Oxygen increasing energy-saving spray gun for industrial furnace

A spray gun and kiln technology, applied in the field of oxygen-increasing and energy-saving spray guns, which can solve the problems of rising instead of falling emissions, large air consumption, and shortening the use time of kilns, so as to prolong the service life, reduce operating costs, and improve energy conservation and environmental protection effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

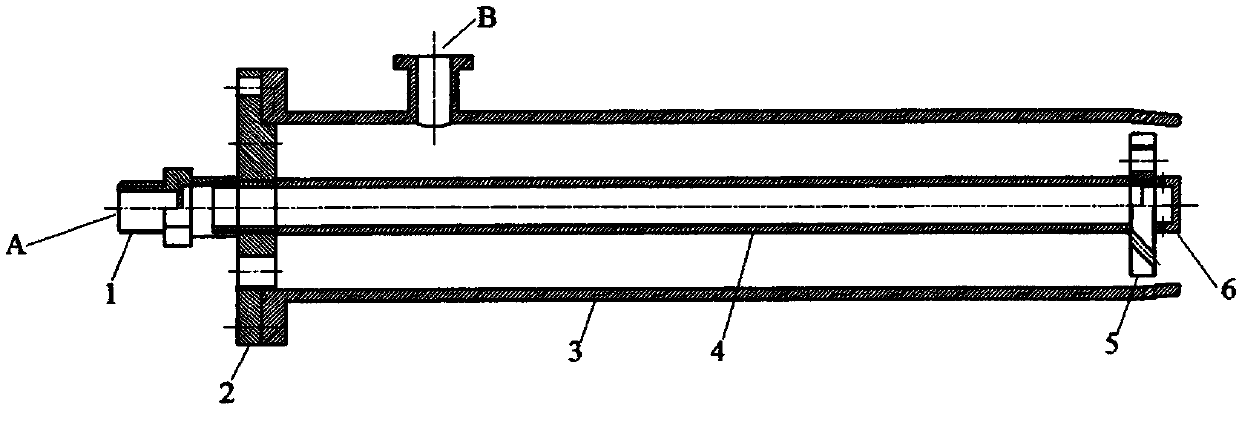

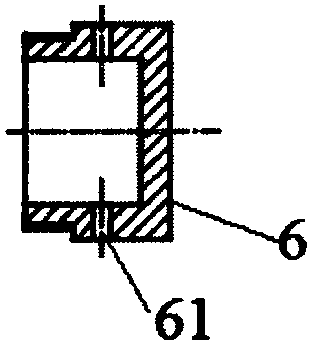

[0032] Figure 4 The structural diagram of the oxygen-increasing and energy-saving spray gun for industrial kilns provided in this embodiment, the oxygen-increasing and energy-saving spray gun for industrial kilns consists of a fuel port joint 1, a spray gun rear end baffle 2, a spray gun outer shell 3, Fuel channel connecting pipe 4, rotating wind plate 5, spray gun burner head 6, oxygen increasing inlet flange 7, oxygen increasing channel outer casing 8 and so on.

[0033] The rotating air plate 5 and the rear end baffle plate 2 of the spray gun are respectively installed on the front end and the rear end of the fuel passage connecting pipe 4. After passing through the rear end baffle plate 2 of the spray gun, it is connected with the fuel port joint 1. The outer casing 8 of the oxygen-increasing channel is coaxially installed on the outside of the fuel channel connecting pipe 4, and the outer casing of the spray gun 3 is coaxially installed on the outer side of the outer c...

Embodiment 2

[0053] Figure 6 The schematic diagram of the structure of the oxygen-increasing energy-saving spray gun for industrial kilns provided in Example 2, this embodiment is basically the same as that of Example 1, the difference is that:

[0054] On the fuel channel connecting pipe 4, at the position close to the rotating wind plate 5, grooves 41 are evenly distributed on the circumference, so that after part of the fuel is pre-mixed with the oxygen-increasing gas in the oxygen-increasing channel outer sleeve 8, it is discharged from the nozzle head 6 of the spray gun. injected into the kiln.

