Torsion impactor based on turbine and gear

A technology of impactor and turbine, which is applied in the field of torsion impactor, can solve the problems of drilling tool failure, such as ROP, and achieve the effect of increasing ROP, eliminating drill sticking, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

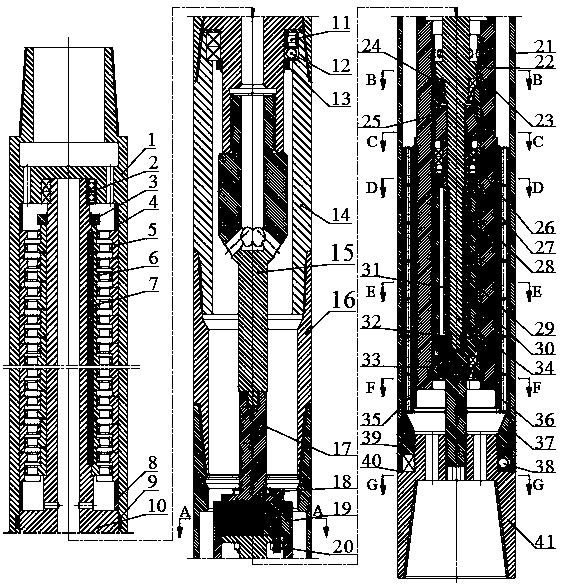

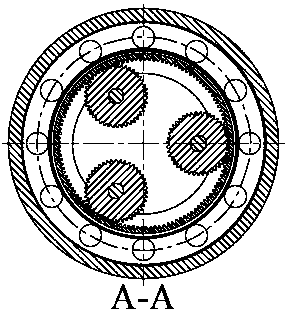

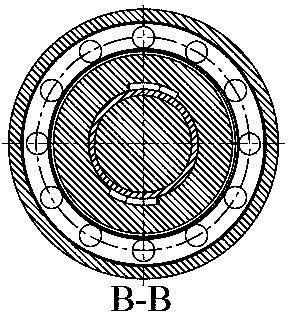

[0024]Referring to the accompanying drawings, the torsion impactor based on the turbine and the gear is characterized in that: the torsional impactor based on the turbine and the gear is composed of the turbine assembly, the conversion joint 14, the impact assembly and the lower end of the turbine assembly is connected with the conversion joint 14. The conversion joint 14 is connected with the short joint 16, and then the impact assembly is connected; the turbine assembly includes the turbine housing 1, the angular contact ball bearing 2, the anti-drop ring A3, the positioning sleeve A4, the turbine stator 5, and the turbine rotor 6. Transmission key 7, positioning sleeve B8, rectangular sealing ring 9, turbine shaft 10, cylindrical roller bearing 11, thrust ball bearing 12, anti-drop ring B13, and the turbine rotor 6, turbine stator 5 and positioning sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com