Working method and device of pre-mixing type secondary combustor

A secondary combustion and working method technology, which is applied in the direction of combustion methods, burners, gas fuel burners, etc., can solve the problems that premixed combustion cannot be applied, and achieve the goal of reducing the excess air coefficient and ensuring safety and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

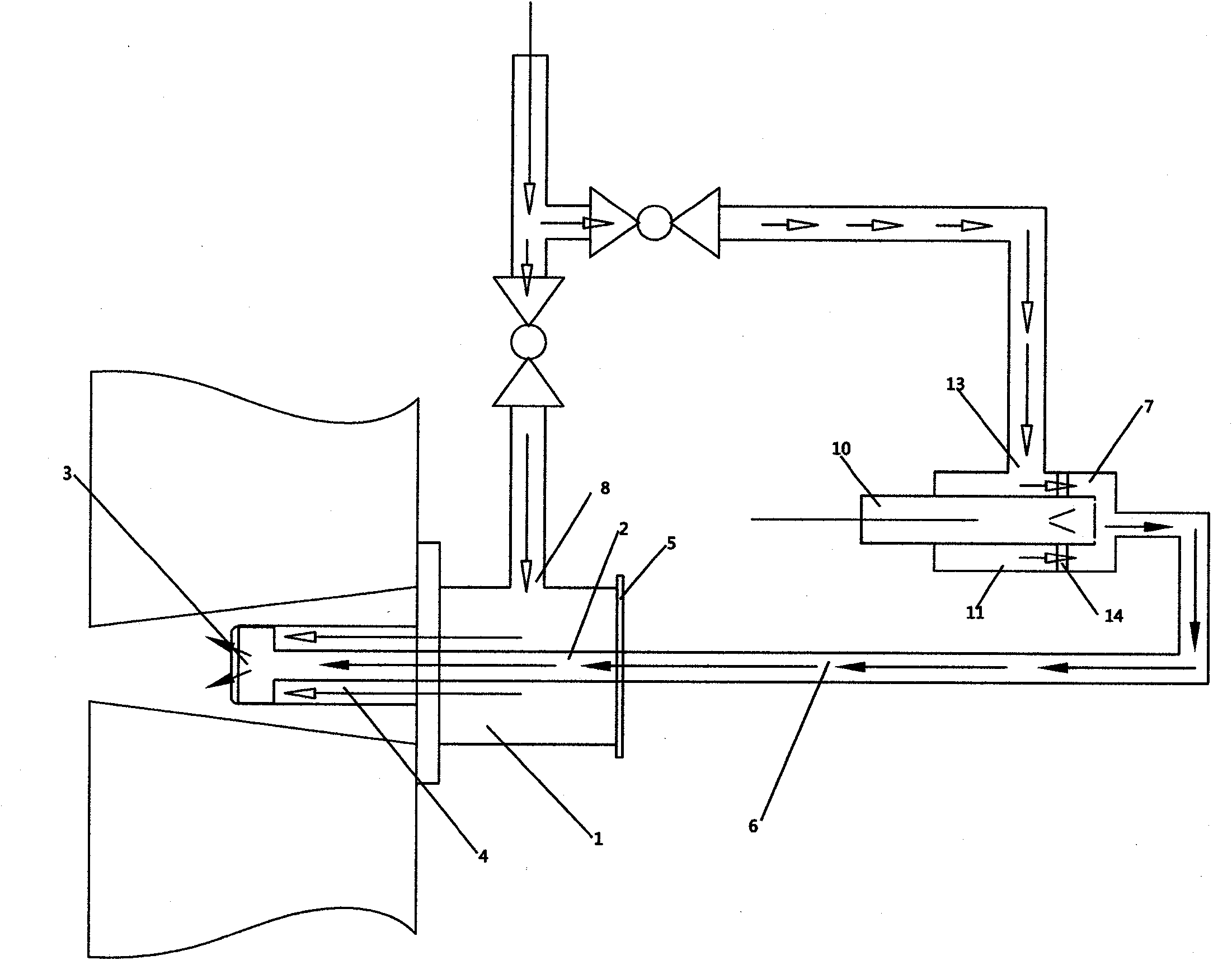

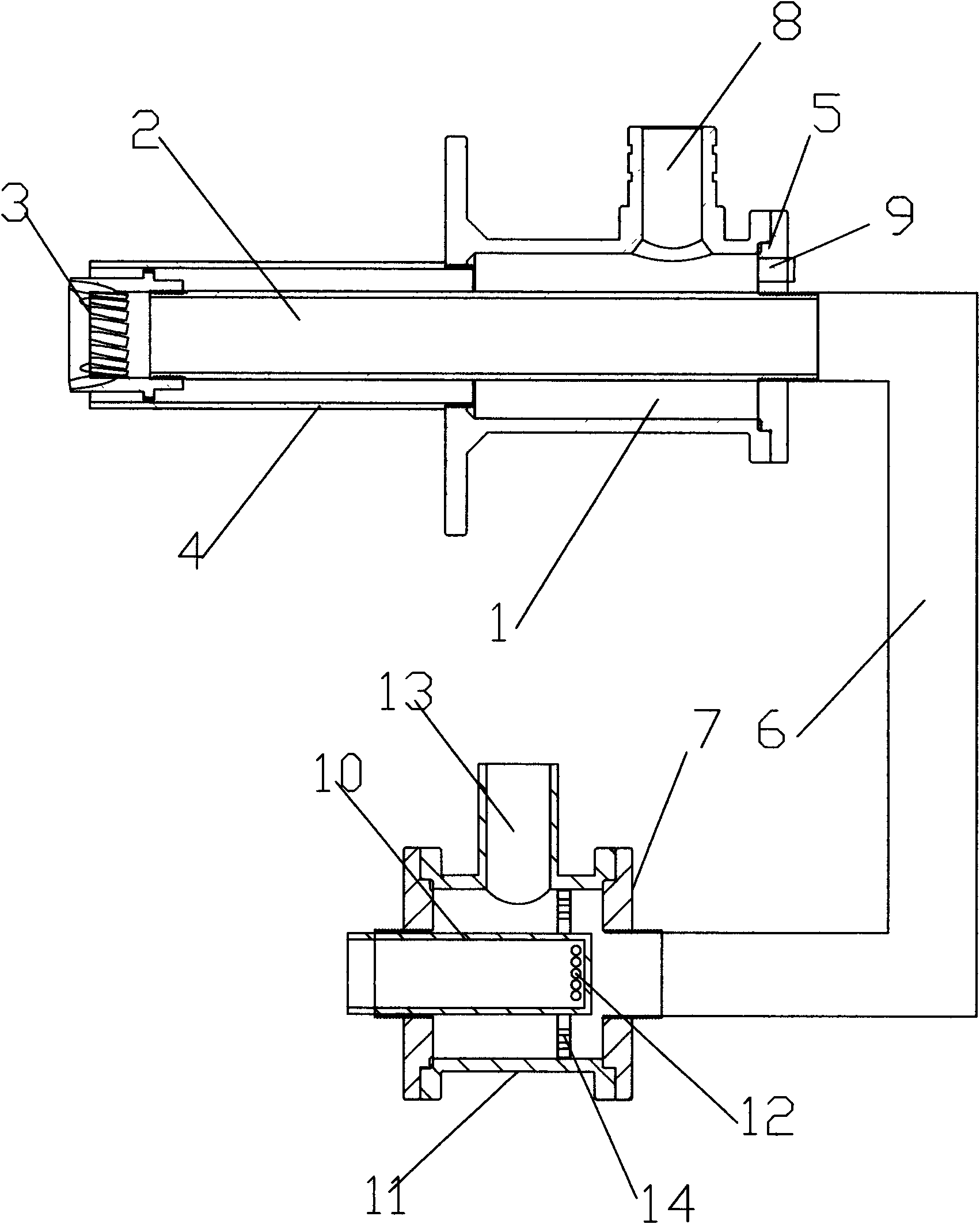

[0024] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] See attached Figure 1-2 , the method of the present invention is: a, combustion-supporting air is divided into two parts by three-way diverter, and i.e. primary air and secondary air are controlled flow by valve respectively;

[0026] b. Combustion-supporting air (primary air) is delivered to the premixer 7 through the delivery pipe to mix with the combustion gas;

[0027] c. Deliver the premixed mixed gas into the premixing pipe 2 through the premixing connecting pipe 6 and output it through the output hole on the burner 3 .

[0028] d. Combustion-supporting air is introduced into the main body shell 1 through the secondary air delivery pipe, and delivered to the combustion burner 3 through the secondary air guide pipe 4 to fully mix with the mixed gas and burn.

[0029] In the step a, the combustion-supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com