Anti-friction centralizer having anti-balling and boosted propelling functions

A centralizer and anti-mud technology, which is applied in the direction of drill pipe, casing, drill pipe, etc., can solve the problems of high resistance and difficulty in moving the drill bit forward, improve the quality of the well wall, facilitate running in and out, The effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

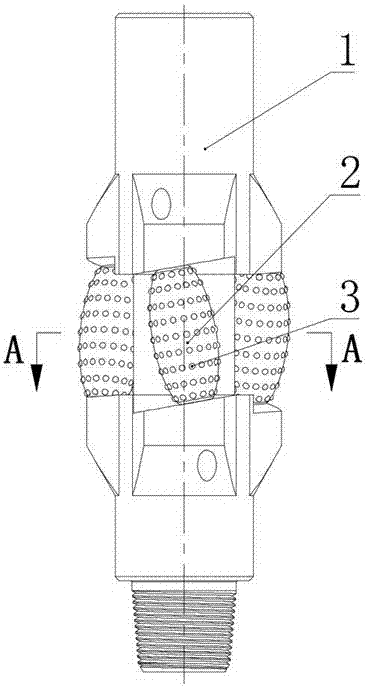

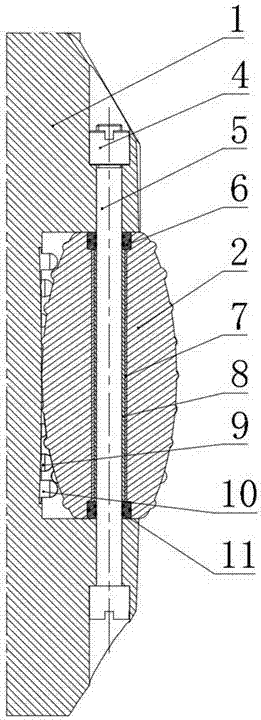

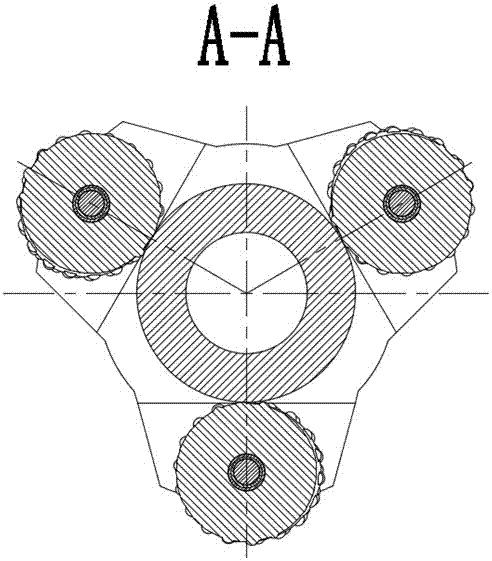

[0020] Referring to the accompanying drawings, the anti-friction centralizer with the functions of mud bag prevention and pressurized propulsion proposed by the present invention is composed of a body 1 and a roller assembly. The front and rear ends of the body 1 are connected between downhole drilling tools through threaded buckles. There are evenly distributed ridges on the outer surface of the cylinder of 1, and each ridge is processed with a gap for installing the roller assembly; the roller assembly consists of a roller 2, an alloy tooth a3, a nut 4, and a bolt shaft 5 , oil deflector ring 6, outer wear-resistant sleeve 7, inner wear-resistant sleeve 8 and O-ring 11, first assemble the inner wear-resistant sleeve 8, outer wear-resistant sleeve 7 and roller 2 in sequence, Then install an oil deflector ring 6 in the stepped holes at both ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com