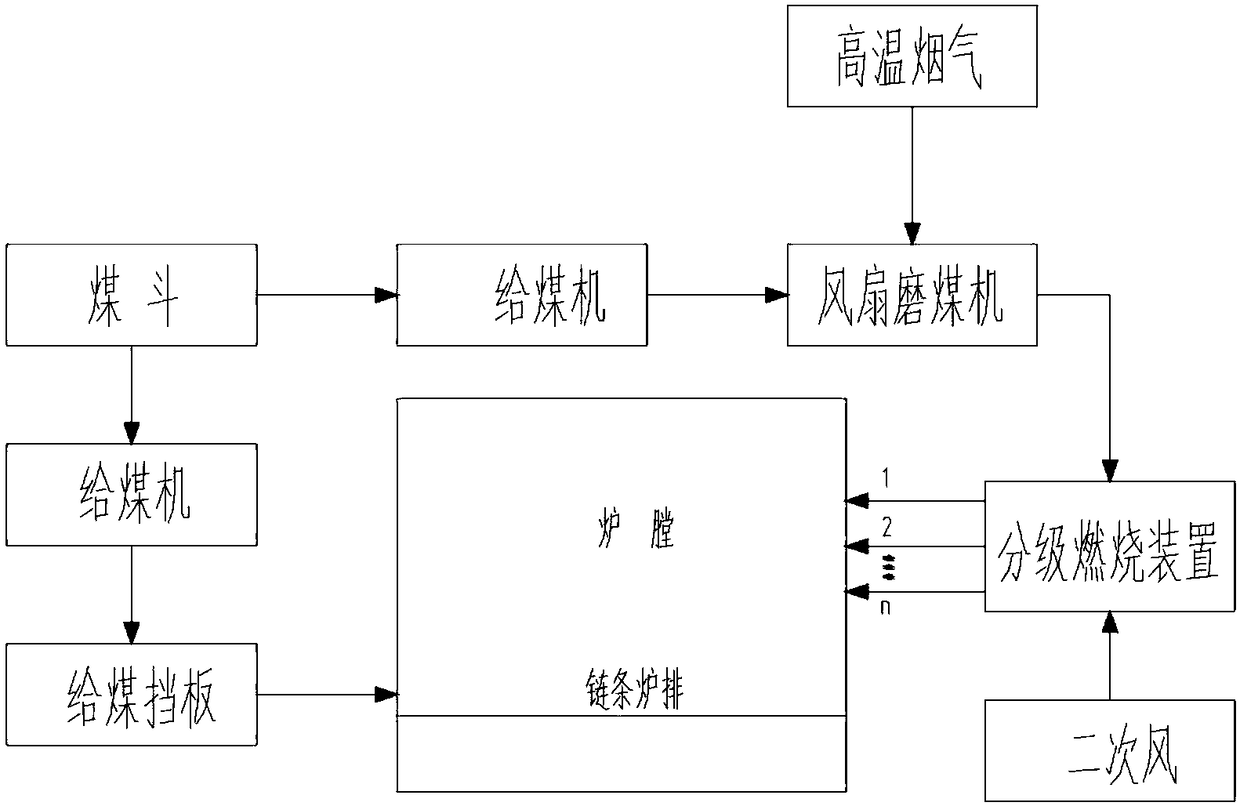

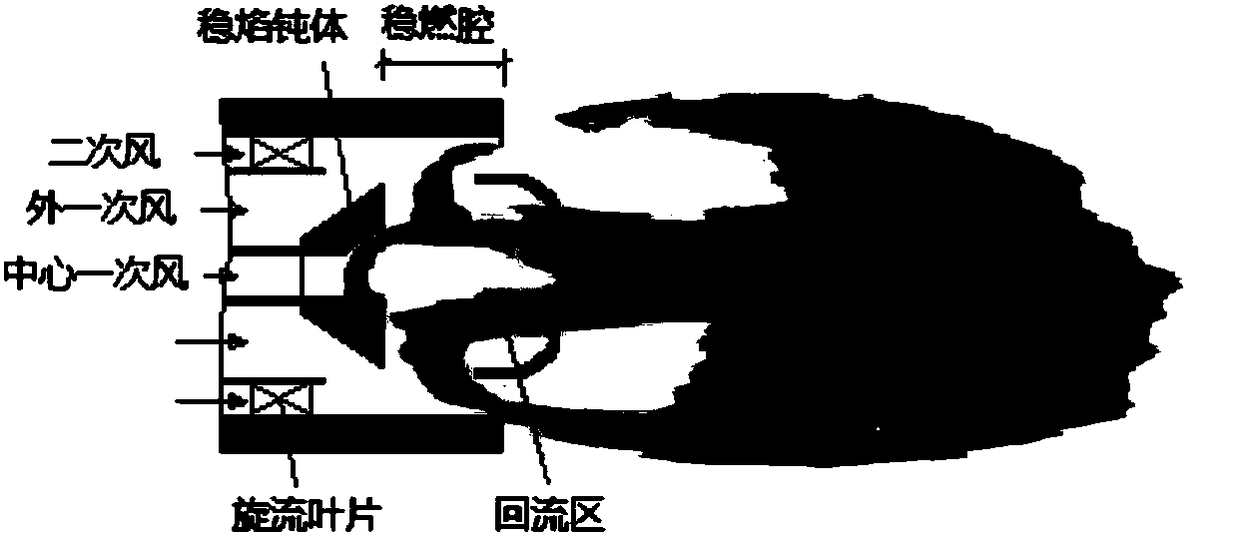

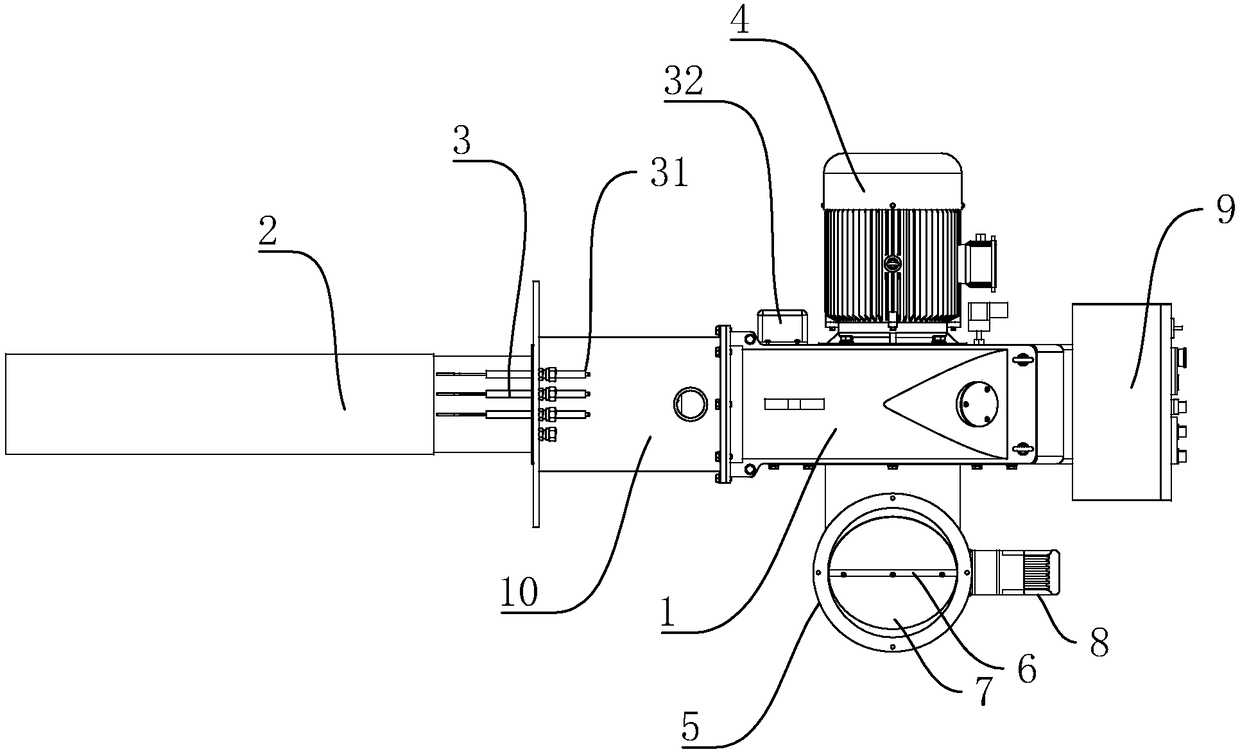

