Axial rotational flow stepless regulation low-nitrogen combustor

A low-nitrogen burner, stepless adjustment technology, applied in the direction of burners, burners burning powder fuel, combustion methods, etc., can solve the problem that the swirl angle of the swirl wind cannot be adjusted, the fuel and air cannot be fully mixed, and the pull method The pipe nozzle does not have the problem of adjusting the axial air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

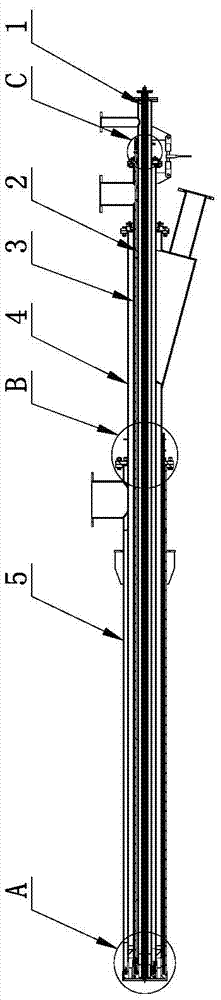

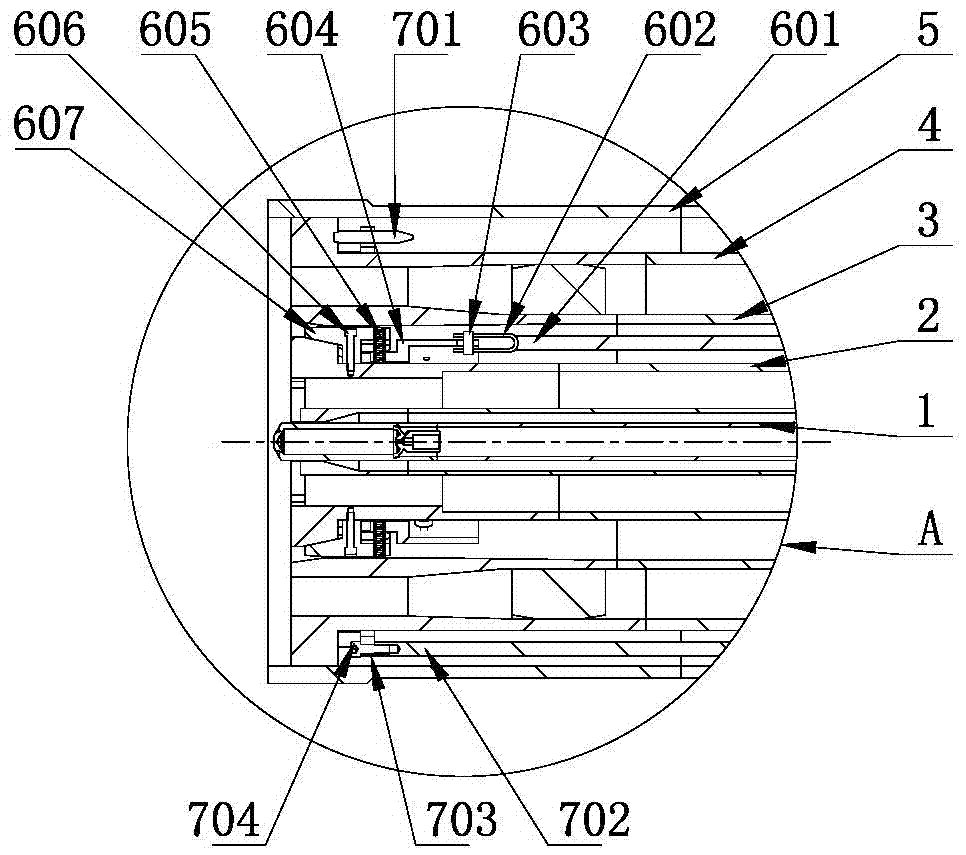

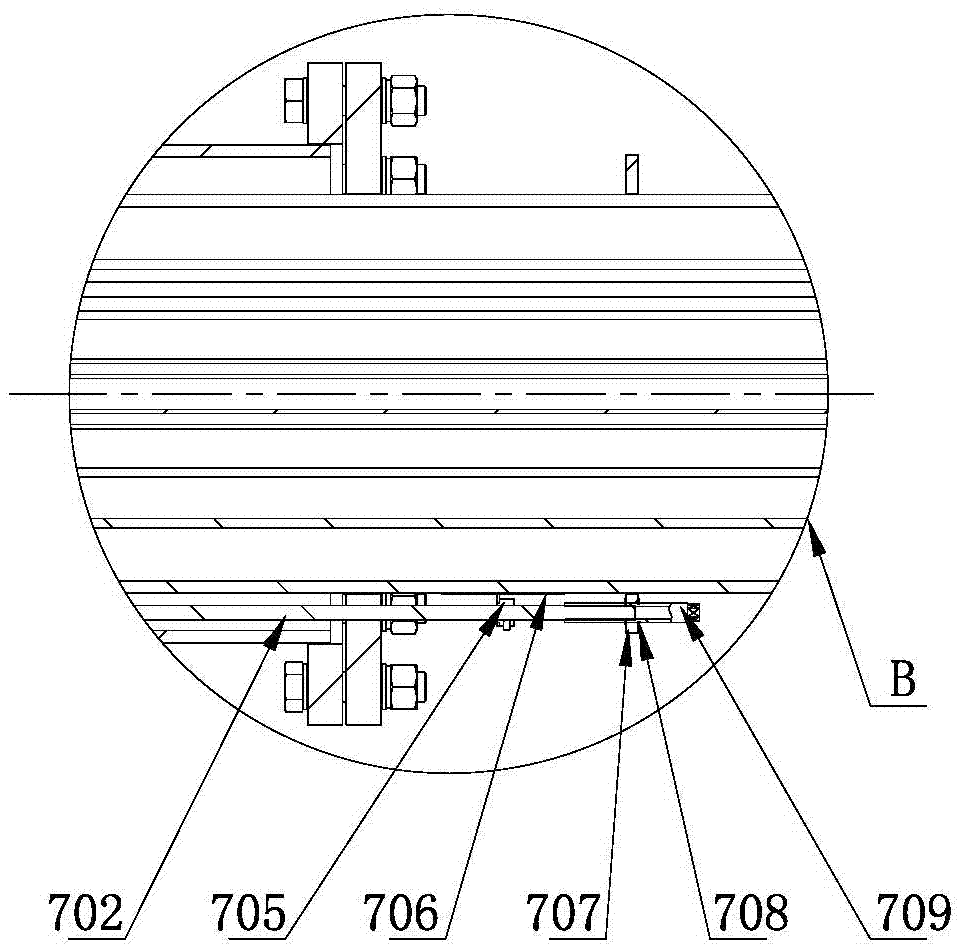

[0025] Such as Figure 1-7 The axial swirling stepless adjustable low-nitrogen burner shown includes an oil gun 1, a central air pipe 2, a gas pipe 3, a coal air pipe 4, and an axial flow air pipe 5 arranged from the inside out. A gas passage is formed between the pipe 3 and the central air pipe 2;

[0026] The gas channel is provided with a swirling wind regulating mechanism 6, which includes a number of swirling wind regulating fan plates 607 evenly installed on the outer periphery of the central air pipe 2, and the swirling wind regulating fan plates 607 are processed into a T-shaped structure. The plate 607 is installed on the outer periphery of the central air duct 2 through the set screw 606, and the set screw 606 passes through the middle part of the swirling wind adjusting fan plate 607 to install the swirling air adjusting fan plate 607 on the central air duct 2, and the swirling air adjusting fan plate 607 can be wound around The positioning screw 606 swings, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com