Integrated low-carbon micro-discharge energy-saving and emission-reduction boiler system

A technology of energy saving and emission reduction, boiler body, applied in the direction of indirect carbon dioxide emission reduction, non-flammable liquid/gas transportation, combustion method, etc., can solve the problems of wasting land resources, affecting the appearance of the city, environmental heat pollution, etc., and achieve full utilization , Good emission reduction effect, heat pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

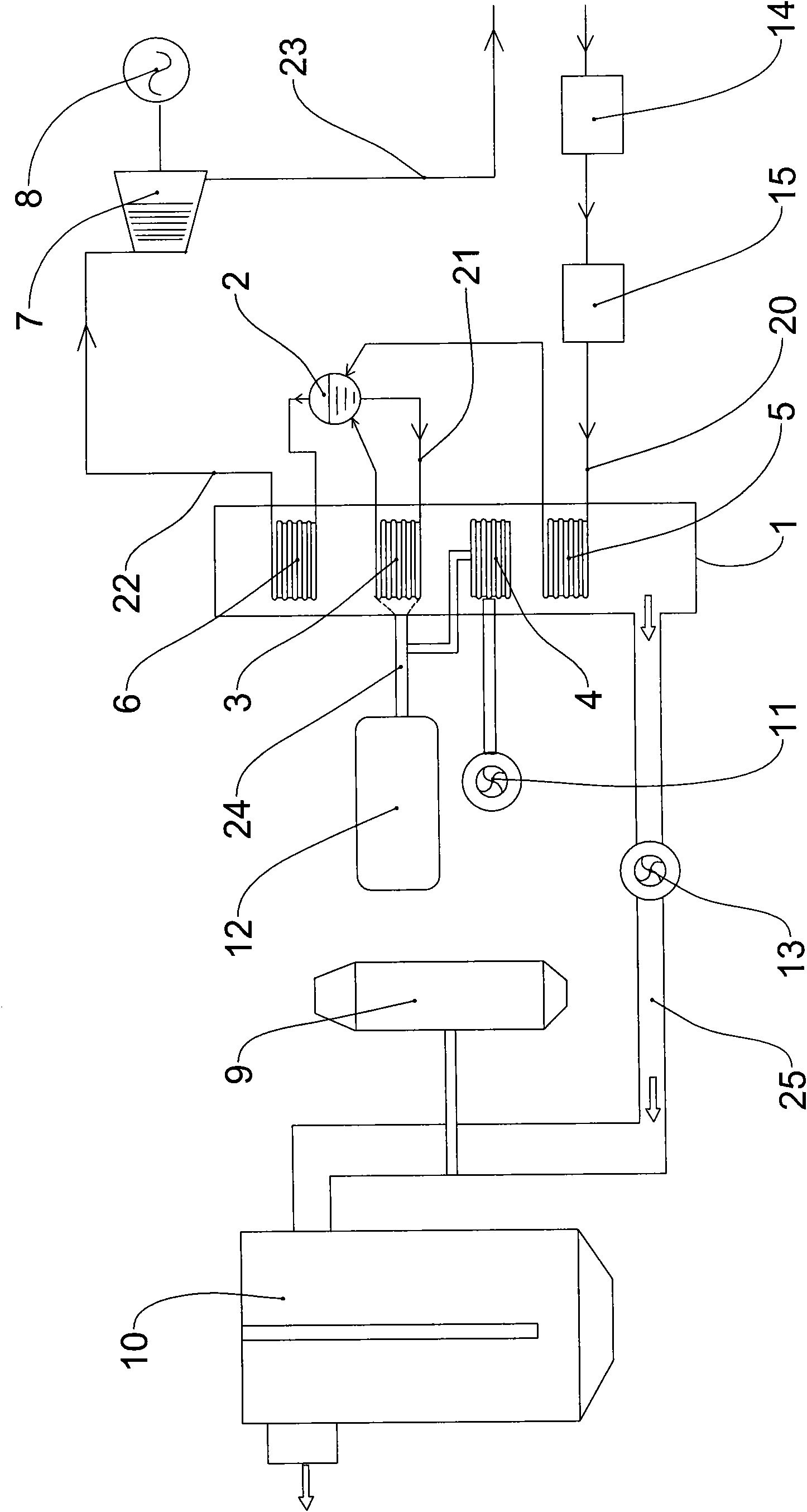

[0019] Such as figure 1 As shown, this embodiment includes boiler body 1, steam drum 2, heat exchanger 3, preheater 4, economizer 5, superheater 6, steam turbine 7, generator 8, flue gas secondary combustion device 9, desulfurization The dust removal device 10, the blower 11, the oxygen-enriched air supply device 12, the flue gas induced draft fan 13, the steam drum 2 and the heat exchanger 3 form a hot water heating circulation loop through the circulating heating pipeline 21, and the economizer 5. It is connected to the water inlet of the steam drum 2 through the boiler feed water pipeline 20. The economizer 5 absorbs relatively low-temperature flue gas, which reduces the exhaust gas temperature of the flue gas, reduces the loss of exhaust gas, and saves fuel , the efficiency is improved, the temperature of the feed water is increased, and the wall temperature difference will be reduced when entering the steam drum 2, the thermal stress will be reduced accordingly, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com