Real-time on-line self-diagnosis method and system for video monitoring equipment failure

A technology for video surveillance and equipment failure, applied in the field of video surveillance equipment, can solve the problems of slow troubleshooting, high cost of human resources, and low degree of automation and intelligence, so as to improve maintenance and repair efficiency and reduce maintenance and repair. cost, increased intelligence, and effectiveness of application benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

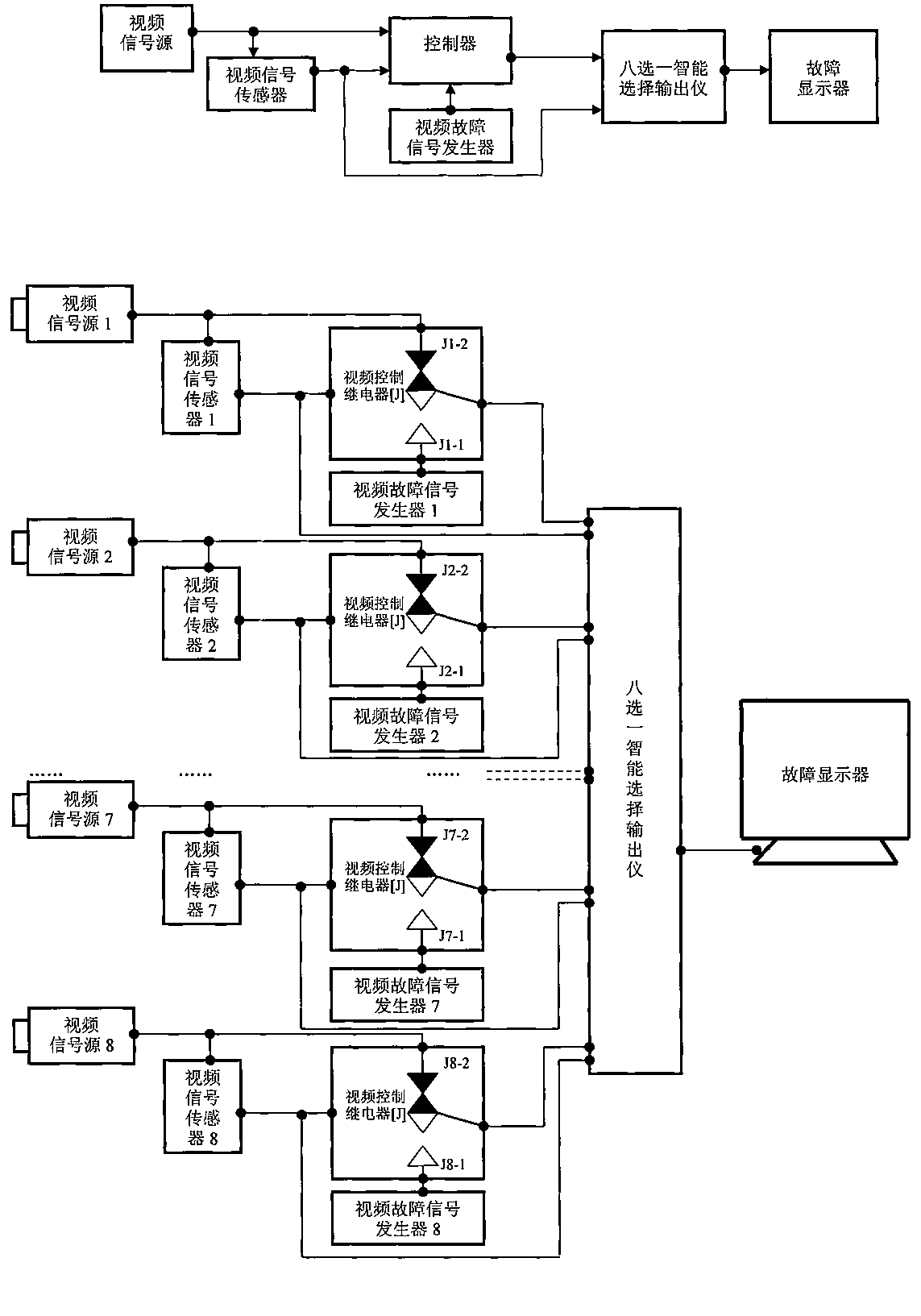

[0012] In order to effectively solve the current backward maintenance mode of video surveillance equipment and instruments, improve the intelligence and application efficiency of remote equipment, reduce maintenance and repair costs, effectively relieve the maintenance work pressure of management departments, save social management and operation costs, and enable remote video The use and maintenance of monitoring equipment and instruments are more convenient and humanized.

[0013] The invention belongs to an online self-diagnosis system for the operating status of video monitoring equipment, which can remotely monitor the operating status of video monitoring equipment online in real time. , the system can automatically detect and judge in real time, automatically alarm the fault, and upload and output the fault information. For the first time, it is proposed to introduce video signal sensing into the field of equipment fault maintenance, which greatly improves the maintenance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com