Three-dimensional vortex burner

A burner and vortex technology, applied in the field of high-temperature flue gas devices, can solve the problems of unreasonable space layout, difficult to guarantee manufacturing quality, insufficient combustion, etc., to achieve smooth air entry into the air nozzle, reduce the amount of renovation works, and save energy. The effect of refractory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solution of the present invention will be further described through specific implementation modes below in conjunction with the accompanying drawings.

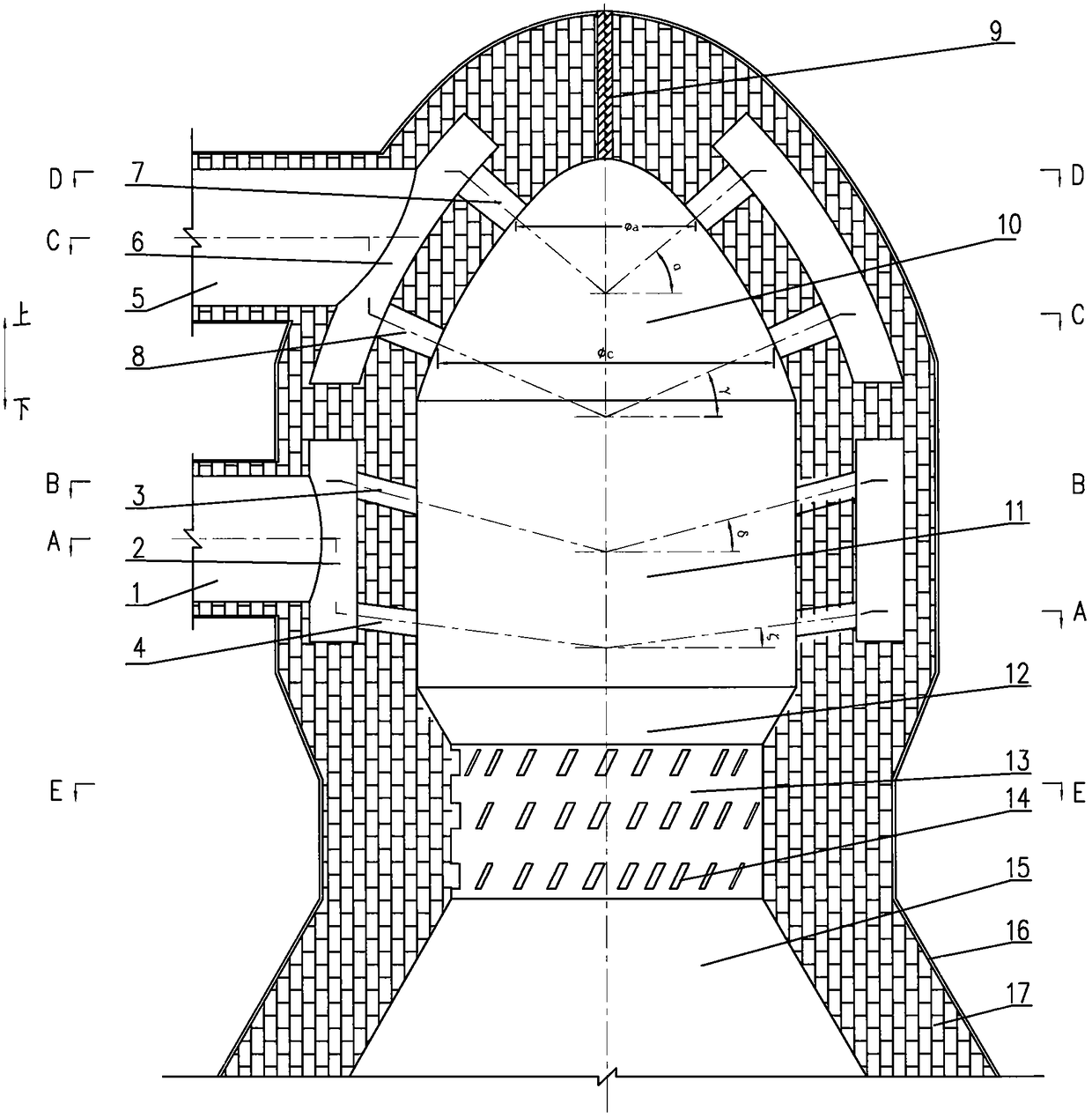

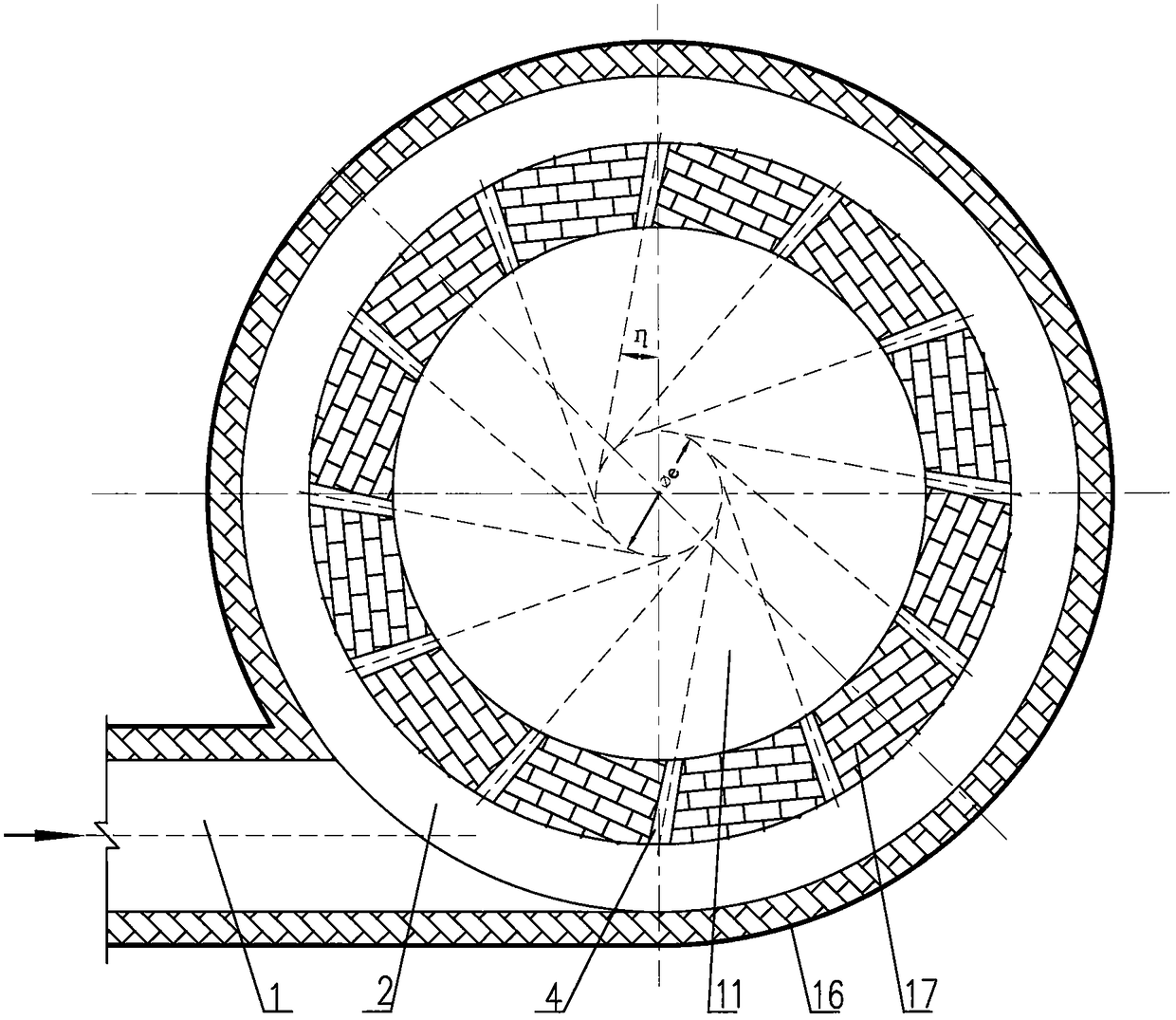

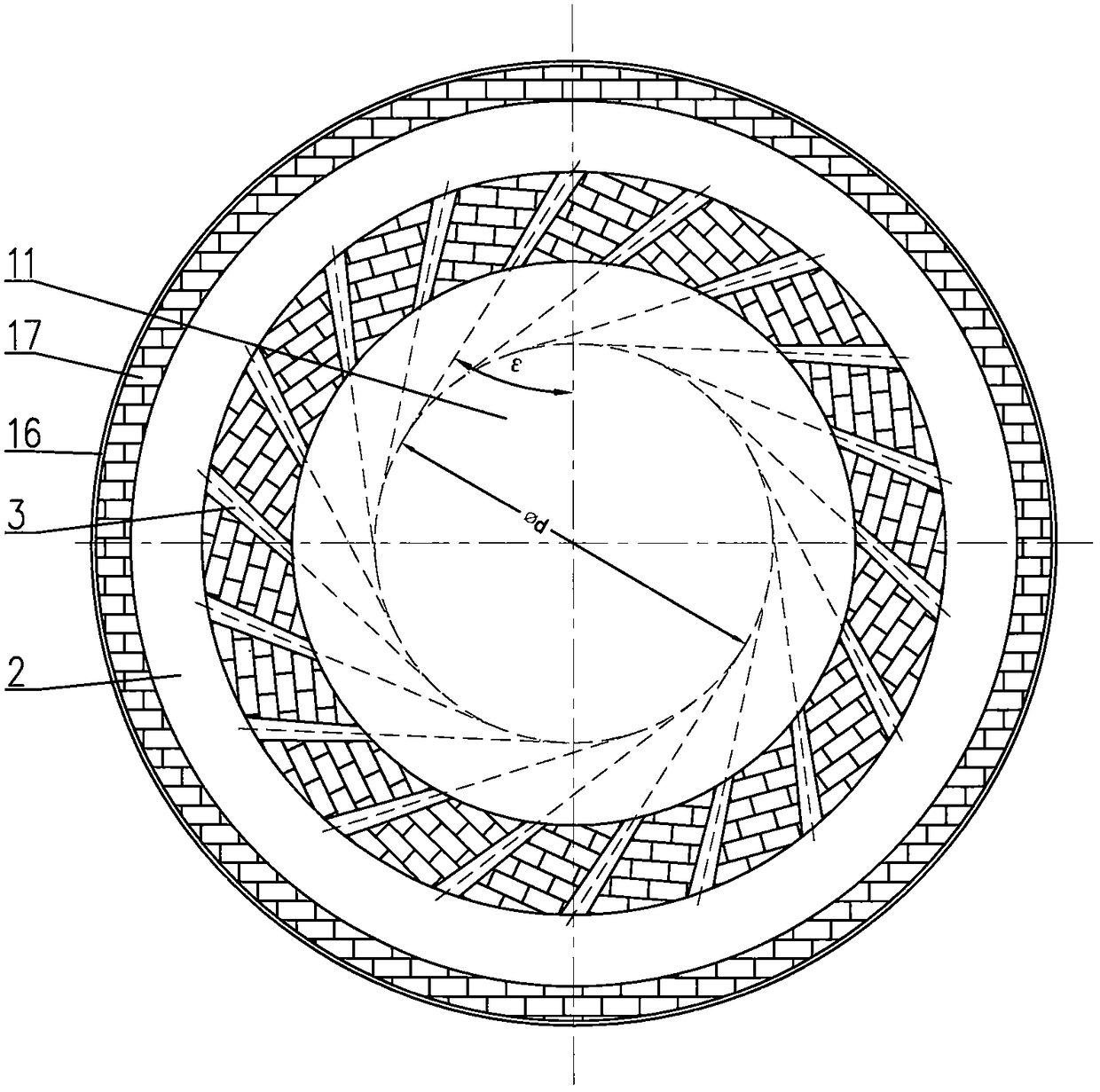

[0047] As shown in the figure: the three-dimensional vortex burner is constructed by steel shell (16) and refractory material (17) into air inlet (1), air ring cavity (2), primary air nozzle (3), secondary air nozzle ( 4), gas inlet (5), gas ring cavity (6), upper gas nozzle (7), lower gas nozzle (8), detection hole (9), rectification chamber upper section (10), rectification chamber lower section (11), Throat constriction section (12), throat (13), throat diversion groove (14), combustion chamber (15),

[0048] The upper section of the rectifying chamber (10), the lower section of the rectifying chamber (11), the constricted section of the throat (12), the throat (13), and the combustion chamber (15) are connected in sequence from top to bottom;

[0049] One side of the upper layer gas nozzle (7) and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com