Combustor for horseshoe flame glass kiln, glass kiln and burning method

A glass furnace and combustion method technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of unsuitable application of horseshoe flame glass furnace, relatively complex process, difficult operation, etc., and achieve emission reduction. The effect is obvious, the process is simple, and the effect of avoiding local high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

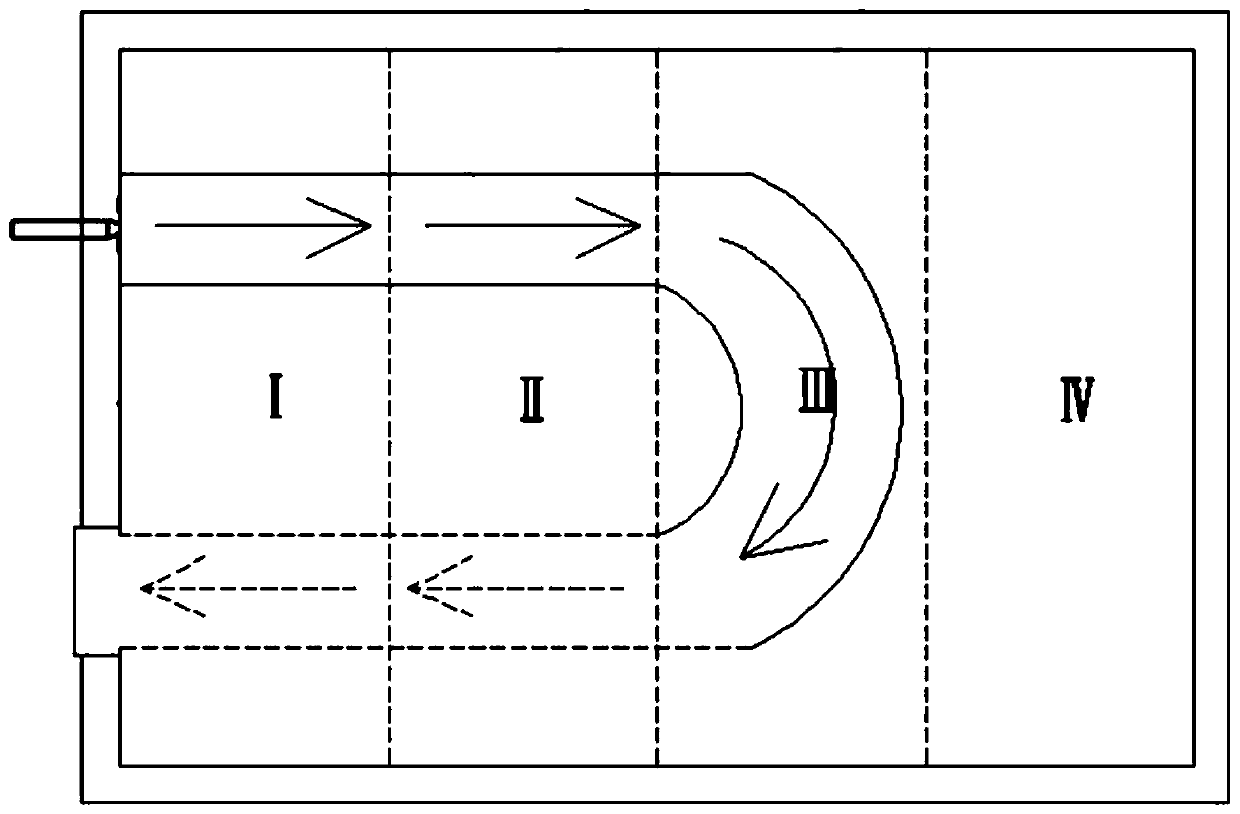

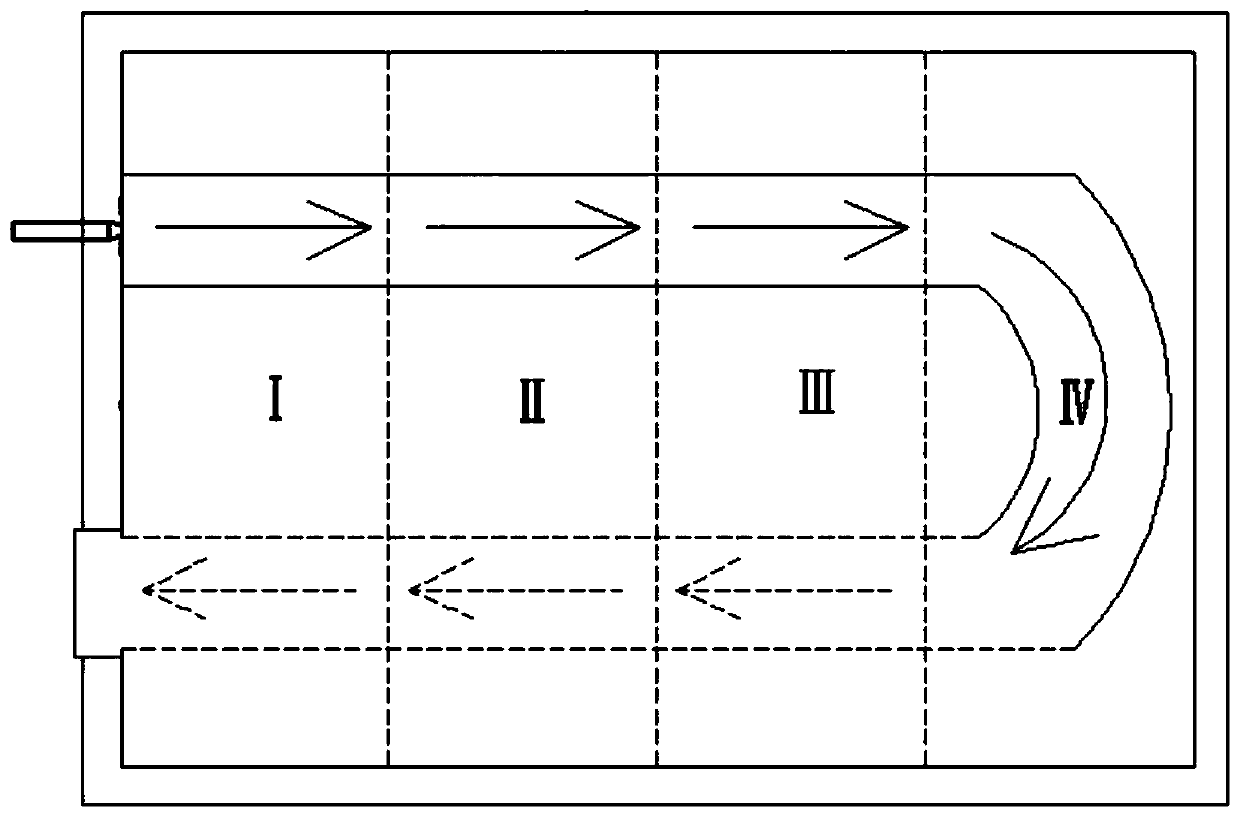

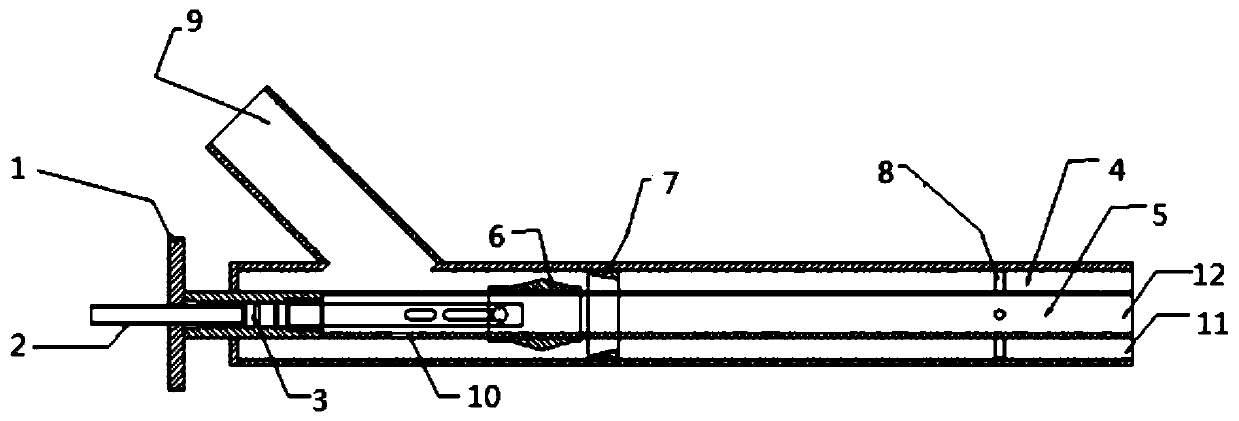

[0041] Use the burner of the present invention to burn in a horseshoe flame kiln of 160 tons per day, the flow velocity of the combustion-supporting air entering the kiln is 10m / s, the open rate of the cross-sectional area of the gas outer chamber 4 is 50%, and the flame coverage area is I, Ⅱ, Ⅲ and Ⅳ; the nitrogen oxide emission concentration is 1600 mg / standard cubic meter.

Embodiment 2

[0043] Use the burner of the present invention to burn in a horseshoe flame kiln of 160 tons per day, the flow velocity of the combustion-supporting air entering the kiln is 10m / s, the open rate of the cross-sectional area of the gas outer chamber 4 is 40%, and the flame coverage area is I, Ⅱ, Ⅲ and Ⅳ; the nitrogen oxide emission concentration is 1800 mg / standard cubic meter.

Embodiment 3

[0045] Use the burner of the present invention to burn in a horseshoe flame kiln of 160 tons per day, the flow velocity of the combustion-supporting air entering the kiln is 10m / s, the open rate of the cross-sectional area of the gas outer cavity 4 is 60%, and the flame coverage area is I, Ⅱ, Ⅲ and Ⅳ; the nitrogen oxide emission concentration is 1900 mg / standard cubic meter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com