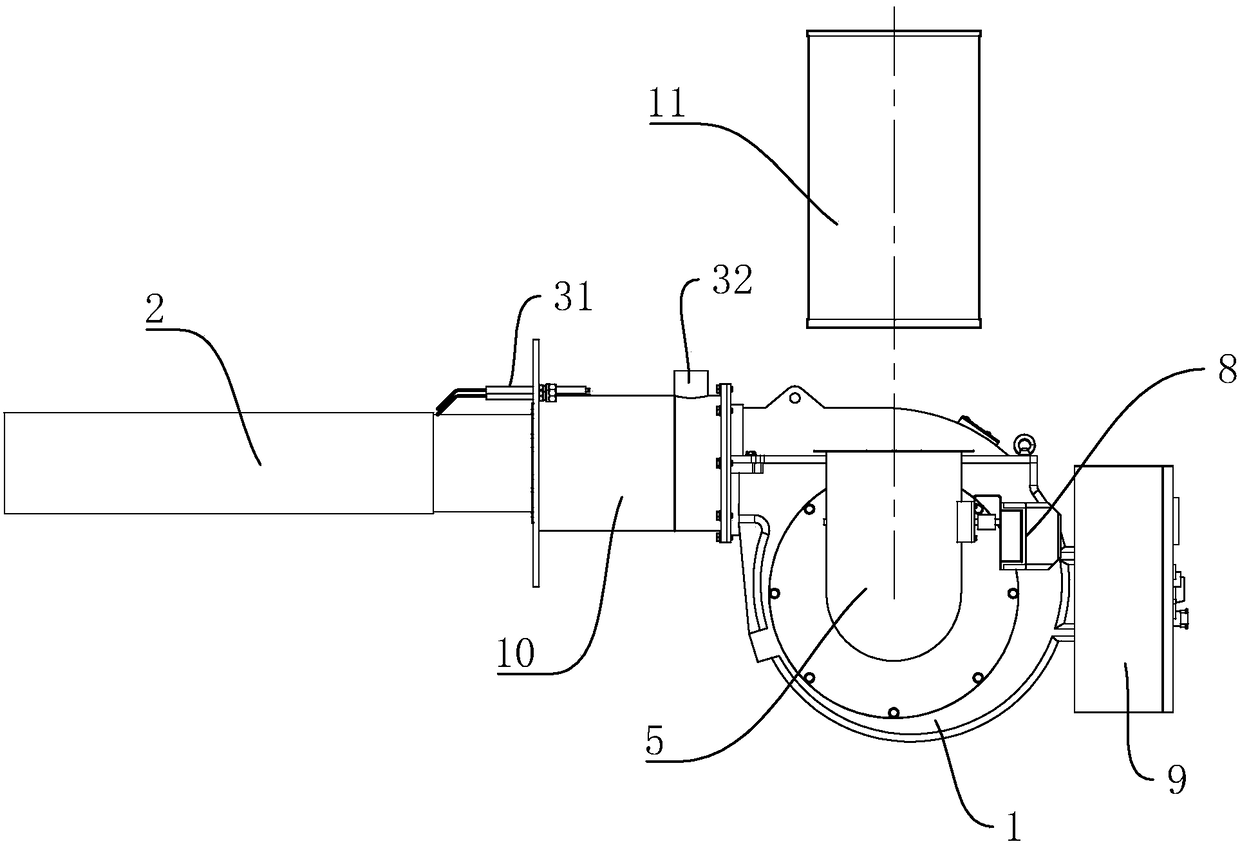

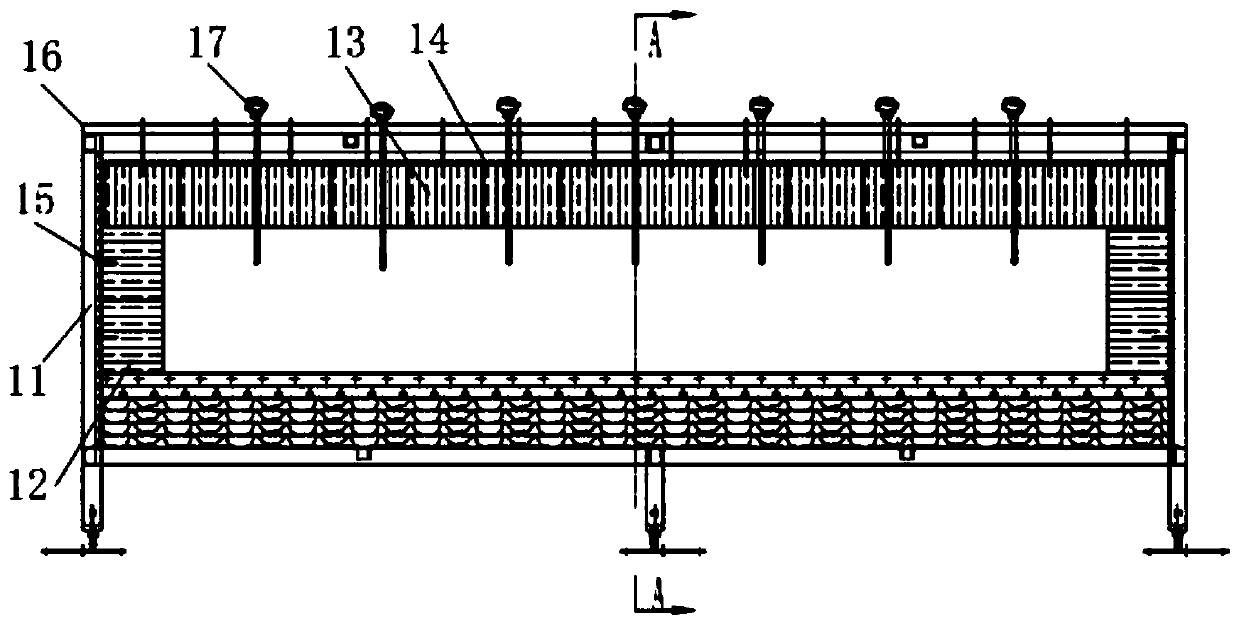

