Method for smelting magnesium by decomposition in vacuum through microwaves

A microwave vacuum and metal magnesium technology, which is applied in the field of microwave preparation of crude metal magnesium and microwave vacuum decomposition and smelting of metal magnesium, can solve the problems of high cost, poor environmental protection, high energy consumption, etc., and achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

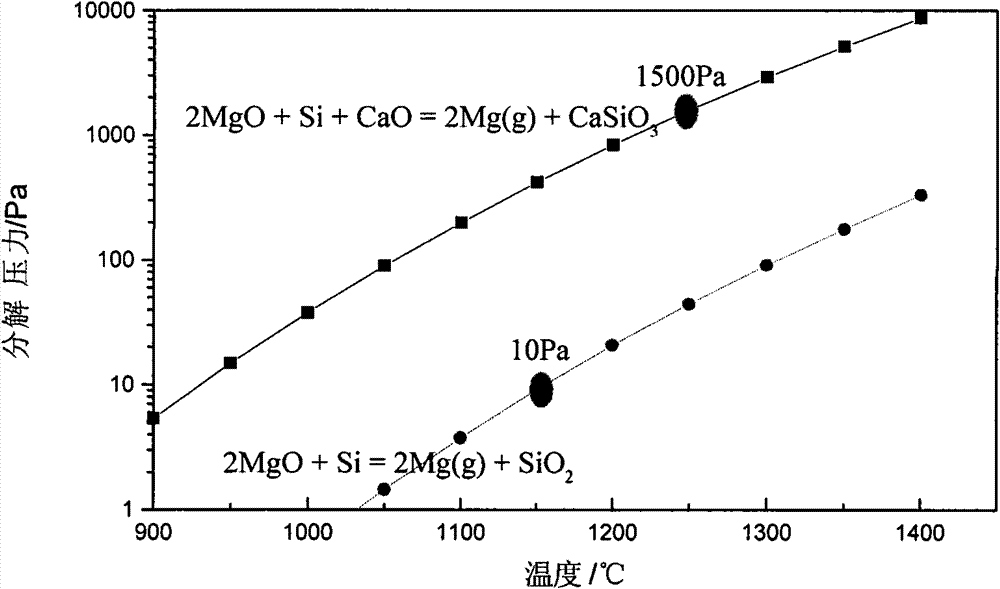

[0048] The raw materials used in the examples include magnesia, lime, dolomite, and ferrosilicon. The mass content of MgO in magnesia is 92%, the mass content of CaO in lime is 85%, the ferrosilicon is 75% ferrosilicon, the mass content of CaO in dolomite is 28.2%, and the mass content of MgO is 19.4%. The main reactor is a 10kg class microwave vacuum furnace equipped with a magnesium vapor condensing system. First, crush magnesia, lime, and ferrosilicon respectively, then mix them evenly according to the ratio in Table 2, press the balls, put a certain amount of balls into a microwave vacuum furnace, and evacuate to the required vacuum degree (see Table 2), and then Heating to the required temperature, keeping it warm for a certain period of time, analyzing the grade of magnesium metal and the amount of residual MgO in the pellet sample after power off, and calculating the decomposition rate of MgO, the results are shown in Table 2. In the test, dolomite was also calcined in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com