Anaerobic pyrolysis treatment system and method for garbage

A treatment system and pyrolysis technology, applied in the field of waste treatment, can solve the problems of easy adhesion to the wall and shaft of the reaction tank, the inability of the equipment to run stably for a long time, and the large energy consumption of cooling fluidized steam, etc. The effect of a small number of equipment and a low total smoke emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

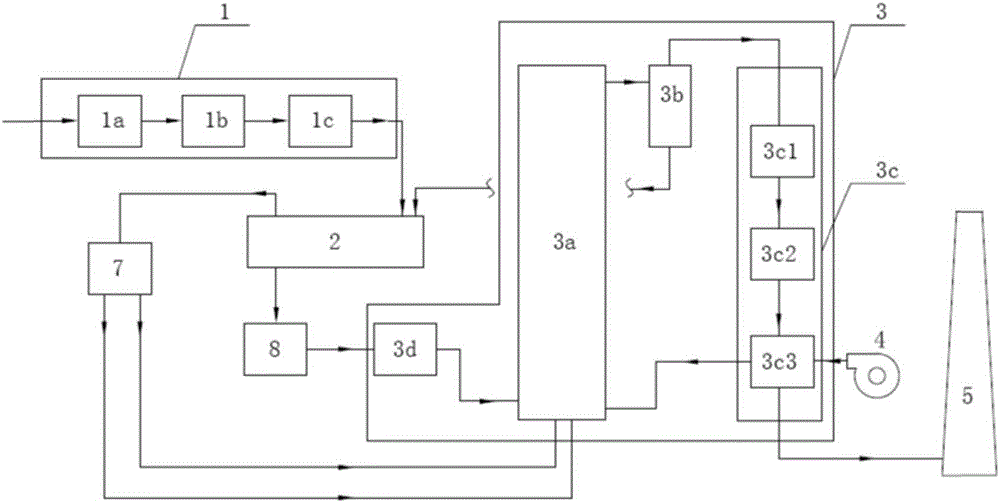

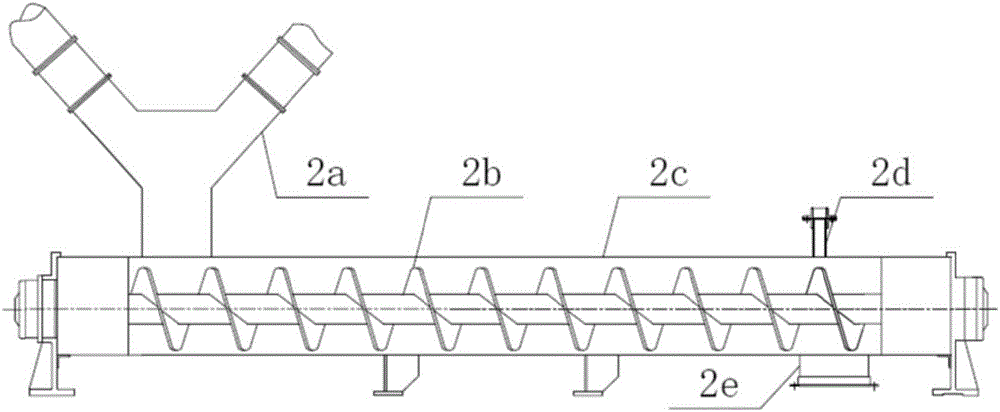

[0031]An anaerobic pyrolysis treatment system for garbage, comprising a pretreatment unit 1, a pyrolysis device 2, a combustion unit 3, a purification device 7, and an intermediate silo 8, wherein the pretreatment unit 1 includes a sorting unit 1a, a crushing unit 1b, The drying unit 1c, and the sorting unit 1a, the crushing unit 1b, and the drying unit 1c are connected in series in sequence, the drying unit 1c is connected to the pyrolysis device 2, and the pyrolysis device 2 is respectively connected to the purification device 7 and the intermediate silo 8, and the combustion unit 3 includes Furnace 3a, gas-solid separation device 3b, waste heat recovery unit 3c, feeder 3d, and waste heat recovery unit 3c includes air preheater 3c3, economizer 3c2, superheater 3c1, purification device 7 through two pipelines and combustion The furnace 3a in the unit 3 is connected, and the intermediate feed bin 8 is connected with the feeder 3d of the solid heat carrier furnace, and in the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com