Layer and chamber integrated clean combustion arrangement

A technology of clean combustion and chamber combustion, applied in the field of combustion devices, can solve the problems of complex structure of gas generator and combustion chamber, inconvenient for use of horizontal boilers, poor processing technology, etc., achieving compact structure, convenient maintenance and repair, The effect of improving the thermal efficiency of combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

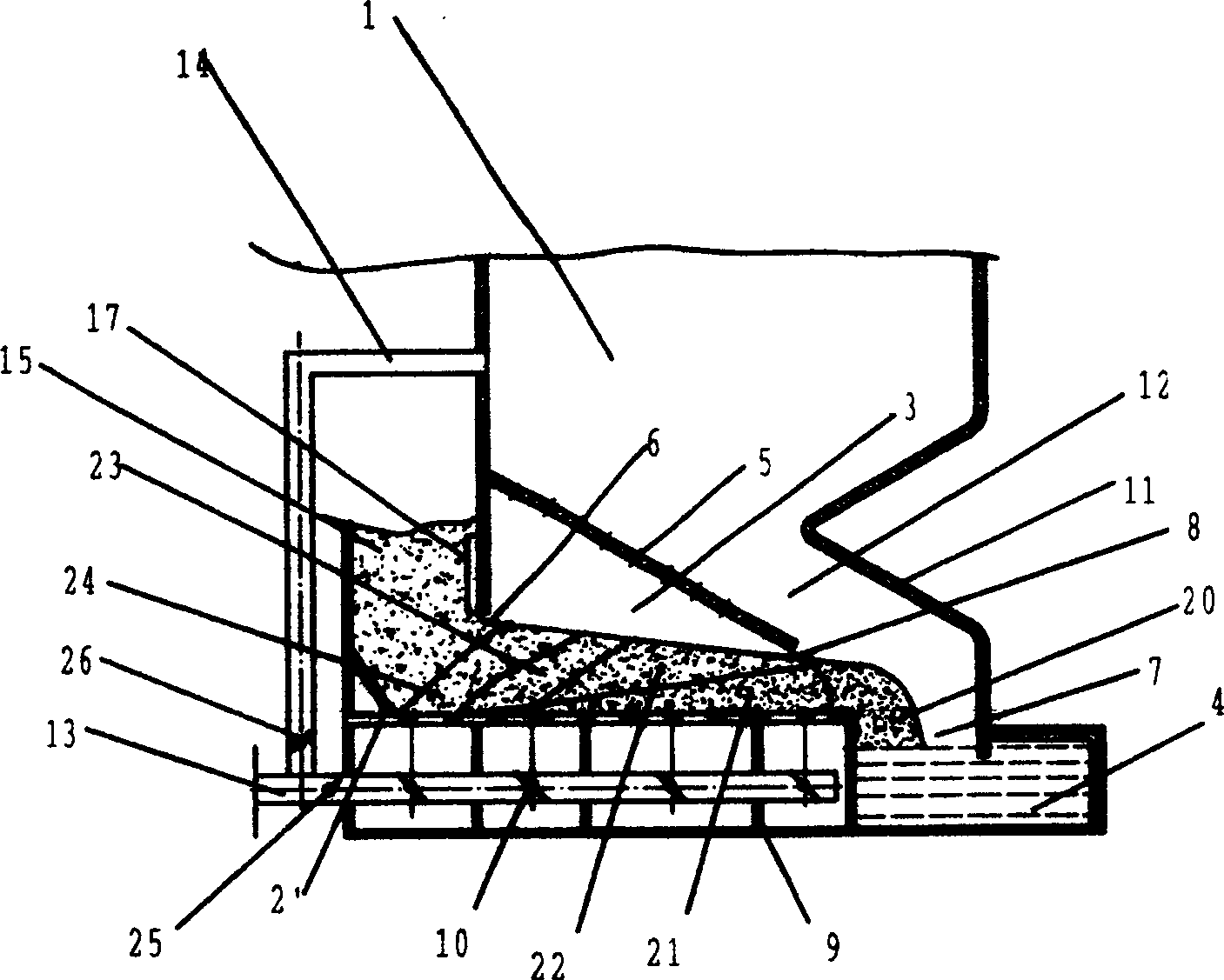

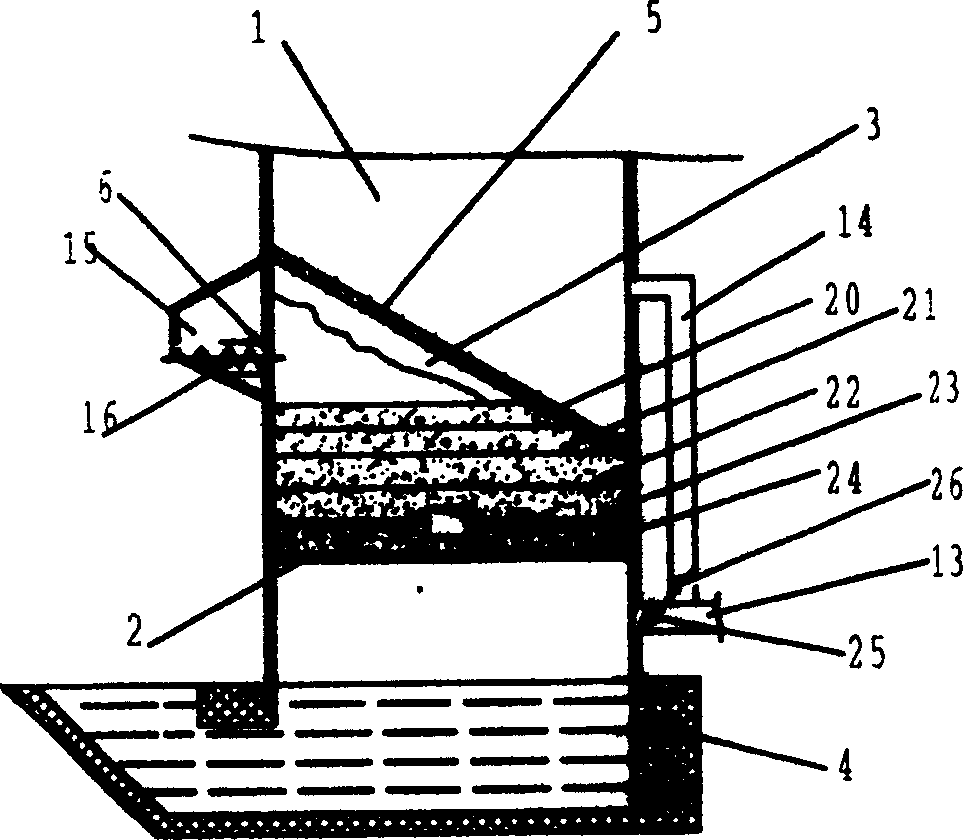

[0020] The parts in the attached drawings are labeled: 1 combustion chamber, 2 fixed grate, 2'movable grate, 3 gas generator, 4 water-sealed tank, 5 air guide hole, 6 coal inlet, 7 slag outlet, 8 coal outlet , 9 dividing plate, 10 adjusting air door, 11 rear arch, 12 oblique passage, 13 primary air inlet pipe, 14 secondary air inlet pipe, 15 coal scuttle, 16 coal feeder, 17 ram, 20 slag layer , 21 oxidation layer, 22 reduction layer, 23 dry distillation layer, 24 dry layer, 25 primary air control damper, 26 secondary air control damper.

[0021] Attached figure 1 It is the basic structure used in vertical boilers. When the vertical boiler with this structure is used, the burnt-out slag falls into the water-sealed pool 4 to produce water vapor. After a large amount of primary air and water vapor are mixed, it passes through the slag layer 20 and enters the oxide layer 21, where a violent oxidation reaction occurs and releases When a large amount of heat and a large amount of carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com