Solid waste treatment incineration device convenient to operate

An incineration device and an easy-to-operate technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of waste of carbon monoxide fuel resources, insufficient straw incineration, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

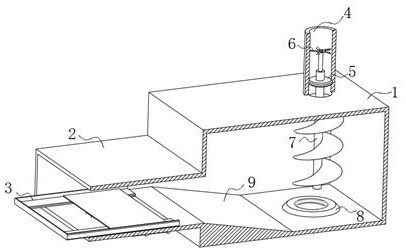

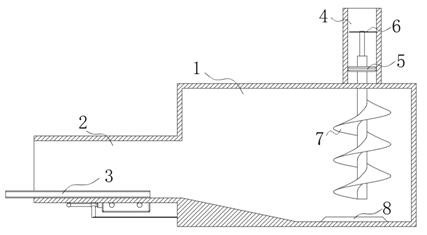

[0028] refer to Figure 1-6 , an easy-to-operate solid waste treatment and incineration device, comprising a combustion furnace 1 body, an igniter 8 and an external carbon monoxide collection device. Exhaust pipe 4 for exhaust, so that the gas generated by combustion can be effectively discharged, avoiding excessive gas accumulation in the combustion furnace 1, and at the same time avoiding exhaust gas from being discharged from the push box 2, so that the exhaust gas and air will form convection, which will not It is beneficial for oxygen to enter the pushing box 2 so that the combustion reaction is interrupted.

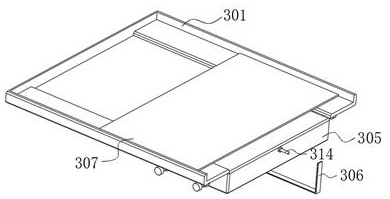

[0029] The pushing box 2 is provided with a propulsion device 3 for advancing the packed straw block, referring to Figure 3-4 Shown, propulsion device 3 comprises double rail 301, baffle plate 302, gas tank 305, placement plate 307 and push rod mechanism, and double rail 301 is arranged on the edge of inner wall bottom of pushing box 2, and baffle plate 302 is arr...

Embodiment 2

[0039] refer to Figure 1-2 As shown, the exhaust pipe 4 is provided with a straw crushing device. The straw crushing device includes a carbon dioxide absorbing disc 5, a fan blade 6 and a screw knife 7. The carbon dioxide absorbing disc 5 is fastened to the inner wall of the exhaust pipe 4, and the carbon dioxide absorbing disc 5 is filled with calcium oxide for absorbing carbon dioxide, which can effectively absorb carbon dioxide in the exhaust gas, and at the same time filter and leave carbon monoxide, and fill the carbon monoxide into the gas storage tank 305 through the carbon monoxide collection device.

[0040] The spiral knife 7 is interspersed on the axis of the carbon dioxide absorbing disk 5, the fan blade 6 is arranged on the top of the spiral knife 7, and the spiral knife 7 rotates downward, and the exhaust gas can drive the fan blade 6 on the top of the spiral knife 7 to rotate, and then drive the spiral knife 7 to rotate, This facilitates the crushing of the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com