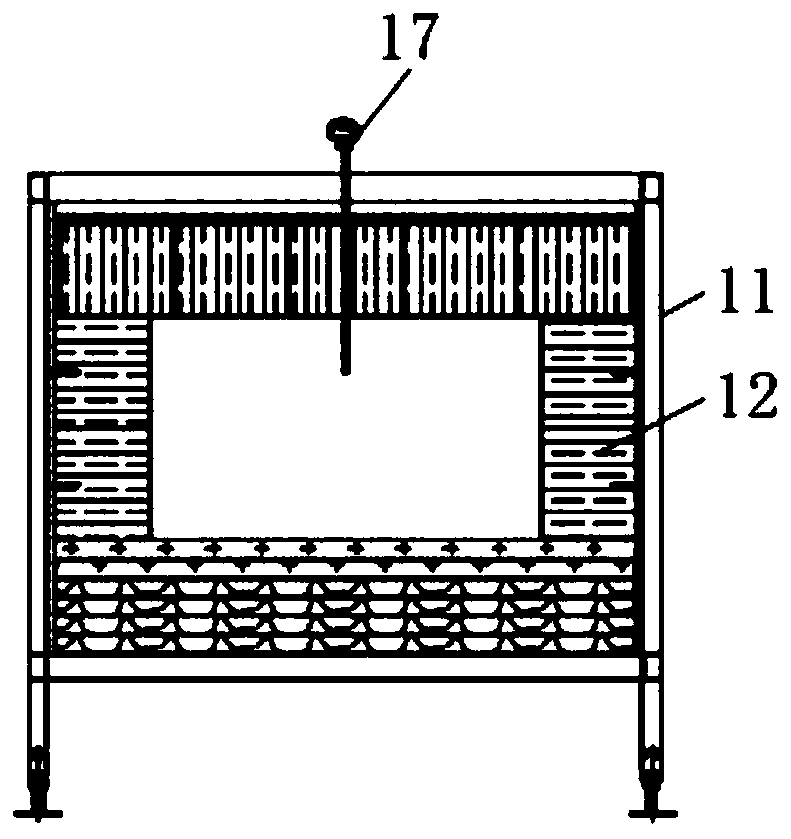

A Composite Control System for Nitrogen Oxide Emissions of Layer Burning Furnace

ActiveCN106352325BHigh speedImprove uniformityEmission preventionDispersed particle separationCycloneEnvironmental resistance

