Waste gas and waste liquid incineration system and method

A waste liquid and waste gas technology, applied in the direction of combustion method, incinerator, combustion type, etc., can solve water pollution and other problems, and achieve the effects of promoting complete combustion, increasing heat utilization rate, and reducing flue gas exhaust volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

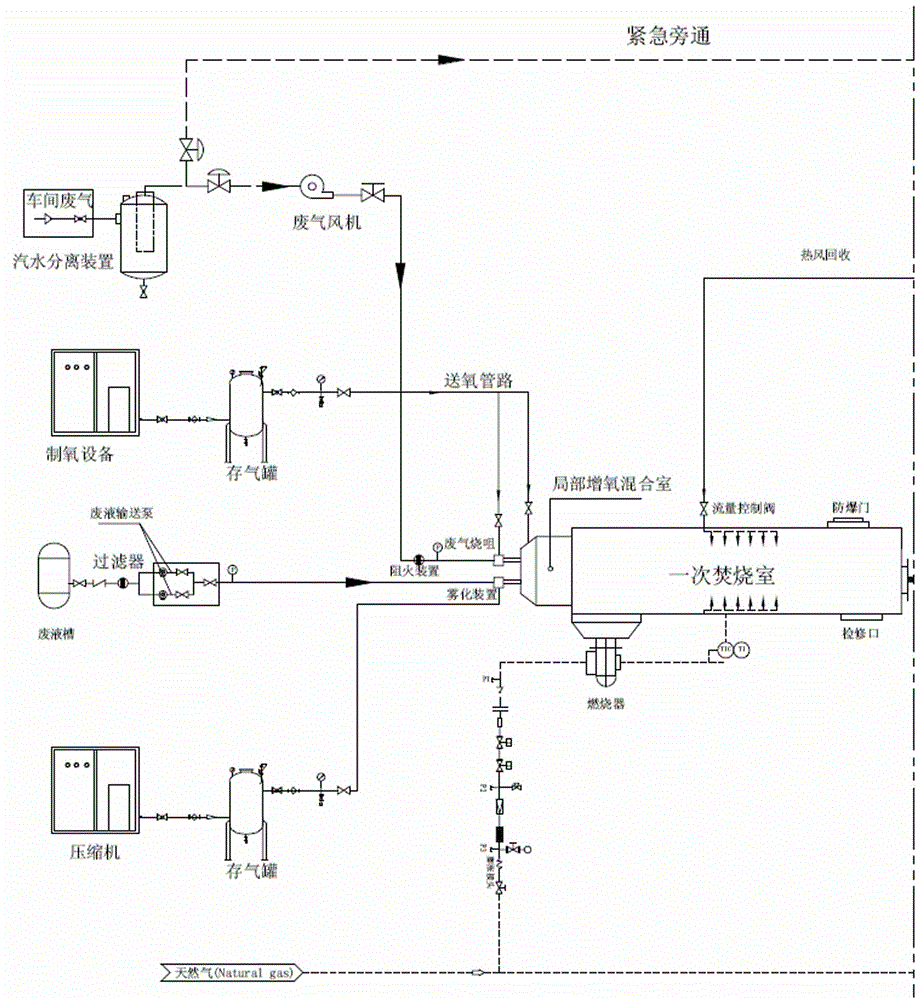

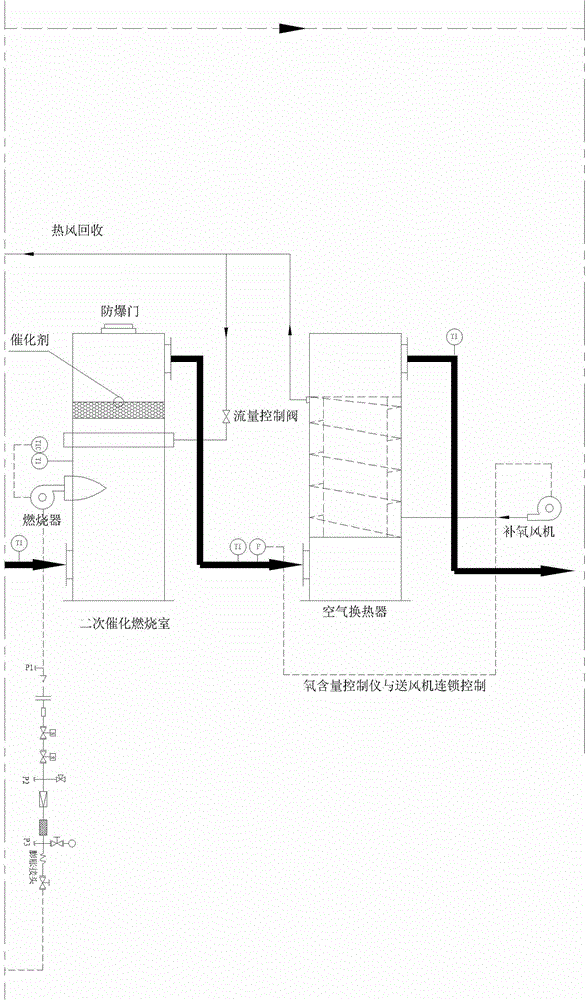

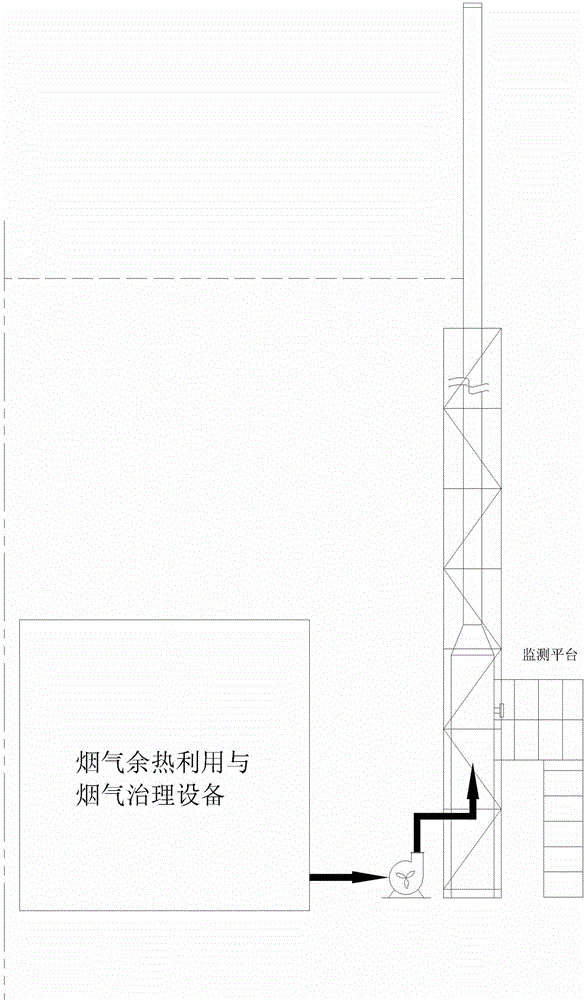

[0035] like Figure 1-2 As shown, a waste gas and waste liquid incineration system in this embodiment includes: sequentially connected oxygen production equipment, local oxygen-increased combustion mixing chamber, primary incineration chamber, secondary catalytic incineration chamber, air heat exchanger, waste heat utilization and smoke Gas purification device: Harmful waste gas or atomized waste liquid, compressed air and pure oxygen are mixed in the mixing chamber according to the set ratio and then passed into the primary incineration chamber for incineration. The waste heat utilization and flue gas purification device includes a waste heat boiler, lye washing device, mist water separator, induced draft fan and exhaust pipe connected in sequence.

[0036] The waste gas and waste liquid incineration system includes a waste liquid atomization device, which is connected with an air compression device.

[0037] The air inlet of the air heat exchanger is connected with the oxyg...

Embodiment 2

[0042] A method for waste gas and waste liquid incineration, specifically comprising the steps of:

[0043] 1) Mix waste gas or atomized waste liquid, compressed air and oxygen in the mixing chamber, wherein the ratio of oxygen to air is 1:25; among them, the waste liquid is mixed with compressed air after high-pressure atomization and then passed into the mixing chamber. The design pressure of compressed air is 0.2-0.3MPa; the ratio of compressed air used per liter of atomized waste liquid is 0.5-1Nm 3 / L; if waste gas needs to be incinerated, the waste gas will be mixed with oxygen through the waste gas nozzle and then flow into the mixing chamber. The pressure of the waste gas nozzle is designed to be 1KPa.

[0044] 2) Enter the mixed gas generated in step 1) into the primary incineration chamber for primary incineration; temperature: 750-850°C, residence time of flue gas in the primary chamber is 2 seconds;

[0045] 3) Enter the flue gas generated in step 2) into the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com