50,000 ton/year natural gas hard carbon black reaction furnace

A technology of hard carbon black and reaction furnace, which is applied in the direction of fibrous fillers, etc., can solve the problem of affecting the quality of carbon black products, the oil consumption of carbon black products, the air preheating temperature cannot be set too high, and the impact on the production capacity of carbon black devices, etc. problems, to improve the combustion effect, reduce the consumption of raw material oil, and increase the furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

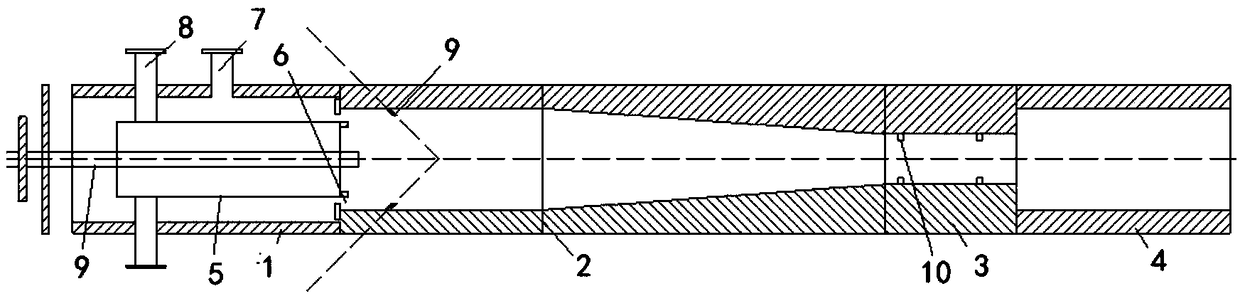

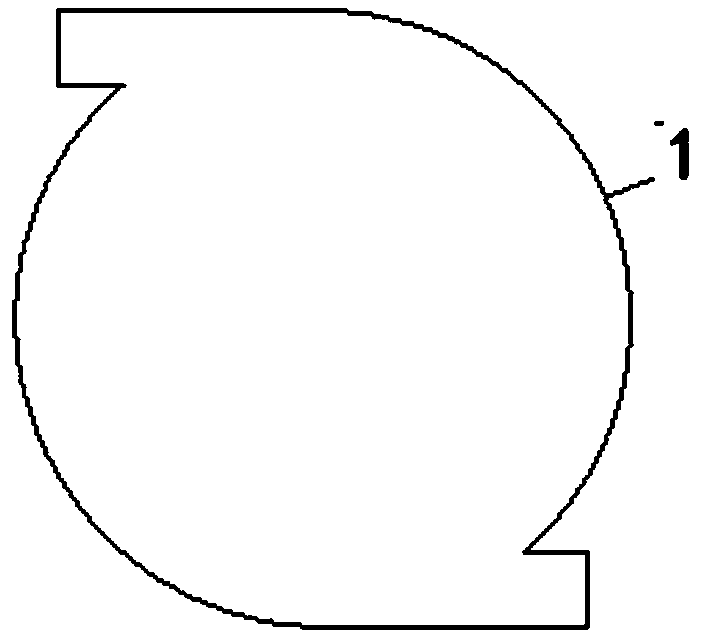

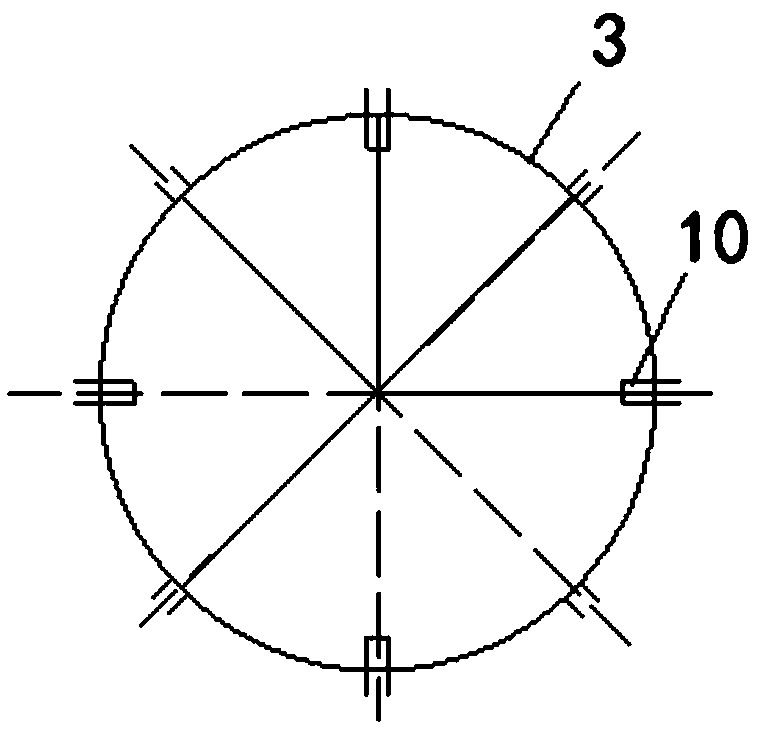

[0013] Such as figure 1 , 2 As shown in, 3 and 4, the present invention is realized in this way. The air distributor 1, the combustion section 2, the throat straight section 3 and the reaction section 4 are coaxially connected in sequence to form a carbon black reactor. An air guide tube 5 is arranged coaxially in the cavity of the air distributor 1, one end of the air guide tube 5 is connected to the reaction furnace panel, the other end of the air guide tube 5 is connected to the combustion section 2, and the air guide tube 5 is connected to the combustion section 2. A vent 6 is reserved at the connection to form an air bypass channel. The bypass air is close to the inner surface of the furnace wall of the combustion section 2, which can prevent the furnace wall from overheating, thereby protecting the reactor, extending the life of the reactor, and Reduce impurities in carbon black products. The middle section of the air distributor 1 is provided with a preheated air intake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com