The invention belongs to the technical field of boiler energy conservation and environmental protection, and discloses a compound control system for the nitrogen oxide discharge amount of a grate-fired furnace. The compound control system comprises a grate-fired furnace body, stage combustion devices with flue gas recirculation, an SNCR (selective non-catalytic reduction) denitration device, a multifunctional flue gas online monitor and a PLC (programmable logic controller) control system, wherein the stage combustion devices are uniformly distributed on walls at two sides of a combustion chamber, an air inlet pipe is arranged in the center of an air inlet end of the stage combustion devices, an adiabatic flame stabilization blunt body is arranged at the other end of the air inlet pipe, a secondary wind cyclone is arranged on the wall at the air inlet end, and a combustion stabilization cavity is arranged at one end far from the air inlet end; and an appropriate amount of a mixture of powdered coal or fuel gas, fresh air and circulating flue gas is sprayed into the grate-fired furnace through the stage combustion devices. The compound control system disclosed by the invention can significantly improve the oxidation reaction speed of a fuel and the temperature uniformity of the combustion chamber, and can achieve full combustion and low-nitrogen combustion of the fuel and reduce the coefficient of excess air, thereby realizing double promotion of denitration efficiency and heat efficiency, and achieving the aims of energy conservation and emission reduction.

Owner:HUAZHONG UNIV OF SCI & TECH +1

low nitrogen burner

The invention discloses a low-nitrogen burner. According to the technical scheme, the low-nitrogen burner is characterized in that a mixer of the low-nitrogen burner comprises a barrel and a gas inlet, wherein an inner barrel and burning-supporting air swirling pieces arranged on the inner wall of the inner barrel are arranged at the gas inlet front end inside the barrel; an air inlet barrel located on the back side of the burning-supporting air swirling pieces in the air inlet direction is arranged at one end, close to the gas inlet back side, of the inner barrel; the air inlet barrel, the inner barrel and the inner wall of the barrel are connected in a sealed manner to form a gas sub-cavity; inclined flow guiding holes are formed in the air inlet barrel; a primary swirling impeller is arranged in the position, located on the air inlet back side of the inner barrel, inside the barrel; and the primary swirling impeller and the air inlet barrel form a primary mixing chamber. Through the arrangement, gas is ejected via the gas sub-cavity from the inclined flow guiding holes, the ejected gas can form multiple single, short and powerful gas flows, air flows sent by a fan pass through the burning-supporting air swirling pieces to form short and powerful rotating air flows, and the rotating air flows are circular and impact the multiple single gas flows, so that the air and the gas of the primary mixed gas reach the air-fuel ratio in the complete burning theory.

