Method for casing pipe downward running operation through casing pipe driving head

A casing driving head and casing drilling technology, which is applied in drilling equipment and methods, earthwork drilling, drilling equipment and other directions, can solve the problems of return spring fatigue, incomplete reset, mutual adhesion, etc., and improve the running rate. ability, increased safety, reduced mutual swing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The method for carrying out the casing operation by using the casing driving head includes the following steps:

[0051] S1. Use a single elevator to lift the first casing that has been connected to the drill shoe and floating hoop, use casing slips to clamp the first casing in the rotary table, and then connect the casing driving head to the drilling tool ;

[0052] S2. Insert the casing driving head into the first casing placed on the turntable, turn the casing driving head 45 degrees to the right, and then lift up the drilling tool, the slips on the casing driving head are locked on the inner diameter of the casing ;

[0053] S3. Lift the drilling tool up, take out the casing slips, lower the drilling tool, set the kelly into the turntable, turn on the pump, start casing drilling, slowly increase the drill pressure and speed until the first casing is drilled. use up;

[0054] S4. After the first casing is drilled, if it is necessary to drill a thick mud well, firs...

Embodiment 2

[0060] Before implementing casing drilling, prepare the required casing driving head first. During implementation, first connect the drill shoe and floating hoop at the lower end of the first casing that needs to be lowered into the well, and then use the single elevator on the drilling rig Lift the first casing that has been connected with drill shoes and floating hoops, put it into the wellbore, and use casing slips to clamp the first casing in the rotary table, and then connect the casing to the drilling tool drive head.

[0061] Then lower the drilling tool, insert the casing driving head into the first casing placed on the turntable, start the drilling rig, make the drilling tool turn right, and drive the casing driving head to turn right 45 degrees (just use 45 degrees as an example, not limited to 45 degrees), and then lift the drilling tool up. At this time, the driving key and positioning key on the casing driving head and the slip key groove are in a straight line, a...

Embodiment 3

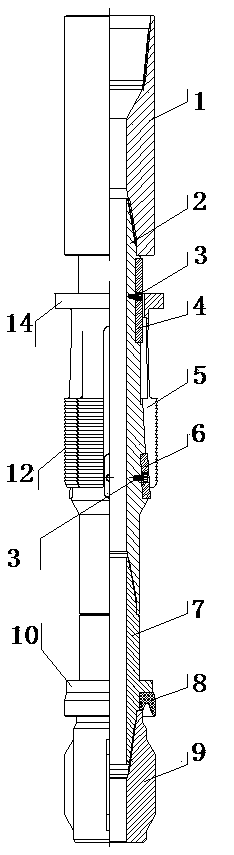

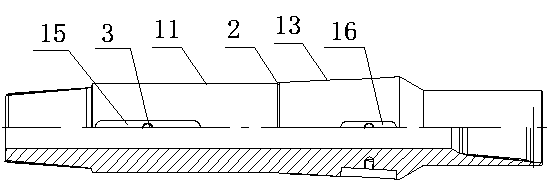

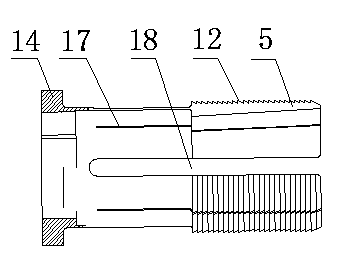

[0068] This embodiment illustrates the casing drive head used in the present invention:

[0069] A casing driving head suitable for casing drilling, including a variable button joint 1, a guiding locking mechanism and a righting sealing mechanism; the guiding locking mechanism cooperates with the casing to lift, lower and rotate the casing; the The righting and sealing mechanism is used to guide and straighten the guiding and locking mechanism that is lowered into the casing and seal the drilling fluid; the variable button joint 1, the guiding and locking mechanism and the righting and sealing mechanism are sequentially connected from top to bottom.

[0070] In this embodiment, the guiding and locking mechanism includes a central shaft 2 and slips 5 sleeved on the central shaft 2, and the central shaft 2 cooperates with the casing through the slips 5 for lifting, lowering and rotating the casing.

[0071] In this embodiment, the central shaft 2 includes a positioning section 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com