A method and a sintering machine for recycling flue gas to form a multi-stage secondary combustion chamber for incinerating solid waste flue gas

A technology of flue gas circulation and sintering machine, which is applied in combustion methods, combustion product treatment, waste heat treatment, etc., can solve the problems of increasing treatment equipment and complex process flow, and achieves the goal of reducing energy consumption, reducing emissions, and reducing dust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

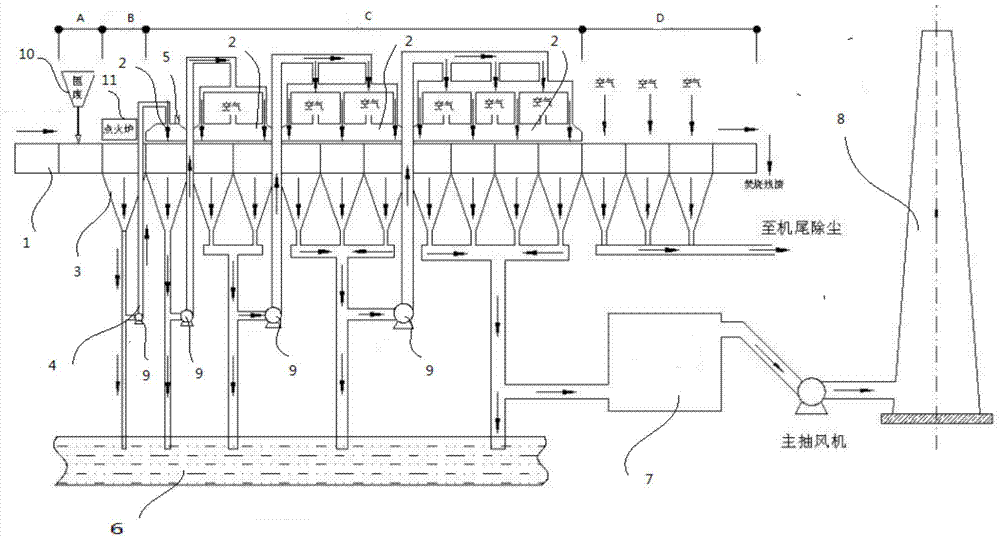

[0027] The present invention utilizes the now mature sintering production equipment, and transforms it on the basis to form such figure 1 The solid waste treatment sintering machine with multi-stage secondary combustion chamber is shown.

[0028] The sintering machine includes a frame, a transmission mechanism, and a trolley. A plurality of trolleys 1 are arranged in series as required, and they run on the frame through the transmission mechanism. The transmission mechanism can be a belt type or a chain type.

[0029] The sintering machine is the same as the traditional one, with a cloth section A at the front end, an ignition section B at the front, an incineration section C at the middle, and a cooling section D at the rear end. A plurality of exhaust hoods 3 are sequentially arranged on the lower frame of the incineration section C, each exhaust hood is connected with a set of negative pressure exhaust pipelines 4, and a fan 9 is arranged on the pipelines.

[0030] In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com