Owner:BEIJING SHENKEBOSI THERMAL ENERGY ENG TECH CO LTD

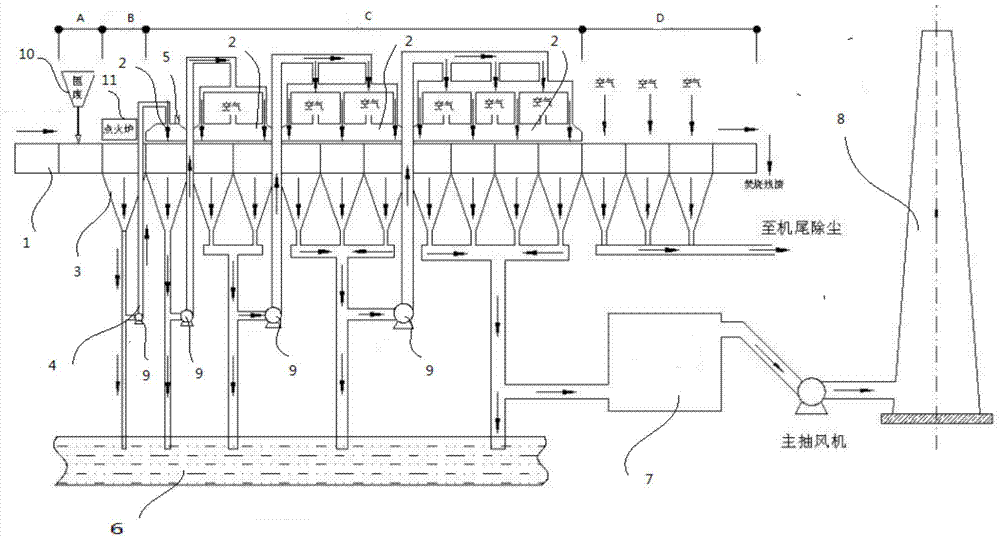

A method and a sintering machine for recycling flue gas to form a multi-stage secondary combustion chamber for incinerating solid waste flue gas

ActiveCN105674290BIncrease full circulationEasy to handleEmission preventionIncinerator apparatusThermodynamicsCombustion chamber

The invention provides a method for circulating flue gas on a sintering machine to form a multi-stage secondary combustion chamber for incineration disposal of solid waste flue gas. The sintering machine is utilized as main equipment for disposing solid waste, flue gas generated in the incineration process is circularly disposed, and the multi-stage secondary combustion chamber is formed through a next-stage combustion material layer. Specifically, a plurality of independent flue gas hoods are sequentially arranged above an incineration section of the sintering machine, and materials of the incineration section are isolated from external air; each flue gas hood corresponds to one or more draught hoods below the incineration section of the sintering machine, a flue gas inlet is formed in each flue gas hood, and each flue gas inlet is connected with a negative-pressure air draft pipeline of the previous draught hood below the incineration section; all flue gas generated by combustion of the preceding stage is collected to an air inlet position of the next stage to be mixed with distributed fresh air to be used as a combustion gas source of this stage, the flue gas passes through a high-temperature combustion zone in the incineration process to be subjected to secondary combustion, and full-amount circulating combustion of the flue gas is achieved; and combustible substances existing in the flue gas are thoroughly combusted, and the construction investment and operating cost of a flue gas purification system project are reduced.

Owner:CHONGQING ANGRUIYUE SCI & TECH

Energy-saving combustion test furnace for testing burner performance

PendingCN110986587AGood energy saving effectHigh combustion air temperatureFurnace typesCombustionExhaust fumes

The embodiment of the invention discloses an energy-saving combustion test furnace for testing burner performance. The energy-saving combustion test furnace comprises a kiln body, an air supply and exhaust system, a combustion supporting system and a detection data acquisition mechanism, wherein the periphery of the kiln body is closed, and the kiln body comprises a kiln frame and a fire-resistantheat preservation layer; the air supply and exhaust system is arranged on the kiln body and used for providing combustion-supporting air and exhausting waste gas; the combustion supporting system isarranged on the kiln body and used for providing fuel for a burner to be tested; the detection data acquisition mechanism comprises a temperature sensor arranged on the kiln body, an air pressure sensor arranged on the air supply and exhaust system and a product placing hole formed in the kiln body. By the adoption of the device, the real environment of the kiln can be simulated, the performance of key parts such as the burner and the fire-resistant heat preservation structure of the kiln is tested through simulated combustion, and detection data can be obtained conveniently.

