Impeller type axial and circumferential compound impactor

An impeller-type, impactor technology, applied in drilling equipment, earth-moving drilling, driving devices for drilling in wellbore, etc., can solve the problems of well wall friction, affecting the drilling speed, damage to the drill bit, etc., and achieve circumferential positive impact High force, high energy conversion efficiency, elimination of stick-slip and sticking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

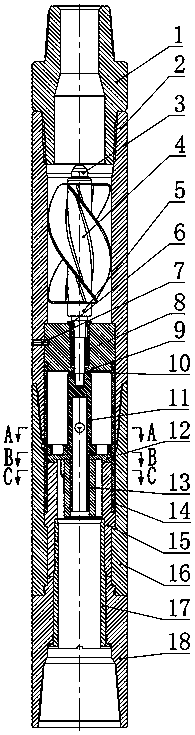

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

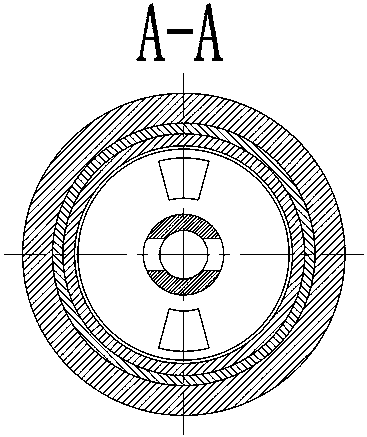

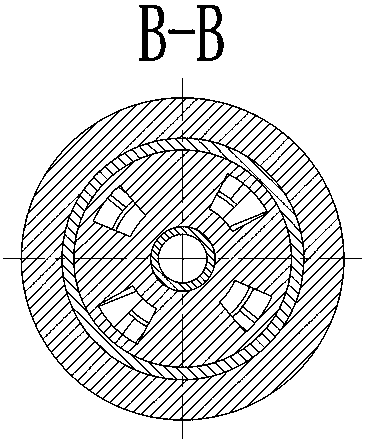

[0023] Referring to the accompanying drawings, the impeller-type axial and circumferential composite impactor is composed of a conversion joint 1, a motor assembly and an impact assembly. The rear end of the motor assembly is connected to the conversion joint 1 through threads, and the front end is connected to the impact assembly; the motor The assembly includes impeller housing 2, lock nut 3, impeller 4, impeller shaft 5, bearing cover 6, screw 7, string bearing 8 and guide tube 10, and impeller 4 is installed on impeller shaft 5 through spline connection , and use the lock nut 3 to axially fix, the front section of the impeller shaft 5 is installed in the guide tube 9, and the string bearing 8 is installed inside the guide tube 9, and the bearing end cover 6 is installed on the end surface of the guide tube 9 through threaded connection , there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com