High dispersion ultra-thin light guide board and manufacturing method thereof

A manufacturing method and light guide plate technology, applied in the innovative field of polymer material preparation, can solve problems such as poor uniformity, shorten optical design time, etc., achieve the goal of strengthening competitiveness, improving product yield, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

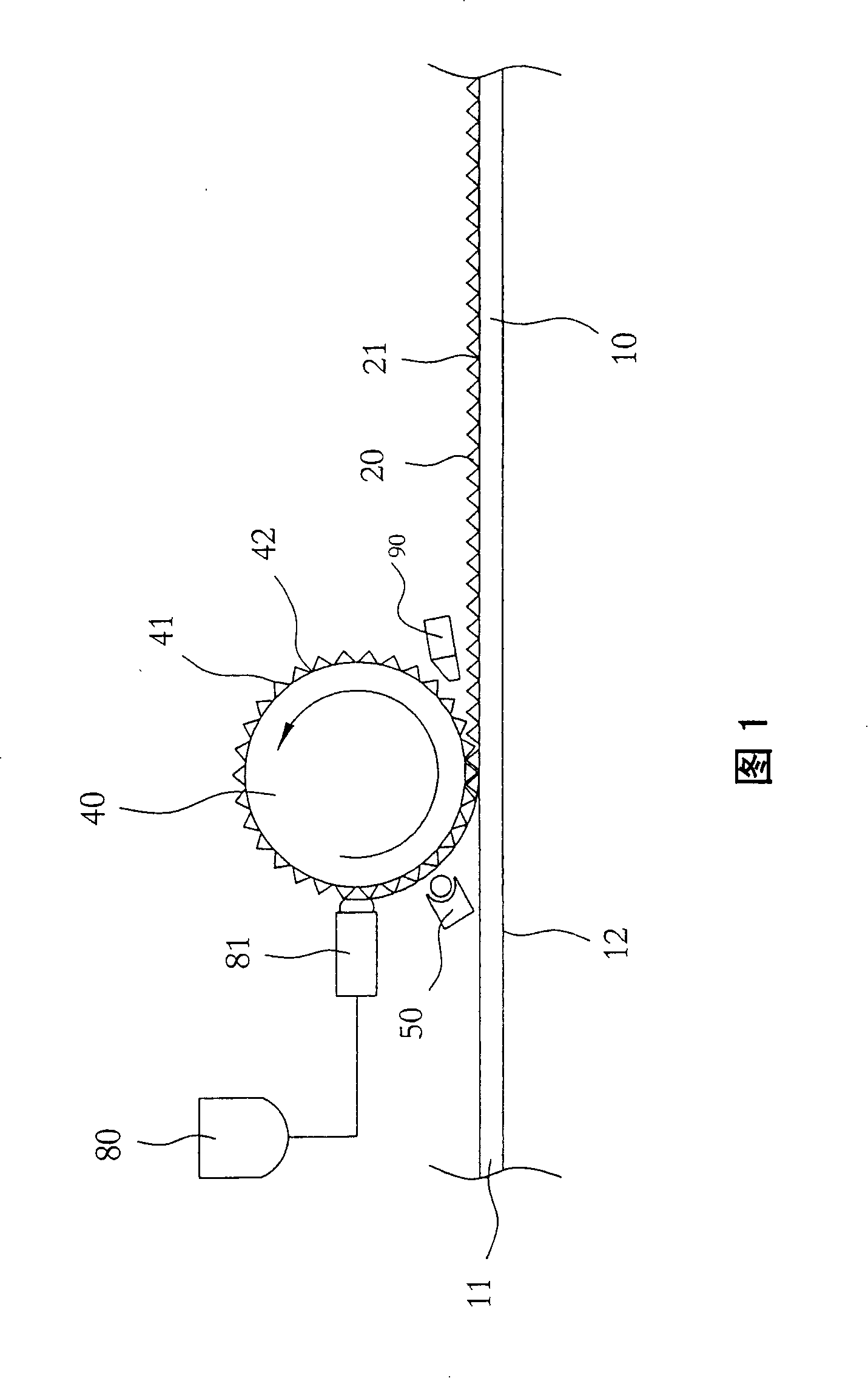

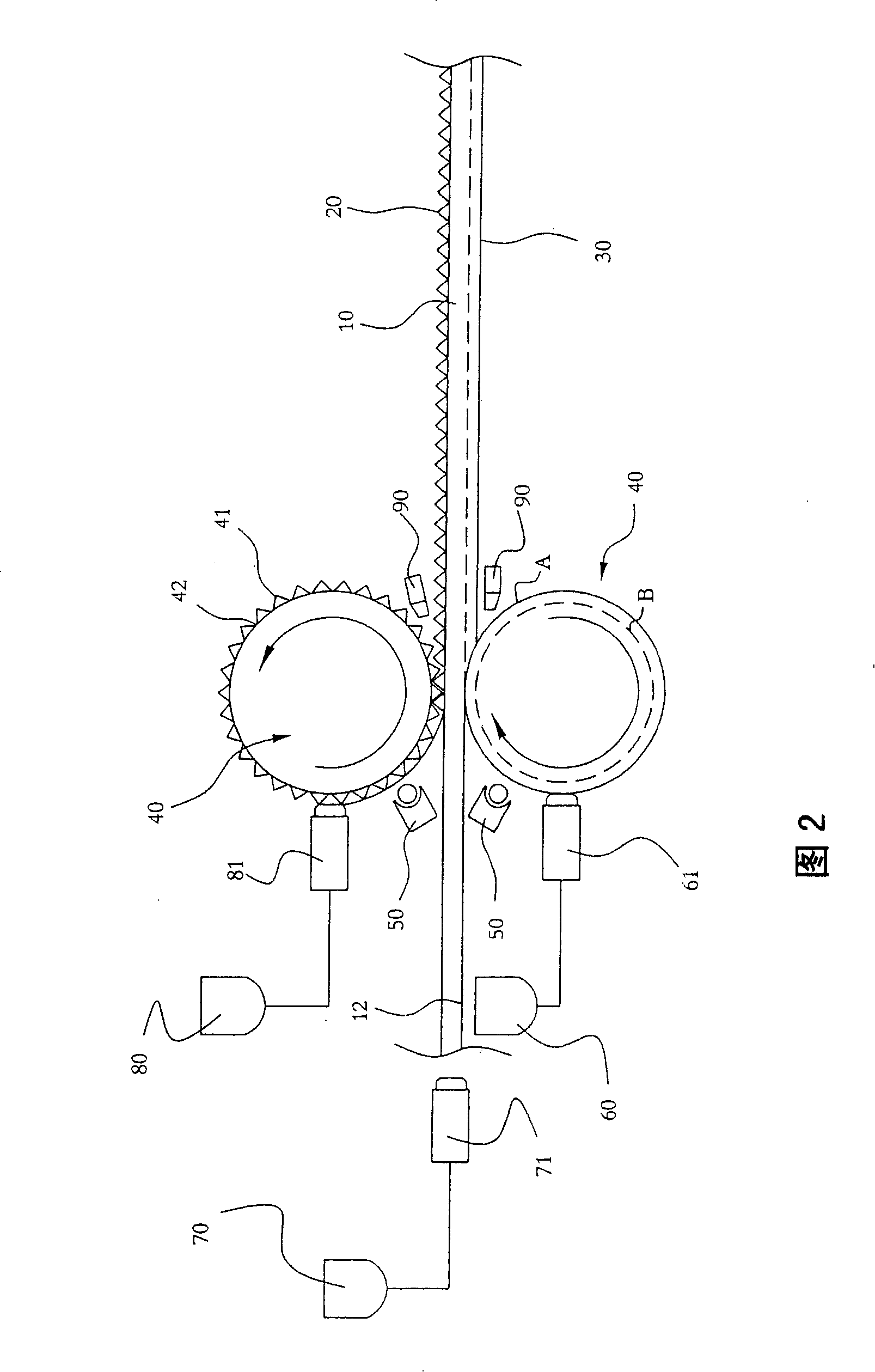

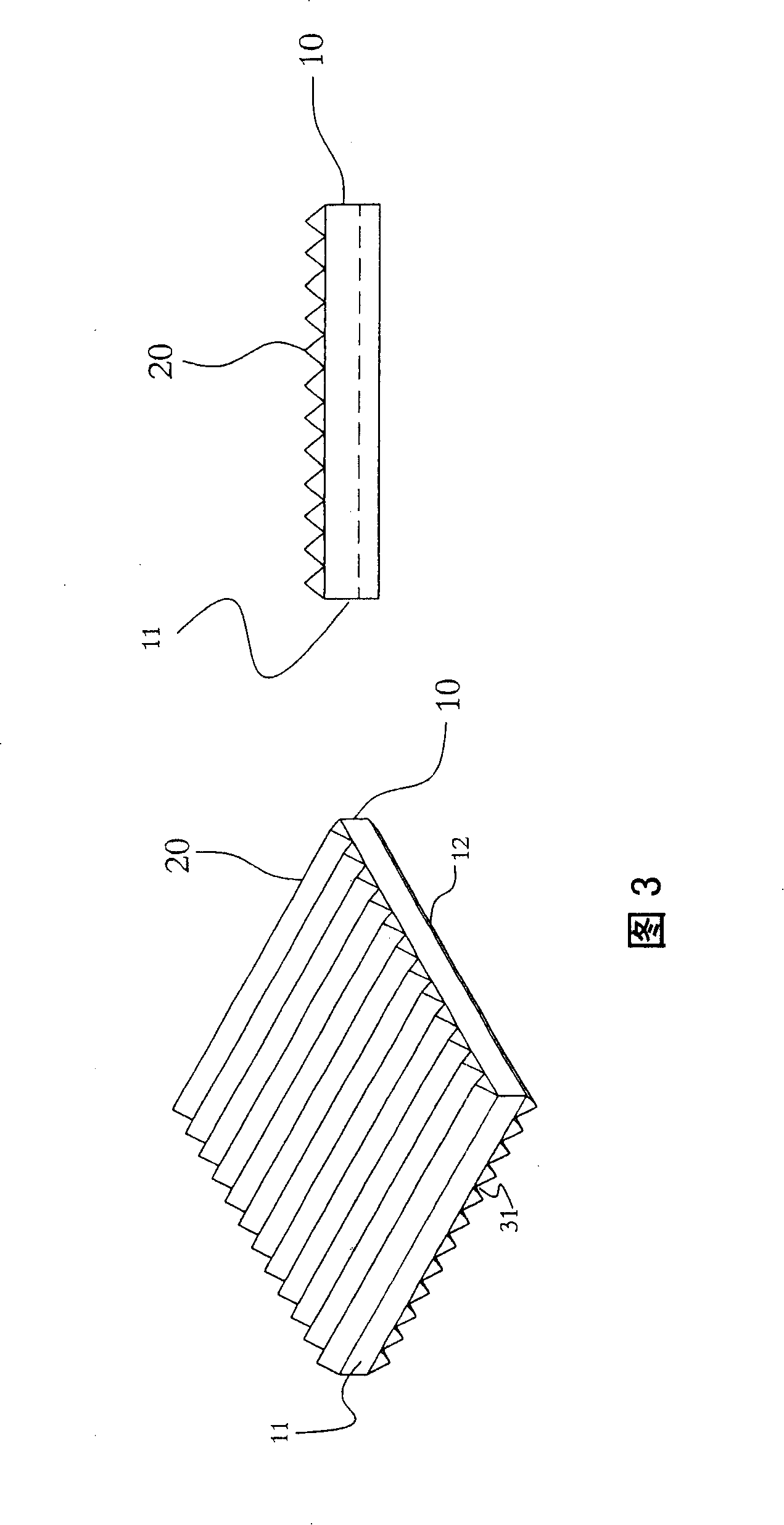

[0040] Finally, talking about the implementation of the present invention, a brief description is as follows: the particle size of 0.5-5μm polysilsesquioxane (Polysilsesquioxane) or other high optical refractive index material polymer particles and optical grade polymethyl methacrylate ( PMMA), mixed in a certain proportion, using twin-screw kneading and extruding sheet molding machine to make the required scattering type high-penetration resin sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com