Owner:DLT TECH CO LTD

Energy-saving environmental protection coal combustion catalyst

InactiveCN101215491BRaise the furnace temperatureReduce burnout timeSolid fuelsElectrolysisRare earth

The invention discloses an energy saving and environmental friendly coal combustion catalyst, the catalyst is prepared through dissolving raw materials with the following mass parts in 100 parts water and evenly mixing, the raw materials and the mass parts are that: sulphuric acid plant residues 20-30, electroplating plant discard solution 25-35, electrolytic copper plant discard solution 25-30, nitrification rare earth 5-10, anionic surfactant 3-5 and soluble calcium salt 2-5. When the coal combustion catalyst of the invention is in use, the coal combustion catalyst is only needed to be evenly sprayed on the coal surface and sufficiently mixed evenly with a mixer. The coal combustion catalyst of the invention is applied to various coal powders spraying boilers, coal slurry boilers, chainboilers, boiling boilers, other forms coal-fired boilers and civil scattered burning coal which enables the use to be convenient use and cost to be cheap and can increase the combustion intensity andthe fire box temperature of the coal, improve the combustion performance of the coal, lower exhaust emission volume, saves the coal by 10-20%, and the like.

Owner:SOUTH CHINA UNIV OF TECH

Combustor for horseshoe flame glass kiln, glass kiln and burning method

ActiveCN111072257ASlow down the intensity of burningReduce surplus factorGlass furnace apparatusChemistryNitric oxide

The invention discloses a combustor for a horseshoe flame glass kiln, the glass kiln and a combustion method. The combustor comprises a combustor body, wherein the combustor body comprises a gas outercavity and a gas inner cavity sleeved with the gas outer cavity, the tail of the gas outer cavity and the tail of the gas inner cavity are both sealed, the head of the gas outer cavity and the head of the gas inner cavity are both open, a gas main inlet is formed in the tail of the gas outer cavity, and an inner cavity gas inlet communicated with the gas outer cavity is formed in the gas inner cavity; the combustor further comprises an adjusting assembly used for adjusting the section opening rate of the gas outer cavity. According to the combustor for the horseshoe flame glass kiln, a stageddouble-flame combustion mode combining long flame and short flame is achieved, the reaction speed of fuel gas and combustion-supporting air is decreased, the severe combustion degree of the fuel gasis decreased, and the local high temperature of a flame space is avoided. Meanwhile, excess air is reduced, the excess air coefficient is reduced, and the purpose of reducing generation of nitric oxide is achieved.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

Composite type coal-saving and catalyzing combustion improver

InactiveCN102732356BIncreased precipitation rateHigh thermal efficiencySolid fuelsCalcium silicateSesquioxide

The invention discloses a composite type coal-saving and catalyzing combustion improver, comprising the following components in weight by percentage: 40-60 parts of accelerating agent, 0.5-1% of inducing agent, 10-20% of catalyst, 8-15% of dispersant and 20-40% of stable sulfur fixing agent, wherein an alcohol-based fuel is used as the accelerating agent and calcium peroxide is used as the inducing agent; the catalyst is formed by 20-30% of nano iron sesquioxide, 20-30% of nano ferrous oxide, 20-30% of nano ferroferric oxide, 5-10% of nano manganese dioxide, 10-15% of sodium carbonate and 10-15% of potassium carbonate; a polyoxyethylene based ether surfactant is used as the dispersant; and the stable sulfur fixing agent is formed by 20-30% of calcium carbonate, 20-30% of calcium silicate and 50-60% of calcium oxide. The combustion improver is added into fire coal and then the fire coal is combusted, so that the coal saving rate can be more than 30% and the SO2 discharging amount can be effectively reduced after the fire coal is combusted.