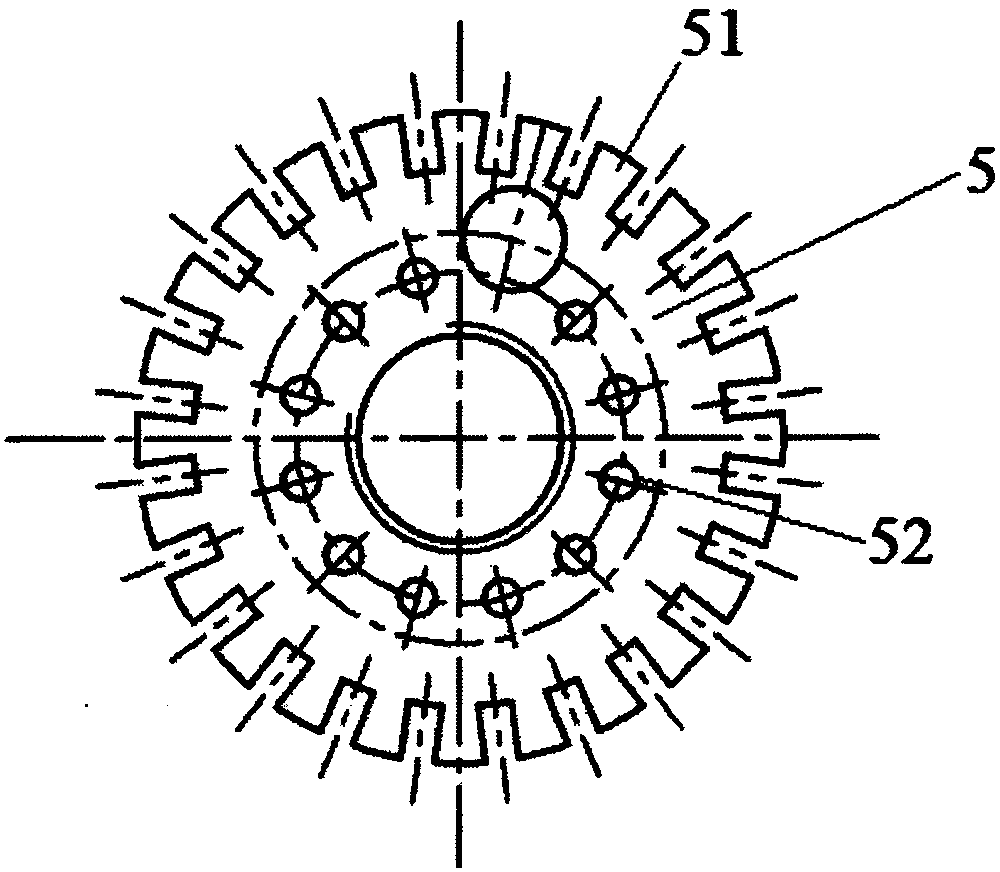

[0055] to combine Figure 7 , the outer periphery of the rotating wind plate 5 is provided with a rotating piece 51, and there is a gap between the rotating piece 51 and the spray gun shell 3, and the air for combustion-supporting wind enters the kiln. The angle of the helical teeth of the rotating piece of the rotating wind plate 5 is 25°-45°, so that the combustion-supporting air is push...

Embodiment 3

[0060] The beneficial effects of the present invention will be illustrated below with a specific application of the oxygen-increasing energy-saving spray gun described in Embodiment 1 on a water gas tunnel kiln.

[0061] The basic conditions for a 100-meter daily-use ceramic water gas tunnel kiln are as follows: the fuel used in the tunnel kiln is cold gas produced by converting coal to gas through a 3.6-meter two-stage gas generator, and the conversion ratio is 1:3. Coal gas is used as fuel in tunnel kilns. According to the production process requirements of high-temperature daily-use ceramics, the firing temperature reaches 1380°C. The atmosphere requirements are oxidation and strong reduction. The daily output is 78 car hours (each car tonnage: 2 tons / car). The coal consumption is 34 tons / day (the low calorific value of coal is 6060 kcal), and the coal price is RMB850 / ton. There are 30 spray guns used in this kiln, which are as follows:

[0062] Number of spray guns in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com