A method and device for gasification, pyrolysis, catalytic regenerative combustion of organic matter

A technology of regenerative combustion and pyrolysis catalysis, which is applied in the field of environmental protection, can solve the problems of reducing the gasification efficiency of organic matter, affecting the stable operation of the system, and high exhaust gas treatment costs, and achieves good treatment effects, compact structure, and safe and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

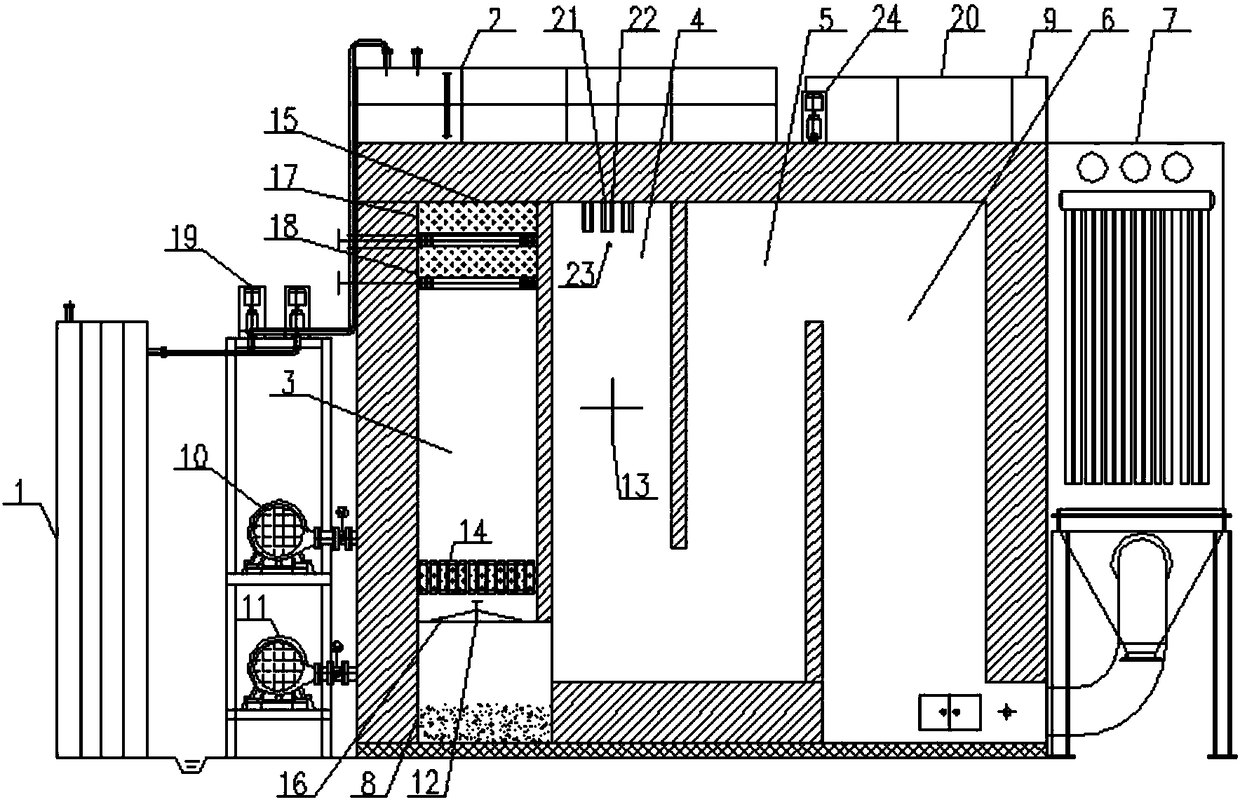

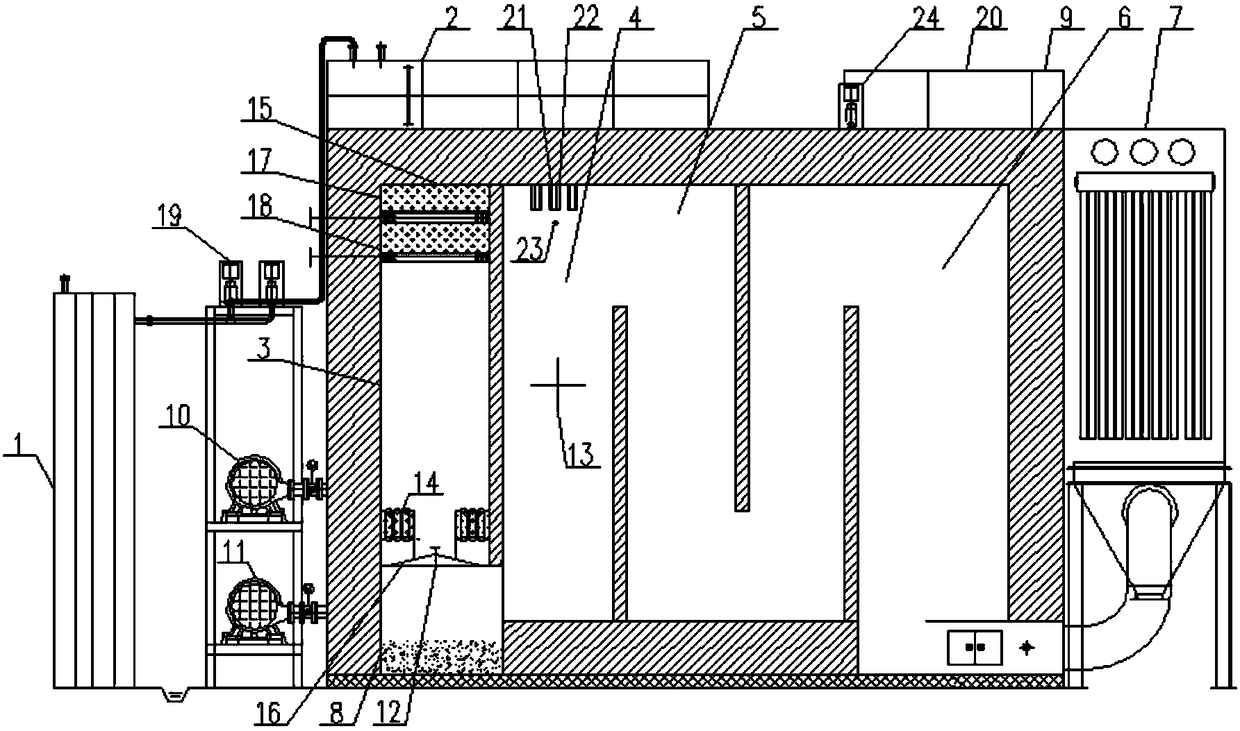

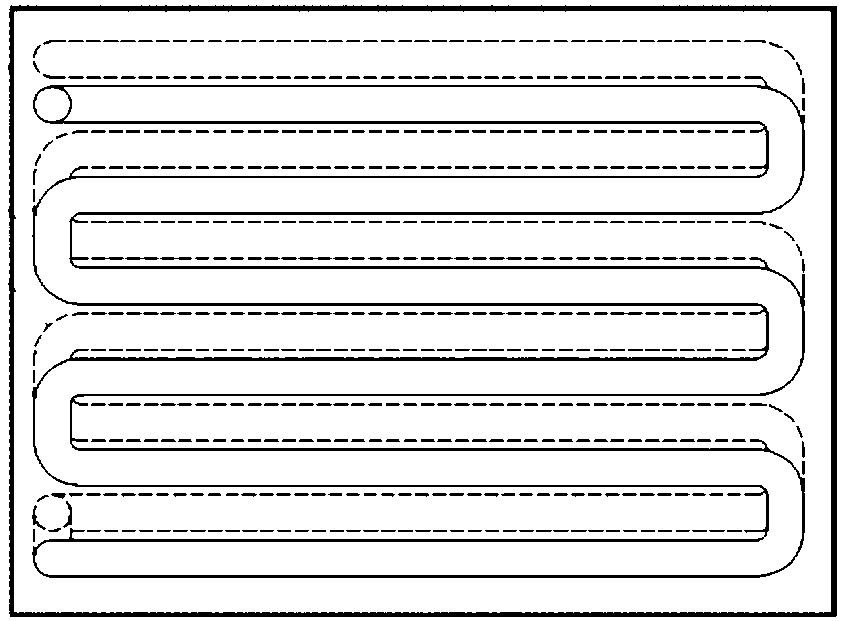

[0031] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0032] Such as figure 1 -As shown in Figure 6, the organic matter fuel, CaO, and dolomite are pressed into a large hole-shaped fuel, before the organic matter gasification, pyrolysis, catalytic regenerative combustion device starts to work, the first closed area 17 and the second closed area 18 are opened, and the organic matter The fuel 14 enters the perforated gasification pyrolysis section 3 through the first closed area 17 and the second closed area 18 in sequence, and falls on the vertical spiral ash removal and air supply integrated device 12. After the feeding is completed, the second closed area 18 is closed , continue to feed, so that the organic fuel is stored in the second closed area 18, the first closed area 17 is closed after the feeding, and the device starts to work at this time, the auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com