Owner:桂林市产品质量监督检验所 +1

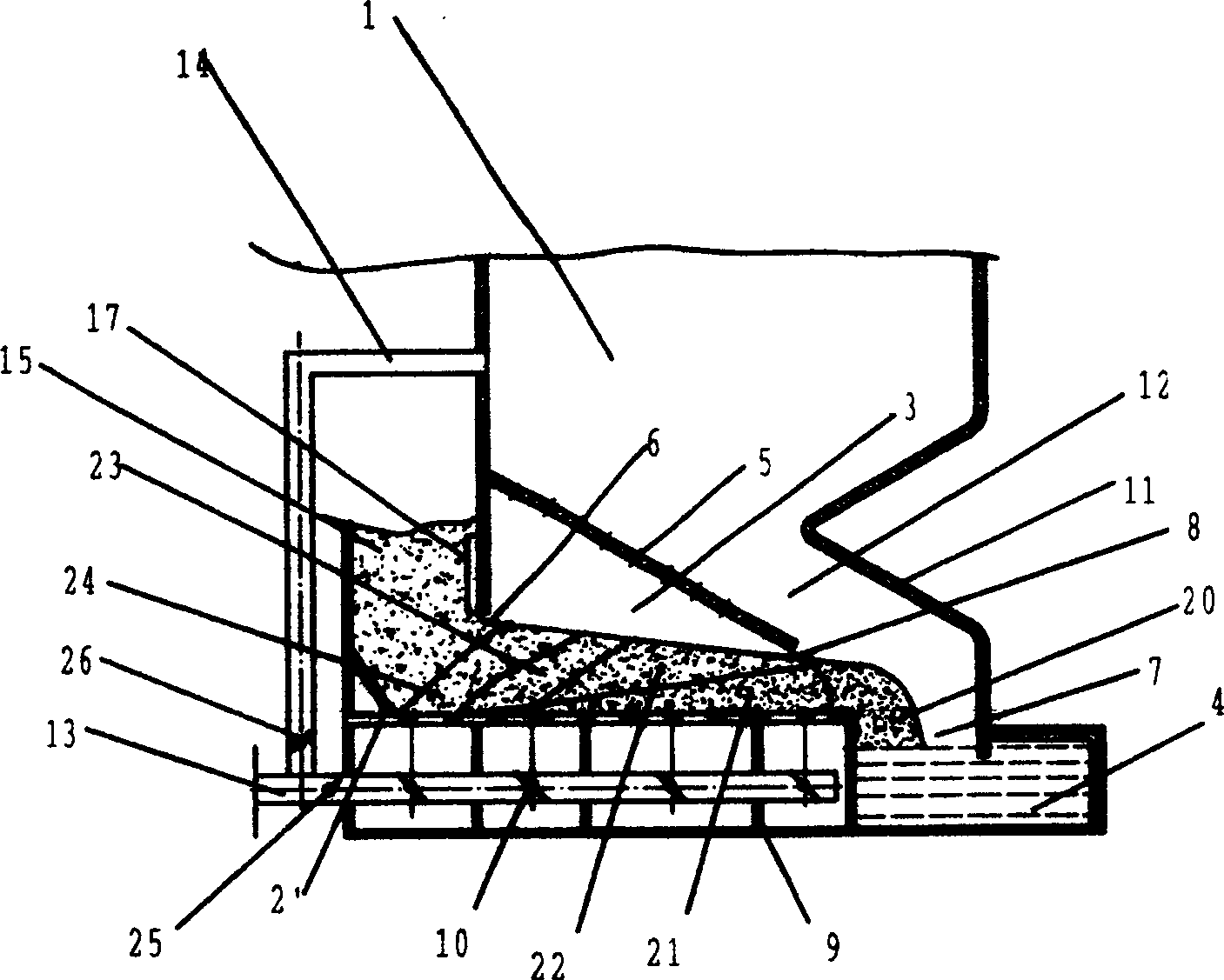

Layer and chamber integrated clean combustion arrangement

InactiveCN1280577CSimple structureCompact structureSolid fuel combustionCombustion apparatusNarrow rangeCombustion chamber

An integrated clean combustion device with layer and chamber combustion, which relates to a combustion device using coal as fuel, belongs to the technical field of combustion devices, and is used to solve the defects of narrow adaptability and poor processability of existing such devices. There are combustion chamber, grate, gas generator, water seal pool, and primary and secondary air ducts. After improvement, the gas generator is obliquely offset on the bottom side of the combustion chamber, and the air guide holes on it are arranged along the inclined top wall. . After adopting the inclined offset structure, the raw coal can be piled up above the fixed grate by intermittent addition, and can also enter from the offset side with the advancement of the movable grate, so that the present invention can be adapted to both vertical boilers and horizontal boilers. type boiler and other coal-fired devices, which expands the application range of the layer chamber combustion technology, and simplifies the structure of the gas generator and even the combustion chamber, and has the advantages of good processing technology, compact structure, and convenient maintenance and repair. It is suitable for various Various vertical and horizontal boilers, industrial coal-fired furnaces and civilian stoves.

Owner:冯栓海

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com